L&T’s focus on quality and safety at the worksite is what endears the Company to Anil Kumar Maurya. “These are two key pillars that determine successful and timely delivery of projects,” he shares fervently, “and I feel reassured by the importance placed on the safety of people and workers with the right equipment, training, and processes in place to minimize risks and maintain a secure environment.” After his initial stint at the Tata Steel Kalinga Nagar project, Anil is currently at the award-winning 435 KTPA Aluminium Smelter Expansion project for BALCO, at Korba.

In his quest for quality, Anil is hugely supported by his seniors and team members, who are ever ready to help him solve technical issues, guide him through tough situations, and share their experience when required. “Whether it’s about managing installations or troubleshooting, they’re always willing to pitch in with practical advice and their support and teamwork have made it easier for me to get the job done right and learn from each experience,” he comments, gratefully.

Dwelling on some the team’s unique initiatives to ensure accuracy when installing equipment, Anil shares a practice he has introduced to fix embedded plates for level and centre lines at each equipment area. “These embedded plates serve as reference points throughout the entire process of installation,” he points out. “Additionally, we use steel plates, which are padded with grout at the foundation to maintain precise levels when placing the equipment. Both these methods ensure proper alignment and levels and have contributed to the overall quality and precision of the project.”

Coordinating for timely deliveries, proper material storage, addressing discrepancies in drawings have been some of Anil’s challenges at site. “Material delivery schedules have been streamlined by working closely with suppliers and vendors, along with a system to track delivery progress,” he shares his mitigation measures. Materials are securely stored in designated storage areas, and are easily accessible, with a clear inventory system, labelling materials, & colour coding that have minimized delays during installation. “To address drawing discrepancies, I communicate with the design team and work with the on-site engineers to confirm requirements to adjust plans accordingly,” he states, adding that the Conquer App has reduced errors, while real-time tracking and documentation of inspection status have improved efficiency and communications.

Hailing from the holy town of Prayagraj in UP, Anil is married to Meera, a homemaker, and blessed with two children, Sanvi and Devansh. Passionate about yoga and running, he always finds time to pursue them and cherishes his time at the Kansbahal Works, taking care of structural fabrication work.

Proud to be in the company of nation-builders, P Shijith truly values the supportive role his seniors and team members at his various project sites have played in improving the quality of his work. “They always encourage me, their guidance and motivation help me to take on challenges with confidence and continuously improve my skills,” he says, adding that his colleagues play an equally crucial role by collaborating effectively to ensure smooth execution at site.

After working on 6 other projects at L&T including the Dhamara Port, Odisha, CHP Parsa Kente, Chhattisgarh, NTPL Tuticorin, Tamil Nadu, JSW Bellari, Karnataka, UAIL Tikiri and Vedanta Lanjigarh, both in Odisha, Shijith is delighted to be part of the Quality awardwinning team at the 435 KTPA Aluminium Smelter Expansion Project for BALCO, and certainly liking what he is doing for he takes pride to talk more about his scope of work.

“For the modular erection of the structural panels for the Alumina Handling Conveying system, we pre-assembled and welded the structural panels on the ground for better weld quality and minimized risk of working at height,” he explains. “For critical erections, I prepared detailed schemes for both structural and equipment erection, to achieve optimal resource utilization and improved productivity.”

Routing the AHS conveyor through the operational area was a challenging exercise as it required a complete road shutdown for erection. “The entire process was carefully planned to align with the shutdown schedules, ensuring minimal disruption to ongoing operations, that helped to optimize time and resources too, allowing us to execute efficiently within the available window,” he says, with a sense of purpose. “What also helped was continuous communication with the operations and shutdown teams that kept all of us aligned during the operation.” Digital tools like Conquer, Material NXT, Sheild, are strengthening the project team’s concerted effort to keep quality in top gear.

On his personal front, Shijith hails from Kerala, is married to Anju, a homemaker, and they are blessed with a daughter, Dhanvi. Apart from spending quality time with his young family, Shijith loves to watch videos on innovations and the latest technologies. He mentions that a critical erection of a 92 MT digester vessel at the UAIL Tikiri site was one of his most memorable moments.

ZERO TOLERANCE

TO DEVIATIONS

Saurabh Kumar

Senior Engineer (Civil), M&M SBG

He is at his first project with L&T, the Quality award-winning 435 KTPA Aluminium Smelter Expansion project for BALCO at Korba, and Saurabh Kumar is a very happy and satisfied man, for it is their thrust on quality that has been instrumental for the project winning this recognition. “My goal is to achieve highest quality at site for I am constructing some of the most critical structures like the rectifier building,” he says seriously. “In busbars, we work with zero tolerances and deviation from drawings, maintaining high quality standards for structures like cable trenches, transformers, erection foundations and busbar columns.”

For a project leadership that puts so much emphasis on quality, Saurabh finds himself in the right place, as he shares some of the quality measures he follows at site. “Our regular inspections of the construction activities ensure compliance with approved plans and specifications and we develop and use quality control checklists to ensure that all construction activities are carried out to accepted quality standards.” He highlights that all material delivered at site are meticulously inspected to ensure that they meet the required standards and workers are continuously trained to maintain high standards of workmanship.

Speaking about challenges, Saurabh flags off the busbar column as a significant one due to its complexity and need for zero tolerance in casting. “Precise casting is to ensure seamless integration with the other components for which we use Auto Level,” he points out, adding that effective communication and coordination between him and the project team help to overcome challenges.

Even as Saurabh is learning the ropes and developing as a construction professional, he acknowledges the vital role his seniors are playing in his growth. “From the day I joined the organization as a fresher, my seniors have guided me to develop my skills and knowledge to improve quality at site,” he says with an air of gratitude. There are no solo performers at a project site and Saurabh’s team members have been equally supportive and cooperative to help him achieve his goals.

Saurabh loves playing cricket during his free time and proudly shares that he captained the winning team that won the ECC Recreation Club Cricket Tournament held in Kansbhal, and somehow that is not surprising as he hails from Ranchi, Jharkhand, a place famous for another of its favourite sons, Mahendra Singh Dhoni. In life, Saurabh is still seeking a partner.

“I successfully completed a critical shutdown job with top quality and safety in just 46 days instead of the scheduled 60 days, a truly memorable achievement,” exults Basanta Panigrahi, about his success at his present assignment at the Quality award-winning 435 KTPA Aluminium Smelter Expansion project for BALCO. Staying on matters of quality, he says that he has successfully executed the foundations for major RP equipment, including a Cold Rolling Mill, Pre-Heating Furnace, Tension Leveller, Annealing Furnace, Edge Trimming Line, and Slitting Line. “All these complex foundations were completed within the specified tolerance limits and handed over for erection without the need for rework,” he adds proudly.

His first project with L&T, a company that he loves because of its excellent work culture, freedom to work, supportive management, and genuine care for its employees and their families, was the SAIL ISP Burnpur project where he gained foundational experience in quality management and execution. Thereafter, Basanta has been associated with major industrial projects, including the BSL Bhushan, Angul, Tata Steel, Kalinganagar, Bokaro Steel Plant, JSW Dolvi, and Vedanta, Lanjigarh. “Throughout my career, I have successfully handled many critical structures, ensuring precision, durability, and compliance with industry standards,” he says with resolve, adding that the guidance and timely decision-making of his seniors and his team members’ commitment to precision and adherence to best practices, have been key to consistently delivering high-quality work.

Sharing his approach to drive quality, he cautions that prior to engaging workers in high-precision and critical equipment foundation jobs, it is critical to ensure their competency through skill assessments to minimize errors and rework. “We conduct regular discussions, training sessions, and interactive meetings with the workforce to reinforce quality requirements and best practices and have introduced a fortnightly inspection system to assess the condition of shuttering materials, for the timely segregation of damaged or substandard materials, to ensure consistent formwork quality,” he says.

To address the risk of working in a functioning plant, workers are given comprehensive safety training apart from ensuring stringent safety measures. Faced with limited working space for material handling and positioning of equipment, the team utilized specialized and customized equipment without compromising on efficiency or safety. “To control the high worker turnover that affects continuity and productivity, we have implemented worker-friendly methods to improve their morale and retain them longer,” he shares.

A native of Kamarangan in Odisha’s Bhadrak district, Basanta’s life partner is Kalpana, a homemaker, and Kirtiman and Swabhiman are their two sons. Reading and playing cricket are his favourite hobbies when he takes a break from driving quality.

“Receiving an appreciation letter from the CEO of BALCO (Vedanta) for completing 704 numbers of 18.2 m tall precast columns for the POT line area, in time, on schedule, with nil safety observations is the most memorable moment in my life,” says an excited Bijan Maity. “This demonstrates the precision, reliability, and consistency of our work while the exceptional surface finish and reinforcement quality reflect my commitment to excellence and strict adherence to quality standards.”

At the BALCO site, Bijan’s responsibility is to precast the POT room and ventilation vault, drawing on his experience gained at the UAIL, Rayagada project, his first with L&T, where he was responsible for the civil execution of the PPT tank foundation, cooling tower, and storage silo. His revels in his association with L&T thus far acknowledging the organization’s transparent programs between the higher management and the execution representatives. “This open and structured approach fosters a sense of ownership, accountability, and efficiency, ultimately driving excellence in project execution,” he states wisely.

To ensure the dimensional accuracy, alignment, and surface finish of the 704 columns, Bijan and team implemented rigorous quality checks, optimized formwork designs, and used high-grade materials for shuttering and casting, closely monitoring the curing process to prevent cracks and ensure structural integrity. “We developed detailed marking templates and prefabricated jigs to accurately install the huge insert plates precisely oriented to meet the structural requirements apart from using laser alignment tools to maintain precision,” he shares.

By engaging experienced rigging teams, deploying high-capacity cranes, and following detailed lifting plans with proper load distribution and strict adherence to safety protocols, he has ensured the safe lifting and erection of all the columns. The team also conduct on-site skill development programs, provide hands-on training, and assign experienced supervisors to guide workers, ensuring improved productivity and quality.

The freedom to make decisions and a collaborative and user-friendly work environment have continually motivated Bijan to solve challenges effectively. At the same time, he is appreciative of the wholeheartedly cooperation and support he receives from all his seniors and departmental in-charges to complete his tasks to quality. “Their guidance and encouragement play a crucial role in my success,” he smiles with a thumbs up.

Hailing from Hindmotor, West Bengal, Bijan is married to Sucandra Santra, a working homemaker. To chill, he listens to music.

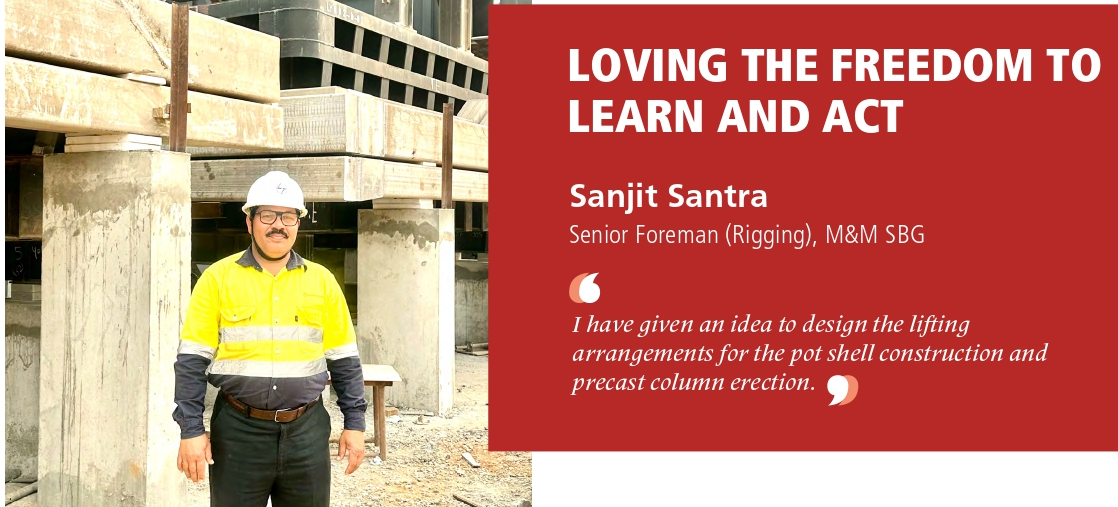

What thrills him most about L&T is the freedom Sanjit Santra enjoys to learn and act that has helped him to execute several projects till date for the Company including the Blast Furnace, the Coke Oven and the Pilot Plant (all in Jamshedpur), the Blast Furnace-3 (in Vizag), the Blast Furnace-2 in Bokaro, Coke Oven in Kalinga Nagar, Coke Oven (in Dolvi), and the Fabrication Yard (at Kansbahal). Currently, he is working as Senior Rigging Foreman at the award-winning 435 KTPA Smelter Expansion Project for BALCO.

Pot shell assembly is one of the most difficult tasks in the project that calls for precision. The team has been mandated to build 304 pot shells, each weighing 56.607 MT, with rigorous specifications, that require a total weld length of 1.2 km per shell and a weld deposition of 0.8 MT, consisting of 507 detailed components. “I have given an idea to design the lifting arrangements for the pot shell construction and precast column erection,” highlights a visibly proud Sanjit. Precasting a total of 704 18-m columns each weighing 28 MT, is another tough assignment and quicker lifting arrangements are both reducing formwork costs and speeding up construction.

Another of Sanjit’s challenges that he faced in the initial phase in the project was to tilt an assembled structure (21 x 5 m, 30 MT) with a tyre mounted crane. Referring to tech interventions, he mentions replacing the conventional bow shackle with a digital bow shackle.

A native of Jamshedpur, Jharkhand, Sanjit’s better half is Baby Santra, a homemaker, and they are blessed with three children: Santanu, Sonu & Shiva. When he gets the chance, he likes to play football.

Sanjit considers the day he joined L&T as one of his happiest.