Driving digital excellence through BIM

Several B&F projects are increasingly adopting technological

solutions to enhance planning and execution.

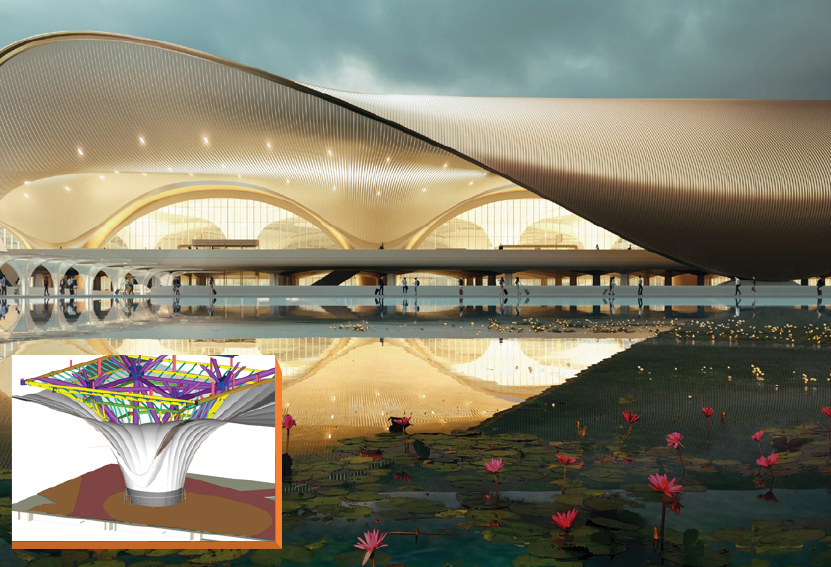

Federated BIM model of the Forecourt Arch Truss

Laser scanning ensuring precision

A standout feature of the new and soon-to-be-inaugurated Navi Mumbai International Airport will be the Forecourt Arch Truss, supporting the roofing, ceiling, and forecourt fascia, a signature architectural and structural element that calls for precision in execution. Any deviation in its steel alignment could trigger a cascading effect of rework across multiple trades, with heavy cost and schedule implications. “We have therefore deployed the Trimble SX12 Laser Scanner as part of our Field BIM strategy,” informs Project Director, Rajesh Pachlot, “which captures precise point cloud data of as-built structures for us to compare them with the design model to detect discrepancies, if any, early.” Apart from generating as-built models to ensure perfect alignment between design intent and site reality, the scanner enables LoD 500 modelling, providing an accurate digital record for future reference.

Time and cost savings have been significant. A survey that would have taken eight days and 160 man-hours with traditional total station methods was completed in just one day and 30 man-hours and by identifying deviations early, rework was reduced, coordination for upcoming works better, safeguarding the project schedule.

“Laser scanning has given us the confidence that all our downstream activities are based on accurate data,” says BIM Coordinator, Md Naiyer Ajam, forcefully.

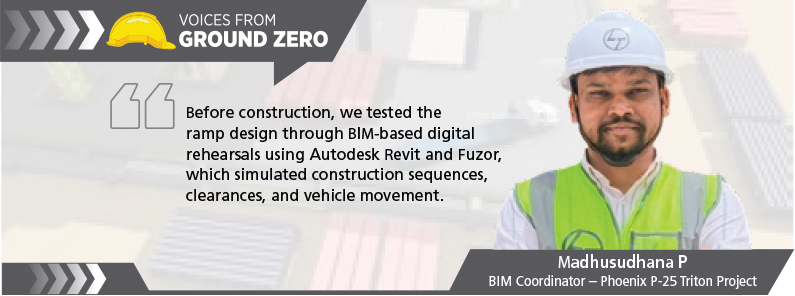

BIM-based digital rehearsals for logistics and safety

At Hyderabad’s Phoenix P-25 Triton Project, soon to be one of the tallest composite structures in the region, Project Manager Sudhakar Prasad D was challenged by a congested site, with limited storage space, and restricted movement corridors. “To address our issues of logistics, safety, and coordination, we turned to BIM by converting traditional planning into a simulation-led execution strategy,” he informs.

Due to restricted access between Basement 1 and the podium, the project team was dependent on vertical lifts and constructed a temporary structural steel ramp for direct material movement. “Before construction, we tested the ramp design through BIM-based digital rehearsals using Autodesk Revit and Fuzor, which simulated construction sequences, clearances, and vehicle movement,” apprises BIM Coordinator, Madhusudhana P. This analysis reduced their initial plan for two ramps to a single optimised 8 m-wide ramp, reducing the construction area by 600 sq. m, lowering material use, and improving circulation.

The same 3D intelligent BIM model became the foundation for monthly logistics plans, updated in real time to maintain smooth site operations. Safety has been modelled in 3D as well, covering shaft gates, safety nets, modular floor protection, and handrails, all linked to the project schedule. Evacuation routes have been simulated to validate compliance, and VR-based safety training is helping workers identify hazards before stepping on site. This approach has reduced reporting time from 180 minutes to 30 minutes, saving 220 man-hours and approximately ₹1.37 lakh.

Phoenix P-25 Triton Project

Before Execution

After Execution

“The digital rehearsals gave us absolute clarity before execution,” shares a satisfied Sudhakar Prasad. “We can foresee challenges and take informed decisions, translating into savings on both cost and time.”

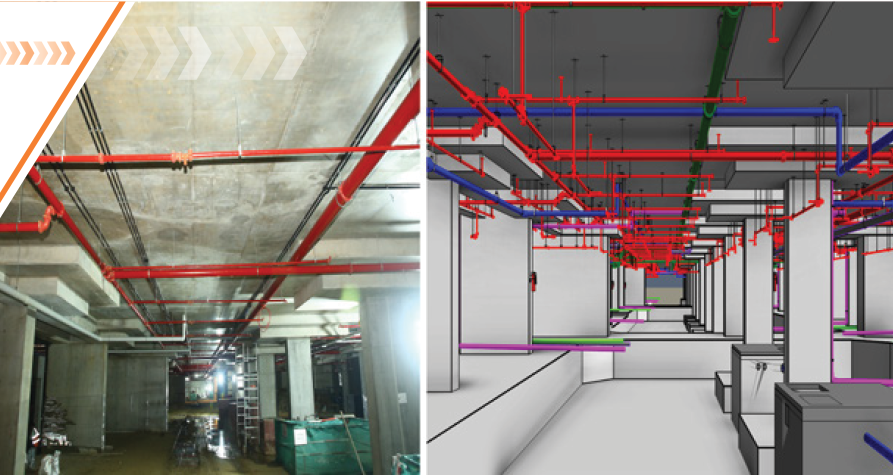

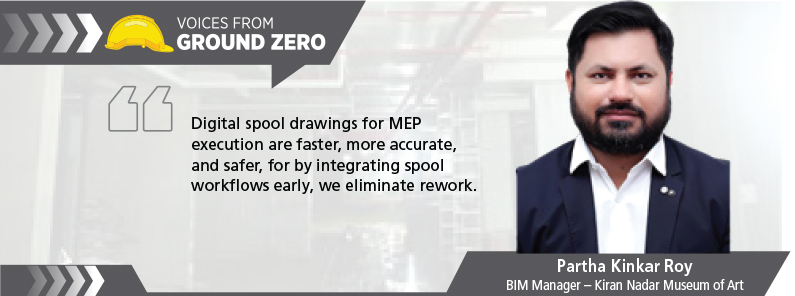

Digital spool drawing innovation for MEP execution

In large MEP projects, moving from design to execution often leads to on-site clashes, inaccurate quantity take-offs, and costly rework that are being addressed by adopting an advanced modelling-to-fabrication workflow using SysQue integrated with Trimble. Project models are upgraded from LOD 350 to LOD 400, by embedding fabrication-level details and with spool drawings generated directly from the enriched models, the project team is being saved delays and inaccuracies of manual drafting.

The approach has incorporated clash detection in Navisworks too, real-time collaboration in BIM 360/ACC, and QR-coded spool sheets linked to the BIM model for easy verification and installation tracking. Off-site prefabrication has become feasible, reducing congestion and enabling parallel work streams. “It is faster, more accurate, and safer,” opines BIM Manager Partha Kinkar Roy, “for by integrating spool workflows early, we eliminate rework, improve coordination, and are delivering measurable gains in speed and quality.”

This method has cut installation times by 25%–30%, reduced material wastage, and improved site safety. Already adopted in other projects such as Kiran Nadar Museum of Art and Common Central Secretariat Project – Buildings 1, 2, and 3, it is now set to be scaled across future MEP-heavy infrastructure and commercial projects.

Site vs. BIM spool model

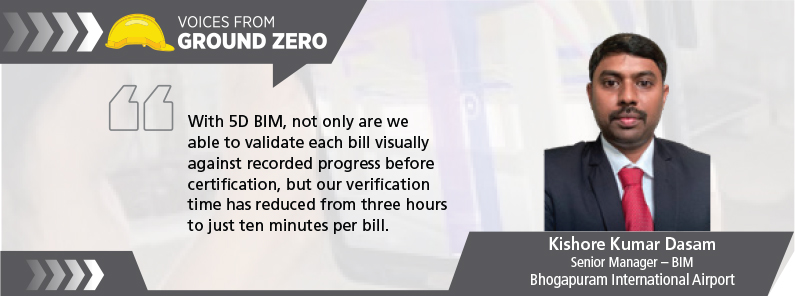

5D BIM for accurate subcontractor billing

The erstwhile manual, time-consuming and error-prone system of subcontractor billing at the Bhogapuram International Airport has been transformed with the adoption of a 5D BIM Subcontractor Management Dashboard by integrating Autodesk Revit with Power BI. Detailed 3D models have been embedded with cost codes and updated weekly with execution data, creating a 5D model with time and cost dimensions, linked directly to an interactive dashboard where progress can be filtered by the subcontractor, trade, floor level, or month. A built-in 3D viewer enables spatial verification, and real-time comparisons of completed versus pending quantities, flagging discrepancies instantly.

“Not only are we able to validate each bill visually against recorded progress before certification, but our verification time has reduced from three hours to just ten minutes per bill,” says Senior Manager – BIM, Kishore Kumar Dasam, with a thumbs up. All finishing work bills are now generated directly from the dashboard and the estimated savings include ₹1.07 lakh per month in billing efficiency and up to ₹40.76 lakh annually from preventing overbilling.

A part of Bhogapuram International Airport’s SOPs, the system now serves as the standard billing tool for all finishing works, offering a scalable and repeatable process for other projects.

“We are enhancing project management across the IC with new digital techniques. Power BI integrated with BIM enables micro-level monitoring of progress and payments,” says Sr. Chief Engineering Manager – BIM, Potu Raghuram. For complex projects like airports, Scan-to-BIM provides stakeholders with clear visibility of workflows and timelines. Fabrication models and spool drawings further streamline prefabrication and installation through a unified Bill of Materials.”

AR in action at GVIAL

RIL Jamnagar Project

A monolithic precast breakthrough for seismic resilience

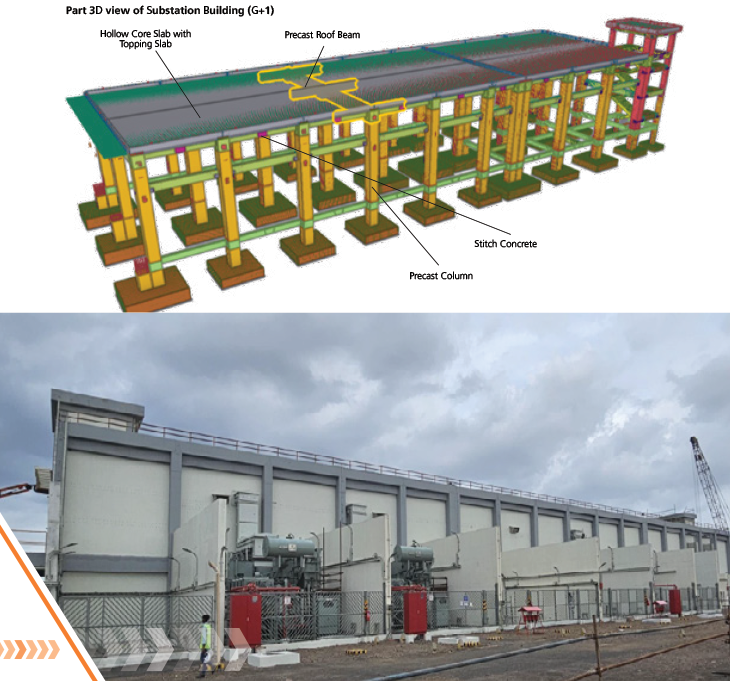

When Reliance Industries Ltd. (RIL) decided to build one of the world’s largest integrated Solar Photovoltaic (PV) manufacturing facilities at Jamnagar, Gujarat, they turned to B&F to construct it. The scale was staggering for the facility has been designed to encompass the complete PV manufacturing chain from polysilicon to solar modules with its own glass manufacturing unit. Within it, six substation buildings and two electrical rooms will soon become the beating heart of the PV cell manufacturing line.

The team’s brief was to deliver civil works, finishes, and complete structural readiness in just eleven months in a high seismic Zone IV+ region prone to wind speeds of up to 50 m/sec. Conventional construction methods would have taken nearly twice as long. Add to that the need for movement‑resisting frames in both directions, an architect’s design that ruled out corbels for beam support, and a shortage of skilled manpower on site. Fully aware of the challenges involved, Project Manager, Syamprasad Vishnubatta, and his team set about thinking out of the box to convert design to reality.

RIL Substation Building – Completed view

Precast floor beam: Part 3D view and with lifitng spreader beam

Reimagining precasting for a seismic zone

“Our way forward lay in precasting but not in its conventional form,” observes Syamprasad. “We re-engineered the system to work like cast-in-situ in terms of monolithic behaviour yet move at the speed of off-site manufacturing.” That called for reinventing the way beam-column joints were conceived. Instead of congested reinforcement at the junction, wet joint stitching was shifted to the centre of the beam, an unconfined, low-stress zone. This small shift had a huge impact. “By freeing up the column tops, we could rapidly place beams on all four sides without rebar clashes, turning erection into a smooth, repeatable process.” Syamprasad’s smile says it all. Senior Construction Manager, Mudasir Nissar Mir elaborates that in a seismic design, the joint is everything and by relocating the joint, they did not just solve a congestion problem but made precasting truly viable for high-seismic industrial buildings.

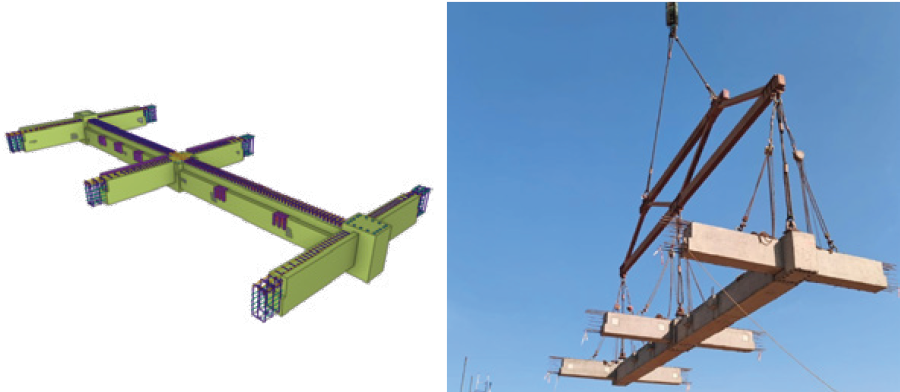

Speed at industrial scale

Innovating further, the team designed the beams as 3D Double-H or H-shaped modules, merging primary and secondary beams into single massive pieces weighing up to 52 T that reduced the number of joints by 70% and the number of lifts by 80%. “Tekla BIM modelling at LOD 350 ensured that every rebar, coupler, and sleeve was placed with millimetre accuracy, feeding directly into over 2,500 shop drawings,” describes Mohd Tarik, Sr. Planning Engineer (Precast). The precast columns were designed to support the heaviest beams without temporary shoring, with the lifting handled using custom-designed strong backs and SPMTs.

The result was an industrial ballet of speed and precision. Foundations and plinth beams were cast in situ while precast elements were manufactured offsite. The moment the foundations were ready, erection began, no waiting, no wasted motion. In just four and a half months, a 150-metre-long substation stood complete; the 250-metre electrical room followed in six months. What might have taken two years was completed in barely half that time.

Moving fast did not mean cutting corners. In fact, steel moulds cast in factories have improved quality well beyond what site conditions can offer. Replacing wet stitches at beam-column junctions with grouted joints has given the team better control over finishes and long-term performance, and eliminating temporary supports meant eliminating the hazards of working at height too, with boom lifts used for safe access during grouting.

The environmental benefits have been equally tangible: less dust and noise, lesser truck movements, and minimal on-site waste. With so much of the work shifted offsite, the disruption to the surrounding ecosystem has reduced significantly.

The innovation has paid off literally and figuratively. Cost savings came from eliminating temporary formwork, cutting handling time, and reducing the need for skilled labour on site. More importantly, the client was so impressed with the speed, quality, and safety of Train-1 that they immediately awarded L&T the Train-2 substation and electrical room works. “This was not just about building substations,” says Dintakurthi Balaji, Manager (Civil), CMPC. “It was about proving that speed and scale can go hand in hand with seismic safety. We have set a new benchmark for industrial construction in high-seismic zones.”

Beyond Reliance

The monolithic precast breakthrough developed by the team has applications far beyond solar PV plants for it can serve semiconductor fabs, data centres, and other vibration-sensitive industrial or commercial buildings. Its success proves that large, complex facilities no longer need to choose between seismic performance and construction speed. “This project is a statement,” concludes Syamprasad Vishnubatta. “If you can do it here, in eleven months, in Zone IV, with structures this massive, you can do it anywhere.