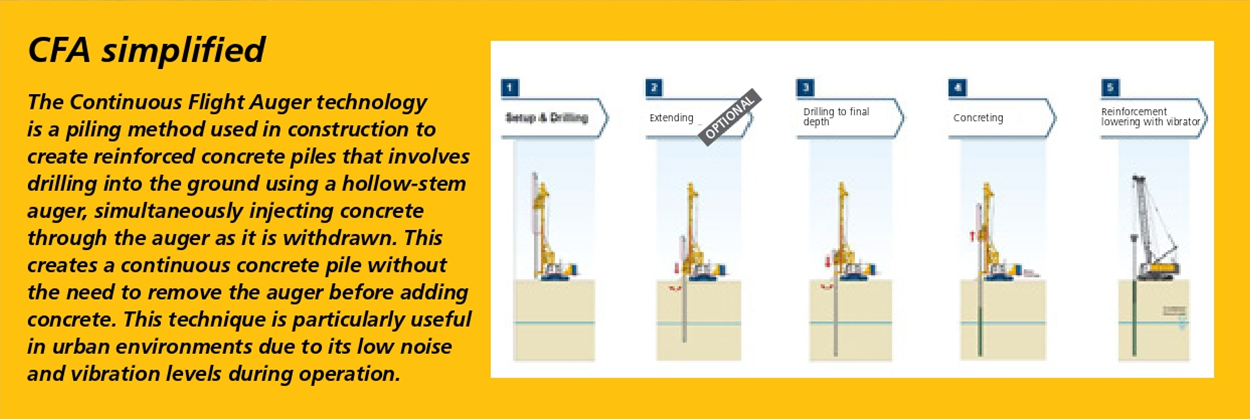

Piling is the most critical aspect of ground engineering and foundation building at L&T GeoStructure (LTGS), which are in turn critical for all construction activities. The business has recently made a significant breakthrough by adopting the transformative Continuous Flight Auger (CFA) technology in deep foundation engineering, which offers a blend of speed, precision, and quality. In fact, LTGS is also the first company in India to adopt CFA for large-scale piling at a project site.

1,300 piles in just 70 days

For Project Manager, K V Vinod at the Piling Works project for Zenith Main Plant at Sanand, Gujarat, life has become so much easier with the introduction of CFA technology. Awarded in February 2025, his project scope is to complete 9,147 piles by the contractual delivery date of September 2025. “Faced with such extremely stringent timelines, the CFA has come to our rescue,” he says, smiling with immense relief. “We have successfully completed 1,300 piles in just 70 days, which has gone a long way in meeting our project timelines by improving our productivity and efficiency in execution.” CFA has a sustainability advantage too as it obviates the use of polymers and bentonite.

Technical innovations when implementing CFA

One of the key advancements in the team’s CFA operations has been the integration of depth sensors and real-time monitoring systems to ensure accurate depth measurement and uniformity across all piles, which are critical for structural integrity. “The use of Self-Compacting Concrete (SCC) has further improved concrete quality, allowing for better flow and compaction without the need for vibration,” points out Assistant Manager – Planning, Aditya Gaikwad.

To optimize load transfer and anchorage, the team has employed modified reinforcement cages with a tapered end design extending 1 m, which has improved the bond between the pile and the surrounding soil, improving overall performance under load conditions.

CFA piling in progress

“With the CFA method, we have achieved up to 450 running metres of boring in a single day, with an average daily output of 350 metres,” shares an excited Suresh Chouhan, Assistant Manager – Civil, “which represents a fourfold increase in productivity compared to conventional methods. Such efficiency has been instrumental in maintaining project momentum and meeting tight deadlines,” he adds energetically.

Executing the 1,300 piles marked a major achievement, utilizing the Sheshba concrete pump for the first time in India, ensuring uninterrupted and high-volume concrete delivery with enhanced speed and precision. “Additionally, we integrated advanced sensors with Jean Lutz software for real-time depth sensing and visual representation of the bore log during piling,” shares M Gomathi Shankar, Assistant Manager – P&M. “With this technology we were able to accurately monitor pile depth and soil strata to adhere to design specifications.”

“The combined use of cutting-edge P&M and digital tools significantly improved quality control and reduced manual errors, setting new standards for CFA piling execution in India,” remarks a pleased Vinod.

An able ally in the Client

After testing CFA as a Proof of Concept at the NRL Project in Assam by executing 100 piles, the technology has both enhanced technical precision and significantly accelerated project timelines for Vinod and his team, which has contributed to the timely delivery of key project milestones, reinforcing the reliability of CFA as a preferred piling method.

In their client, CG Semi Pvt. Ltd. (a joint venture between CG Power & Industrial Solutions Limited and Stars Microelectronics (Thailand) Public Co. Ltd.), the team has found an able ally, whose timely approvals at every critical stage, including design validation, trial pile performance, and quality benchmarks, have helped them to maintain workflow continuity and minimize administrative delays.

“We won our client’s confidence in the methodology through a series of successful soil trials conducted prior to full-scale deployment that validated the suitability of CFA for the site’s geotechnical conditions and ensured compliance with all structural and safety standards,” highlights Soumalya Dolui, Engineer – QA/QC.

Cage lowering

Certainly, Vinod would have been happier if he had had the services of more than one CFA rig to complete the entire piling process deploying CFA, but since there was only one available, the team decided to use it at the assembly building, which totally involved about 2,900 piles, out of which 1,300 were completed using CFA. “Using the conventional method in tandem, we have achieved an average productivity of 75 running metres per day, and with CFA, productivity significantly increased to 300 running metres per day,” he informs.

For LTGS, this breakthrough has major advantages. “The strategic use of CFA technology, combined with innovative design and robust quality control, has proven to be the cornerstone of our success in foundation works,” sums up R Ganesh, Head & Chief Executive, L&T GeoStructure, “and I am confident that this approach will continue to set new benchmarks in speed, safety, and structural performance.”