“BIM“ED FOR SUCCESS

Kishore Kumar Dasam

Senior Manager (BIM), B&F IC

For Kishore Kumar Dasam, the journey from a GET in 2008 to Senior Manager BIM has been nothing short of transformative, embracing the rapidly evolving digital technologies in construction and implementing them at project sites. Initially, after two years at the Serene County Housing project in Hyderabad, he got an opportunity to pursue M.Tech. in Construction Management at IIT Madras through the BIS programme, post which he moved into BIM coordination, procurement, and project scheduling at TCS Adibatla, before taking on larger responsibilities in Chennai.

Another turning point in his career came at the Apollo OMR project with the introduction of the concept of Field BIM, using iPads to access 3D models, project documents, and checklists directly on-site.

”It transformed how teams worked, making information accessible instantly and reducing delays,” he recalls. Ever since, Kishore has been at the forefront of BIM adoption across projects, training teams, and embedding technologies into project workflows, taking over as BIM Manager for the Bhogapuram International Airport project in June 2024, where the scale and complexity of work have provided a fertile ground for advanced digital interventions.

He mentions using cloud collaboration through Autodesk ACC, for multiple Stakeholders to access and edit live design models bridging communication gaps and quickening design delivery, apart from championing 5D BIM, integrating quantification with subcontractor billing. “Manual verification was time-consuming, but with 5D BIM, the process is faster and more accurate, giving Subcontractors confidence and the project greater cost control,” he explains. Laser Scanning for as-built verifications and VR for client approvals have further enhanced efficiency with quicker client approvals and mock-ups saving the need for costly revisions.

Yet, the journey has not been without challenges. Convincing subcontractors to adapt to BIM workflows remains a hurdle that has been addressing through BIM kickoff meetings and regular coordination sessions, gradually building their capability. He firmly believes that streamlined communication and authentic project data are key to delivering large projects with speed and is excited about the possibilities of Al in construction management.

Beyond work, Kishore hails from Kakinada, Andhra Pradesh. He is married to Ramya Sree, a bank employee, and they are proud parents of two daughters, Ashna and Anha. Though painting and craft remain his passions, his busy schedule often keeps him away from them. His most cherished memories include his selection at L&T during campus interviews, his IIT Madras journey, and the birth of his daughters.

Reflecting on his 16-year journey, Kishore remains a proud L&T‑ite. “As a passionate civil engineer, L&T was my dream company and I truly believe that if something cannot be achieved by L&T, it cannot be done by anyone else.”

Technology is not just a tool for S Mariram but a catalyst for transformation, having championed advanced BIM workflows to introduce speed, scalability, and sharper decision-making to major projects like ITC Green in Bangalore, TIMS in Hyderabad, and TC4 at the Manapakkam HQ campus in Chennai. “Every project we deliver contributes to the progress and development of the country, and being part of that story inspires me every day,” he says reflecting on his journey with L&T.

Mariram’s work has spanned 4D BIM for faster sequencing, 5D BIM for cost-time integration, BIM for Safety, and BIM-to-GIS integration, complemented by Power BI dashboards for data-driven decisions in real time. “For me, success lies in building scalable workflows that deliver tangible value, not just implementing BIM as a checkbox,” he reflects.

“I am proud of our BIM for Safety initiative using Generative Design Dynamo scripts to automate the modelling of safety components through edge and face selection,” he says. “This digital workflow accelerated model creation and introduced the Digital Fall Protection Tracker Form, enabling site teams to monitor compliance in real time, marking a big step forward in our Mission Zero Harm.”

Like any change, the digital shift was not without resistance, with initial hesitance to shed conventional practices, which Mariram tackled with patience and structure, conducting awareness sessions, demonstrating benefits through real results, and offering hands-on training to bridge technical gaps, drive adoption & build trust in the new systems. “Once teams saw how digital tools improved collaboration and decision-making, they became active champions themselves,” he smiles.

A strong support system has been central to his journey. My immediate supervisor, B.S. Mukund, has been a guiding force whose strategic direction and timely feedback have motivated me to innovate, while my colleagues have been great collaborators, helping scale solutions seamlessly across projects,” he notes with gratitude.

Real-time project visibility is key to delivering large projects, according to Mariram, and integrating BIM with 4D and 5D scheduling give management and site teams immediate insights into progress and costs. “Data-driven insights are the backbone of timely delivery. When you have the right information at the right time, you can make proactive decisions and prevent delays,” he emphasizes. Looking ahead, he sees automation in BIM modelling as the next leap. An intelligent system capable of handling repetitive modelling tasks would, he says, “free up engineers’ time for higher-value activities like design optimization, safety planning, and integration, making project execution smarter and faster.”

Beyond work, Mariram stays grounded with his family. A native of Tirunelveli, he is married to S. Sivagami, an Assistant Professor in Chemistry, and together they are raising two daughters, Yalini and Mahati. Photography, food exploration, and long bike rides are his favorite pastimes, though he treasures simple family outings the most.

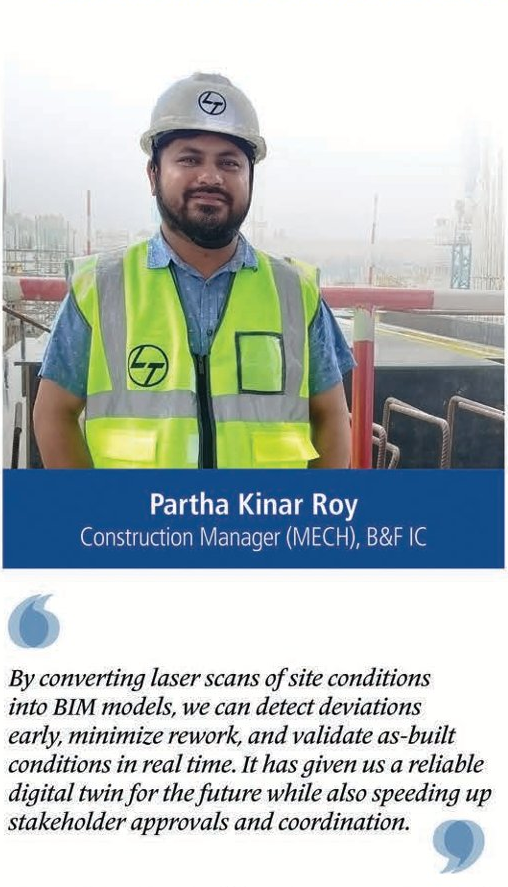

DRIVING PRECISION AND SPEED WITH BIM

With nearly two decades of diverse project experience, Partha Kinkar Roy brings a rare mix of technical skill and innovative thinking to his role as BIM Manager on the Kiran Nadar Museum of Art (KNMA) project in Delhi, where he leads BIM execution and coordination through digital-first practices. From airports and IT parks to healthcare institutions and high-rise towers, his career has spanned India and overseas, featuring landmark projects such as Bangalore & Delhi International (T3) airports, Salalah International Airport in Oman, ITC Colombo One in Sri Lanka, and several medical colleges across Odisha and West Bengal.

At the heart of his approach lies Scan-to-BIM technology, a game-changer to improve accuracy and accelerate progress. “By converting lase laser scans of site conditions into BIM models, we can detect deviations early, minimize rework, and validate as-built conditions in real time,” Partha explains. “It has given us a reliable digital twin for the future while also speeding up stakeholder approvals and coordination.” Complementing this are 4D sequencing simulations, 5D cost control, VR/AR walkthroughs, and real-time dashboards that bring clarity and transparency across the project lifecycle.

Partha credits both his seniors and his team for encouraging him to deliver solutions at speed and scale and giving him the freedom to push initiatives like 4D/5D and Scan-to-BIM. “My agile and collaborative team, maintains high-quality models, running coordination sessions to ensure data accuracy. Thish balance of leadership support and team adaptability is what makes our BIM strategy effective.”

Challenges are not new to Partha, but he sees them as opportunities for improvement. Aligning multiple disciplines to a common BIM workflow was a particularly tough hurdle. “Data inconsistencies and ownership issues can easily slow things down,” he notes, implementing a centralized BIM execution plan with version control and weekly Navisworks coordination meetings for faster clash detection, smoother collaboration, and sharper accountability across teams.

Early alignment and real-time visibility are key to delivering large projects quickly. “When time and cost data are linked with BIM, deviations become instantly visible for correction,” he remarks, wishing for a technology that can directly generate MEP spool drawings from coordinated BIM models, to eliminate at delays and bring fabrication and installation closer to automation.

Away from his digital dashboards, Partha finds joy in painting, a hobby that fuels his creativity. But his most cherished memory remains the day his daughter Pravi was born, a moment that deepened his sense of responsibility both at home and at work. “What makes me most proud at L&T,” he adds with conviction, “is the freedom to innovate and the chance to set industry benchmarks. Being a part of projects that shape nations gives my work true purpose.”

Over the past eight years, every project has been an opportunity for Vishnu Datta Ayenampudi to break new ground in digital construction, steadily evolving from an execution engineer to a BIM specialist, contributing to some of L&T’s iconic projects.

Beginning his journey at the Motera Cricket Stadium, Ahmedabad in 2017, he transitioned from field execution to planning and later to piloting B&F IC’s BIM implementation initiatives as BIM Coordinator initially at the IIT Bhilai campus project and thereafter at the Kiran Nadar Museum of Art, Delhi. Presently, he leads BIM initiatives at scale at the Alluri Sitarama Raju International Airport, Bhogapuram, where he has developed dashboards for subcontractor billing, integrated with BIM models, with live progress data for quick verification and validation of quantities. Apart from transparency, the system ensures that “not a rupee more is paid than what is due.” Additionally, it has streamlined processes, accelerated decision-making, and reinforced trust between L&T and its partners.

“BIM implementation is as much about change management as it is about technology,” Vishnu opines, crediting his seniors & teammates for creating a supportive environment to excel. “The encouragement and flexibility of leaders like Mr. Subrata Dutta, Mr. Venugopal Kurup, Mr. Pranab Krishna De, and Mr. Kishore Kumar Dasam have been invaluable.”

Executing an airport project throws up unique challenges, especially visualizing the dense clusters of service lines running across buildings that were tackled with cloud-based solutions, simplifying complex models for the site team. “These have both improved clarity and boosted the confidence of younger engineers to confidently engage with senior experts and vendors,” Vishnu highlights.

His eight years have taught Vishnu that understanding the client’s success parameters and aligning resources accordingly are key to delivering at speed, rather than getting lost in day-to-day firefighting. He sees laser scanning technology as a game-changer going forward for proactive execution.

A native of Koduru, near Guntur in Andhra Pradesh, Vishnu and his wife Janani share roots in agricultural families. His mother, Vijaya Lakshmi, is a schoolteacher. While Vishnu pursued engineering, Janani carved her path in software engineering. Newly married, he balances his professional commitments with personal joys, often finding time to unwind with a game of badminton. He fondly recalls his campus days at IIT Madras and the excitement on his colleagues’ faces when they experienced BIM for the first time.

For Vishnu, pride in L&T comes from being part of something bigger. “To be a small part of L&T’s digital transformation journey, which is shaping the future of India’s construction industry, is a matter of immense pride.”

DATA, DASHBOARDS, AND DELIVERY

Valliappan M

Assistant Manager (BIM), Digital Engineering, Divisional Corporate

Digital technologies no longer being an option but the future of construction is a truism that tech pros like Valliappan M have come to believe, and with every project, he is seeing how tools like BIM, data dashboards, and collaborative platforms are transforming the way we do business. “In projects like ITC Green, Bengaluru, and TC4, I learned how 4D BIM could fast-track sequencing and visualization, while 5D BIM integrated cost and time seamlessly,” he shares. “Developing BIM-enabled Power BI dashboards gave me the satisfaction of seeing how data-driven insights improved reporting efficiency and added real value for stakeholders.”

One of his recent achievements has been implementing a Common Data Environment (CDE) through the ACC module that enables site teams to access the latest drawings, visualize 3D models, and raise issues in real time, significantly improving collaboration and site progress.

Yet, the road has not been without challenges. Valliappan recalls how monitoring progress through traditional strip charts and spreadsheets often slowed decision-making. “The answer,” he shares brightly, “was a Power BI-enabled 4D BIM dashboard that converted raw data into clear visualizations, presenting a consolidated view of planned versus actual progress and activity-wise completion, for effective monitoring.”

The biggest lesson he has drawn from his experience is the power of integrating BIM with project controls. By linking scheduling, cost, and progress tracking to the model, teams can spot issues early and make proactive, data-driven decisions. He elaborates that it is not just about having BIM; “it’s about using it as a central hub for everyone to access the same accurate information in real time. That transparency is what will truly drive speed without compromising quality.” He hopes for Al-powered BIM tools that can automatically track construction progress using site photos, drones, or laser scans, while also assessing quality parameters like alignment and floor flatness.

Valliappan credits his growth to the guidance of his seniors, flagging off his immediate supervisor, B S Mukund, for his constant support and mentorship. “His trust and timely feedback have motivated me to innovate, while encouragement from other seniors helps me learn and contribute effectively.”

He has a passion for acting and drama script writing, a passion that fuels Vicky Kumar’s storytelling instincts, giving him a different perspective on problem-solving that is certainly helping him script his success story with L&T. At his first project with the Company-Delhi’s landmark Kiran Nadar Museum of Art (KNMA)-he is making a mark in the areas of BIM and digital project execution. The museum’s architectural complexity, especially the use of exposed white concrete with embedded MEP services, demands precision, and rising to the challenge, Vicky has spearheaded digital initiatives that have accelerated progress and enhanced collaboration.

Implementing Autodesk Construction Cloud (ACC) as the project’s digital backbone is a highlight of his contribution. Moving away from traditional paper-based processes, the entire project ecosystem of over 170 stakeholders — including vendors, PMC, client, and consultants — now work seamlessly onacommon platform. “From RFIs and approvals to shop drawing reviews and daily micro-level activity tracking, ACC ensures transparency, accountability, and real-time visibility,” Vicky adds.

Flagging off another innovation, Vicky mentions SysQue-based spool modelling for MEP fabrication and erection. By creating detailed models and generating LOD 400 spool drawings, the team’s prefabrication is tailored to exact site conditions. “It has reduced errors, ensures compliance with OEM standards, and has improved installation efficiency,” shares Vicky, “an especially critical advantage in a project where every embedded service must align perfectly with exposed concrete finishes.”

A highpoint in Vicky’s career is winning the PI Award for these digital interventions that he describes as both a proud milestone and validation of the team’s efforts. He attributes his success to the guidance and trust of his seniors, who have given him the space to lead key initiatives. He praises the collaboration and adaptability of ahilityof his team members too.

Vicky’s biggest learning from KNMA is that collaboration and transparency are the true enablers of speed and scale. “Digital tools, when fully embraced can transform support systems into engines of efficiency and quality,” he remarks insightfully. Looking ahead, he sees Al-powered clash detection and resolution as the next breakthrough that could save even more time and reduce rework.

Originally from Bhojpur, Bihar, he is proud of L&T’s culture of innovation and empowerment. “L&T isn’t just a workplace; it’s a platform for building legacies. Being trusted to contribute to that journey is both inspiring and fulfilling,” he says with conviction.

Harnessing the power of digital tools to keep every stakeholder aligned is what Md Naiyer Ajam considers critical to deliver the iconic Navi Mumbai International Airport, and as both BIM Coordinator and Project Planning & Control Engineer, he has been at the forefront of driving innovation at the fast-track greenfield airport project, his first with L&T.

“Executing a project of this magnitude in just 2.5 years requires precision, foresight, and seamless coordination,” he explains, to achieve which Naiyer has led the early implementation of 4D BIM to simulate construction sequencing, allowing the team to communicate the scope and proper sequence of work, keeping everyone on the same page while enabling digital progress monitoring through 3D plan-versus-actual reporting.

The team has introduced 3D laser scanning to capture actual site conditions in point cloud format, that are compared with the design model to detect deviations that have reduced rework, saved time, and ensured accuracy in substructure and finish works.

The unwavering guidance of his seniors and his team’s collaboration have been the cornerstone of his success. From Project Director, Rajesh Pachlot, and Project Control Head, Rahul Pal encouraging fast-tracked digital adoption to the technical expertise of Scheduling Head, Deepak Danai; Planning Head, Pravin Balani; and BIM Managers, Kishore Kumar Dasam and Potu Raghuram, in rolling out 4D BIM and laser scanning, Naiyer credits this culture of mentorship and teamwork for them to push boundaries.

Balancing speed with accuracy while managing multiple parallel activities were causes for worry. “Leveraging 4D BIM, VR, AR, drones, and laser scanning have ensured that deviations are identified early, and bottlenecks visualized in advance, for stakeholders to make quicker, better decisions,” Naiyer points out. “Speed,” he affirms, “comes from clarity, and clarity from connected data.”

Looking ahead, Naiyer envisions a real-time integrated project dashboard that links live site data — progress updates, deviations, bottlenecks — directly with all stakeholders, enabling instant decision-making and true transparency.

A native of Sheohar, Bihar, Naiyer enjoys swimming and exploring new places when away from site. “My proudest moment so far has been receiving the BIM Excellence Award 2024 at the annual townhall,” he notes, adding that for him, being an L&T‑ite is all about growing through innovation, learning, and recognition, where new ideas are encouraged and achievements celebrated. “My training as a Field BIM Coordinator from the BIM Academy strengthened my technical foundation and prepared me to apply BIM tools effectively,” he says, signing off.

Madhusudhana’s BIM journey has been both purposeful and rewarding. Having started his career as a QA/QC Engineer at Kalpataru Project International Limited, he spent over two years monitoring quality standards on a large residential project before discovering his deeper interest in the digital transformation of the construction industry. After upskilling himself through a specialized BIM course, he joined L&T and, for the past two years, has been shaping digital adoption at Phoenix P‑25 Triton, the tallest composite structure in South India.

“Being a vertical high-rise, the project presented a critical challenge limited horizontal space for material and equipment storage,” he explains. To address this, he introduced BIM-led logistics planning. “Digitally integrated 3D modelling of temporary works and Autodesk Construction Cloud (ACC) Docs have streamlined coordination, ensured transparency, and enhanced safety & quality. This transformative approach has improved efficiency, minimized waste, and delivered exceptional project outcomes, benefiting all stakeholders involved.” A notable example is the podium logistics plan, where a temporary ramp was digitally rehearsed. Initially designed as a two-way ramp, it was optimized through 4D simulation to a single one, reducing the ramp area by 600 m², saving material costs, and ensuring compliance with fire NOC requirements.

Equally transformative was his use of BIM for safety management By digitally tracking fall protections at floor edges, shafts, and cut- outs, the team reduced reporting time from 180 minutes to just 30 minutes — a saving of 220 manhours over the project. “The 3D model gave the execution team clear visibility of hazards, enabling proactive planning and timely controls,” he shares. Beyond logistics and safety, BIM has been extended to documentation, AR/VR-based interfacing, and progress monitoring, for smoother workflows across the board.

Grateful for the mentorship he has received, Madhusudhana credits Project Manager, D. Sudhakar Prasad; Planning Manager, Savu Ramya Sri; and Senior EHS Manager, Jose Gladson, for championing the BIM initiatives, and colleagues like Kishore Kumar Dasam and Potu Raghuram for their technical guidance. “Their encouragement and collaboration have been instrumental in driving adoption and demonstrating the value of BIM to everyone on site,” he acknowledges.

The Chitradurga native finds balance in badminton, movies, and exploring new cities. Recognition has also been a source of pride; winning the BIM Excellence Award in both 2024 and 2025 remains among his most memorable achievements. Looking ahead, he envisions integrating BIM with loT sensors and AI analytics for real-time, predictive safety management. Although relatively new, Madhusudhana is thankful to L&T for opportunities to excel. “The organization values innovation and empowers individuals to contribute meaningfully — and that makes me a proud L&T‑ite!”

Planning, seamless coordination, and solving challenges before they escalate are what make large projects tick, according to Vivek Chaudhary. Until recently stationed at Reliance Industries Limited’s Solar and Glass Factory projects in Jamnagar, Gujarat, where he led precast erection works, he is now playing a new role at CIDCO’s Navade Project in Navi Mumbai, continuing to apply his experience in fast-track execution.

Since joining L&T in 2010, Vivek has built a wealth of experience across diverse projects, ranging from fabrication and erection works at MHI Turbine and Foundry shops in Hazira, large-scale equipment erection at Grasim’s VSF division in Bharuch, underground piping at Reliance’s Jamnagar plant, and precast erection at the iconic Motera Cricket Stadium, to industrial structures for Hero Motors, JCB, JSW Cement, and more. “Each assignment has contributed to my learning curve, but RIL Jamnagar stands out for the scale, pace, and complexity of precast execution,” he reflects.

At RIL Jamnagar, Vivek introduced several practical innovations to accelerate site progress such as devising a supporting arrangement scheme for 85 MT roof beams cast in two parts, optimizing logistics plans for modular roof beams, and coordinating crawler crane boom configurations for multiple job fronts. Managing logistics between the precast yard and site, ensuring workmen retention under stringent client guidelines, and leading a team largely from mechanical engineering backgrounds into a new domain of precast erection were among his key challenges. “We tackled them with micro-level scheduling, daily progress monitoring, and structured coordination with our CMPC and EDRC teams as well as the client,” Vivek shares. “Identifying bottlenecks early and timely decisions made all the difference.”

Vivek credits his seniors for their clear priorities, experience and empowerment, allowing him to take quick decisions. “My team supports me by collaborating openly and working with trust, which is what really drives execution at speed,” he notes.

A native of Varanasi, Vivek unwinds by watching movies in theatres and going on family shopping trips. His wife Sarita, who earlier worked in a government bank, now manages their home and children, Dhruv and Vivaan. “They are my anchor and motivation,” he smiles.

Looking back at his journey, Vivek is proud to be a part of L&T’s legacy of nation-building. “Every project we deliver demonstrates world-class engineering while creating lasting value for society. That purpose, along with L&T’s culture of quality and trust, is what inspires me every day.”

Having built his career brick by careful brick over the past two decades, Reegan Paulsingh D has moved from quality control to planning, precast technology, and project management. His track record of projects is spread across the country, starting with the Ultratech Cement Plant in Andhra Pradesh in 2006 to the iconic Statue of Unity in Gujarat, Yashobhoomi (IICC) in Dwarka, and currently the PV Solar Manufacturing and Glass Factory in Jamnagar. “Each assignment has honed my ability to handle scale and deliver with excellence,” he says with a determined smile.

Focused on accelerating the pace of execution at the Jamnagar project, Reegan and team have championed innovative construction aids like using rubber bush templates on column coupler faces and precision templates on floor/roof beam columns for sleeve pipe positioning, which have reduced errors and rework while scoring high on speed, accuracy, and quality.

Casting a 55 T SS floor/roof beam stands out as one of the team’s major challenges that demanded meticulous planning, precise calculations, and skilled execution to ensure structural integrity and safety. “With careful attention to detail for critical factors such as material selection, formwork design, reinforcement detailing, and concrete pouring techniques, we successfully achieved it,” exults Reegan.

His experience has taught him that effective project management, coordination, and communication are critical factors to deliver large projects. “Clear goals, realistic timelines, and adaptability are key to staying on track,” he points out. Looking ahead, he sees Al-driven predictive analytics as a game changer for forecasting risks, optimizing resources, and enabling sharper decision-making for large projects like his.

The mentorship of his seniors and their constant effort to promote a culture of collaboration have contributed to Reegan’s continued success. “Working in an environment that values efficiency, constructive feedback, and innovation is incredibly rewarding.” Reegan adds fervently.

A native of Tenkasi, Tamil Nadu, Reegan eega enjoys listening to music. He is married to Priya, a homemaker. “One of the most memorable moments of my life was when God blessed us with a baby boy, Jennish Antony. His arrival filled our home with happiness and joy,” he shares emotionally.

Proud of L&T’s strong commitment to social responsibility, Reegan says, “Our initiatives in education and technical training have greatly enhanced employability in the construction industry, building future-ready talent.” He signs off with a thumbs up.

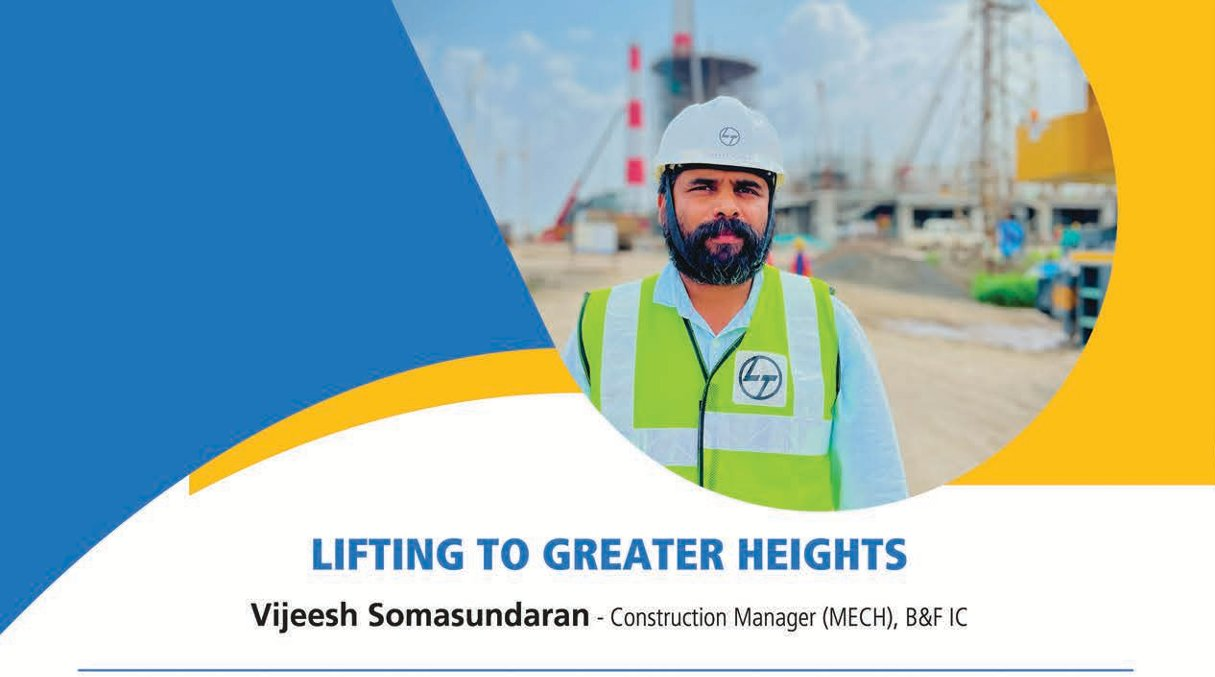

A nice blend of proactive planning, effective coordination, and smart use of technology are the secret sauce to deliver at speed and scale as per Vijeesh Somasundaran. During his decade-long association with L&T, he has overseen some complex and large-scale erection and fabrication works across industries, from cement and power to petrochemicals and iconic stadia. “Every project we deliver is not just an engineering feat, but a contribution to nation-building,” he says passionately, “and it is that sense of purpose that inspires me to give my best every day.”

At RIL’s Solar Glass Factory and PV Solar Manufacturing Facility in Jamnagar, Vijeesh has been entrusted to execute structural steel and precast erection works — massive in scale and intricate in detail. “To meet the challenge, we have implemented super-lift configurations in a 450 MT crawler crane for column erection, devised efficient logistics schemes for roof beams, and optimized boom lengths for cranes to suit multiple job fronts,” he shares. “Even small improvements in crane planning or logistics can save enormous amount of time and effort on site.” His team has also adopted man-lifters in place of scaffolding, accelerating work fronts and enhancing safety.

To manage the challenges of retaining workmen at Jamnagar under strict client camp guidelines and long-haul logistics between casting yards & site locations, Vijeesh’s response has been structured and pragmatic: daily micro-level scheduling, milestone tracking, and regular coordination with cross-functional teams. By anticipating risks, escalating issues early, and maintaining close follow-up with clients and vendors, he ensures smooth progress without compromising safety or quality. “Early identification and resolution of bottlenecks is the key lesson I’ve carried across projects,” he reflects.

Teamwork, for Vijeesh, is as critical as technology. He credits his seniors for their clarity, trust, and empowerment, and his team for their spirit of collaboration. “The culture of guidance and support around me allows us to work faster and more efficiently,” he notes.

Looking ahead, he sees Al-driven predictive project management tools as a game-changer. With smarter micro-scheduling, real-time analysis of productivity, and proactive risk alerts, Vijeesh believes that engineers can shift their focus from reporting to execution, making large projects more predictable and efficient.

Hailing from Wayanad, Kerala, Vijeesh finds balance through driving, playing football, and watching movies with his wife Vidya and daughters, Vedika and Vanika. His most cherished memories go back to family time, which keeps him grounded amid the steep demands of project life.

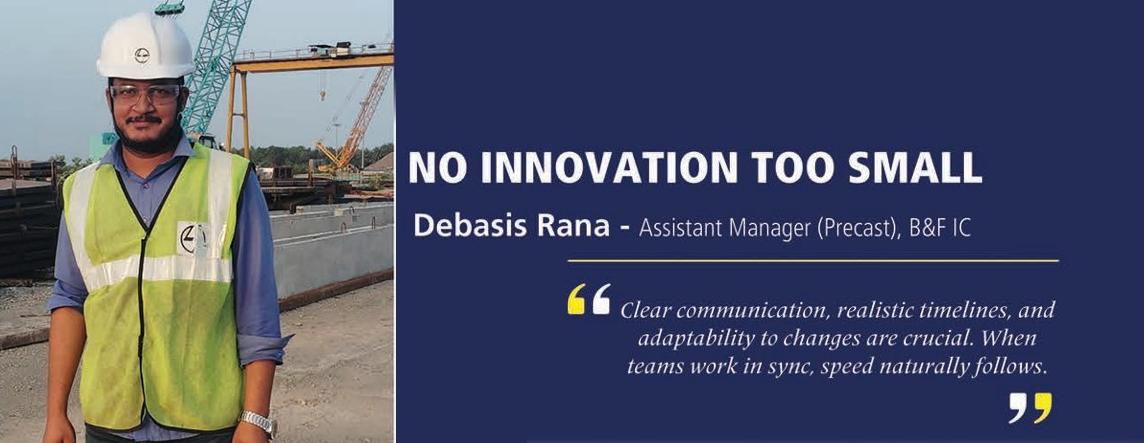

Debasis Rana considers it a privilege to be a part of L&T, and at his first project with the Company, the RIL Jamnagar site, he is pulling his weight in the demanding world of precast construction. “One of my biggest challenges was casting the SS floor and roof beams weighing over 50 tonnes,” he shares. “Such massive elements require meticulous planning, precise calculations, and skilful execution to ensure both safety and structural integrity.” From material selection & formwork design to reinforcement detailing & concrete pouring techniques, Debasis and his team carefully designed and executed every step to achieve this feat successfully.

Talking about innovation, Debasis mentions introducing simple but effective solutions such as using a rubber bush template in column coupler faces and templates for floor and roof beam columns to maintain sleeve pipes in proper position. “These initiatives have significantly improved speed and accuracy at our site,” he remarks.

Revelling in a culture that helps him grow, Debasis credits his seniors and colleagues for their mentorship, setting clear goals, and promoting efficiency through collaboration. “They encourage innovation and empower us with the right resources, helping to deliver better results,” he says with josh.

When asked about the key to timely project execution, he emphasizes effective project management and coordination. “Clear communication, realistic timelines, and adaptability to changes are crucial. When teams work in sync, speed naturally follows,” he notes. Looking ahead, he is excited about the possibilities of technology. “Al for predictive analytics would be a game-changer that can forecast outcomes, identify risks early, and optimize resources, to save time and reduce uncertainty,” he observes thoughtfully.

A native of Jajpur, Odisha, Debasis is supported by his wife, Diptimayee, who manages the home front. He enjoys playing cricket whenever time permits. One of his proudest milestones at work is when the team achieved 3,000 cum. of concreting in a single month for precasting work.

For Debasis, being an L&T‑ite is about more than just executing large-scale projects. “Iam proud of L&T’s commitment to corporate social responsibility, particularly in education and skill development. Knowing that our work contributes not only to building infrastructure but also to empowering people makes the journey meaningful,” he concludes thoughtfully.

Ensuring that every element of a complex project comes together seamlessly is Mohd Tarik’s concept of planning, and as Senior Planning Engineer — Precast at RIL’s Solar Glass Factory and PV Solar Manufacturing Facility in Jamnagar, he is ably managing massive volumes of precast elements with foresight and planning.

At the Solar Glass Factory, which combines units for batch processing, melting, annealing, cutting, and deep processing, the scale is immense: 20,500 cum. of precasting and 5,000 precast elements for erection, while the PV Solar manufacturing facility, envisioned as one of the world’s largest solar giga factories, consists of 13,700 cum. of precasting and 3,500 precast elements to be planned, tracked, and erected in sequence. “I realized the need for meticulous coordination and real-time monitoring,” Tarik remarks with a tight smile.

“We used Tekla to digitally track precast elements to visualize each component in the 3D model, track its production and erection status in sequence, and coordinate seamlessly between the casting yard and erection teams,” Tarik shares the team’s strategy to meet these challenges. He notes with satisfaction that the system has helped avoid mismatches and delays, significantly accelerating site progress.

Tarik is quick to acknowledge the clear direction and trust from his leaders & seniors and his team members’ collaborative support to achieve his targets. “Early identification and resolution of bottlenecks saves the most time, as even small issues can snowball into major delays if left unresolved,” he points out. Looking ahead, Tarik believes that the integration of Al into project management could be a significant breakthrough. “I feel that smarter planning, predictive insights, and automated data analysis will allow engineers to make faster, more informed decisions and focus more on execution,” he remarks smartly.

Hailing from Azamgarh, Uttar Pradesh, Tarik finds creative expression through sketching, a hobby that lets him reflect and recharge. When asked about his most memorable moment, Tarik travels back in time to his school days, when he created a thermocol 3D model of his school building, which was roundly appreciated by his teachers — perhaps the first spark of his passion for engineering!

For Tarik, being a part of L&T is all about nation building. “We deliver not only world-class engineering excellence but also create long-term value for society in areas such as energy, transportation, and urban development,” he says with pride. “That sense of purpose keeps me motivated to give my best every day.”