With water infrastructure becoming more complex, and the growing demand for smarter, sustainable, and integrated project delivery, several WET IC projects are adopting technology for smarter, cleaner, and sustainable water management.

Water for every acre

The Kalisindh and Parwati Projects of WET IC in Madhya Pradesh have been heaven sent for the farmers in the region. “Our ISP Kalisindh Phase 1 covers 282 villages benefitting 182,000 farmers, while the ISP Parwati Phases 1 & 2 benefit 83,340 farmers in 268 villages,” informs Kishore Kalsangra, Project Manager (Instrumentation), “and they will benefit even more with our new OMS technology supporting micro-irrigation.”

A smart, tech-driven solution that precisely controls water distribution in micro-irrigation, the Outlet Management System (OMS) ensures that crops get just the right amount of water, boosting farm output and saving resources. In micro-irrigation, a large Culturable Command Area (CCA) is broken down into bigger sections called ‘chaks’, typically 20–30 hectares, and each of these chaks is then further divided into 8–10 smaller plots, or ‘sub-chaks’, each about 2.5–3 hectares in size.

“One OMS unit is set up for every 20–30-hectare chak with a 100 mm inlet and eight to ten 50 mm outlets connected by HDPE pipelines,” informs Design Head (Mechanical), Srinivasan Boominathan. Inside each OMS unit are flow control valves, solenoid on/off valves, air release valves, and flow meters, all managed by a small Remote Terminal Unit (RTU) that runs on a solar-powered battery, constantly monitoring water flow and pressure through the SCADA dashboard. Data is wirelessly transmitted over a license-free radio band to a nearby gateway (which can handle up to 20 units), which in turn sends the data to a secure cloud server using GPRS. In case the wireless connection drops, the RTU saves the data and uploads it later with a timestamp.

Life is easier both for the farmers and for irrigation managers as they can log in on their phones or PCs for real-time updates and to monitor precisely how much water each sub-chak receives for accurate and efficient irrigation, using automation and auto-scheduling to significantly reduce water waste.

Several challenges to overcome

Prior to implementing OMS, the team faced challenges with respect to component performance, services, and consistency from their third-party vendor. “The vendor was manufacturing their own key components, creating a monopoly situation that limited procurement flexibility and cost control, leading to supply disruptions and execution delays,” rues Planning Manager – OMS, Vikash Vinod Sharma. While operational challenges with the control valves to remotely regulate flow resulted in inconsistent flow control, the communication network was solely dependent on the proprietary LoRaWAN network that was integrated with the RTU to provide data to the control room. Communication failures were therefore common due to inadequate gateway coverage, high node density, and dependence on the proprietary LoRaWAN with open-source servers.

The team had to additionally contend with a vendor who enjoyed a significant price advantage, being a monopoly player importing components, apart from high dependency for spare parts replacements. The lack of expertise in automation and communication led to long delays in commissioning, resulting in longer downtimes that in turn resulted in inconsistent water supply to the sub-chaks.

Introducing the in-house OMS

To overcome the challenges faced during the previous OMS implementation by an external vendor, Murali Mohan Murty, Vice President & Head – Urban Water & Water Management, spearheaded the development of an in-house OMS. This initiative commenced with the establishment of a dedicated task force led by S Devanand, Head – Large Water Systems (North & West), supported by design heads Srinivasan Boominathan (Mechanical) and Sivakumar Santhanagopalan (Instrumentation), with a mandate to design a unique, flexible, and reliable OMS that is easily serviceable with easily accessible spare parts.

After exploring various micro-irrigation technologies and vendors from across India and globally to understand their products & performance, the team shortlisted compatible vendors based on their ability to be flexible and reliable, with the capacity to supply key components like RTUs, gateways, flow meters, and control valves on time. “We preferred to go with an open-source platform for LoRa communication instead of the proprietary LoRaWAN system,” explains Vikash, “and developed an integrated system by selecting interchangeable parts from multiple suppliers, making the design flexible & scalable. Running multiple Proof of Concept (PoC) tests at the internal facility for all selected components helped us to validate whether they worked well together and as expected,” he adds.

The OMS system has been redesigned into two sub-headers, each managing 10 hectares, with each sub-header controlling the water flow for one 2.5-hectare sub-chak at a time during rotation, with the help of a flow meter, a pressure transmitter, a dual-solenoid electronically operated diaphragm flow control valve (EOFCV), and four solenoid-operated on/off valves. Any change in water pressure is detected by the RTU, which quickly checks the new flow data from the flow meter and instructs the EOFCV to adjust and keep the water flowing at the right level.

“Internally, we set up a test bench to prove that this new solution works by training an in-house team to assemble the components and develop customized RTUs and gateways that can handle 50–60 RTUs,” shares Kishore, “which has enabled us to improve the system to be more reliable, efficient, and easier to maintain.”

“To monitor and control the flow rates accurately, an industrial-grade RTU was designed with a Proportional Integral Derivative (PID) control feedback system, a LoRa gateway, and a WebSCADA interface,” apprises Design Head (Instrumentation), Sivakumar Santhangopalan. “The LoRa SPI architecture supports up to 20 devices per gateway, which has improved our communication reliability, giving us over 99.99% uptime, even in densely populated areas.”

Implementing 10,041 units across some 2,00,000 hectares is a matter of pride for M Raja, OMS Execution In-charge, ISP Kalisindh Phase 1, and S Shreenivas, OMS Execution In-charge, ISP Parwati Phases 1 & 2; thanks to their success, L&T’s OMS solution is being extended to Parwati Phases 3 & 4 for 4,839 units covering 1,00,000 hectares.

The scalable, future-ready architecture developed for the OMS RTU can easily be integrated with smart farming techniques without any redesigning. By establishing a competitive vendor ecosystem, the team has created avenues for better price negotiations and long-term partnerships, while strategic sourcing through universally compatible diaphragm valves, standardized components, and customized RTUs/ gateways has broadened the vendor network. “Not only have we improved our project control and eliminated supply bottlenecks, but we are ready for future implementation and operations,” sums up Kishore.

Making each drop count

The sad reality is that over 40% of supplied water goes unbilled due to aging infrastructure, leaks, faulty meters, and/or unauthorized consumption – much higher than the recommended 15% by the Central Public Health and Environmental Engineering Organization (CPHEEO). While attempting to plug this leak manually is daunting and hugely time-consuming, typically requiring from 6 months to a year to check and rectify matters in every District Metred Area (DMA), the better option was technology.

An ML tool to reduce NRW

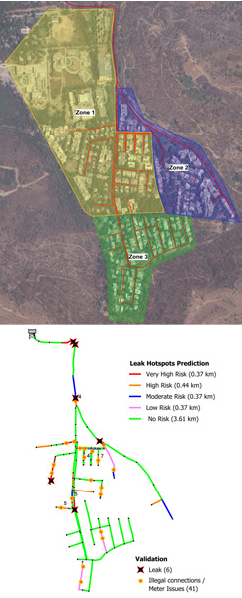

The Hydraulics Team at the Water Technology Centre (WTC) has developed an in-house Machine Learning (ML) tool that analyses historical and real-time sensor data to pinpoint leakage ‘hotspots’ down to specific pipe segments, reducing detection time to under 90 days, regardless of the DMA’s complexity.

“This meticulously engineered ML solution provides actionable insights and redefines decision-making, driving a digital revolution,” shares Bharanidharan B, Manager – Research (Digital Hydraulics), WTC. The network is divided into smaller zones for analysis, collecting data on pipes, layouts, and monthly household water usage. Initial water losses are identified by comparing supplied versus consumed water. A hydraulic model of the distribution network is created using EPANET and integrated with R software to simulate various leak scenarios. The ML algorithm predicts main loss locations, guides field validation, and helps reduce water losses.

In Pune’s Panchavati area, this integration of ML with hydraulic modeling has reduced non-revenue water (NRW) from 52% to 28%, enabling proactive intervention using existing infrastructure and significantly minimizing manual efforts.

For Rajesh C, Project Manager of the Pune 24×7 Package, the gains are more grounded. “The ML tool has played a crucial role in transitioning from intermittent to 24/7 water supply, while simultaneously optimizing operational efficiency and resource utilization. Happy with its success, we are now expanding it to 10 more areas,” he shares, sounding like he is onto a good thing.

However, preparing the inputs for Bharanidharan and team to develop the tool was arduous, having to first break the network into smaller zones for better analysis and gather data from pipes, layout, and monthly water usage from homes in the area, then identify initial leaks and compare the water supplied to water consumed to find the starting amount of lost water. Using EPANET software, the team created a computer model of the water network, which was then connected to the R software to test different leak-finding formulas. The chosen formula (ML algorithm) was then used to predict locations of the main water losses, validate them in the field to confirm the leaks, and then reduce the amount of water lost.

Pinpointing the leak points narrowed down by ML, on ground, using acoustic technique

Specific data is collected from each new area, and common rules are created using AI. “Soon, users can simply enter details for any area, and the AI will instantly pinpoint leaks and suggest fixes,” states Rajesh enthusiastically. “We are also building an easy-to-use interface to make this powerful analysis accessible soon.”

This smart tool promises huge savings and less water wasted. Increased revenue, extended life of equipment, and reduced operational costs are some of the obvious and immediate benefits. The tool has importantly ushered in a data-focused culture, helping employees gain new skills and improving public health by reducing contamination risks.

Rock-ready automation

To conquer the challenges of laying pipes in rocky and hard terrains, a WET team, along with the L&T Equipment Division, has implemented L&T TPL35, a new method using automation that significantly saves both cost and time by automating trenching, pipe laying, and backfilling. “Equipped with features like a pipe reeling drum with jib crane, trench-cutter, pipe feeder, scraper, and sand hopper, this trencher cum pipelaying machine can automatically lay HDPE pipes up to 110 mm in diameter and partially automate laying HDPE pipes up to 200 mm in diameter,” highlights Easwaran Maran, Advisor (P&M), WWW SBG.

The L&T TPL35 in action at the site

The L&T TPL35 fresh off the manufacturing facility

While teething issues with the TPL35 are getting resolved, at the RWS Mandya project site, Neeraj Kumar, Head – P&M (WWW SBG), and team are quite enthusiastic about the process automation. Earlier, they relied on a cumbersome multi-equipment approach to lay pipes, using a crane for pipe unloading, an excavator with a breaker for trenching, a team of 5–6 workers for pipe handling and lowering, and a backhoe loader for backfilling. “The process was slow, inefficient, human-dependent, unproductive, and often hampered by the non-availability of the right equipment,” bemoans Neeraj.

Additionally, the narrow village roads posed a constant challenge as the normal-sized excavators and breakers would often block traffic and the team frequently struggled with labour shortages.

“The new machine has dramatically sped up trenching and pipe laying by 3–4 times, significantly reduced our pipe laying costs, in both soft and hard ground, eliminated the need for multiple pieces of plant and machinery, and most importantly, reduced the required workforce from six to just two people.” Certainly, Neeraj is a happy man too.

Connecting communities

For arid western Rajasthan, the Rajiv Gandhi Lift Canal (RGLC) has been a vital source since 1996, drawing water from the Indira Gandhi Main Canal. The increasing water scarcity and climate change led to RGLC Phase III, a technologically advanced extension that aims to meet the water demand beyond 2054 by integrating advanced water management practices energy-efficient pumping, and enhanced monitoring. The project will run alongside the existing RGLC, increasing water delivery by pumping 396 MLD of raw water from the Escape Reservoir to meet regional demands.

The project will supply water to several urban centres, including Jodhpur City, Phalodi, Pipar, Bilara, Bhopalgarh (all in Jodhpur district), and Samdari (Barmer district), in addition to several rural areas covering 1,830 villages in Jodhpur, 211 in Barmer, and 126 in Pali. The system will also cater to specific high-demand sectors like the Delhi–Mumbai Industrial Corridor (DMIC), the RIICO industrial areas, and various defence establishments.

With the project team busy building a 216 km cross-country pipeline network and related pumping stations, it was critical for them to track progress in real time, to assess the status of trenching, pipe stringing, welding, laying, and backfilling operations along the entire pipeline route.

Huge savings

“For the first time in WET, the RGLC project has implemented drone technology for automated progress tracking, providing near-real-time visual updates and accurate construction milestone data,” shares a proud Project Manager, Pratik Raj. “The drones capture images of specific areas every two months, and this data is then processed using image analytics and Digital Terrain Models (DTMs) to precisely measure physical progress.” The drone-based monitoring is helping the project save approximately ₹1.23 lakhs annually and has streamlined reporting, boosted efficiency, and lowered overall costs compared to traditional approaches.

Cross-country MS pipeline laying in hard rock strata

The RGLC project team

“Aerial images of the Right of Way (ROW) for the MS pipeline alignment were crucial for logistics planning too,” highlights Pratik, “to assess terrain conditions and provide timely feedback to the logistics team, for efficient transportation of the 12-m-long MS pipes on trailers, while at the same time avoiding problematic pathways and preventing asset idling.”

The digitized drone-based survey data was superimposed onto the proposed pipeline alignment, which revealed major utilities like transmission lines, structures, culverts, and trees directly in the path. Shifting these utilities was part of the contract and not separately payable, potentially costing over ₹1.5 crores. However, by using the spatial data, the pipeline alignment was rerouted, significant saving utility relocation costs.

“Beyond measuring, the drone system helps with precise quality assessments including verifying 2D alignments for pipe centrelines and civil structures, managing risk, and checking quality for proactive site management,” highlights Pratik, adding that their data-driven approach has significantly improved transparency, decision-making, and communication at site.

Technology integration is a critical imperative for superior water management; by embracing technologies like advanced mapping & 3D modelling, drone-based monitoring, and robust water infrastructure solutions, the teams at WET IC are paving the way for more efficient, sustainable, and resilient water delivery, ultimately securing vital resources for communities and ecosystems facing growing demands and climatic shifts.