“Every day is a chance to learn something and create lasting memories,” says Himanshu Sudhir Nagar, his voice firm with purpose. “Whether on-site or with my family, I personally cherish every moment.” A native of Delhi, he is steering the MAHSR C4 Section — Elevated Viaduct and Station at Vapi, Gujarat as Planning Head since December 2020. During his nearly two decades-long association with L&T, he has significantly contributed to Metro projects importantly various packages of the Delhi Metro and HED port jetty construction.

At the MAHSR C4 section, while drone-based surveys and 3D modelling have enhanced accuracy of planning, minimized rework and optimized material flow, Himanshu is particularly pleased with the use of WhatsApp groups for real-time tracking of site progress & resources, and resolving issues that has slashed delays due to communication gaps.

“To address the issue of shortage of workers, I collaborated with subcontractors for back-to-back labour and machinery deployment, boosting profitability and productivity at the project,” says Himanshu, flagging off a personal triumph, adding that cross-training workers has improved flexibility and reduced skill dependency.

To address staff accountability, he implemented shift-wise progress reporting and a “1 staff 1 work” principle, fostering motivation and recognition. “Structured communication with accountability at the individual level drives speed,” he notes wisely. Seniors like mentor Rakesh Kumar Jha provide clear direction and empower decision-making. “Their trust fuels my confidence,” Himanshu beams. His team’s collaborative spirit, sharing best practices and automating tasks, sustains momentum. “Speed comes from clear goals and empowered teams, not rushing,” he reflects.

He envisions a multi-functional robotic system for labour-intensive tasks like reinforcement tying and concrete pouring to achieve precision and enhance safety. “By automating high-effort activities, we can significantly reduce worker fatigue, improve precision, speed up project timelines, and enhance overall safety and quality at projects,” he says, purposefully.

“My wife Nitika Nagar is a dedicated family manager,” Himanshu blushes with pride. He cherishes his sons, Arush (14) and Aarav (11). He unwinds playing badminton daily and teaching his kids in the evenings, strengthening their bond. “These sessions, at times are short but recharges me,” he says warmly.

L&T’s empowering culture inspires him. “I admire the limitless opportunities to learn, grow and take on new challenges, the freedom to take decisions, and the recognition of contributions,” he notes with passion. “This combination of trust, appreciation, and career growth makes me feel valued and motivates me to give my best every day,” he signs off on a high.

“For me, civil engineering is not merely a job but a deep-rooted passion demanding dedication beyond the clock, as success is measured not by time, but by the achievement of project goals and the impact of our work,” shares Vijay Prakash Tripathi, as he and his team strive to deliver at the MAHSR C‑4 project. Looking back at his 13-year-long career, he says, “My career quite literally began onon thee open roads at a national highway project where it was all about speed and efficiency, completing long stretches whare fint keeping quality intact and where I first appreciated the value of precast systems.”

At the MAHSR project, initially he found establishing the precast yard particularly demanding. “The sheer scale of work, combined with an aggressive schedule and high-performance benchmarks, truly tested our planning, coordination, safety, quality and execution,” he observes. Of course, the team faced several challenges including that of manpower, material supply, weather disruptions, local festivals, time constraints. “We, however, planned and executed well, mostly ahead of time, enforcing strict safety protocols and conducting quality training at appropriate intervals.’

“Managing resources, time and work discipline are the power keys of project Success,” he affirms. “One of our hallmark contributions was the adoption of tracking real timelines for FSBG activities enabling real-time quality management and reducing cycle time of activities. He adds that they have deployed digital tools like Shield, ConEase, Rebar Pro, and Material NxT.

“As a Precast Manager, I have developed a reputation for streamlining the casting yard by implementing quality assurance systems and fostering collaboration between design and field teams,” Vijay says, proudly sharing, “In fact, our C‑4 Section‑2 team was honoured with the Best Quality Award for MAHSR C4.” He is particularly grateful for PD Zamshed Ali Sir’s supervision & guidance. “Under him, several casting yards achieved record outputs with near-zero rework within the given time frame.” He is thankful too to Mohit Gupta, Shambhudas Buruguru, Sushil Kumar Sharma and, Rajesh Shinde for their constant support, collaborative spirit, and invaluable encouragement.

“We took ownership of the project from top to bottom starting with the precast yard operations, extending our efforts to deck furnishing works as well,” he says with determination. “We proudly handed over a 7 km stretch to IRCON, maintaining the highest standards of quality and completing the work well within the scheduled timeline.”

Hailing from Lucknow, the city of Nawabs, Vijay’s life partner is Akanksha, a homemaker, and the apple of their eyes is their daughter, Aadrika. *My hobbies include listening to: songs, outdoor games and travelling,” he laughs, mentioning that his life’s Sweetest moment was the birth of his daughter.

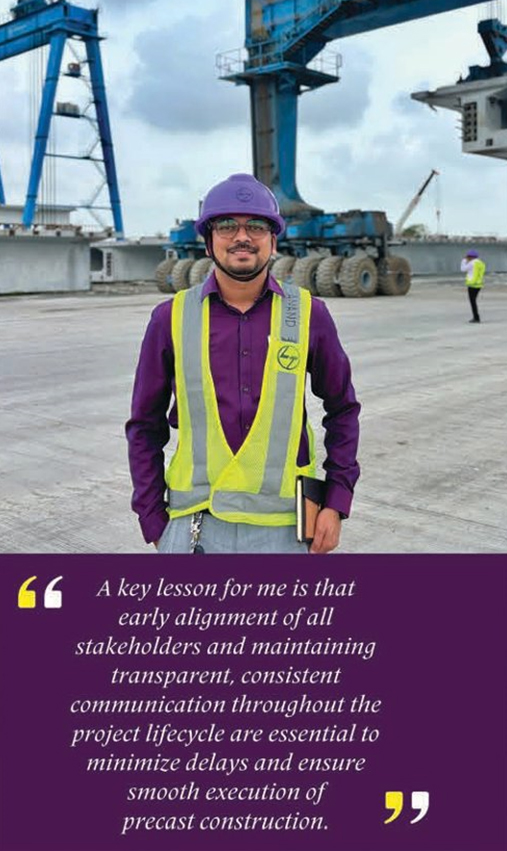

“In my experience, critical for delivering large-scale projects are effective planning, combined with real-time, data-driven decisions and clear communication,” states Anand Budihal from the MAHSR C‑4 project, his first with L&T, as he speedily aligns himself to the demands of a tough project. “A key lesson for me is that early alignment of all stakeholders and maintaining transparent, consistent communication throughout the project lifecycle are essential to minimize delays and ensure smooth execution of precast construction.”

As a Planning Engineer, Anand is responsible for seamless project execution through sound scheduling and coordination. “I prepare and deliver daily, weekly, and monthly progress reports to internal stakeholders, and am involved in strategically planning and monitoring the full span box girder casting sequence in alignment with the Launching Girder (LG) movements to optimize erection timelines,” he shares, purposefully. Thrilled to be a part of the team to introduce the Full Span Launching Method (FSLM) in the country, he mentions a tagging system for efficient rehandling and re-erection of the full-span box girders at multiple locations.

“My schedule management includes updating progress reports to reflect real-time status, coordinating with resources across casting yards to maintain productivity and prevent bottlenecks,” he shares. A digital native, Anand reels off a suite of digital solutions deployed at site including the FSLM Tracker for real-time girder lifecycle monitoring, Material NXT, Oracle Primavera Unifier & RFI workflows. “Additionally, I have completed professional certifications in Project Management, Primavera P6, and Power BI, empowering me to drive data-informed planning and decision-making.” he adds with josh. “In essence, I actively use and contribute to the implementation of project management tools and technology in real time.”

Anand acknowledges the role of his seniors and team members in his steep learning curve, with their continuous guidance, technical expertise, always encouraging him to think innovatively. “I am blessed to be guided and mentored by ARN Sir (TFL, MAHSR C3), TSRM Sir (GM and Head — Technical Services, MAHSR C4), WRM Sir (Project Director, MAHSR C4/S3), and Ajay Mane Sir (Precast Head, MAHSR C4/S3),” he says with feeling.

Proud to be the first engineer in his family having post-graduated in Advanced Construction Management from NICMAR, Anand’s life partner, Dr. Chetana is a practising doctor. His father, Hanumaraddi, runs a business, while mother, Ms. Gangu, is a homemaker. His varied interests include traveling, exploring new places and foods, painting and drawing. Flagging off two memorable moments, he shares, “I met SNS Sir and delivered a presentation on segmental precast construction and received the award for the Best Casting Yard in terms of Quality and Safety from GV Sir!”

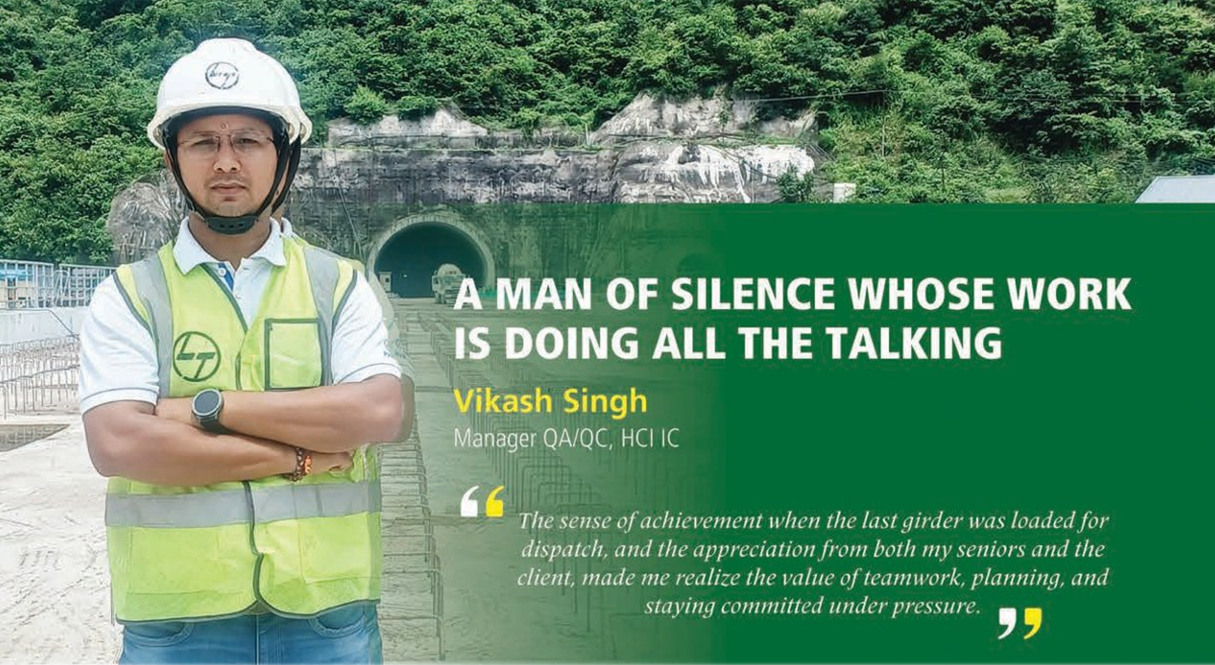

“I’m someone who prefers to stay quiet rather than talk unnecessarily for I believe in speaking less but making sure that whatever I say has value and meaning,” says Vikash Singh, with deep meaning, but for a man who likes silence, his work at the RVNL Package 2 project, his first with L&T, is doing a lot of talking. “I have been involved in the fabrication and erection of bridge works from the initial stages to final completion, including bridge load testing,” he explains. “This package includes 3 major composite-type road and rail bridges, with a total fabrication scope of 2,400 MT.”

Completing the fabrication of steel bridge girders with fabricated structural steel was critical for Vikash. “To meet our tight schedule, we adopted advanced fabrication technologies,” he says, like using an automatic CNC drilling machine that was particularly effective for welded girders and other fabricated components. “The automatic SAW beam welding machine played acritical role during the entire process of I‑girder fit-up, welding, and straightening,” he mentions, happy that the adoption of all these technologies has significantly accelerated fabrication while enhancing precision and efficiency.

Apart from fabricating & delivering 2,400 MT of steel bridge girders, Vikash and the project team had to manufacture & deliver 97,800 HSFG bolts & spherical bearings. “Managing multiple vendors performance, ensuring strict quality compliance, and maintaining smooth coordination with PMC, RVNL, and RDSO across various stages of the inspection and supply chain were particularly demanding,” says Vikash, for which he took several steps like regular monitoring and follow-ups with all vendors, close coordination with inspection agencies and continuous communication with stakeholders to align schedules.

“One of my most memorable moments was the successful and timely fabrication and dispatch of the steel bridge girders,” says Vikash, his eyes glowing. “I still remember the intense coordination between the fabricator, our management and the RVNL team, where every hour mattered. The sense of achievement when the last girder was loaded for dispatch, and the appreciation from both my seniors and the client, made me realize the value of teamwork, planning, and staying committed under pressure,” he says passionately.

Since the start of his career in construction in 2012, Vikash dreamt of joining L&T and his dreams were realized in 2021. “While every aspect of L&T makes me proud, the most special one is deeply personal, my father proudly telling others, “My son works at L&T.”” Hailing from Jaunpur, Uttar Pradesh, Vikash’s life partner is Pooja, a homemaker, and they are blessed with two children, son, Ayansh and daughter, Aruhi. He loves playing cricket that helps him relax and stay connected.

As Assistant Manager, Planning, at the challenging RVNL Package 2 project, young Yash Dhakre could not have asked for a better proving ground to hone his skills. After joining as a GET in 2020, his five years thus far with L&T has been a blend of on-site execution and critical planning roles. “For my first two years, I was involved in site planning for four tunnel faces, focusing on resource optimization and cycle time monitoring before I was transitioned to the main planning office, where I now manage specialized works with external agencies and implement end-to-end material management systems. I’m also closely involved in cross-departmental coordination for project approvals.,” he shares, sounding proud of his workload.

He is quick to flag off several key innovations introduced at site like adopting a ‘cost per meter’ basis for the supply of rock tools instead of purchasing them outright. “This was a first for us, and the model has since been adopted by other projects based on our suggestions,” he shares with a winning smile. Other improvements, he mentions, include introducing automatic wheels for jumbos to eliminate the need for external shifting equipment, wheel-mounted ventilation fans in long tunnels, and various gantry modifications to meet specific site requirements.

A tracking system provides real-time data on material availability and consumption, which has resulted in zero progress holds while risk assessments conducted for critical activities avoid supply disruptions especially during the monsoon and the Kawad Yatra. “To ensure continuous progress on critical works, we have developed various sub-agencies to handle specific tasks,” adds Yash. “The most crucial factor for success is robust planning combined with the availability of alternate plans,” he avers. “Having a clear strategy and a backup plan is essential for executing work efficiently and on time.”

Giving a glimpse of his personal life, Yash says, “I’m from a family of farmers, with my father tending to our land, my mother running the home and I am the eldest of three siblings. I am immensely proud to be the first civil engineer to come from my Pawawali village in Agra, Uttar Pradesh.” Both his younger brother and sister are still pursuing their education. His hobbies include bike riding, travelling and updating himself with the current events from around the globe. “One of my most memorable moments was buying my first bike with my own money and completing 750 km in a day,” he grins.

Yash admires L&T’s culture of training, learning, and grooming for their trainees. “L&T expertly guides you from a college mindset to a professional one,” he says in conclusion.

Ever since joining L&T in 2014 as a DET at the Kalpakkam site, Khem Singh has been enjoying his experience. “L&T is not just an employer; it is like a second home to me. Over the past 10 years, I have had the opportunity to work on some of the nation’s most iconic infrastructure projects, supported by seasoned professionals.” These iconic projects include KKNPP POC 3–6, Kochi Metro, KKNPP MPCW 3 & 4 and currently at the RVNL project Package 2 overseeing tunnel lining works of the Main Tunnel (2,730 m) and the Escape Tunnel (1,828 m). “I have also been involved in excavating the MT3F4C and ET3F4 sections, in addition to managing the Byasi Station civil works,” he adds for good measure.

If being a part of a company that plays a key role in nation-building makes him stand tall with pride, Khem considers himself fortunate to work with dedicated teams and supportive seniors who have played a vital role in shaping his professional growth, especially mentioning Prabhu Kumar (GM- Operations, Hydel) and his Project Manager, Rajesh Chopra. “Their mentorship during high-pressure scenarios have helped me grow into a confident and independent decision-maker,” he says passionately, adding that he is grateful to L&T for giving him the opportunity to pursue his B Tech that has enhanced his technical knowledge and academic credentials.

On the matter of tech solutions adopted at his site, Khem mentions the transition to motorized overt jumbos that has reduced shift time from 30–45 minutes to just 5–10 minutes per 12 m panels, with improved safety, adopting the ConEase App for real time tracking of quantities and GPS tracking tracking of all site machinery through the Aether App.

As for site challenges, Khem mentions the erection and commissioning of the first 3‑Line track tunnel gantry, which involved erecting an exceptionally large gantry with a radius of 12.1 m while maintaining minimal tolerance levels. “We completed the process in 26 days, followed by the successful completion of the 146.84 m 3‑line track lining within 75 days,” he shares triumphantly. “Being my first experience working on NATM tunnels, initially I was unfamiliar with underground construction methods but overcame this challenge through continuous learning, hands-on involvement, and support from experienced colleagues.”

Large projects, to Khem, demand perfect time management combined with experience-based planning, clearly defined roles, effective collaboration, open communication and collective accountability.

Khem hails from Karsog, District Mandi, Himachal Pradesh, is married to Manisha, who is a Branch Postmaster, and they are blessed with a daughter, Kiana, whose birth is his life’s most fulfilling moment. “To unwind, I enjoy playing cricket cri and chess, and regularly follow current affairs,” he informs smilingly.

After graduating, Ajit Patel started preparing for a government job. “However, due to our poor financial situation, my mother was not in favour of it despite my attempts to convince her,” he recalls. “But minutes after our conversation, an email from L&T changed everything,” he smiles gratefully; “it launched my career with L&T as a DET in 2015.”

An initial stint at the 99 MW Singoli Bhatwari Hydro Electric Project was Ajit’s first proving ground, where he learnt the ropes tackling the Head Race Tunnel excavation and lining. Presently, as Tunnel Engineer at the RVNL Package 2 Tunnelling Project, he is navigating the final stages of tunnel lining using NATM.

Large scale projects especially involving tunnelling, require advance planning and flexibility, he believes, to prepare teams particularly in unpredictable geological conditions. “Of course, real time monitoring, timely decisions and immediate action are critical as also strong coordination between planning, execution and support teams.”

At the RVNL project, the team’s primary focus has been to find ways to speed up construction like constructing additional faces using the same resources to access the Cross Passage through the Escape Tunnel. “By planning and executing parallel benching excavation during the heading support phase,we reduced the cycle time of the Main Tunnel while fully automatic drilljumbos, semi-automatic drill jumbos, robo-arm shotcrete machines, haggloaders, and survey instruments have ensured precision,” he says passionately. Additionally, he would love to have a Tunnel Seismic Prediction (TSP) tool to better predict geological conditions 100–150 m ahead.

Ajit’s decade-long association with L&T has enrichened with the guidance, technical Support, and trust from his seniors that have empowered him to lead effectively and make confident decisions. He credits his team’s cooperation, clear communication, and Shared responsibilities to overcome challenges, emphasizing that their strong team dynamics and leadership have been key to maintaining pace and quality, a culture of engineering excellence and collaboration that drives growth at L&T. Extremely grateful for the opportunity to work on challenging projects, he says, “being part of L&T gives me a sense of pride and responsibility in building the nation’s infrastructure.”

Married to Renu Patel, a homemaker, this native of Varanasi, Uttar Pradesh, cherishes the time he gets to spend with their one-year-old son, Ahan. “Spending time with family and my kid gives me a sense of happiness and peace,” he says dreamily, adding that reading, movies, music, and travel are other ways he finds to unwind.

EXPERIENCED, YET STILL LEARNING AS HE GROWS

Prosengit Koley

Assistant Manager (Survey), HCI IC

He is already into his 5th project at the RVNL project Package 2, but Prosengit Koley is quick to acknowledge that he is still learning on the job. “I have gained hands-on experience in handling modern survey equipment, having worked across varied terrains and different construction phases but I found the Grid System of surveying new to me that I have learnt and adopted very quickly,” he says with a sense of achievement.

He agrees that helping him to succeed is the L&T culture of support, transparency, and shared ownership that are driving him to consistently perform with speed and scale, with his seniors giving him job clarity and identifying priorities basis work scheduling, empowering him to set his goals effectively. “They give me the opportunity to take ownership and independently make decisions,” he says thankfully. “In fact, they have advised me to develop my communication skills that I am working on,” he smiles. His team members willingly share best practices, equipment or tools and valuable learnings that are saving him redundant efforts and enhancing his problem-solving ability.

Reverting to his tasks on hand at the project, Prosengit mentions that the advanced surveying instruments and working methodologies were initially challenging for him but he quickly learnt the ropes from his seniors. “The most challenging and crucial task for me during Total Station work was traversing to fix a control point inside the tunnel,” he shares, “in poor conditions with heavy water seepage, excessive heat, and poor visibility due to dust making it difficult to achieve traverse accuracy.” To overcome these issues, the team established wall control pillars by spraying shotcrete on it, avoided wall brackets at deformation zones and to combat the conditions inside the tunnel, utilized off days for control survey works.

“At RVNL 2, we implemented drone-based aerial surveying equipped with high-resolution cameras to capture aerial data of large areas for muck reconciliation and stockpile measurement instead of relying solely on traditional ground surveying,” he informs, that reduced the time required for initial and follow-up surveying from several days to just a few hours. He mentions using software like Agisoft Metashape, Global Mapper and Autodesk to process the data and get an Orthomosaic Map for Site monitoring, progress tracking, volume calculations, and as-built documentations.

Elaborating on his work method, Prosengit says that the important first step is to understand the job requirements, then plan properly and execute as per the plan. At the same time, analyse mistakes by finding out reasons and solutions, replan and execute again. A native of Singur, West Bengal, Prosengit loves bike rides and Spending time with his parents.

COMPLETE ALIGNMENT TO PROJECT GOALS IS AN IMPERATIVE

Annamalai S

CSP, Manager (EHS) — HCI IC

“Clearing the Certified Safety Professional (CSP) exam on my first try felt like unlocking a new level in my career,” Annamalai S says, his face alight with accomplishment. Currently, as an EHS leader at the NDCT Units 7 & 8 of the Rajasthan Atomic Power Plant, his challenges are particularly tough. “Reviving an abandoned project is always difficult, but taking up the high-risk scope of the NDCT and Cooling Water Pump House demanded top-tier OH&S systems,” he notes, delighted that they have successfully completed Unit 7 fifty days ahead of schedule and the construction of the entire project with major demobilization 3 days ahead of the original contractual completion date.

Focused on maintaining a robust OH&S framework, Annamalai says, “There should be collective commitment for precise execution, including that of leadership, team alignment, and ownership,” adding that trust is built by backing subordinates even when their decisions sometimes not as intended. Happy with his mentorship from his seniors and HQ management, he says that it has enhanced his skills and empowered his decisions. “I believe that authority comes with responsibility. Not restricting myself to identifying EHS concerns, I find appropriate solutions to demonstrate that safety representatives are not disablers but enablers.” He has empowered teams to work more efficiently & confidently to ultimately contribute to the timely revival of a critical national infrastructure project.

The SHEILD App has been Annamalai’s ally for digital safety management, real-time logging of observations, automatic escalations, and trend analysis for data-driven decisions. “It has transformed how we track unsafe acts and resolve issues,” he nods enthusiastically, looking forward to a wearable digital PPE to monitor workmen’s health throughout shifts.

Having started his journey with L&T as a DET in 2012 at the Hyderabad Metro Rail Project, he moved to the Kudankulam Nuclear Power Project 3 & 4 in 2019, initially as EHS Officer and thereafter as Deputy EHS Head, before getting the opportunity to lead the EHS function at RAPP since 2022. “Each role has been a step towards safer, stronger projects,” he shares with a determined smile.

“What I find most admirable is how L&T treats each employee equally, irrespective of their roles and functions,” he says with awe, “giving each employee ample opportunities to update their knowledge & skills and challenging roles to unleash his or her potential.”

Hailing from Tirunelveli district, Tamil Nadu, Annamalai is married to Uma Maheswari, a homemaker, and enjoys his free time with his sons, Aadhyan and toddler Aadhiran. Listening to music and long drives are what invigorates him too; “Those moments ground me,” he rounds off with feeling.

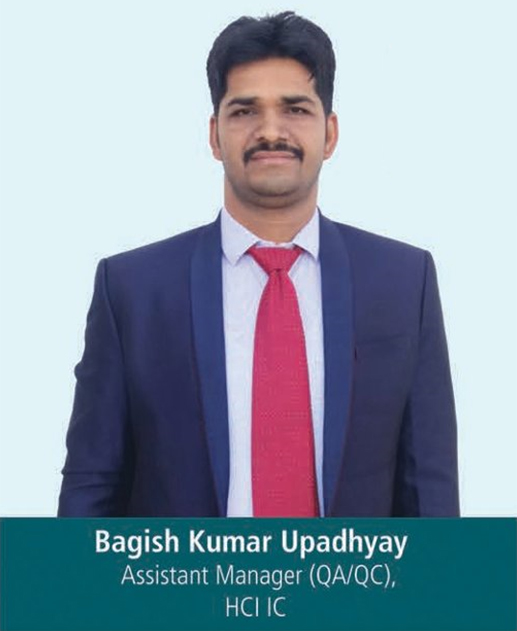

ISSUING DEBIT NOTES HAS BROUGHT THE COMPANY GREAT CREDIT

Bagish Upadhyay is most satisfied with one of his initiatives to drive Quality at his Rajasthan Atomic Power Plant site. “It was a targeted approach to minimize rework by systematically identifying recurring quality deficiencies, and with our zero-compromise approach to quality, we started to issue debit notes to contractors whose work did not meet the specified standards,” he states resolutely. Their strong accountability mechanism delivered remarkable results, much to Bagish’s delight.

Observing that certain vendors were exercising monopoly for being on the NPCIL-approved list, Bagish facilitated the approval of alternative vendors to enhance competition. “Additionally, through rigorous quality risk assessment, we made sure that adequate quantities of river sand were stockpiled in advance, which ensured continuous seamless concrete production throughout all seasons, enabling us to meet project schedules,” he notes. He also mentions developing a pumpable and flowable concrete mix design in line with the project scope.

Tech tools have been an integral part of Bagish’s Quality Management System, with the use of the ConEase App to monitor concrete production, reduce wastage and deliver concrete in time from the batching plant and the Sanyog App to raise NCRs for quality-related deficiencies. “Through Sanyog, we track and monitor the number of training sessions conducted and assess monthly training requirements, enabling a systematic approach to continuous skill development,” he elaborates.

Having started his career with L& T in 2010 as a DET at the Srinagar Alaknanda Power Plant, Bagish has since worked at the Kakrapar Atomic Power Plant (Units 3 & 4) as Quality Engineer and at RAPP he got the opportunity to head the QA/QC function. From his experience, he feels that unwavering dedication from leadership, active participation of project heads in every on-site operation, enabling team members to make decisions while supporting them even if outcomes are not as intended, and shared responsibility among all stakeholders are vital to execute a project successfully. “At my site, the management team and the HQ Quality team continuously guide us to strengthen diverse capabilities, aiming to become a leader in speed and scale,” he says with confidence.

He believes in doing right first time and L&T’s inclusive culture that values every employee equally inspires him, revelling in the abundant opportunities the Company offers to unlock full potential. A native of Kushinagar District, Uttar Pradesh, Bagish is married to Sweta, a homemaker, and they are blessed with two children, son, Adarsh and daughter, Vaishnavi. Playing with them and long drives refresh him.

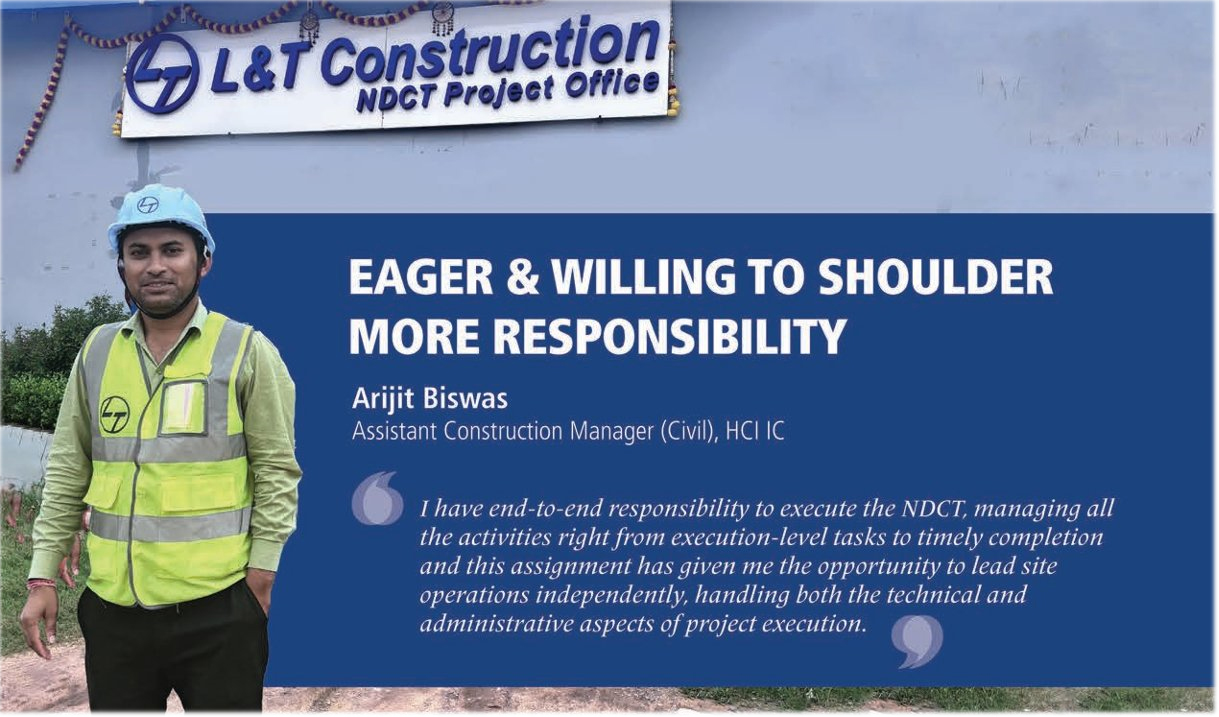

As Section In-Charge for the NDCT-8A under the RAPP NDCT Packages 7 & 8, Arijit Biswas’s major challenge was to complete the NDCT within 3 years. “After completing the shell in November 2024, normally it takes another 12 to 15 months to finish all the internal works but we had only 8 months left with the same workforce strength,” he shares with a worried face. “I have end-to-end responsibility to execute the NDCT, managing all the activities right from execution-level tasks to timely completion and this assignment has given me the opportunity to lead site operations independently, handling both the technical and administrative aspects of project execution,” he says with a resolute smile.

To address Arijit’s challenge and ensure timely project completion, the team took several steps after discussions with the management. “The criticality of executing the NDCT lies in its height of 184 m and therefore we planned and successfully installed two tower cranes. to improve lifting efficiency, achieving 7,261 running metres against the previous record of 5,215 running metres,” he explains. The operational area to be covered by each tower crane was clearly defined to optimize material handling, minimize interference, and ensure site Safety and strategically targeted the peripheral areas for concreting using a boom placer to significantly reduce dependency on manual concrete placement; to further improve productivity, they opted for precast beam erection.

“Additionally, we planned to-start 4 ducts immediately after slab completion, to ensure continuous workflow and better alignment with the structural schedule,” adds Arijit, “and installed precast duct sections by lifting and placing them in their designated positions at site that speeded up construction and ensured better quality and accuracy compared to casting ducts in place.” He also mentions the effective use of Rebar pro and ConPro Apps.

His formula to manage large projects is relatively simple and straightforward: divide the Scope into manageable chunks, create a detailed micro-level plan, understand the drawing well, mobilize material & men and train them well, allocate & utilize resources properly.

Beginning his journey with L&T as a DET, Arijit was first at the KAPP NDCT package as Site Engineer followed by a stint at the KKNPP HTS package as Senior Engineer (Civil) before his present assignment at RAPP.

On his personal side, a native of Hridaypur, Chapra in West Bengal, Arijit comes from a humble background, His father is a farmer and his mother, a homemaker, whose values and dedication have hugely impacted him. He is married to Kuheli, a homemaker too, and the love of their lives is their 4‑year-old daughter, Rashi. When free, he loves to play cricket and watch movies.

“We decided to forgo traditional methods in favour of innovative ways of construction,” states Aswin T from his RAPP project where he is Section In-charge, looking after the construction of the 184 m tall Natural Draught Cooling Towers. “With the help of the design team, we adopted precasting in various areas, especially beams, which enabled us to break records of constructing 7.26 km of internal structures in a single month,” he says proudly, adding that his most memorable moment was successfully completing the NDCT 7A structure 50 days ahead of schedule. “The management believed in me and assigned a challenging task to complete a unit which was in the critical path.”

Having worked for 8 years on major nuclear power plant construction projects at Kakrapar, Kudankulam, and Hisar, Aswin has developed a sound knowledge of nuclear power plant construction that he is bringing to play at his current assignment. “We adopted mechanization for the internal works with telehandlers & boom lifts and modularization for rebar cage tying at lower levels and erections, implementing precast ducts to reduce time and cost of the structure.” To coordinate better with the various teams from different departments for smooth workflow, Aswin planned their daily activities well in advance, at least a day before, and communicated them to all the concerned departments for seamless execution.

The active use of digital tools like the Rebar Pro, ConEase, and ConPro Apps have improved site productivity and enabling real time monitoring of progress. “By revising the work Sequence, we reduced manual material handling and with continuous Support and guidance from site management, we adopted a systematic approach of constructing the internal structures from the periphery towards the centre which saved us a lot of time,” he informs with an energetic nod. He attributes their success largely to planning with foresight. “Anticipating challenges and preparing contingency plans helped us maintain momentum,” he Says, “because execution speed is directly proportional to clarity in planning and communication.”

Aswin is thankful to his seniors, especially Project Manager, Manikandan C, for guiding him and helping him to resolve bottlenecks with their experience and strategic inputs. “My team members are proactive and collaborative, which creates a high-energy environment focused on speed and scale. We remain aligned and motivated with our regular reviews, open communication, and shared goals,” he adds, all praise for his colleagues.

“College days taught me the joy of shared goals and the power of unity, a spark I carry with me every single day,” recalls Kopparapu Venkata Sai Chandra, with warmth of shared memories and he is glad that that same sense of sharing has carried on into his professional life as well, at the NDCT RAPP 788 Nuclear Power project where he joined as a PGET in 2023. “My seniors and team members have always been strong pillars of strength, in fact, I fondly refer to them as my encouraging partners’,” he laughs. “Their continuous encouragement motivates me to explore and learn new concepts, provide me opportunities to take on challenging tasks that push me beyond my comfort zone.”

Well-armed thus, Chandra has thrown himself, along with his ‘encouraging partners’, to completing their project within a stringent 36-month timeline that involves coordination across multiple departments, each with its own set of priorities. “On the tech front, we gained a decisive edge by leveraging Primavera P6, which provided real-time insights into progress and milestones. This smart use of technology proved pivotal, enabling us to successfully complete Unit‑7 a remarkable 50 days ahead of schedule, and the overall project 3 days before the contractual due date and an extraordinary 132 days ahead of the impacted schedule,” he highlights. Additionally, he mentions the Tracalogy software to monitor fuel consumption, GPS to track vehicle locations, optimally using P&M, the Rebar Pro and ConPro Apps to streamline rebar and concrete management. “These tools have significantly cut wastage and ensured accurate bulk material reconciliation,” he says enthusiastically. He hopes for an Al-powered dashboard to manage P&M, materials, and manpower daily, flagging shortfalls and generating comprehensive reports.

He is impressed with the project team’s relentless drive towards achieving a common goal. “The focus that people had on the very first day remained the same until the very last day of concreting,” his own drive evident. “Every day, we were occupied with clear tasks and defined targets, and it is essential to create and sustain such an environment to complete projects of any scale on time. More importantly, this collaborative environment has not only enhanced my skills and confidence but has also shaped me into a more capable and resourceful professional.”

Hailing from Palvoncha, Bhadradri Kothagudem District, Telangana, and still single, Chandra unwinds by watching news and hanging out with friends, squeezing in time despite L&T’s demanding pace. “Those moments bring back college-day vibes,” he smiles. His most cherished memories are from college, filled with laughter, late-night conversations, and lasting bonds.

L&T’s tagline as nation builders fills him with pride. “Every project we deliver strengthens our company’s connection to this legacy,” he says, and the team’s digital solutions and team synergy are powering RAPP 7&8 forward.

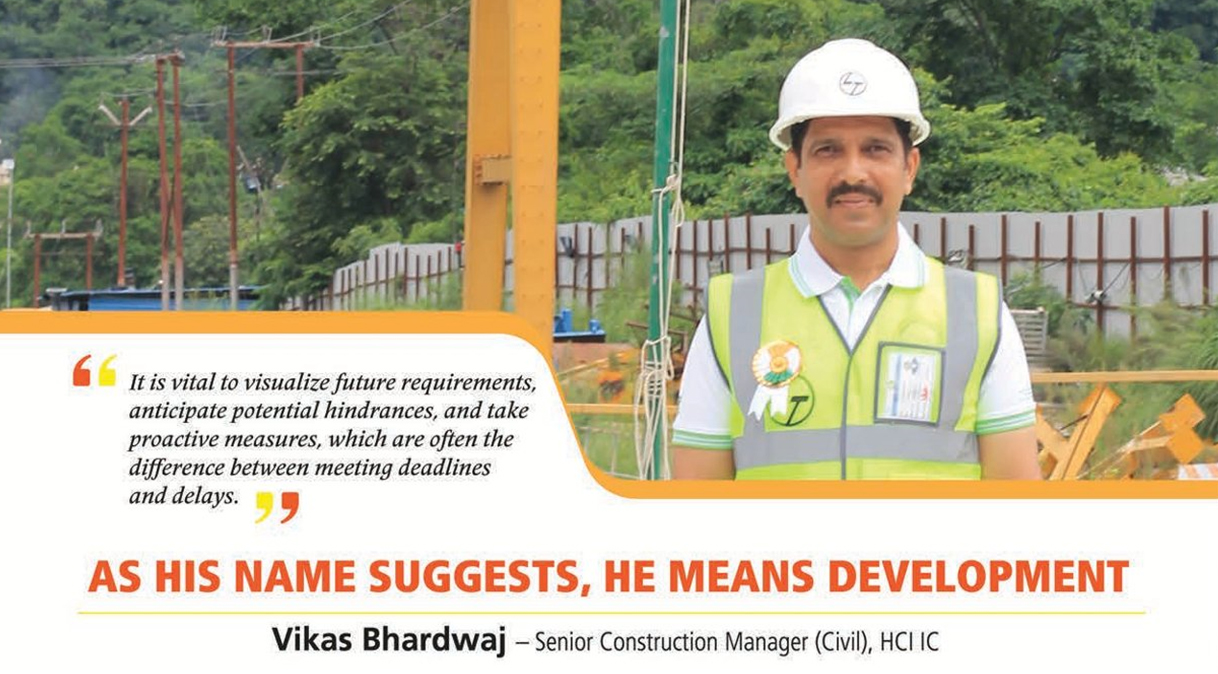

He goes by the name of Vikas, and just as his name connotes, he is on a‑continuous path of development. Vikas will agree that ever since he joined L&T in 2006 as a Senior Engineer at the Parbati HEP Stage-lll (520 MW) project, he has enjoyed the opportunity to work on some truly nation-building projects including the 330 MW Srinagar HEP, 171 MW Lata Tapovan HEP, Chennai Metro CMRG-004, and the CTP‑2 and CTP-14 Packages in the Western Dedicated Freight Corridor Project. Since 2021, he has been Section In-charge at RVNL Package‑4, leading NATM-based tunnel works from excavation to lining, ensuring safety, quality, and team coordination. “These experiences have strengthened my technical expertise, adaptability, and belief in teamwork and engineering excellence,” he says with gravity.

Focusing on the RVNL project, Vikas mentions the sudden formation of a large cavity as a severe challenge the team faced due to the intrusion of riverbed material inside the tunnel, which they resolved with continuous efforts, innovative treatment methods, and expediting the work sequence. Liaising with the local community has been another complex issue that they have been dealing with patience, transparent communication, and trust-building measures to ensure smooth progress.

A major step in their quest for precision, safety, and efficiency was to introduce automated machinery like automatic drill jumbos that has significantly reduced human intervention and delivered accurate tunnel profiles and alignments. By installing advanced sensors in equipment, they monitor fuel consumption, location, and utilization, enabling better resource management and pilferage control. “On the digitalization front, we have embraced several platforms to streamline processes and communication,” apprises Vikas, “including ConPro for concrete issuance tracking, Rebar Pro for reinforcement management, INSETIA for client and customer communication, Sheild for safety observations and the Sanyog App for quality compliance.”

Vikas readily acknowledges the role his seniors and team members have played in his success: the former for their clear direction, timely decisions, and the trust to try new ideas. “My team’s dedication, skill, and teamwork have been equally important, ensuring we meet deadlines and overcome challenges together,” he says with steely determination. Micro-planning, strong teamwork, regular monitoring, timely decision-making, and efficient resource planning are according to Vikas the key ingredients for successful project delivery. “It is vital to visualize future requirements, anticipate potential hindrances, and take proactive measures, which are often the difference between meeting deadlines and delays,” he points out wisely.

A native of Mukerian, Punjab, Vikas’s life partner is Shama, a teacher, and they are blessed with a son, Tezal. He starts his day with yoga and ends it with a book, and his most memorable moment was interacting with SNS during a site visit.

With over 24 years of experience, Lakshmi Kant Singh brings to his RVNL Package 4 project rich experience of having been extensively involved in numerous large-scale infrastructure projects. “To date. I have successfully launched ten TBMs and have worked on more than 15 underground projects across India and serving as a Mechanical In-Charge and Project Service Engineer, I have consistently delivered high-performance results in some of the most technically demanding environments.”

Continuing to build his credentials with L&T, LKS, as he is better known, says, “The value placed on people at L&T is undeniably high. The emphasis on safety standards, positive work culture, and the respectful relationship between senior leaders and their subordinates make us proud to be part of a company that is truly building the nation.” He adds that there is always guidance and from the senior leadership. “New ideas are consistently welcomed with a positive attitude.”

One of the primary challenges for LKS and team at the RVNL project was to dismantle the TBMs located within the cavern, an unprecedented, first-of-its-kind operation in India. “Another significant aspect involves maintaining the TBMs with minimal breakdowns, which has been crucial for us to complete the project in record time in the Himalayan terrain,” says LKS, with obvious pride. A major contributory factor to the high-performance of their TBMs is their deployment of cutter wear detectors to accurately assess cutter wear in advance. “Our actual cutter consumption has reduced by 53% compared to initial estimates, and our proactive approach to effectively monitor the wear & tear of the cutterhead has facilitated timely maintenance and ensured optimal performance throughout the operation.”

Al is undoubtedly the next big leap in technology and in LKS’s opinion, with accurate and relevant data preventive maintenance can be enhanced, production optimized, faults detected faster, unnecessary inventory avoided, more insightful reports generated, and even unsafe working conditions identified.

Strong teamwork, focus, discipline and motivation are key factors for his success in delivering a diverse range of sectors, including metro rail, hydroelectric, defence, nuclear, and specialized port and harbour projects throughout his career. He flags off his involvement in executing the world’s largest underground cavern project for crude oil storage, India’s longest twin railway tunnels, and India’s second-longest railway tunnel.

A native of Chechar, Vaishali in Bihar, LKS’s life partner is Meenakshi, a homemaker, and their family is complete with daughters, Parineeta and Pavani and son, Praneet. “Time doesn’t simply exist for us to use; we must create it for the things that matter,” he shares.

L&T STANDS FOR “LOVE & TRUTH’

Nitin Sharma

Construction Manager (Civil), HCI IC

“For me, L&T stands for ‘Love and Truth,” reflecting the values and the way the company operates,” says Nitin Sharma, sharing a new expansion for L&T. “I take pride in the strong systems and processes that L&T maintains, ensuring consistent standards across projects, and this commitment to quality, integrity, and excellence is what makes me proud to be an L&T‑ite.” Having joined the Company as a DET in 2011, Nitin has had the opportunity to work first at the Singoli Bhatwari Hydro Electric Power Project and then at the Sitamma Sagar Multipurpose Project.

Currently, he is at the RVNL Package 4 Project as Section In-Charge. “I am responsible for excavation activities using the NATM method, managing the ventilation shaft (a critical work front in the project), the upline and downline single tracks, and the TBM exit cavern,” he apprises, adding that he has planned all the NATM works to be completed on target to launch the TBM ahead of schedule. Daily micro-planning, breaking down targets into achievable day-wise goals and monitoring them closely seem to the secret of his success.

One of Nitin’s major areas of concern have been executing works in the ventilation shaft and the TBM exit cavern due to space constraints, geological variations, and safety risks that demand precise planning. “I have also had to manage simultaneous excavation on both the upline and downline single-track tunnels with tight timelines,” he says tightly. Not one to be deterred, Nitin has prepared to overcome his challenges by optimizing the work sequencing, adopting digital tools, improving coordination within his team, and strengthening safety measures.

Technology has been a huge help for Nitin and the project team, and he readily mentions the various tech solutions deployed at site including the digital tunnel monitoring & reporting system, drone-based progress mapping, laser profiling for NATM excavation, Material NxT for material tracking and the ConPro App. “All these measures have minimized downtime and improved accuracy to maintain continuous work fronts,” his smile is of a winner. “My Seniors and mentors have played a key role in helping me deliver with speed and scale,” says gratefully, heaping praise on his Project Director, Rakesh Arora, and Project Manager, S D Vats, for their clear direction, timely decision-making, and practical guidance for critical work fronts. “They also encourage the use of digital tools and proactive coordination with all Stakeholders,” he adds.

“I am from Ajmer, Rajasthan, and got married to Chandani in 2017, and we have been blessed with a wonderful daughter, Samaira,” Nitin shares with feeling. “My wife is a homemaker and a constant support in my personal and professional journey.” His hobbies include playing cricket, badminton, and athletics, especially the 200 m sprint.

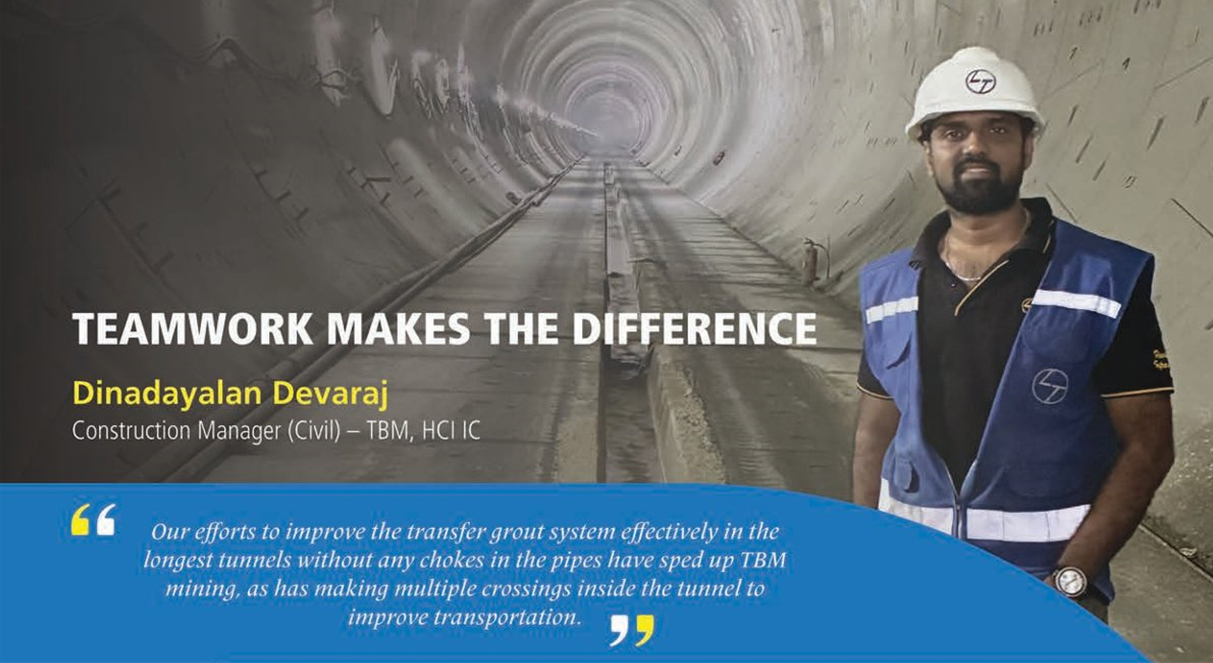

According to Dinadayalan Devaraj, at the challenging RVNL project, Package 4, strong teamwork is the essence of all successful infrastructure projects, where each member contributes their skills, ideas, and efforts towards a common goal. “Hard work pays well too,” he nods, “which is one of the main reasons why we achieved a world record in single shield TBM tunnelling progress in a month, and completed my project on time,” he adds with pride, mentioning that he is working in India’s longest railway twin tunnels of 15 km each in the tough Himalayan geology. Unsurprisingly, his life’s best moments are the breakthroughs of the TBMs Shiv and Shakti.

He brings with him the experience of having worked at multiple TBM tunnel projects across India and one of the biggest metro rail projects in Saudi Arabia. “I have been involved in designing and constructing tunnels of various diameters (9.7 m, 9.1 m, 6.67 m) and, in the process, faced and overcome various challenges including geological complexity. I have also been part of several successful tunnel breakthroughs,” he adds with purpose.

At the RVNL project, the focus of the entire project team and that of Dinadayalan. too is to speed up the tunnelling progress. The implementation of the Tunnel Seismic Prediction (TSP) system by Amberg Technologies has been a great help to them to identify potential hazards ahead like faults, weak rock zones, and water bearing areas, and thereby minimize delays. “Our efforts to improve the transfer grout system effectively in the longest tunnels without any chokes in the pipes have sped up TBM mining, as has making multiple crossings inside the tunnel to improve transportation.” He additionally mentions the use of walkie talkies in the tunnels for improved communication. On the tech front, Dinadayalan looks forward to an AI-powered workflow automation to reduce loads in data entry, report generation, and routine communications.

“I am proud to be part of an organization that values people and delivers excellence,” he shares passionately, evidently enjoying his association with his seniors and team members. “Their guidance, encouragement, and expertise have played a pivotal role in the successful completion of the tunnel breakthrough in my project,” he says gratefully. “Their valuable insights and constant support have not only helped me overcome challenges in the tunnels but also enhanced the overall quality and safety of our work.”

On the home front, Dinadayalan, a native of Puducherry, is married to Vinitha, an HR executive, and they are blessed with two children: Nadish and Vedha Shri. Yoga keeps him buzzing. “I practice it daily for an hour before coming to work which makes me energetic throughout the day,” he says with josh.

AT THE RIGHT PLACE, AT THE RIGHT TIME

A product of IIT Guwahati, young Rishabh Srivastava is at his first project with L&T at the RVNL Package‑4. “My role focuses on Environment, Health, and Safety, making sure that we stay safe, compliant, and sustainable every step of the way,” he shares his area of responsibility, adding that at L&T, his dream career destination, he has found just the right ingredients that sync with his mindset. “L&T is a wonderful organization that balances engineering excellence with a deep commitment to sustainability and safety,” he shares proudly. “From day one, I’ve experienced a culture of learning, collaboration, and responsibility that pushes me to give my best and make a real impact.”

With this motivation and impetus, Rishabh says that he is particularly proud of one of their sustainability initiatives at site of turning waste into a resource, whether it is related to plastic waste, C&D waste or wastewater. “To a large extent, we are reusing treated water from our Effluent Treatment Plant (ETP) for batching and dust suppression, and repurposing waste concrete blocks to improve site aesthetics,” he notes, steps that have saved time, conserved fresh water and enhanced sustainability at site.

He reels off a few aspects that are noteworthy: “Using 100% green grid source of energy, by shifting from DG to grid source of electricity for TBMs as well, have reduced 44,21,866 tCO2 scope 1 emissions; by using solar streetlights, solar blinkers, and translucent sheets the team has saved 8,366 4 kWh of energy, and with recycling saved 20% fresh water & 7% steel. The recognition has followed: Best Project in Environment & Sustainability at HCI IC, 2nd prize of upcycling artistry at HCI IC, recognition by RVNL for installing an ETP at the site, and 2nd place in CII at the national level.

“Managing wastewater was a big challenge since we use river water extensively,” he points out. “To address this, we installed sedimentation tanks, ETP, and STP to treat and reuse water for different activities that has reduced the freshwater consumption which is now being supplied to nearby villagers. Our project became the first among nine packages on this line to get recognized for this effort,” he shares with an air of achievement, Rishabh attributes team success to clear communication and strong coordination. “Planning is essential, but adaptability and quick problem-solving keep the project moving by balancing speed with safety and quality.”

“I’m from Lucknow and unmarried, but my parents, Mr. Vijay Kumar Srivastava and Mrs. Rita Srivastava, and sister Mrs. Vertika Srivastava are my biggest supporters,” he gushes. “| enjoy music, cricket, cycling, and trekking. Joining my first project in this dream location has been my most memorable moment so far,” he signs off with stars in his eyes.

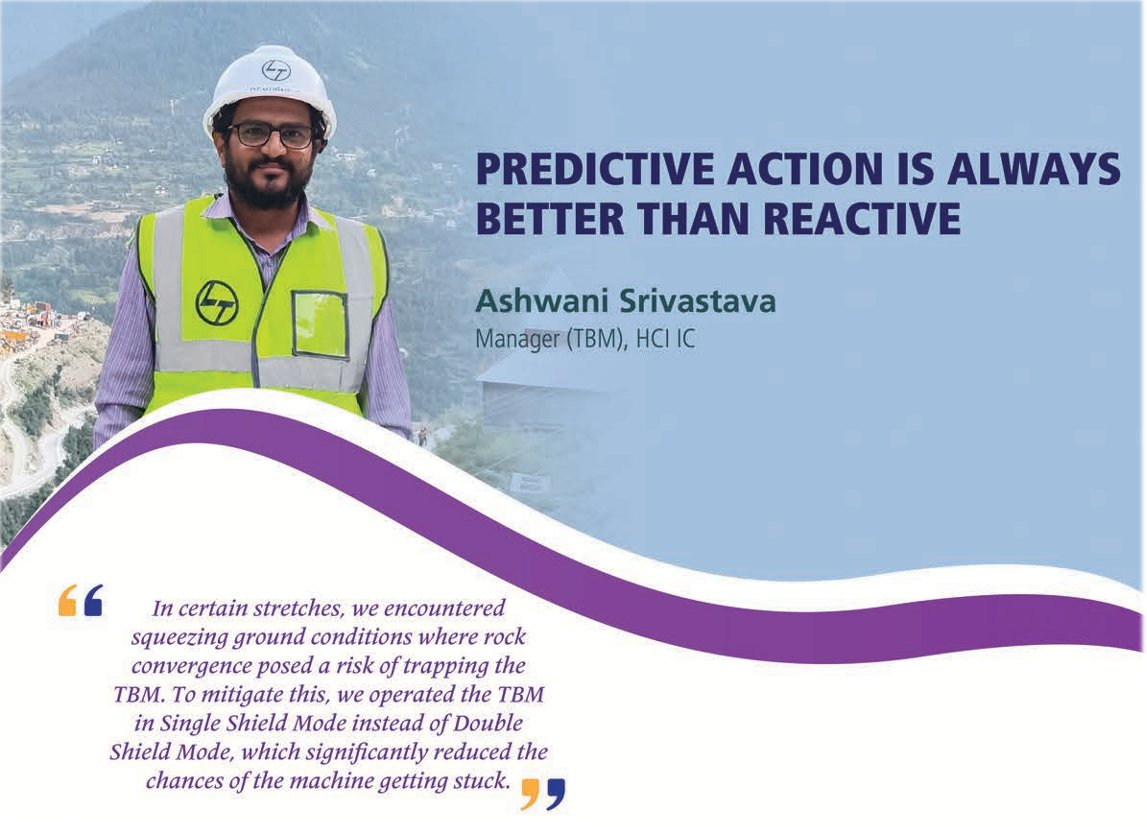

TBMs are at the centre of Ashwani Srivastava’s life as he and the Pakal Dul Hydro Electric project team battle Himalayan challenges to deliver a particularly tough project. “The cutterhead is the most critical part of the TBM and we take special care to monitor its wear and tear,” his shares about his favourite subject. “We conduct regular Cutterhead Interventions (CHIs) to inspect, repair, and replace disc cutters and reamers, to ensure reliable performance in the challenging geology.”

By digitally tracking and documenting these CHIs, maintaining records of disc cutter changes and logs of hydraulic oil/grease consumption, the team has improved traceability, reduced downtime in planning, and speeded up decision-making. “By planning and executing parallel activities like rail line and pipeline extensions, back up gantry wheel alignments, conveyor alignment and extensions during CHIs, we have minimized separate stoppages, saved valuable time, and improved overall production rates,” he says, with josh.

The team’s many challenges include sourcing skilled manpower, arranging resources in time, combatting adverse weather conditions like snowfall, heavy rains, frequent landslides & shooting stones, local strikes, and the ever-present geological unpredictability. Training unskilled labour, maintaining buffer stock of critical materials, planning logistics in advance, a well-monitored inventory system, and closely coordinating with supply chain teams are reducing downtime. “In certain stretches, we encountered squeezing ground conditions where rock convergence posed a risk of trapping the TBM,” Ashwani mentions. “To mitigate this, we operated the TBM in Single Shield Mode instead of Double Shield Mode, which significantly reduced the chances of the machine getting stuck.” After a pause, he adds, “Predictive action is always better than reactive, whether it is related to TBM cutter change, hydraulics troubleshooting, or resource planning.”

A project of this complexity & magnitude demands excellent teamwork and Ashwani is grateful to his seniors for their strong guidance in project planning, managing risk, and making resources available in time. “They have given me a free hand to decide helping me to work quickly and effectively while their trust and encouragement motivate me to deliver results with responsibility.” He appreciates his team members too for their coordination, commitment, diligence in following technical instructions, sharing their views and past experiences to deliver at speed & scale.

A Bihari by birth, Ashwani’s life partner is Medhavi, a homemaker, and they are blessed with two daughters, Aadhya and Garvita, whose births he cherishes, that gave him a renewed sense of responsibility. Sharing highlights of his career, he mentions working on the Delhi Metro and Kolkata Metro projects and being involved in constructing India’s first under-river 520 m long tunnel, beneath the Hooghly River.

One aspect that has dominated Krishan Pratap Singh’s career of 12 years is executing TBM-driven tunnelling projects across India and therefore he is on familiar territory at the Pakal Dul Hydroelectric project, tasked to execute two Head Race Tunnels using Herrenknecht Hardrock Double Shield TBMs. “My expertise spans installation, operation, maintenance, refurbishment, design modifications, and technology upgrades of TBMs,” he shares, giving a glimpse of his career journey that includes several projects outside L&T. Praising the company he now keeps, he says, “L&T encourages experimentation, innovation, and constructive suggestions, that Significantly enhances productivity and supports continuous learning.”

The projects remote location, unexpected mechanical breakdowns, difficult geological conditions, limited tool availability, unskilled manpower are Some the project team’s mountains of challenges and Krishan’s experience is being fully tested to overcome these. “We have strengthened preventive maintenance practices, provided hands-on troubleshooting training to the team, and planned better for critical spares and tools,” he explains. “Above all, teamwork and proactive communication are helping us enormously.”

His dozen years in construction have taught him that successful project execution is always about teamwork and he acknowledges the guidance, motivation, and clear strategic direction of his seniors. “My team members demonstrate strong dedication, ownership, a proactive problem-solving mindset and their unwavering focus on safety and high performance are standing us in good stead,” he says gesturing togetherness.

After a moment’s thought he says that precise planning tailored to site-specific conditions, combined with disciplined execution are what empower teams to deliver large projects speedily. “Of course, effective resource allocation, preventive maintenance, and timely decision-making are essential to maintaining momentum,” adding that teamwork, adaptability, and continuous monitoring are equally vital to ensuring timely completion and overcoming unforeseen challenges, like he has been experiencing at Pakal Dul. Believing in the huge benefits of technology, he hopes for an Al-driven predictive maintenance system to analyse TBM performance data in real time and forecast potential component failures well in advance. “It will significantly reduce unplanned downtime, improve operational efficiency, and enhance overall project reliability,” he says purposefully.

A native of Gorakhpur, Uttar Pradesh, Krishan declares that ”Despite a demanding work schedule, I make it a priority to maintain a healthy balance between professional responsibilities and personal interests.” Married to Pratibha Singh, a practicing psychologist, he cherishes moments with his son, Aadhavan, whose first words and steps are his most joyful memories. “His welcome after long site days refreshes me,” he-smiles. Apart from spending quality time with his family, he enjoys reading about emerging technologies and traveling.

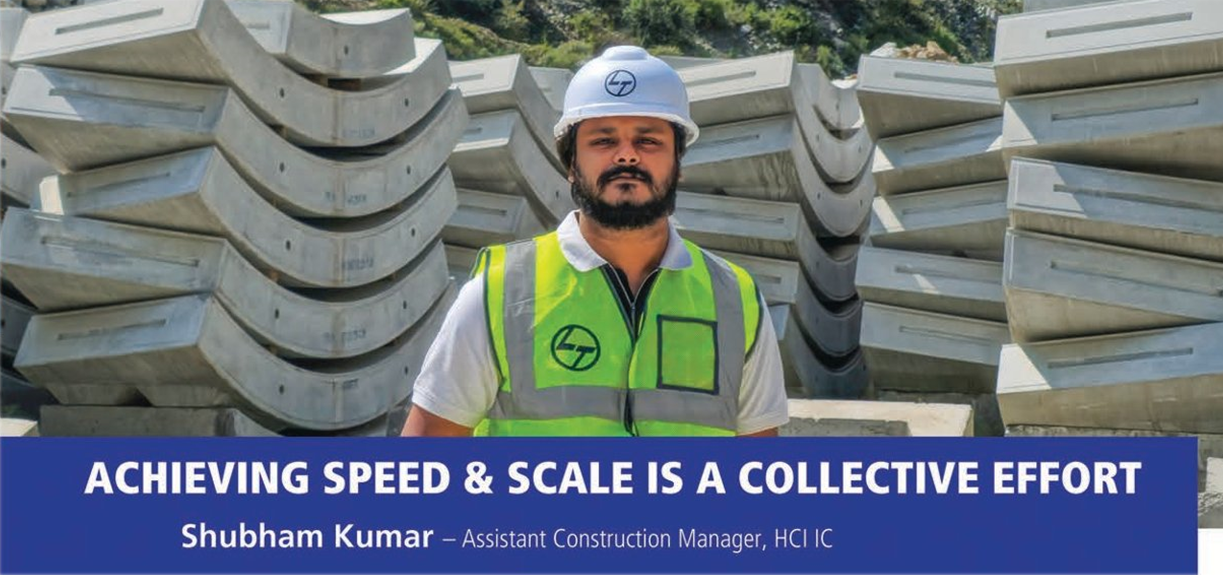

“I have been given opportunities to take ownership, adopt innovative digital practices, learn from industry leaders and this trust and empowerment motivates me to continuously deliver better and grow as a professional,” declares Shubham Kumar, evidently thrilled with the company he keeps. Having joined L&T as a GET, he is at his first project, the HEP HRT-TBM project at Pakal Dul where he is working in the planning department looking after job costing, ACE/JCR, MPCS schedules, and high value subcontracting.

Clearly, his experience has been great for he says, “At L&T Construction, achieving speed and scale is always a collective effort, and I have been fortunate to receive continuous guidance and support from my seniors and active cooperation from my team members, to deliver results effectively,” he says with a sense of achievement. Mentoring from his seniors has helped him to anticipate challenges and take preventive actions and is impressed by their clear direction and set, well-defined priorities that are aligned with organizational goals. “With my team’s support, we collaborate across disciplines, to minimize rework and improve overall productivity.”

Being involved with planning & control, on-time and regular availability of data is a must for Shubham. “Our digital Apps provide the team with real-time site progress, material consumption details, TBM movement status, and more at just a click. Our Integrated Digital Project Monitoring System, digital attendance and productivity tracking, mobile-based quality & safety Apps such as Sanyog & SHEILD, and loT & sensor-based monitoring such as GPS have improved our accuracy in monitoring and reporting, speeded up decision-making, and enhanced coordination among stakeholders, leading to significant acceleration in the project timeline,” he says with a winning smile.

By engaging with geotechnical experts and using Tunnel Seismic Prediction devices, the team is better prepared to counter unexpected strata conditions and obstructions while regular pre-start briefings, multiple trainings & assessments are helping them upskill the workers, 80% of whom must be local as per contract.

Proactive planning, real-time monitoring and swift decision-making are key to delivering large projects like Shubham’s. “TBM excavation is our major scope of work that demands meticulous planning of TBM operations, real-time monitoring of machine performance & ground conditions, and availability of regular spares & segment supply chain,” he explains.

A native of Bokaro Steel City, Jharkhand, and still single, Shubham likes to play cricket and engage in activities like running and workouts to stay energetic and disciplined. “I also like to listen to music as it relaxes me after a long day,” he smiles, stretching his arms.

Kunal Deore began his professional journey with L&T during one of the most uncertain times in recent history: the peak of the pandemic. “At a time when layoffs, placement regrets, and hiring freezes were the norm across industries, receiving-an offer from a company as reputed and resilient as L&T was not just a career milestone; it was a moment of immense relief and pride,” he shares, with his eyes glistening. “After joining, L&T ensures that professionals like me are not just keeping up but constantly growing, adapting, and contributing meaningfully to the larger vision,” he adds with fervour.

Having debuted in 2021 as a PGET from NICMAR at the Pakal Dul Hydro Electric Head Race Tunnel project, Kunal has been busy with client billing, budgeting, cashflow, progress reporting & monitoring, analysing extra item & insurance claims, making business presentations, managing client relations, driving digital adoption & implementation and much more.

“With our tech tools, we have bridged the gap between planning and field execution,” he shares, “and by reducing manual data entry, our data is more accurate, capable of instant updates for our look-ahead schedules.” He proceeds to reel off their suite of digital tools including ConEase, Procube, WRENCH, WAS/WMS, & RebarPro.

The team’s planning and execution have often been disrupted by harsh weather conditions, limited connectivity, logistical constraints, and unpredictable geological conditions and Kunal is particularly pleased with their robust tunnel communication system with GPON technology that maintains communication with all inside and outside the tunnels. Additionally, it gives the team real-time visibility and control over multiple work fronts. “One technology that I believe could significantly enhance our efficiency in remote hydro projects like Pakal Dul is the integration of AI-powered predictive analytics with real-time site data,” muses Kunal, with a nod.

Acknowledging the pivotal role played by his seniors, Kunal mentions their strategic direction, timely guidance and trust that has given him the freedom to innovate, empowering him to explore digital tools and implement process improvements that have positively impacted site productivity. “Their emphasis on data-driven decision-making and proactive risk management has encouraged me to adopt techniques like real-time dashboarding while the dedication and openness to digital tools of my teammates have smoothened implementation,” he says gratefully.

From Nashik, Maharashtra, and still single, Kunal steals time for movies, documentaries, and travel to explore new places, despite the project’s demands. “Those crazy little escapes from the daily grind are what we all live for,” he says with a hearty laugh.

SEASONED BY CHALLENGES

Syed Mohd Faisal

Assistant Construction Manager (Civil), HCI IC

The three and a half years that Syed Faisal has spent at the Pakal Dul Hydroelectric Project in Jammu & Kashmir, his first with L&T, have been hugely rewarding and a learning experience for him. “It is a technically challenging project, with one of the key highlights being constructing the twin TBM tunnels in a mountainous terrain,” he shares with a serious look. “We have had to face several logistical, technical, and environmental challenges that have helped me grow both professionally and personally.”

Describing his growth from a Junior Engineer to his present position, Syed says with satisfaction, “I have enjoyed the opportunity to take ownership of activities & lead precast works independently and have developed strong capabilities in planning, material estimation, execution, and monitoring, particularly in precast operations, thanks to the knowledge and experience l’ve gained over the years.”

Some of the challenges he refers to in the tough Himalayan terrain includes limited space for enabling works, setting up the casting yard, segment stacking, and transportation and being contractually bound to have 80% locals in the workforce made it difficult to mobilize skilled workers initially. However, Syed and the project team had mitigation measures. “We optimized space by redesigning the stacking yard layout & increasing storage from the planned 400 to 580 rings and focused on on-site training and skill development for local workers to gradually improve their productivity, and with our close coordination, planning, and team effort, we have managed to keep the project on track,” he smiles.

Considering himself fortunate for the opportunity to work closely with a very dedicated and humble team, Syed is all praise for the strong, supportive leadership that has encouraged continuous learning and upskilling. “My seniors guide us with clear planning and quick decision-making, which speeds up work, trusting and supporting new ideas,” he remarks, adding that the team’s strong coordination and problem-solving skills have improved both their pace and efficiency.

On the tech front, Syed mentions the deployment of their Tunnel Segment Management System and an in-house Digital Steam Monitoring System and looks forward to Al-based solutions for progress tracking, quantity estimation, and predictive maintenance. Strong leadership and clear accountability within the team are key to delivering large and tough projects like his. “When responsibilities are clearly defined and each team member takes ownership, work moves faster and with better coordination,” he says, resolutely.

Hailing from Barabanki, Uttar Pradesh, Syed’s better half is Huma Siddique, who has done her B Tech in Biotechnology and is currently pursuing higher studies. He loves playing cricket and exploring new places when he finds the time for them.