AMAALA Utilities PPP Project, KSA

A mega-scale sustainable tourist destination

With the world accelerating its shift towards sustainable energy, Renewables IC is leading the charge to meet the growing demand while setting new benchmarks in tech- powered project delivery, and in the process, building a future of clean energy in the Gulf – faster and smarter.

Supporting Saudi Arabia’s ambitious Vision 2030, the AMAALA Utilities Project, located 40 km north of Al-Wajh in the Tabuk Province, underpins the luxury tourist destination AMAALA, with off-grid, sustainable utility infrastructure for power and water – an integrated system designed and delivered by L&T for the first time at such a scale. The challenge before Project Director Swapan Deb and team was to deliver the entire scope within a 21-month timeframe from the Notice to Proceed. “To enhance productivity and accelerate progress, we increased modularization during execution, moving from the conventional style of execution to a more mechanized and automated implementation. Our robust planning and strategic deployment of smart systems won us the day,” he exults, “helping us to hit critical early energization milestones, like commissioning the Staff Village and Triple Bay substations, in just 183 days.”

The extensive scope of the AMAALA Project encompasses three distinct zones:

- Central Infrastructure Hub – dedicated to energy generation and transmission

- Staff Village – equipped with both power & water utilities and marine infrastructure

- Triple Bay – integrated power and water utilities infrastructure

The power infrastructure constitutes a hybrid model featuring 248 MWp solar PV, a 759 MWh battery energy storage system (BESS), and 52 MW internal combustion engines (ICEs), centrally managed at the Power Hub, with energy distributed via overhead and underground transmission networks. On the ‘water’ front, being executed with support from WET IC, the project includes 37 MLD RO plants, sewage treatment plants, 48 ML tank farms, and a 19 km piping network covering potable, raw, treated sewage, and irrigation pipelines. Marine components involve seashore micro-tunnelling using Microtunnel Boring Machine for seawater intake and outfall, executed at 27 m below sea level.

Smart systems for operational excellence

“A critical enabler was the deployment of a SCADA-based Transmission Demand Management System (TDMS) architecture,” shares Chandan Kumar Turala, Project Controls Manager, “an important part of a smart power grid control system that follows the supply–demand balance changes, to ensure frequency regulation, voltage control, and load following/ramping for reliable, efficient, and uninterrupted power supply.” The sophisticated TDMS uses SCADA technology to monitor and control the demand for electricity, enhancing efficiency, improving reliability, and optimizing energy, vital for such a large-scale off-grid development.

A Micro TBM

BIM 7D steering the tech march

“With 7D BIM we integrated the project’s design, construction, and lifecycle management with sustainability and facility maintenance data,” informs Supriyo Ghosh, Digital Officer. “Beyond the traditional 3D modelling, BIM 7D incorporates time scheduling (4D), cost management (5D), sustainability analysis (6D), and facility management (7D).” This comprehensive approach enabled real-time collaboration, better visualization, optimized resource allocation, and predictive maintenance planning. “7D BIM improved our efficiencies, reduced risks, and supported long-term operational excellence for the complex utility infrastructure,” Supriyo adds for good measure.

Tunnelling responsibly

The team had the unenviable responsibility to maintain the rich and diverse ecosystem in which the project was executed. Bordering the Red Sea, the ecologically sensitive marine environment was home to more than 1,200 species of coral and fish 10% of which was endemic, found nowhere else in the world. “Our micro-tunnelling technology minimized disruptions to the seabed when constructing the seawater intake (2 lines of 650 m each) and outfall (1 line of 870 m) pipelines, each with a 1,600 mm internal diameter,” apprises Swapan. The method involved precision tunnelling 27 m below sea level, using barge-mounted equipment and secant pile jacking shafts onshore, supported by coral rehabilitation, turbidity control measures like silt curtains, and environmentally compliant machinery.

Lighting the night

‘Dark sky lighting’, an environmentally responsible illumination method, minimizes light pollution while preserving natural night environment. “With shielded, full cut-off fixtures and warm-toned, downward-directed lighting with dimming controls, we have improved visibility and safety, protected the local ecosystems, supported human health, and taken a major step towards sustainable urban planning,” informs Chandan.

Communities that adopt dark sky practices benefit from reduced energy costs, increased awareness of natural rhythms, and a stronger connection to the night sky, which conserves energy and promotes eco-tourism by preserving the clarity of the night sky.

With the project about two-thirds complete, Swapan and team are well on track, steadily progressing towards successful project completion.

DEWA VI 1,800 MWac Solar PV Project, UAE

A cornerstone of Dubai’s ambitious clean energy strategy

The ultramodern desert metropolis of Dubai is chasing ambitious targets of achieving 25% clean energy by 2030 and 100% from clean energy sources by 2050. As a part of the Dubai Clean Energy and Net Zero Emissions Strategies, the DEWA VI Project is the sixth phase in the development of the Mohammed bin Rashid Al Maktoum Solar Park – one of the world’s largest renewable projects based on the independent power producer (IPP) model – with a planned production capacity of 1,800 MW, covering over 20 km2 to be installed in three phases (Phase A: 600 MW, Phase B: 400 MW, and Phase C: 800 MW).

The scope of work for Renewables IC includes the design, engineering, procurement, construction, testing, and commissioning of the solar PV plant, constructing two 132/33 kV substations, laying 132 kV underground cables, and building medium-voltage power distribution facilities. “Our primary challenges include managing massive earthworks in tough terrains, overcoming global supply chain disruptions, and delivering the 1 GWac solar capacity of Phases A & B in just 14 months, with 10 months to construct the 132/33 kV substation and associated 132 kV UG cabling works,” notes Project Director Sathya Narahyana R R.

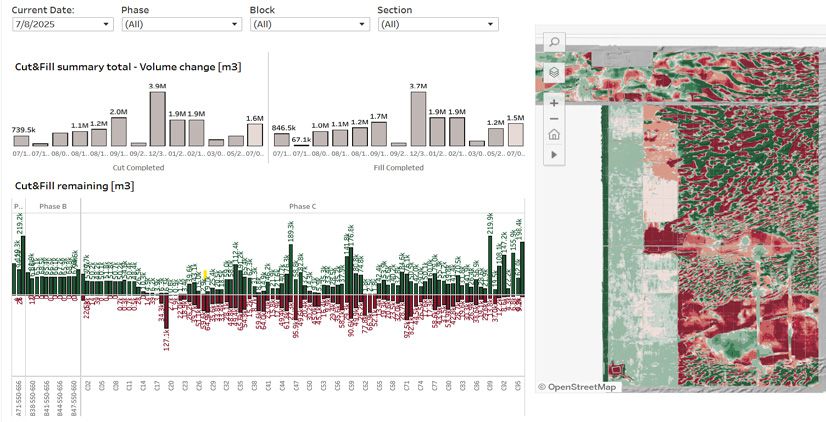

Traversing tough terrain

In pursuit of their project milestones, Planning In-charge Ashish Kumar Gupta and team set about meticulously grading, levelling, and preparing the site with a stable and level foundation to mitigate risks during and after construction. “We executed sand cut & fill works to the tune of 29 million cubic metres, with sand dunes rising to heights of up to 17 m,” remarks Ashish, adding that for the difficult hard-rock terrains, the team opted for trenchers instead of breakers to prepare the surface to erect the panels.

“Robots surveyed and marked tracker post locations, while the module mapping dashboard efficiently plotted the area for the plant,” reveals Digital Officer Kalyani Gutta. “Additionally, drones are carrying out IR thermography to highlight areas with abnormal temperatures indicating potential problems in the installed panels.”

An important factor in any solar plant is the pitch distance, the distance from the axis of one tracker to the next, which influences the plant’s Ground Coverage Ratio (GCR) of how much area is covered by the PV modules. The maximum electricity output from each solar panel depends on the environmental conditions and the design of the plant, including the tilt angle and spacing between the panels. A well-designed PV plant balances costs against system efficiency to provide the lowest levelized cost of energy (LCOE).

Ashish explains that the pitch determines how much each row of solar panels is shaded by the adjacent rows, which reduces the amount of sunlight they can absorb, while a larger distance limits the number of panels that can be installed at site. “The pitch distance in our project is the shortest we have executed in any project, at 3.8–4.5 metres; our plant has attained the lowest LCOE of USD 1.6215 per kWh for any of DEWA’s solar IPP projects thus far,” he says rousingly.

Precast pushing progress

Prefabricating the building for the substation & O&M and precasting the foundations for the lightning arrester and weather monitoring system speeded implementation, while prefabricated, containerized MVPS and inverter skids further eased execution. “For the 132 kV cable routing, we used flat formation laying for the first time with DEWA, a new method that improves cable installation efficiency, reduces the number of joints, decreases installation time, and enhances long-term performance with more reliability,”adds Ashish.

Tech providing the decisive edge

The DEWA VI Project, a first of its kind in the UAE, involves cutting-edge technology such as the latest N-type TOPCon cell technology for the bifacial modules, horizontal single-axis trackers, second- & third-generation robotic cleaning systems, and 8.8 MVA MVPS blocks with 8 maximum power point tracking (MPPT) modules. “The sky camera–based system forecasts parameters like global horizontal irradiance (GHI), temperature, wind speed & direction, relative humidity, and precipitation,” informs Kalyani.

Drone survey for cut & fill

Robot survey

“Wireless ARCS, SMB, and tracker communication both eased installations and reduced communication downtime,” she mentions, adding that the team used advanced tools for design, analysis, and execution:

- PVsyst for simulating & evaluating system performance

- PVcase for design & yield optimization

- CYMCAP for power cable ampacity & temperature rise calculations

- CYMGRD for design & analysis of grounding grids

- CDEGS for analysing electromagnetic problems related to grounding, earthing, lightning, & interference mitigation

“We maintain efficiency, reliability, and precision with this comprehensive suite of advanced software along with other tools like STAAD.Pro, Civil 3D, Ansys, and ETABS,” she adds purposefully.

With Phase A done and Phase B close to completion, Sathya Narahyana and team are thankful for the tech arsenal at their disposal to deliver the project on time to DEWA.

2,000 MW Ar Rass 2 and 1,425 MW Al Kahfah

Solar PV Projects, KSA

Among the region’s largest single-site solar PV installations

2,000 MW Ar Rass 2 Solar Plant

1,425 MW Al Kahfah Solar Plant

Amidst the deserts of Saudi Arabia, 7,952 acres of land in Ar Rass in the province of Al- Qassim will soon be home to more than 3 million solar panels at the Ar Rass 2 Solar PV Plant; and further north, around 140 km southeast of the city of Hail, at the Al Kahfah Solar Plant.

“As of 30 May 2025, we have successfully completed constructing the 2,000 MW power plant,” proudly proclaims Avesh Kumar Verma, Project Director – Ar Rass 2 Solar Plant.

“Despite the massive scope and challenging remote location, we have energized our project on schedule and within budget,” beams Abdul Hanif Khan, Project Director – Al Kahfah Solar PV Plant.

Both these solar plant projects stand as a benchmark for Renewables IC, exemplifying speed, scale, and technological innovation.

Alluding to the magnitude of work at the Ar Rass 2 project to be completed in 33 months, Avesh reels off the numbers: 554,000 vertical posts, 41,000+ trackers, 3.6 million modules, 248 MVPS stations, and three 132/33 kV pooling substations.

The mandate for Abdul and team at the Al Kahfah project is just as demanding: 399,000+ vertical posts, 26,781 trackers, 2.7 million PV modules, 137 MVPS stations, two 132/33 kV pooling stations, and 2.7 million CBM of grading & levelling, to be completed in 27 months.

Seamless coordination of a multidisciplinary workforce and a robust logistics network are imperative to maintain progress. “We constructed and installed 1 GW of the PV array in 12 months,” observes Mohammed Irtequa Aman, Project Controls Manager – Al Kahfah Solar Plant.

Latest tech to ease operations

The Al Kahfah Solar Plant uses terrain-following trackers that are adaptable to the contours of the land, reducing the need for extensive earthwork at sites with sloped, uneven, and challenging terrains. “By eliminating the need for additional grading and levelling (G&L), the requirement for equipment, machinery, and manpower has been reduced,” notes Irtequa Aman, “in addition to reducing time, cutting costs, and minimizing environmental impact.”

“With terrain-following trackers reducing the original scope of G&L work of 45.7 million sqm to 27.9 million sqm, we reduced the duration of the activity by almost 40% while maintaining the natural condition of the land, provisioning for a comfortable vertical tolerance with shim kit,” notes Abdul.

Leveraging a digital project ecosystem

“AI-based drones monitor daily progress at the Ar Rass 2 site, while timelapse cameras document construction milestones,” notes Avesh. “Over 15,000 activities are monitored through dynamic bottleneck identification in Oracle P6 with Predictive Scheduling,” remarks S N H Prasad, Project Controls Manager. “Primavera presents us with weekly & monthly progress reports, look ahead plans, monitoring planned vs actual schedules, asking rates for productivity, client reporting, and much more.”

Grading & levelling and inverter skids at Al Kahfah

Prasad adds that HAP software was used for the design and energy analysis of the HVAC system, to optimize the return ducting, reducing the cost & time for manufacturing & installation.

Microsoft SharePoint is used for digital data storage and transfer to both internal and external stakeholders. “Other digital applications developed for the project, such as RFID cards for the workers & visitor gate passes, are integrated to the SharePoint cloud to enable collaborative data transfer and ensure transparency,” reveals Mohamed Ali Varusai, Digital Officer of Gulf 1 BU.

Cloud-based monitoring to keep assets in check

To transform the challenging rocky terrain into a viable site for a solar plant, the G&L work required mobilizing over 500 pieces of equipment for each site, a substantial capital investment. “Given the scale of the operations, it is crucial to closely monitor and maintain this extensive fleet of machinery,” notes Mohamed Ali; “we have equipped all our P&M assets with GPS trackers and cloud data collection for real-time tracking, monitoring, and control across both sites.” An RFID & face scan system, vehicle access control system, and license plate reader track all entry & exit points to restrict unauthorized entry, while a CCTV network combined with time lapse & drone cameras protect the assets.

Advanced machinery like trenchers and surface miners have been identified and mobilized from other countries by the P&M team to adhere to the team’s stringent timelines. “The cloud-based data helps us monitor all equipment for productivity and maintenance,” Irtequa Aman adds. These initiatives aided the Al Kahfah team in achieving 283 km of LV trench excavation using the trenchers and rock-breaking excavators.

Pooling substation precast works and automatic panel-cleaning robots at Ar Rass 2

Smart construction strategy drives progress

Both solar plants incorporate an evolved design featuring inverter skids, which support off-grid hot commissioning in accelerated timelines, standardized design, and minimal interconnection risks. “These pre-integrated skids enable plug-and-play electrical deployment, reducing onsite assembly time by 30%,” reveals Prasad. “The skids use pile cap foundations instead of the typical cast-in-situ foundations, further saving cost & time.”

“Automated tracker installation rigs improve our accuracy and productivity,” adds Irtequa Aman, “while precast concrete applications for HCIS lighting poles, camera pole foundations, and substation building superstructure works have significantly reduced on-site construction time by 40%.”

With such smart strategies in place, it is no wonder that Avesh, Abdul, and their teams are powered to delivering two massive solar plants to help realize Saudi Vision 2030.