An innovative platform to optimize

solar PV plant design

The significant global effort to combat climate change, reduce carbon footprint, and generate renewable energy is driving the proliferation of solar PV plants across the globe, reflecting the growing consensus to build a greener, more sustainable future.

“With the number & size of solar PV projects increasing and the engineering challenges becoming more intricate, we need to have a fresh outlook and develop state-of-the-art expertise, and create software tools for designing large-scale solar PV power plants,” observes Srinivasan S, Executive Vice President & Head – Engineering, PT&D. “The Integrated Engineering & Design Platform (IEDP) aims to integrate as well as automate the working of third-party software and in-house optimizer tools into our engineering processes with minimal manual intervention.” The aim of the IEDP is to improve decision-making for selecting optimal solutions during tendering and increase the team’s capacity to deliver more within compressed timelines. “A futuristic platform powered by AI, it enhances the value that engineering can bring to the overall business in terms of optimized engineering solutions/costs,” he adds. “The IEDP will also significantly help in accelerating engineering delivery during the project execution, setting us up to meet the growing demand for renewable energy infrastructure.”

Identifying drawbacks in the existing system

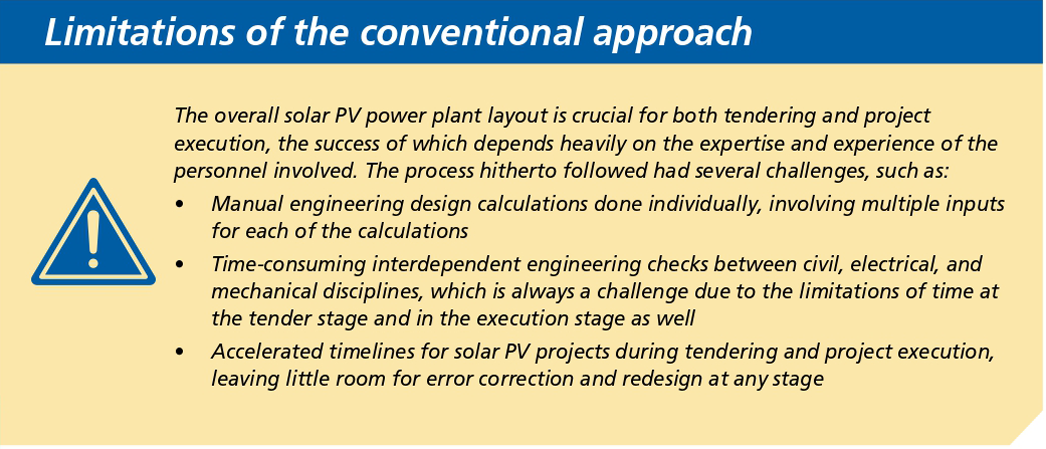

As competition hots up, securing tenders in the solar PV space calls for a strategic approach to navigate the evolving landscape of PV module technology, module mounting types, and land utilization patterns. “Achieving the lowest possible Evaluated Bid Value (EBV) or Levelized Cost of Energy (LCOE) is key and a critical benchmark, representing the per-unit cost of energy over a project’s lifecycle, and essential to demonstrate a project’s economic viability and attractiveness,” explains K Rajapandiyan, Head – Engineering, International BU, Renewables IC. To be competitive requires multiple iterations of analysis to fine-tune multiple variables, such as the area of the power plant, tilt angle/ tracking range of the mounting structures, and PV module capacity needed to meet generation commitments.

This iterative process involves scrutinizing technology choices, optimizing project design, and incorporating the latest advancements to ensure the most cost-effective solution, with precision. Hitherto, this was done using multiple third-party software manually, which limits the number of iterations possible in a short time.

IEDP – a solution for the emerging world

“The IEDP is a powerful platform that combines solar PV plant engineering with cutting-edge AI,” remarks T Madhava Das, Whole-Time Director & Senior Executive Vice President (Utilities). “All that we look for is optimum cost – be it at the estimation or execution stage. In the hands of designers and decision makers, this tool is a perfect choice.”

To develop the IEDP for solar PV plant design, the team took as reference recent projects like the 230 MW Solar Plant at Ettayapuram, Tamil Nadu; the 210 MW Grid-Connected Solar PV Power Plant at Babarzar, Gujarat; and the 1.8 GWp Solar PV Power Plant at Sudair, KSA. “We organized workshops to understand project requirements where all teams signed off on the functional requirements,” recalls Hema Gopalan, Senior Manager (Systems). “Daily scrum calls improved collaboration and coordination in an agile environment of development, with weekly progress reviews to assess and discuss advancements, challenges, and accomplishments.”

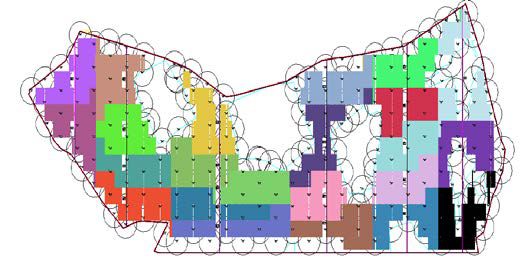

The solar PV plant layout drawing generated from automated scripts; each colour signifies an individual block of the plant

“User acceptance tests were smoothly performed to handle dependencies on interfacing with third-party software,” points out Subhramita Kundu, Senior Design Engineer – Renewables. “Multiple use cases were run based on the desired results, requiring several workarounds to achieve the desired outcome.”

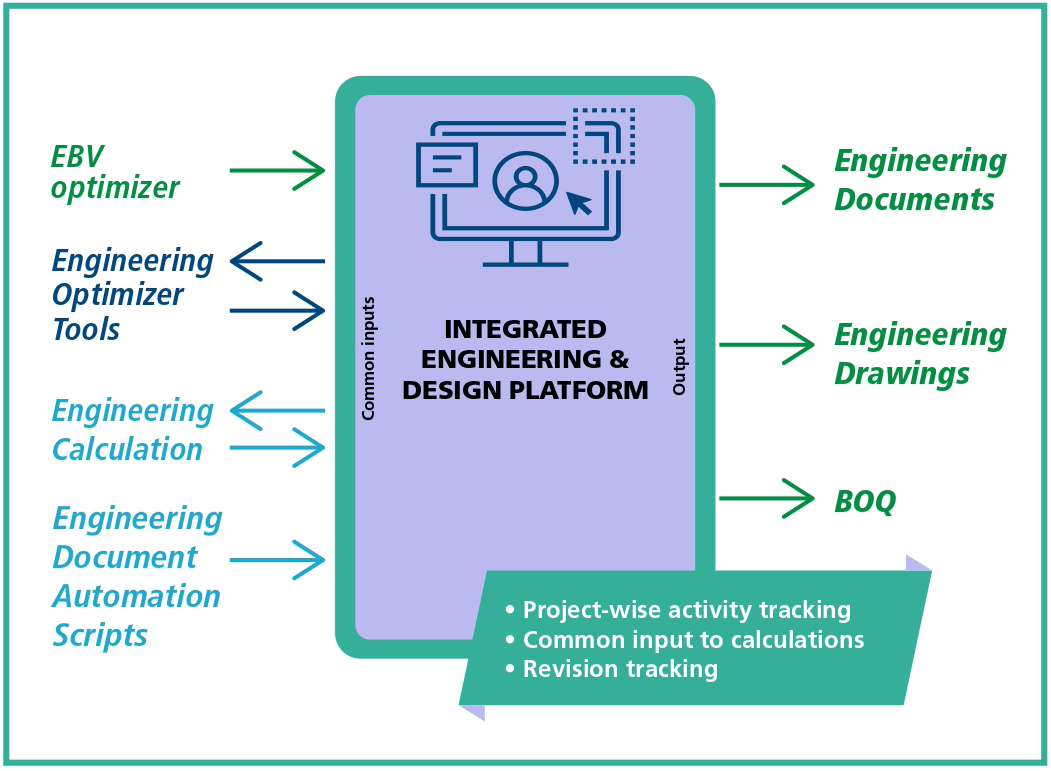

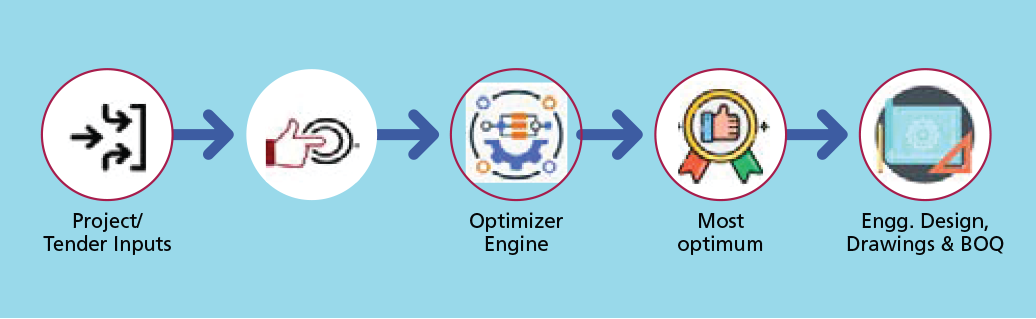

“The IEDP for solar PV plant engineering aids in integrated, iterative analysis using Robotic Process Automation (RPA) and multidisciplinary engineering design calculations on a common platform with automated flow of inputs and drawings prepared with automated scripts, all with minimal manual intervention,” explains A Kalyanasundaram, Head – Engineering Competency Development. It is structured around three key elements: Optimizer Tools, Automated Drawing Generation Scripts, and Automated Engineering Calculations, all linked by a common portal.

Optimizer Tools: RPA technology automates iterative tasks and, by systematically conducting simulations and minimizing errors, frees up human resources for strategic decision-making in project development.

“The outputs of each iteration are automatically tabulated, and the optimizer selects the most optimal configuration,” reveals V Rangaraj, Head – Engineering, Domestic BU, Renewables IC. “By performing maximum possible iterations, we have improved our ability to offer more efficient and effective engineering solutions,” adds D Asokan, Head – Civil & Structural Engineering.

“Cutting-edge AI algorithms are used to develop the optimizer tools for civil engineering,” explains S Kumaran, Senior Engineering Manager – Renewables. “It’s interesting to note that human intervention is required only to define input parameters and iterative ranges for simulations.”

Automated Engineering Calculations: The engineering calculation module integrated into the platform allows users to perform engineering calculations and extract documents for project submissions, eliminating multiple user inputs for common parameters and facilitating superior data tracking. “The dependent calculations are interlinked for the platform to automatically take the output of one calculation as the input for another,” adds Steffy Maria Joy, Engineering Manager – Renewables. “The portal also tracks the revision history of documents and the status of all defined activities.”

Automated Drawing Generation Scripts: In-house-developed scripts automatically create the overall solar PV plant layout by taking the basic design parameters as input to generate the required drawings and BOQs. “This expedites the engineering process, ensuring consistency and accuracy in engineering deliverables,” remarks Geetha Hariharan,

Head – Engineering (SS & UPD BU).

IEDP Portal: “The front-end of the portal serves as a collaborative platform for engineers to perform and track engineering and design activities, developed by adapting various integration technologies,” notes Sathiyamurthy S, Senior DGM (Systems).

Reaping the benefits of tech

“The AI-powered IEDP optimizes material & quantity through engineering & design,” notes A Ravindran, Senior Vice President & Head – Renewables IC. “The integrated nature of this platform will improve productivity and reduce turnaround time, representing a significant leap in solar PV plant engineering.”

“By consolidating all engineering data on a centralized platform, manual effort has reduced by about 23% and improved the effectiveness of our design and tendering processes,” Rajapandiyan declares triumphantly. With the promise of optimized solutions during tendering enabling improved costs and faster turnaround during client engagement as well as the accuracy, it is not surprising that this cutting-edge tool finished as the First Runner-Up in the Pi-Awards 2024 under the ‘Service’ category.

By utilizing various automation technologies, the IEDP sets a base platform to drive productivity, and the Renewables engineering team has already started using it to work out multiple iterations with quicker turnaround. With the extensive use of automated drawing generation scripts, the time taken for detailed engineering drawings has significantly reduced too. Further enhancements are planned based on user experience and feedback.

“We plan to implement the IEDP for our Transmission Lines and Substation businesses,” Srinivasan signs off. “By automating a large part of the engineering & design process and streamlining the tendering stage, we hope to support PT&D businesses in building a greener and sustainable tomorrow.”

Developing tech solutions for a smarter

power grid

Beside the rear gate of the Manapakkam campus, there sits a one-of-its-kind Digital Substation to address limitations faced by utilities in conventional substations. “It was a pilot project for L&T to implement a digital substation concept for 33 kV, 11 kV, and 415 V voltage levels and interconnect two energy centres inside our HQ campus, reveals Biju P K, Head of Idea & Incubation Office (IAPAC & EMEA Region) at the Digital Energy Solutions (DES) arm of PT&D IC. “It is the first vendor-agnostic digital substation in the world,” The DES team collaborated with Siemens and commissioned the brownfield project in 2021. To showcase interdependency of the Intelligent Electronic Devices (IEDs), 5 different makes of Bay Control & Protection Units (BCPU) and Merging Unit s(MU) from popular names like GE, ABB, SEL, Siemens, and NR, were retrofitted along with two different makes of Remote Terminal Units (RTUs). “The substation is based on the IE61850 standard, for interoperability with different makes of IEDs and MUs,” adds Biju.

The Digital Substation at Manapakkam HQ

What is a ‘Digital’ Substation?

The main difference between a digital substation and conventional ones is that the relays are based on the process bus system compared to the conventional Substation Automation System (SAS) system.

The benefits of going digital are:

- Reduced cabling, cable trenches, and cable trays

- Faster implementation with fewer chances of error

- Reduction of switchyard footprint space by around 30%

- More reliable and redundant communication skeleton

- Ease of adding new equipment to the network

- Virtual, cloud-based monitoring

- Fibre optics used between switchyard and relay panel instead of copper cables, leading to better efficiency

All these advantages ensure better control, protection, and efficiency of the substation. “Our digital substation services additionally include features like frequency- and power-based load shedding, robust cybersecurity, network traffic monitoring, and web HMI (Human Machine Interface),” points out Biju. Apart from Digital Substations, the larger objective of the DES business is to help make the power grid smarter. “Smart power grids will be the future of energy,” shares Jayant Kumar, Head – Digital Energy Solutions. “We have developed an advanced technology integration platform to support the effective exchange of information between electrical installations and decision platforms. We offer fast, reliable, secure, and smart solutions to help our PT&D clients operate their mission-critical power applications far more efficiently.”

DES is a proud member of the vPAC Alliance, a collaborative effort between technology innovators and utility companies to accelerate the digital transformation of power system substations, seeking to establish a standardized, open, and secure software-defined architecture for seamless interoperability, facilitating the development of cutting-edge protection, automation, and control solutions to modernize electrical grids. “By leveraging advanced technologies such as software-defined infrastructures and virtualized protection relay solutions, the alliance aims to simplify remote management and substation upgrades, for enhanced efficiency and reliability in the grid,” elaborates Jayant.

Delivering the PPC solution at Ettayapuram

Power Plant Controllers (PPCs) manage and optimize power plant operations. While PPC systems available in the market are generally hardware-based, DES’s PPC system is software-based, and hardware agnostic, configurable on any machine with the Windows & Linux (Ubuntu) operating systems.

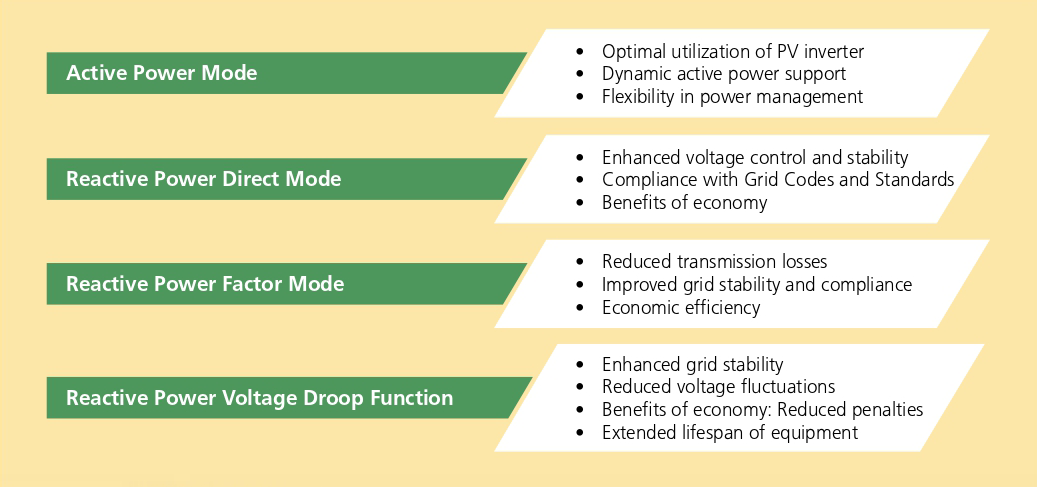

In Ettayapuram, Tamil Nadu, where PT&D’s Renewables BU has executed a 230 MW Solar PV Power Plant, DES is delivering their PPC using a master-and-slave system. “We configured the slave PPCs virtually for multiple points of interconnection (POIs),” explains Devendra Vishwakarma, Chief Technology Officer – DES, “regulating and controlling the networked inverters, devices, and equipment at the solar plant to meet specified setpoints. Grid parameters can be changed at a point of common coupling as per CEA and CERC guidelines.”

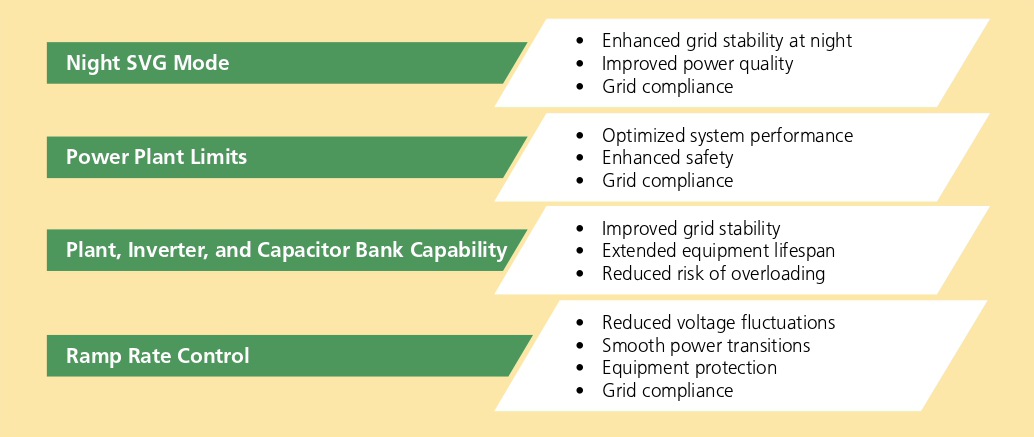

DES’s PPC solution for the Ettayapuram Project has the following functions and benefits:

“The commissioned PPC system is compatible with any inverter,” explains Sunil Singh, Head – Business Segment (IASEA). “It communicates with field devices and systems like PV-SCADA, Power Quality Meters (PQMs), and all individual inverters to issue the setpoints to field inverters to regulate the generation of solar power.”

Thanks to this system’s auto ramp limit control feature, the customer, National Thermal Power Corporation (NTPC), has achieved grid stability with the solar plant, capable of dispatching active and reactive power setpoints at the plant level. NTPC is immensely satisfied with DES’s PPC system, which is helping them curtail power generation as per the grid code. “This system’s HMI screens have easy user interface & custom menu structures,” adds Sunil, “and we can access it using modern web browsers from within the plant network & from remote locations with different authentication and roles.”

Apart from the Ettayapuram site, DES has delivered their PPC solutions at NTPC’s 20 MW Floating Solar Plant at Auraiya, Uttar Pradesh; GSECL’s 25 MW Solar PV Plant at Palitana, Gujarat; and GSECL’s 40 MW Solar PV Plant at Haripar, Gujarat.

Providing the L&T-Spark™ suite at Saudi Arabia

In Saudi Arabia’s Al Qassim province, PT&D is rendering EPC services for the 700 MW Ar Rass-1 Solar PV Independent Power Plant, where DES is providing 5 software solutions centred around L&T-Spark™ that include PPC, Plant Settlement System (PSS), Meter Data Acquisition (MDA), and Cybersecurity & Forecasting.

L&T-Spark™ is a high-end technology integration platform for utility grid control room operation, especially designed to work in conjunction with field-proven energy management systems (EMS) & distribution management systems (DMS) of leading OEMs. “This platform integrates the tertiary controls from the T&D control room with the grid automation controls at the substation and/or plant control rooms,” explains Devendra.

Power Plant Controller: “Our fully redundant software-defined PPC is user-configurable to comply with all International Grid Codes and interconnection requirements,” Devendra notes, “capable of providing tailored power plant controlling functionalities at the comfort of a click for any specific project as per the Saudi Arabian Grid Code.”

Plant Settlement System: The PSS is an essential component for a solar project that deals with the financial and operational reconciliation of energy generation and distribution. “Our PSS ensures accurate energy measurement & monitoring, billing & invoicing, and financial settlement, which includes revenue distribution and regulatory compliance such as tariff management,” explains Avinash Mali, Head – Operations (MEA). “It adheres to the Power Purchase Agreements (PPAs) too, integrating with the SCADA to ensure seamless data flow & operational control.”

Meter data acquisition: MDA involves the systematic collection, transmission, and data processing from various meters installed at different points, integrating with the SCADA for comprehensive monitoring & control and with the EMS to optimize energy distribution and usage within the plant.

Cybersecurity & Forecasting: Cybersecurity is essential to protect the integrity, confidentiality, and availability of the control systems and the data they process. “Through our PPC solution, we ensure proper access control, network security, and data security using secure communication protocols such as HTTPS,” mentions Avinash, “by ensuring compliance with relevant regulations & standards customized as per the grid codes for better decision-making, risk management, and strategic planning of various aspects of solar energy production and operation.”

Developing a V2B solution in California

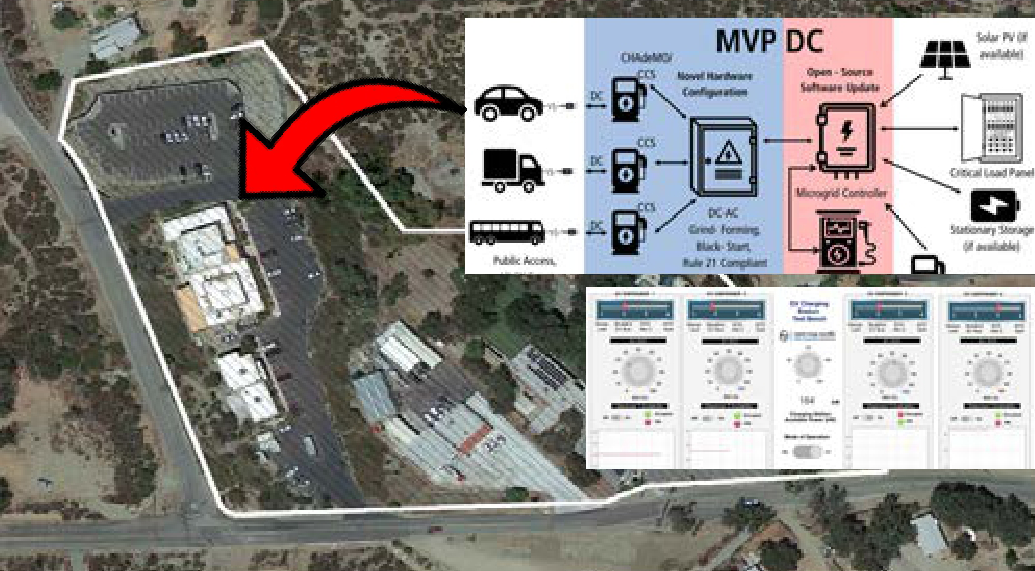

Across the oceans in California, USA, DES is currently developing a digital product that functions as a Multi-Vehicle DC Platform (MVP DC) vehicle-to-building (V2B) coordinator between a microgrid controller and bidirectional EV chargers, for EVs to act as ‘batteries on wheels’ in a microgrid.

“The MVP DC control algorithm will help demonstrate microgrids that are powered with EVs, supporting critical loads during long outages such as public safety power shutdowns in California,” shares Arindam Maitra, Head – Energy Innovation and Services (EIS). “The platform is designed to be interoperable with different vehicle makes and types and will be compatible with the two leading vehicle interfaces: Combined Charging System (CCS) and CHAdeMO.”

Novelly designed, the MVP DC system that integrates DC-DC converters to feed a central DC-AC grid-forming inverter, will be controlled by a new open-source control algorithm to address critical V2B goals like managing charging/discharging across multiple EV types and makes, grid-forming and blackstart capability, interoperability with any commercial microgrid controller, operational resiliency, and replicability & scalability.

“Microgrids have been demonstrated widely to improve the resiliency of buildings and communities,” says Arindam. “This project takes an innovative approach, aiming to demonstrate the new V2B technology as a reliable backup power source to be demonstrated across three investor-owned utilities in California.”

As we surge towards the future of energy as we know it, DES, PT&D is riding the tech wave and fast enabling the smart grid of tomorrow.

Powering the future of mobility

It is hot & humid in Chennai, but comfortable in our airconditioned electric vehicle (EV), we easily negotiate the traffic, enter the L&T Manapakkam campus, and drive past its very own EV Charging Station, a striking symbol of the future of mobility. The Government of India aims to have 30% of EV penetration by 2030 – an ambitious goal that is a part of the broader commitment to reduce greenhouse gas emissions and combat climate change.

NKDA EV Charging Station in NKDA Parking, West Bengal

As we disembark, Kavitha Lakshmi A, Head of PT&D IC’s New Electrics initiative, shares an interesting tidbit: “We commissioned our campus’s charging station in April 2022 with just one car using the facility, but today, ten unique EVs are charging their batteries here at least twice a month.”

We head to her office in the TC-3 Building, where Kavitha explains her scope of work: “We design, supply, install, and commission Public EV Charging stations comprising Electric Vehicle Supply Equipment (EVSE), along with incoming electrical supply featuring smart metering, canopy housing, and charge point management systems.” Thus far, the team has executed EV charging infrastructure projects for the Agency for New and Renewable Energy Research and Technology (ANERT) in Kerala and New Town Kolkata Development Authority (NKDA) in West Bengal.

The infrastructure facilities include the construction of pedestals, supply & installation of roof canopies, parking spaces with clear markings, vehicle stoppers to avoid collisions, illumination, and signage, to improve durability, safety, and aesthetics.

What does an EV Charging Station require?

The EVSE installed at each site serves as a public charging infrastructure that includes both fast and slow/moderate chargers. The EVSE rating and associated parameters like DC voltage and DC current are selected to cater to various e-4W models of different car manufacturers running on Indian roads, while the charging connectors/guns are chosen to ensure electro-mechanical hardware compatibility and communication interoperability between the EV and the EVSE. “These EVSE units are interoperable and manufacturer-agnostic, with type testing conducted at the Automotive Research Association of India (ARAI) as per AIS 138,” Kavitha informs. “Connectors can be parallelly operated thanks to the dynamic load-sharing features that facilitate regulated DC charging through a combination of Controlled Voltage Charging (CVC) and Controlled Current Charging (CCC), to optimize the charging process based on the State of Charge (SoC) of the vehicle battery.”

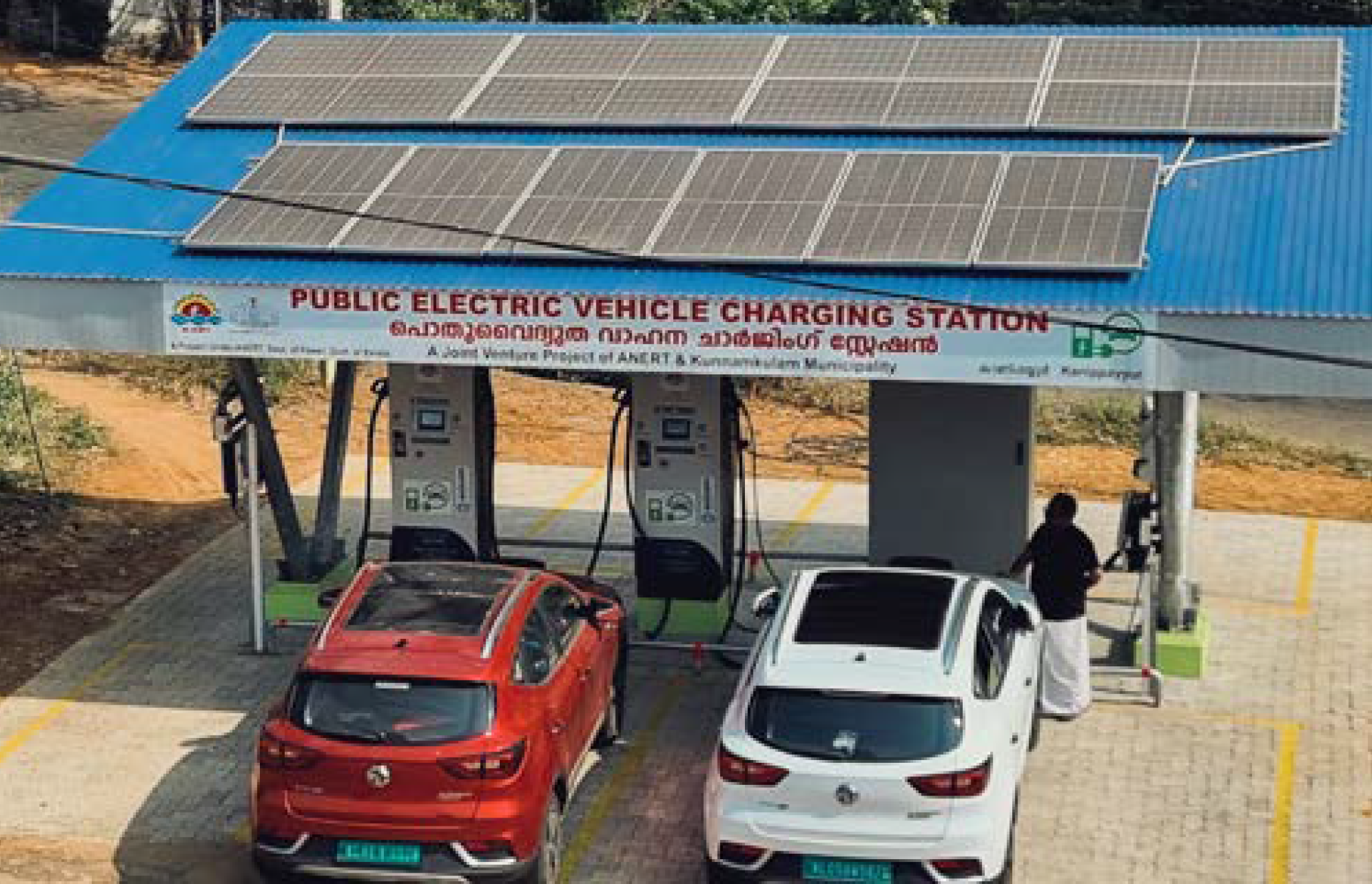

“We have delivered EV charging infrastructure at 6 locations for ANERT and 12 for NKDA,” informs Kavitha. The ANERT stations include two fast DC chargers, each of 60 kW, with two connectors of CCS2 & CHAdeMO compatible with e-4W of various manufacturers including higher-end models and slow/ moderate charging through 7.5 kW Type 2 AC connectors & Bharat AC-001 with 3 × 3.3 kW sockets. The twelve locations of NKDA are equipped with 142 kW fast DC chargers with 60 kW rating of two CCS2 connectors/guns and Type 2 AC connector of 22 kW for slow/moderate charging.

“Ensuring a reliable incoming power source is crucial for increased EVSE uptime and attracting more EV owners,” continues Kavitha. “We conducted comprehensive assessments of the nearby Discom facilities, as EVSEs pose a bulk LT power demand. Dedicated 11/0.415 kV transformers with substation equipment, panels, and associated cables have been installed to meet these requirements. We have deployed smart energy meters with Discom-mandated accuracy and cloud-hosting capabilities to monitor energy consumption digitally and remotely.”

“We explored more than 30 locations to finalize 6 suitable sites and obtained the necessary NOCs,” reveals A Balaji, Project Manager for the ANERT Project. “It was a moment of pride to commission the first public EV Charging Station with the latest tech-savvy features!” he adds with a grin.

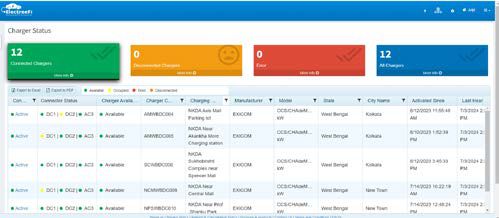

Stations powered with IoT-enabled technology

The EVSEs, smart meters, and CCTVs deployed at the public charging stations are all Internet of Things (IoT)-enabled with cloud-hosting features. GPRS services with adequate signal strength and encryption are critical for seamless operation of the stations, along with the necessary cybersecurity measures. “The Charge Point Management System (CPMS), following the Open Charge Point Protocol (OCPP), hosts details about EVSE uptime, availability, charge status, power consumption, and so on,” elaborates Kavitha. “The CPMS acts as the brain of the EV charging stations for remote monitoring and management. We have partnered with reputable network service providers for online booking, billing, and data related to charging details, and all the payments at the stations are fully digitalized.”

A ‘smart’, digital payment system: “Charging a vehicle at our stations requires authorization through a mobile app or RFID, and the amount is auto-deducted from the customer’s linked bank account. After the payment is authorized, the charging process is initiated,” explains Balaji. “This user authentication mechanism strictly adheres to the Open Charge Point Protocol (OCPP) for unmanned operation of the stations.”

Smart meters: Smart energy meters on the input side provide insights into utility-side energy consumption patterns through cloud hosting and web/mobile apps. The CCTV surveillance systems help reduce physical damage and theft. In addition, the ANERT stations are equipped with roof-top solar panels, and these smart meters also monitor solar power generation at the stations.

“Proper hand-shaking between the EVSE and CPMS was vital to establish connectivity between the EV charging stations, backend systems, and EV user interfaces through reliable Internet services,” relates Arindam Bhattacharjee, Project Manager for the NKDA Project. “We closely coordinated with the local Discom, West Bengal State Electricity Distribution Company Limited (WBSEDCL), to align the power capacity requirements of the charging stations.”

On the green road to the future

At the ANERT stations in Kerala, a 5 kWp solar grid-connected system with net metering has been deployed, which features crystalline silicon terrestrial PV modules with a string inverter capable of exporting power to the grid. PV arrays are installed on the canopy and orientation is designed to maximize solar energy yield while ensuring ease of vehicle entry/exit to the charging station. A dedicated energy meter records the solar system’s energy generation. Thus far, ANERT has generated approximately 40 MWhr of green energy thanks to this system.

“To date, our EV charging infrastructure projects for ANERT and NKDA have reduced approximately 290 tonnes of CO2 emissions, contributing to a sustainable future in mobility,” Kavitha notes with her trademark beaming smile. “By implementing advanced technology and robust charging infrastructure, we are beginning to play a pivotal role in India’s transition to a cleaner, greener transportation system; in our own way, we truly are riding the tech wave towards a sustainable future!”

ANERT EV Charging Station in Kunnamkulam, Kerala