RVNL Package 2

Finding smart ways to enhance efficiencies

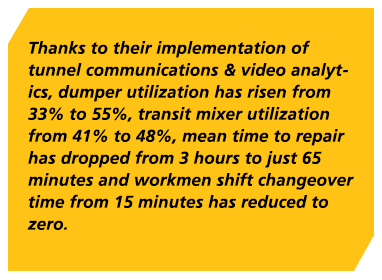

March 2026 looms before Project Manager, Rajesh Chopra, and his team of Himalayan warriors as they push forward to deliver the tough RVNL Package 2 by constructing several tunnels, bridges & formation works. While the team’s efforts to establish a robust tunnel communication system, deploy video analytics, monitor fuel consumption and digitalize drill jumbos & shotcrete machines for enhanced efficiencies have already been dealt with*, here are some more ways they are smartly using technology to fast-track construction.

Smart surveying – where it all began

Very early in the piece, the team realized the difficulty of using traditional methods of surveying considering the time & manpower required to establish control points, conduct detailed tunnel section scans, and ensure precise alignment across long tunnel stretches, that could potentially impede the pace & progress of construction for Paramjit Singh, Senior Construction Manager – Civil, in charge of Project Planning & Controls. Further, manual ground surveys could hardly provide comprehensive 3D visualization for rapid site assessments and accurate volumetric calculations of the extensive earthworks, directly impacting project speed and financial accuracy at scale. “By adopting drones for the survey we reduced manhours, accelerated data acquisition, got accurate 3D visualization and improved billing accuracy for large-scale operations,” he shares, “and, by expanding our capacity to map and analyze extensive terrains quickly, we can monitor progress more efficiently.”

Differential GPS survey: Establishing precise control points across wide geographical areas using traditional traverse surveying would have been a protracted and laborious process, taking up to 15 days that could have directly impacted the speed of set-up and the team’s ability to maintain consistent alignment over long tunnel sections, Paramjit points out. By adopting Differential GPS survey, they reduced survey time by a whopping 87% to just 2 days. “By accelerating our foundational survey, the process accelerated work, allowing us to rapidly establish accurate baselines, critical for scaling our operations and advancing multiple tunnel fronts concurrently.”

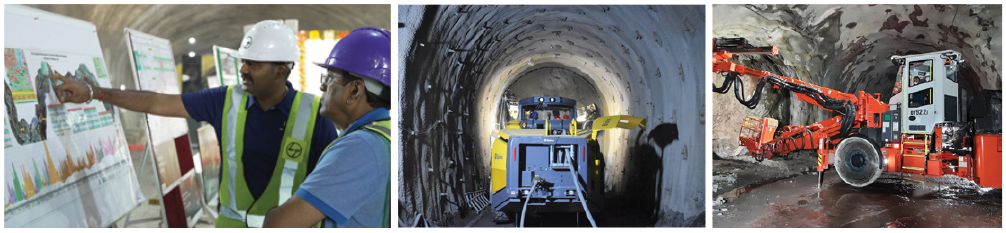

3D Scanner: Using traditional equipment to capture detailed and accurate data for mass quantities of open works and 200-m tunnel sections would have been slow and inefficient, taking approximately 400 minutes per section, severely limiting the team from conducting frequent quality control checks, measuring progress, and adapting quickly to changing ground conditions, thereby impeding operational speed and the scale of detailed analysis. The answer lay in a 3D Scanner that delivered accurate scans with multiple data points and was exceptionally efficient for large volumes. “The 3D scanner could scan a 200-m tunnel section in just 60 minutes, enabling us to comprehensively scan numerous tunnel sections, speedily and accurately,” says a delighted Sanjeev Kumar Tyagi, Construction Head.

Gyromat 3000: Determining true bearings for underground survey works, especially for long and complex tunnel alignments, traditionally involved slower, imprecise methods. Even a minute’s inaccuracy could be compounded over kms risking misalignment between multiple tunnel fronts and ultimately hindering scalability across vast underground networks. “With the Gyromat 3000, we have a most accurate instrument for our underground survey works being deployed for the first time in India’s private sector,” exults Paramjit. Gyromat 3000 empowered the team to maintain exact alignment over extremely long tunnel lengths and scale up tunnelling operations, guaranteeing positional accuracy.

Mastering the underground

“To effectively manage the inherent geological uncertainties of the Lesser Himalayas, we conducted Tunnel Seismic Prediction (TSP) tests, an advanced method developed by AMBERG Technologies AG,” informs Rajesh, “to detect changes in the rock mass, such as irregular bodies, discontinuities, critical faults and fracture zones, ahead of the tunnel face.” By observing and evaluating the elastic body waves generated by artificial sources (detonation charges or impact hammers), the team leveraged seismic reflection to deduce crucial information about the ground’s mechanical properties, including elastic moduli.

The advantages of TSPs are numerous: early warning of adverse geological conditions to implement preventive measures and enhance safety protocols, to design and deploy appropriate ground support in advance to significantly reduce the risk of face collapse and cavity formations. “Most importantly, by proactively identifying the problematic zones, we can adapt our tunnelling methods and resource allocation to prevent unexpected slowdowns and cost escalations,” observes Rajesh.

Automated rebar jumbo movement

The traditional rebar jumbos, used for waterproofing membrane and rebar installation, relied on manual mechanical force and auxiliary equipment like pick-and-carry cranes, along with significant manpower, to move between panels on rail wheels which was time-consuming, and hazardous due to the risk of the moving jumbo tilting from the rail line. The team ‘innovated’ an automated movement system, incorporating an electric motor and gearbox enabling the jumbo to move automatically and independently, eliminating the need for external mechanical equipment, reducing the need for additional manpower, and dramatically reducing the time previously spent on resource arrangement and movement. Quality In-charge, Lekh Raj is thrilled with his team’s innovation. “Not only has this enhancement significantly accelerated panel-to-panel transitions, boosting project speed, but it has also improved site safety by mitigating the risk of tilting, ensuring smoother and more efficient operations.”

To round off, Rajesh shares the impact of some of their several tech inventions. Thanks to their implementation of tunnel communications & video analytics, dumper utilization has risen from 33% to 55%, transit mixer utilization from 41% to 48%, mean time to repair has dropped from 3 hours to just 65 minutes and workmen shift changeover time from 15 minutes has reduced to zero. The team’s fuel monitoring is also reaping rich dividends as also their digitalization of over Rs. 200 Crores worth of assets deployed at site.

“It is a mandate for my team to look at and evaluate every aspect of project execution to see if we can deploy technology to improve our efficiencies,” sums up Rajesh, who is charging himself and his team to meet their March 2026 deadline.

Rajasthan Atomic Power Plant Units 7 & 8

Leading with technology to construct India’s first indigenously designed nuclear power plant

Young Project Manager, C Manikandan and his vibrant team at the Rajasthan Atomic Power Plant Units 7 & 8 are helping their client, NPCIL, by speedily completing a project that was left incomplete by another contractor. While the reactor side of Units 7 & 8 were ready by 2020, the EPC works on the Natural Draught Cooling Towers (NDCT) had ground to a halt and Manikandan’s team from Heavy Civil Infrastructure IC stepped in, bagging the mandate for the balance works after a re-tendering process. The scope includes completing & commissioning four 184 m-tall NDCTs, two cooling water pump houses, 641 m of cold-water tunnels, fabricating & erecting 1,515 m of cement mortar lined and coated pipes, plus various mechanical and electrical installations.

Committed to deliver

“From the outset, our goal was clear: to deliver the project at least one day ahead of the contractual completion date,” declares Manikandan, enthusiastically, “and we succeeded. Unit 7 was completed with an impressive 50 days to spare, and Unit 8 is on track to finish ahead of schedule, the result of our focus on speed, scale, smart execution and tech adoption.”

Keenly appreciative of the client’s requirements, the team had hit the board running by commencing RCC pour of 101 cum of pond floor on the contractual start date itself. The introduction of the cup lock system with site specific schemes, along with precasting, modularisation, mechanisation & technology have powered the team to crash cycle-times. “The internal structure was completed in a record 7 months,” notes Manikandan, “by replacing the cast-in-situ beams with precast ones as approved by the regulatory body and tying the rebar cages, including that for the Hot Water Well riser, on the ground before raising them that enabled parallel construction.”

Harnessing the power of technology

Recognizing the transformative potential of technology, the team has proactively integrated a range of digital applications into their daily workflows throughout the project lifecycle, facilitating real-time tracking, efficient monitoring, and seamless coordination of project essentials. “These tech tools have enhanced our visibility into progress metrics, resource allocation, compliance, streamlined communication and contributing significantly to timely, data-driven decisionmaking and overall project success,” apprises Planning Manager, Anish Achuthan Kutty.

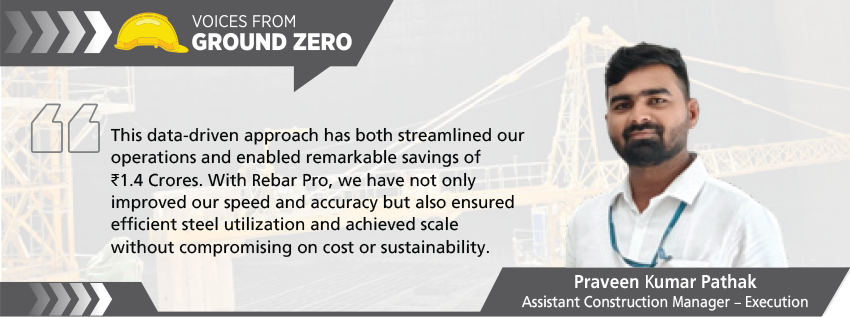

Streamlining rebar management: The digital App, Rebar Pro, has effectively streamlined rebar management, reduced material wastage and rebar fabrication has become more efficient with the integration of the Bar Bending Schedule into the digital workflow. “By aligning fabrication directly with site requirements, the system ensures precise cutting with minimal excess,” points out Praveen Kumar Pathak, Assistant Construction Manager – Execution. Offcuts generated during fabrication are systematically recorded and repurposed for subsequent rebar needs, effectively reducing material wastage. “This data-driven approach has both streamlined our operations and enabled remarkable savings of ₹1.4 Crores,” he highlights.

The advantages of Rebar Pro are many: it enables precise tracking of rebar inventory from receipt to fabrication and placement, optimizes usage of offcuts by reducing procurement cost & scrap, ensures material traceability & seamless reconciliation with drawings and contributes to sustainable construction practices by minimizing rebar wastage. “With Rebar Pro, we have not only improved our speed and accuracy but also ensured efficient steel utilization and achieved scale without compromising on cost or sustainability,” sums up an elated Praveen.

Efficiently tracking concrete: The ConEase App has streamlined the monitoring of concrete production and dispatches, precisely aligning it with site requirements through multi-level verifications before initiating concrete production. “With this robust layer of control and accountability we can track the quantity of concrete produced and the volume received at site in real time,” says Anish, “and this end-to-end visibility enables seamless monitoring, accurate reconciliation, and efficient resource utilization, significantly contributing to quality control and operational efficiency.” Apart from eliminating the need for manual logbook entries, ConEase presents organized and easily retrievable data, structurewise, batching plant-wise, and month-wise, ensuring better traceability and efficient record-keeping.

GPS & fuel sensors: While GPS sensors track vehicle movements in real time, fuel sensors continuously monitor fuel levels, to instantly detect irregularities such as sudden drops or unauthorized fuel removal. This integrated digital system has improved fleet efficiency & operational transparency, enabling them to identify and trace a total fuel removal of approximately 3,356 litres. Based on this data, a penalty of ₹3 lakhs has been recovered from vendors involved in unauthorized fuel withdrawals thus far, reinforcing accountability and control across the system.

Sensor fusion technology: “We continuously monitor the process and performance of NDCTs using sensor fusion technology that integrates smart sensors including ultrasonic flow transmitters, hot and cold-water temperature sensors, RH and temperature transmitters for wet and dry bulb readings, TDS analysers for water concentration, and motionless thermal mass flowmeters for air velocity measurement,” informs Aman Kumar, Construction Manager – Electrical & Instrumentation. He adds that commissioning of electrical components – such as transformers, PMCCs, VVVFDs, panels, and instruments – was accelerated using on-site testing kits. A comprehensive understanding of each component has led to accurate diagnostics and proactive issue resolution, resulting in smoother commissioning.

An App to keep safe: With the SHEILD App, the team logs and monitors safety observations in real time for automatic escalation of issues if they exceed specified timelines and tracks the status of observations. Safety representatives are authorized to acknowledge or reject compliances based on safety norms. SHEILD also enables comprehensive data tracking on a daily, monthly, or project-wise basis and categorizes various unsafe acts & unsafe conditions for the team to analyse trends and take data driven decisions.

Machines in motion: When the team first arrived at site it had a green overgrowth, replete with crocodiles, monkeys and various old and rusted P&M assets of the client lying around. “We overhauled the assets with OEM support in exactly 60 days,” says Thirumalai Swamy, P&M Head, with a thumbs up, “and with sensors started to digitally track them to achieve the desired productivity levels.” Further, the addition of an anti-collision device in tower cranes ensured smooth and safe operation of two tower cranes in a single NDCT.

Success for Manikandan & team has been thanks to them tackling this monumental project with precision and strategy. “We broke the project down into manageable, achievable deliverables, closely monitoring each milestone, and meticulously allocating resources aligned with the construction schedule,” explains Anish, signing off.

This disciplined approach coupled with technology and modularisation has helped in project completion an impressive 3 days ahead of its original contractual completion date, a feat that marks a historic first for nuclear projects in India. For this achievement, NPCIL honoured the team with a Construction Completion Certificate, with Shri Sharat Kumar (ED, Projects – PHWR) stating, ‘This young team of L&T led by Mr. Manikandan C have gone beyond the traditional norms and worked beyond their boundaries to make this day possible.’

RVNL Package 4

Raising the bar in Himalayan tunnelling

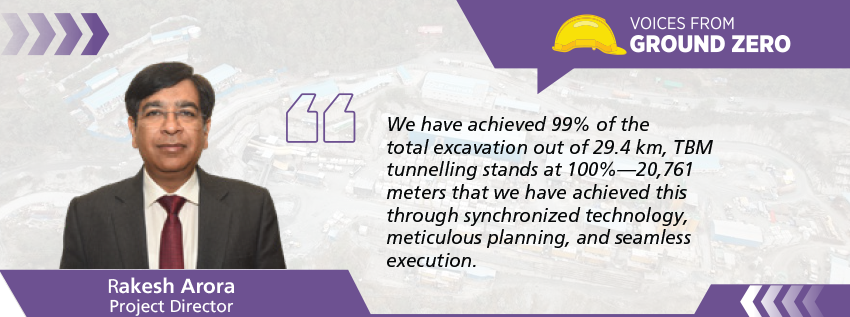

In the heart of the Himalayas, the RVNL Package 4 team has delivered a breakthrough of national significance with the ahead-of-schedule breakthroughs of two massive TBMs, ‘Shiv’ & ‘Shakti’, on the Rishikesh–Karnaprayag rail line. “We have achieved 99% of the total excavation out of 29.4 km, TBM tunnelling stands at 100%—20,761 meters that we have achieved this through synchronized technology, meticulous planning, and seamless execution,” says Project Director, Rakesh Arora, triumphantly.

Relying on an integrated digital eco-system

From launch to breakthrough, every TBM operation phase was driven by interconnected digital technologies, central to which was ISETIA, a cloud-based project management suite, that provides real-time visibility across tunnelling progress, schedules, risks, and BIM data. Simultaneously, HK Connect offers live dashboards, tracking TBM parameters and sensor data for real-time performance optimization.

A major contributor to risk mitigation was the Tunnel Seismic Prediction (TSP) enabling teams to detect geological anomalies up to 100 m ahead of the TBM face. “The TSP detects water-bearing strata, faults, and unstable ground before they became risks, enabling smoother, safer tunnelling,” explains Senior Geologist Manoj Kumar.

By integrating smart systems and engineering innovations, TBM Shakti achieved its breakthrough on April 16, 2025, 12 days ahead of baseline schedule while TBM Shiv, set a world record by excavating 706 m in June 2025, 760 m in 30 days, 791 m in 31 days and achieved the breakthrough on June 28, 2025, 2 days ahead of baseline schedule, demonstrating peak performance in one of the world’s most challenging tunnelling environments.

Other digital solutions driving efficiency for Rakesh & team are the ConEase App, that controls demand of concrete by reducing excess material onsite, the Rebar Pro App that optimizes TMT steel use, minimizing waste & aiding accurate reconciliation, the Shield App that keeps the site safe, the Quality Sanyog App that streamlines the QA/QC process, Primavera & TILOS for advanced planning & scheduling and Material NxT for real time material management & traceability.

Automation powering progress

Ground-level construction automation took shape with a fully automatic carousel system that ramped up precast segment production to 30 rings per day, helping complete all the 12,223 segments ahead of schedule. An in-house skid jack system moved the two 168-T TBMs into launch position in just 14 and 8 days respectively, against the original timelines of 120 and 30 days. “This system eliminates the need for welding reaction frames, reducing labour and boosting speed by 33%,” highlights Rakesh.

The Workmen Application System and Segment Documentation System (SDS) provided real-time control over tunnelling which streamlined workflow coordination and resource planning, with production reaching 642 rings equivalent to 1,091.4 m of lining instead of the originally planned 600 rings. These platforms ensured synchronized workflows between labour, casting yards, and tunnel advancement. As Shamim Ahmed, Project Control Head, noted: “From transporting over 110 TBM consignments to assembling them four weeks earlier using the CARL system, every logistical challenge was resolved through technology, teamwork, and planning leading to tunnel breakthroughs ahead of baseline schedule.”

Dismantling TBMs smartly

The advanced lifter gantry system and a strand jack assembly, engineered for precision, safety, and efficiency in confined tunnelling space of 73 m was pressed into service to smartly dismantle the two TBMs.

The lifter, designed with Synchronized Lifting and Travel technology, ensures uniform height maintenance across all four legs, preventing load shifts or instability. A detachable encoder continuously measures travel distance and leg speed, feeding real-time data into the CARL Master Control System, which governs automated ramp-up and ramp-down to reduce load swing during lifting.

Operators manage the lifter remotely via a Radio Remote Control, which includes a digital display showing leg height, load weight, and pressure for each support. The CARL system adds another layer of safety, capable of initiating an automatic shutdown during overloads or exceeding preset height limits. The cutterhead weighing 207 T was successfully tilted and lowered onto 12 resting stools using the lifting system.

Once lifted and dismantled, the TBM’s heavy-duty components will be transported to the portal on Self-Propelled Modular Transporters (SPMTs) while other structural parts will be moved on Multi-Section Vehicles (MSVs).

Accolades & industry recognition

The team’s exemplary performance has won them several awards & recognition from various industry bodies across disciplines. Recognition from the Ministry of Railways for TBM Breakthrough & Transport, Golden Peacock Award for Risk Management, Winner in the IPM Conclave 2023 (Innovation in Engineering & SCM), 2nd Place Energy/Carbon Footprint Award from CII, Excellence in Precast – Casting of 12,220 Rings and client appreciation for their WTP Installation. On the safety front, the project has clocked 20 million safe manhours, a Bronze 2-Star Trophy from World Safety Organization (WSO) & the Silver Award for EHS Excellence from CII.

Pakal Dul HEP, HRT-TBM Package

A tech-first approach to overcome Himalayan challenges

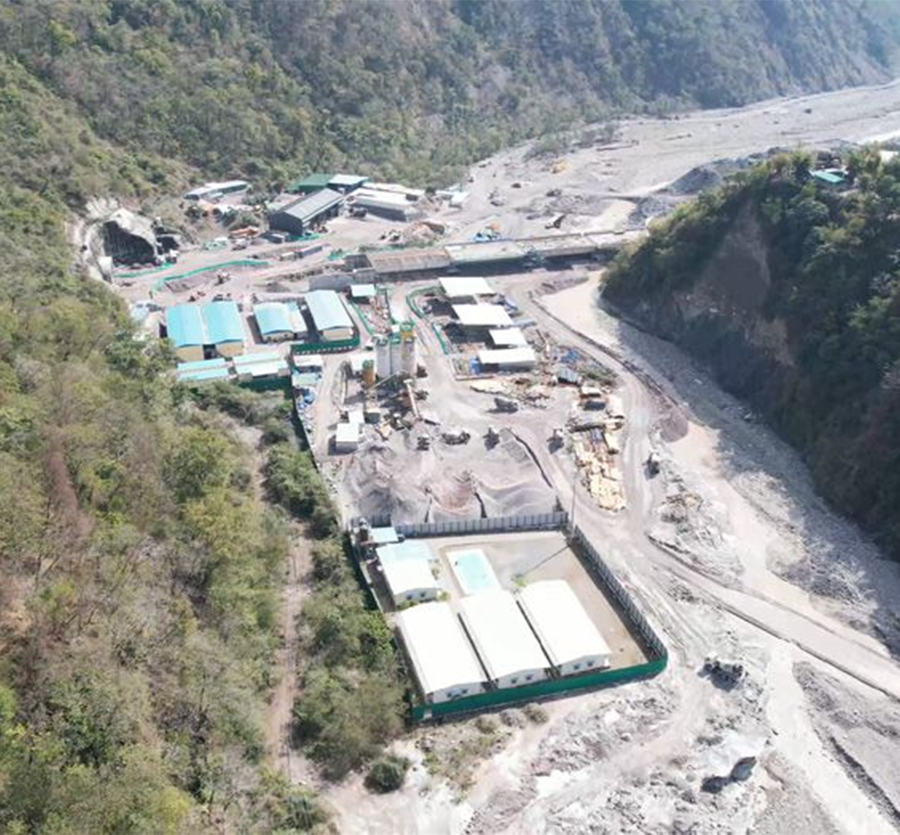

TBM portal faciities

In the rugged mountains of Kishtwar, Jammu & Kashmir, the Pakal Dul Hydroelectric Project (1000 MW) is giving expression to India’s renewable energy ambitions. Monitored by the Ministry of Power as a project of national importance, this storage scheme on the Marusudar River, located in the Indus Valley, leverages a 417 m gross head to generate 3330.18 MU annually. Under the leadership of Project Manager, Ashiwani Kumar Tripathi, a Heavy Civil Infrastructure IC team is driving the HRT-TBM Package, to deliver twin 7.35 km-long head race tunnels (7.2 m diameter) using advanced TBMs. Their scope also includes TBM and NATM adits, a 77 m-high portal excavation, a 36 m-span bridge, 10,446 precast tunnel lining rings, and a massive 2.16 lakh cum portal excavation, split evenly between rock and overburden, fortified with designed slope supports and instrumentation, all within a 66-month commissioning timeline.

A tech-driven approach for speed

“We have been mandated to execute precise tunnelling in an extremely unpredictable geology while adhering to stringent timelines and security protocols,” says Ashiwani,“ and have embraced a tech-first approach, integrating tech tools and innovative engineering to improve our speed, safety, and quality,” he states pragmatically that has already translated into the team’s successful excavation of over 9 km of tunnels, supported by modular precasting and TBM optimization.

From superior surveying methods, automated curing systems to geophysical predictions, the team has deployed solutions tailored to the site’s demands that have streamlined processes like segment production, fuel management, and tunnel alignment, manage geological uncertainties, resources and control quality.

“By breaking down this colossal project into smaller, achievable milestones, we track every detail with our digital platforms,” observes Krishn Mohan Singh, Project Planning and Controls Lead.

An attempt to tame the terrain

It was obvious for the team from Day One that the rugged mountainous terrain, steep gradients, and dense forest cover would render conventional ground-based and topographic surveys challenging, repetitive, time-consuming and inaccurate. Their task was further complicated by geopolitical constraints due to the proximity to sensitive border zones with security-related restrictions and limited access, often requiring special permissions.

“By deploying DGPS Survey, we established and verified control points, ensuring accurate positioning and correlation between different survey points,” says an exultant Construction Head, Omprakash Thakare, “and with the Wriggle Survey, we were able to determine the actual position and orientation of the TBMs.” The survey ensured accurate tunnel alignment and its construction according to design specifications, helping the team detect deviations from the planned tunnel alignment to take timely corrective actions, reduce errors and minimize rework.

Looking before you tunnel

For TBM Lead, Marius Du Mont Barnard, it was imperative to have a fair sense of the geological anomalies/uncertainties that the team could encounter when tunnelling for which they have deployed the TSP (Tunnel Seismic Prediction) 603 developed by Amberg Technologies. It delivers a controlled impact to the ground or rock surface through an impact hammer to generate seismic waves that propagate through the rock mass and are analysed to understand ground properties and image the structure. The Amberg TSP Impact includes a trigger mechanism that ultra-accurately synchronizes the impact event with the deployed TSP 603 Receiver/Transceiver devices ensuring precise recording of seismic wave arrival times through its own wireless transmission system.

Certainly, the TSP has taken a huge load of Marius’ back. “We can now detect geological anomalies such as faults, shear zones, fractured rock, and cavities ahead of the tunnel face early, identify water-bearing formations to prevent water ingress during excavation and with our predictive modelling for long tunnel sections our decisionmaking for excavation and support strategies has improved immeasurably.” He pauses for a moment and laughs, “Basically, it has drastically reduced the chances of the geology springing unpleasant surprises at us during tunnelling.”

Digitizing the tunnel segment production lifecycle

A digital end-to end visibility and control over the entire lifecycle of tunnel segment production is a huge shot in the arm for the team thanks to their Tunnel Segment Management System (TSMS) that obsoletes the inefficient paper-based checklists and manual tracking method. It integrates all critical production and inspection checkpoints into a single digital platform including RFIs, rebar cage & concrete prepour checklists, integrating concreting data, monitoring the steam curing process, demoulding & post-pour checklists and mandatory QA/QC approvals for every stage.

“In fact, the system does not allow progression to the next activity without clearance from QA/QC, ensuring strict adherence to quality protocols and accountability,” says an immensely satisfied Puneet Kumar Sharma, Senior Manager QA/QC. “Apart from integrating with apps like ConEase for concreting data, with TSMS, we enjoy the benefits of centralized traceability, reduced paperwork, faster cycles, and compliance assurance, producing high-quality rings efficiently.”

TBM navigating through 300 rm radius in Adit Tunnel

Tunnel Segment Casting Yard

Automatically controlling the temperature for steam curing

Maintaining the right curing temperature is critical to achieve the desired concrete strength and durability. However, traditional methods using manual temperature checks with handheld thermometers at intervals during the steam curing cycle was time-consuming, inaccurate and inefficient often resulting in inconsistent temperature control adversely impacting the curing process that could in turn result in issues with the strength of the segments, shrinkage cracks and increase in cycle times.

To address these many issues, the team has introduced an automatic temperature control system utilizing temperature sensors embedded within the segment covers to continuously monitor the temperature and automatically adjust the curing pipeline valves to regulate the temperature in real-time. “By ensuring that the required temperature is maintained consistently, without the need for manual intervention, our operators and supervisors can monitor the temperature of the steam curing cycle in real time with a digital display at the curing chambers,” informs Raj Kamal Thapa, Senior Manager Casting. The system alerts if the temperature goes out of the predefined range and automated data logging ensures consistent records for QA/QC and audit trails. “What’s more, it has reduced the manpower required to monitor and log and, most importantly, it has improved the quality of our concrete reducing rejection and rework,” he smiles, with a thumbs up.

Staying in touch inside the tunnels

It is imperative to stay connected deep in the tunnels for coordination and monitoring for which the team has a dedicated system to ensure seamless internet, voice, and data transmission. Krishn’s relief is obvious for this system has enhanced real-time collaboration, from TBM operations to emergency responses by supporting IoT integrations, accelerating decision-making and supporting the team’s other tech tools like TSMS and fuel monitoring.

Stop. Monitor. Save.

With fuel pilferage and inefficient consumption plaguing equipment operations, the team has resorted to an integrated digital system with RFID-enabled dispensers, fuel sensors, GPS trackers, and IoT gateways. “Now, fuel is dispensed only after RFID scanning, with sensors tracking filling, consumption, and anomalies in real-time,” informs Bala Tharmar, Senior Manager P&M, “while a centralized monitoring system detects discrepancies, enabling geofencing and theft alerts.” Bala’s face is alight as he shares that their fuel efficiency has improved hugely e.g., Hydra Crane from 5L/hr to 2L/hr, pilferage eliminated (from 100L/month to nil), and 834 litres of drained diesel recovered, yielding significant cost savings.

Even as the team’s concerted EHS efforts led by EHS In-charge, Vseem Zahir, to drive Mision Zero Harm has succeeded in preventing any LTIs thus far, Ashiwani’s unerring focus remains on delivering this vital infrastructure ahead of time despite all the challenges that he and his hardy team members continue to face and overcome with elan.