A WELL-ROUNDED PERSONALITY

R Selvakumar

Senior Construction Manager, Renewables IC

With 20 years’ experience in water and wastewater projects across India, North Africa and the Middle East, an active member of the International Water Association, a Chartered Engineer (UK) & PMP-certified, Selvakumar Rajendran is a well-rounded personality. Starting his journey with L&T in 2021 at the Industrial ETP Project, Qatar, thereafter a high-spirited stint at the Ad Dakhiliyah Water Transmission Project (Phase ll), Oman, he is presently, at the Amaala Utilities PPP project, leading the marine works for the Sea Water Reverse Osmosis (SWRO) plant as Project Manager.

“This is a pioneering seawater intake and brine outfall pipeline project using the micro-tunnelling method in collaboration with a specialist subcontractor, aimed to reduce disturbance to the coral reef ecosystem along the pristine Red Sea coast,” he shares. “My critical consideration is handling multiple stakeholders, to deliver an agile, safe and sustainable solution keeping the requirements for this solar-powered desalination plant.”

Technology has been the team’s major ally. “4D BIM modelling has enabled detailed constructability analysis to update the execution methodologies, while material tracking with the 3D BIM model section-wise has resulted in flawless supply chain management,” he apprises. Their data-driven decisions are based on project scheduling tools for resource management, cost optimisation and risk mitigation. Non-intrusive, remote-operated video modules surveys the seabed along with LiDAR-based monitoring. Remote-operated cameras along pipeline are used for quality inspections safely. Multi-beam Bathymetric survey tools, IVMS systems, and QR codes for digital documentation complete their extensive list of digital interventions.

Pragmatic Stakeholder management and digital integration are, according to Selvakumar, key to delivering large-scale projects with Speed, mentioning that at the Ad Dakhiliyah project, proactive coordination and real-time monitoring helped meet client requirements. “Similarly, here at the AMAALA Project, I initially found managing complex stakeholder interfaces (clients, consultants, statutory bodies, operators, & other contractors) extremely challenging with the potential to delay the project, but with our structured stakeholder management strategy and digital tools we have been meeting our milestones.”

He wishes for AI-led robotics solutions for construction and installation in complex environments for zero-harm objectives. “Automated AI-based systems for enhancing precision, supports productivity, reducing risks, and accelerating progress,” he smiles.

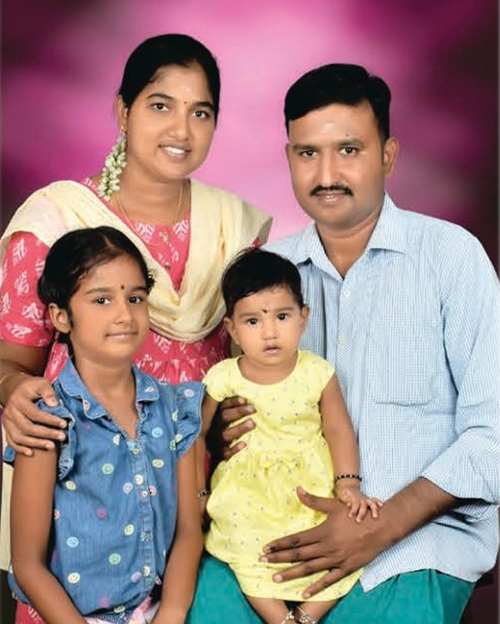

Born and raised in Chennai, Selvakumar is married to Gajalakshmi. A former national-level athlete and international-level martial art (Silambam) player, she is now a homemaker, raising their two daughters, Hananya and Krushika. His hobbies include reading books, listening to music and exploring emerging technologies. He fondly recalls a Q&A session with Dr. A. P. J. Abdul Kalam at his campus as one of his life’s most memorable moments. “During this interaction, Dr. Kalam’s lasting wisdom inspired me to pursue a career in sustainable water projects,” he says with stars in his eyes.

With a hobby like running, Chandan Turala is well-endowed to keep up with the tough asking rate of executing large-scale projects. Presently, at the Amaala PPP project, as Project Controls Manager, he is bringing to play his rich 19 years of experience as Planning Head for several infrastructure projects to stay ahead of the curve. “Ours is a multi-disciplinary project and if we have been executing thus far with excellence and efficiency, it is thanks to the exceptional collaboration and dedication of Team Amaala,” he says, with total conviction.

A diversified and technically complex undertaking, the Amaala Project has placed some demanding targets before the team who are mandated to construct substations, PV plants, overhead electrical lines, Seawater reverse osmosis (SWRO) plants, conduct micro tunnelling operations, lay pipeline works and build sewage treatment plants (STPs). “With intense client coordination, this initiative requires precision, agility, and relentless teamwork and that’s where we are scoring,” remarks Chandan, with a punched fist.

Initially, coordinating with the client posed significant challenges for Chandan. “However, through clear and consistent communication, I was able to fully understand their requirements and successfully bridge the gaps,” he says with an assertive nod. “I am regularly apprised of the challenges faced by the team, and we organize proper brainstorming sessions with the requisite stakeholders to address them. My wise seniors are also supportive, helping me along with proper guidance.”

A great ally for Chandan and his team has been technology, and he mentions the implementation of BIM enabling the execution team to perform clash analyses and strategize the sequence of works. “The Schedule has been developed in P6 with resource and weightage loaded for better monitoring and better control over the timeline,” he adds. Thinking ahead, Chandan says that it would be great to have an integrated AI-driven decision support platform tailored specifically for large scale construction projects. “It should be a system that brings together data from scheduling tools, supply chain networks, and site execution activities on to creative dashboards,” he says smilingly.

Apart from running, this native of Visakhapatnam, Andhra Pradesh, loves to spend quality time with his wife, Chandraja, homemaker and son, Charan Kamesh, especially during the monsoon, filling the rainy days with fun & laughter.

Undoubtedly proud of his association with L&T, Chandan says, “It’s empowering to be part of a culture that thrives on innovation, prioritizes employee well-being, and treats every obstacle as an opportunity to grow stronger together.”

Fourteen years ago, N R Vijay joined L&T’s KSA operations, where he was involved in several substation and OHTL projects; after a couple of domestic stints, he is back in the Kingdom as Project Manager (PV, SS, BESS, & ICE) at the AMAALA Project, located within the Prince Mohammed Bin Salman Royal Reserve, one of the most environmentally sensitive and strategically important geographical areas. “Our proactive steps like controlled equipment movement, waste management systems, and regular environmental monitoring have ensured that the project progresses smoothly,” he mentions.

Drilling through hard rock formations for the PV tracker posts was one of the team’s major challenges. “We addressed the shortage of good conditioned down-the-hole (DTH) drilling machines by mobilizing additional ones from other sources, which increased our drilling capacity and helped us stay on track with our targets,” he shares.

BIM has empowered Vijay and his team to identify project interfaces across all disciplines, detecting bottlenecks & issues in real time. “We are enjoying the benefits of immediate resolution and more effective decision-making, as BIM enhances clarity and understanding among all stakeholders, ensuring alignment with scope and overall project coordination, thus enabling smooth and efficient progress, ” Vijay notes with a satisfied smile.

Constant monitoring through daily KPIs and on-site presence keeps the team aligned & accountable, with a shared sense of ownership. “It is key to adapt quickly, resolve issues early, and align each team member with project goals, which creates a high-performance environment,” he adds.

Thinking ahead, Vijay is eager to have an integrated real-time progress monitoring system with on-site issue reporting and resolution capabilities. “This system would combine digital tools like mobile apps and IoT sensors to track construction progress accurately and instantly flag any delays or problems as they arise, Project managers would get immediate alerts to assign resources or take corrective actions without waiting for manual updates.”

A native of Tiruchirappalli in Tamil Nadu, Vijay is married to Rathi, a homemaker. Their most cherished moments are the birth of their two daughters, Yazhini and Kavithayini. Although his work keeps him busy, Vijay tries to unwind by listening to music when he can.

What motivates Vijay every day is the pride of working for a Company that supports learning and empowers people to tackle challenges head-on. “I would like to especially thank Mr. Sasikumar Raghava Nair, Mr. Sekar Balasubramaniyan, Mr. Rajesh Kumar, and my current Project Director, Mr. Swapan Deb, for guiding me, giving me opportunities to develop my abilities, and helping shape my career path,” he grins, signing off.

Proudly, Karthick Swaminathan shares the Certificate of Appreciation he has received from the CEO of ASCE (the customer) for his efficient and timely completion of the Staff village STP civil works at the Amaala Utilities PPP Project. Equally thrilled to be a part of L&T, he says with gusto, “I enjoy the culture of making employees feel like they are part of something significant, offering opportunities for skill upgrades and career advancement and executing near-impossible projects and making them a reality within very stringent time frames.”

No stranger to delivering large-scale projects having previously executed EPC projects like micro lift irrigation projects, 2X660 MW supercritical thermal power plants and 2.0 million tons per annum cement plants, Karthick’s present assignment is testing him to the fullest.

Digitalization has been effectively implemented in this project by preparing BIM models for all the structures, he mentions, helping the team to identify conflicts or interferences between different building systems (structural, architectural, MEP etc.) within a 3D model. “Detecting these clashes early in the design and pre-construction phases has helped us prevent costly errors, delays, and rework during the actual construction process,” he observes.

Another capital move by the team has been to precast the water structures and replacing the conventional cast-in-situ roof slabs for the water storage tanks with precast hollow core slabs to save construction time and cost. “By using precast for the irrigation and potable water tanks too, we successfully completed construction within the available short period of time,” he says, smiling broadly.

However, completing the 5 ML & 10 ML RCC storage tanks within a stringent timeline of 6 months as stipulated by the client was no laughing matter for Karthick and team. “After discussing the matter with our Project Director and adopting hollow core slabs, we identified a manufacturer from the nearest project site in Saudi Arabia and then convinced the client to accept this proposal, which was later applauded by them upon successful completion,” he explains their MO. “To expedite civil work, we executed the 7 m high concrete wall in a single lift with self-compacting concrete, and thus successfully completed the SV Irrigation Tank 1 and Pumphouse for the early water package in time.”

To achieve speed & scale, Karthick recommends regular reviews & feedback sessions to identify and address issues & potential risks in real time through open communication.

A native of Kumbakonam, Tamil Nadu, Karthick’s better half is Dhivya Mayan, a homemaker, and they are blessed with two children, daughter, Yaadhavi K and son, Mithran K. He unwinds by playing chess & carrom, especially on weekly holidays.

His 16-year association began with L&T E&GP OC in the Kolkata Region as ISD Supervisor. In 2022, he moved to HQ to oversee and support EIP requirements across all PT&D projects and presently at the AMAALA PPP Project as IT & Digital Officer, Supriyo is helping create business value through data and advanced technologies such as the cloud, Al, IOT, automation, and more.

Supriyo is excited about the use of VR technology, which has already significantly enhanced project visualization and collaboration at the AMAALA site. “Stakeholders are experiencing immersive 3D walkthroughs of designs, enabling early detection of design issues, ” he notes with satisfaction. “It also offers an interactive learning experience in EHS by simulating real-life scenarios in a controlled environment.”

“With the In-Vehicle Monitoring System (IVMS), we have enhanced operational efficiency, improved safety standards, and supported compliance with site regulations,” he explains. This telematics solution collects real-time data from vehicles and machinery, monitors driver behaviour, vehicle performance, location, and safety compliance, The Rocket M5 and PowerBeam devices for CCTV and site office connectivity have eliminated the need for costly network video recorders (NVRs) and external internet connections for sub-satellite offices, he informs.

“Despite significant advancements in digital infrastructure, remote locations still struggle for connectivity — particularly in rapidly expanding areas where stable, high-speed internet access remains limited or inconsistent,” Supriyo rues. “After thorough assessments to identify coverage gaps at our site, we have collaborated with local service providers to enhance network infrastructure, implementing alternative connectivity solutions such as mobile hotspots and satellite communication where necessary.” Additionally, Supriyo has prioritized the use of offline-capable digital tools to proactively monitor and maintain operational continuity in remote or low-coverage areas.

“My seniors and team members have been instrumental in my growth as a Champion of Speed & Scale,” he says with gratitude. “Their support not only empowers me to take on complex challenges with confidence but also helps foster a high-performance, future-ready digital environment.” The most crucial aspect of delivering large-scale projects with speed, according to Supriyo, is effective collaboration combined with agile project management. “One key lesson I have learned is the critical importance of proactive planning and continuous stakeholder engagement,” he adds with a sharp glint in his eye. “As Digital Officer, I have realized that anticipating potential risks early, maintaining transparent communication, and fostering collaboration across teams help ensure timely delivery. Agility and adaptability while staying aligned to project objectives is essential to meet deadlines without compromising on quality.”

Hailing from Kolkata, Supriyo is married to Soma, a homemaker with a master’s in hospital administration; they are blessed with a Son, Agasthya. “I enjoy reading books on new developments in technology,” Supriyo notes, unsurprisingly!

“The entire team had one goal: commissioning the first transformer as per the target date,” declares Anantharama Shetty with steely determination. “And we successfully commissioned it in a record time of just 8 months from the groundbreaking date!” His eyes light up as he recalls the intense daily reviews by senior management and the unrelenting pace the team maintained. “This achievement was particularly significant, given the tight deadlines and complex scope. It clearly demonstrated our team’s discipline, commitment, and ability to execute under pressure.” Spoken like the seasoned leader that he is!

Currently spearheading the DEWA VI Project his first with L&T — Anantharama is leading the construction of two 132/33 kV Pooling Substations (PSS), applying his 24 years of rich experience in executing power and infrastructure projects across India and the Middle East.

Considering the stringent timeline, the team constantly innovated to optimize construction sequencing — for example, by progressing MEP and civil works in parallel, they gained early access to equipment rooms. “Installing the fire pump before the precast slabs enabled multiple work fronts to be opened simultaneously,” he adds. “Swapping cast-in-situ panels for precast ones and starting excavation across the entire substation plot early on further helped compress the schedule.” The team opted for the skidding method to install PSS‑2 transformers, avoiding the risks and inefficiencies associated with traditional lifting techniques.

Located 100 km from Dubai, the site posed additional logistical challenges, especially in managing civil subcontractors. To overcome this, the team supplemented subcontractors with manpower from labour companies, ensuring civil works stayed on track. “Selection of qualified subcontractors and structured monitoring are crucial for executing large-scale projects efficiently,” Anantharama emphasizes.

Always mindful of worker well-being, Anantharama and his team schedule night shifts to combat extreme heat, ensuring adequate rest and better working conditions for site teams.

Hailing from the scenic Udupi district in Karnataka, Anantharama is a proud family man. He is married to Praveena and blessed with two sons: Sudhamshu, currently in the 10th grade, and Sooryamshu, in the 6th grade. Morning walks and listening to podcasts are his favourite pastimes, Anantharama admits with a smile; “I don’t get much time for other hobbies; my daily site commute alone takes over three hours!”

“What makes me truly proud to be an L&T‑ite is the commitment to pushing boundaries in engineering & technology and delivering high-quality projects that positively impact communities and industries,” Ravikumar Veluchamy declares grandly. “Being part of such a forward-thinking and responsible company inspires me every day to give my best!”

Having been involved in project management and handling multiple projects simultaneously, including 132 kV cable laying projects within the DEWA network and 11 kV projects in the AI Ain network, Ravi is currently Project Manager — Electrical at the 1.8 GW DEWA VI Project. “I strongly believe in feeling the pulse of the ground-level staff,” he shares, “so we introduced daily brief but focused meetings with site teams for real-time progress tracking and seamless communication.”

With instant updates from the ground, Ravi & team can proactively resolve issues before they escalate. “There is a notable improvement in site productivity and a significant acceleration of project timelines, all achieved without compromising on safety or quality standards. In addition, we integrated regular brainstorming sessions before key decision-making moments, which has fostered team collaboration, encouraged diverse perspectives, and led to more effective, well-informed solutions.”

One of Ravi’s main challenges was completing all five circuits within the stipulated timeline. “I coordinated tasks with multiple teams simultaneously to ensure that the project stayed on track, and with our enhanced communication channels we can identify bottlenecks early.”

“Importantly, I’ve learned the value of timely decision-making when faced with unexpected challenges to execute projects on time,” Ravi states earnestly. “To stay prepared, I developed contingency plans and closely coordinated with suppliers and subcontractors to ensure timely adjustments and resource availability.” Effective communication and proactive coordination among all internal and external stakeholders are other crucial factors, he adds. “Ensuring that everyone from the project team to subcontractors & suppliers are aligned towards delivery helps identify potential issues early and enables quick decisions to keep the project on track.”

Ravi is excited to see what the future holds in the form of AI-powered project management and design tools and would love to use drone cameras with microphones for monitoring a mass construction workforce.

Hailing from Pudukkottai, Tamil Nadu, Ravi is married to Uma, who is a bank employee; they are blessed with two children, Jasmita and Sabareesh. “The days they were born remain the most memorable and cherished moments of my life,” he shares with glistening eyes. Ravi enjoys watching movies. “I try to make space for it regularly on the weekends because it helps me relax,” he says, signing off with a peaceful look.

Kalyani Gutta joined L&T in 2008, working as a Planning Engineer in APDRP projects of 33/11 kV substations in Warangal, Karimnagar, and Nizamabad. “From 2013 to 2020, I was at the Hyderabad Metro Rail Project’s PSS scope in Planning & Contract Management. My current work in the Renewables sector is very special,” she adds. “It feels good to play a part in helping the environment and working towards a sustainable future. Knowing that our projects support clean energy makes me proud to be a part of the team at the 1,800 MW DEWA Phase VI Solar Power Project in Dubai, as Project Control — Cost Management & Digital Officer.”

One of the challenges that Kalyani faced at the project was resistance to new digital tools and technologies at the site level. “Through training sessions, we demonstrated the benefits of tools like drone Surveys & IoT-based monitoring and ensured gradual implementation with hands-on support to build confidence, ” she says.

At the site, Kalyani & team have implemented a speed control and vehicle monitoring system via LPR camera & radar. “Tracking speed violations and vehicle movements enhances Safety, accountability, and operational efficiency,” she elaborates. “Violation notices hold the contractors accountable, influencing performance reviews and contractor selection. Our real-time notifications ensure prompt action on safety concerns.” These accurate records aid in compliance reporting and audits, demonstrating proactive safety management.

“Of course, we had some resistance from subcontractors & drivers to the speed violation notices and fines,” Kalyani adds, nodding. “But we enforced compliance through contract clauses, used the speed camera data transparently, conducted awareness sessions on safety benefits, and maintained strict and consistent follow-up.” Additionally, tracking vehicle entry & exit has optimized logistics, improved traffic flow, and reduced delays in operations.

“In my experience, I’ve learned that aligning all stakeholders early, with clear roles, timelines, and priorities, significantly reduces delays,” Kalyani observes wisely. “Identifying the bottlenecks and taking quick actions to clearing them will drive the project towards completion as per the planned schedule.”

A native of Vijayawada, Andhra Pradesh, Kalyani is married to Seshu Babu Garimella, who is Manager — Accounts at Veritis Group. She enjoys watching movies and her morning walks. “There are many moments to cherish, but watching our kids, Ganadeep and Geetanshi, grow and supporting their journey is deeply fulfilling,” Kalyani signs off, finding meaning in her role as mother.

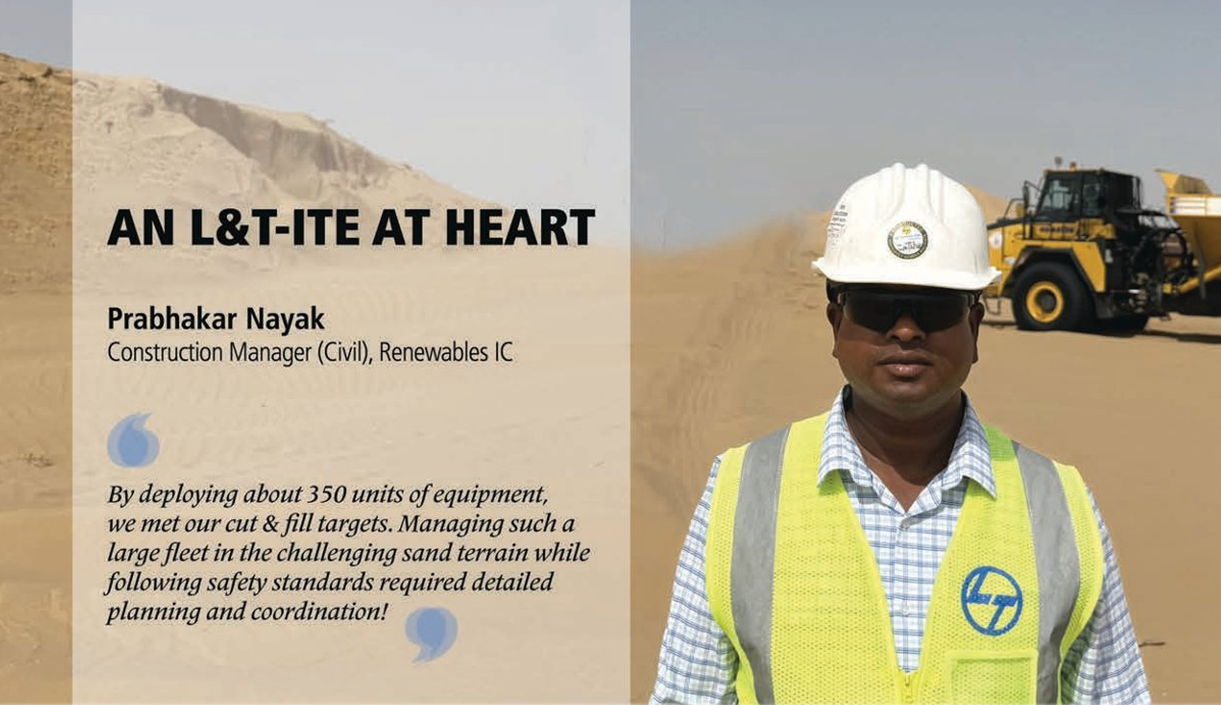

Joining L&T in 2008, Prabhakar Nayak has been on a road of steady growth, having served in several road projects in TI IC. After 10+ years in the UAE, he was transferred to Renewables IC in 2023, to manage the earth works at the DEWA VI Project. “We implemented GPS technology on our dozers and graders to enhance top layer preparation, resulting in significant time and cost savings,” he remarks enthusiastically. “Productivity doubled; dozer output increased from 1,000 to 2,000 cum., and grader coverage rose from 4,000–5,000 sqm to 11,000 sqm within tolerance per 10 working hours.”

At the DEWA VI site, the shortage of gatch, a stabilization layer for the-entire plot area of 21 sq. km, was initially a concern. “Since our plan to procure it from external sources proved to be too expensive, we explored alternatives by conducting additional trial pits within the project limits and discovered that suitable gatch material was actually available on-site,” he grins. “It avoided external procurement and saved us the additional cost burden.”

Prabhakar and team established a dedicated internal crew for cut & fill operations that involved managing large-scale earthworks, posing logistical difficulties. “By deploying about 350 units of equipment, we met our cut & fill targets. Managing such a large fleet in the challenging sand terrain while following safety Standards required detailed planning and coordination!” he says, wiping sweat off his brow. “Further, GPS-enabled dozers and graders enhanced productivity, effectively doubling output and ensuring that project timelines were met.”

Thorough planning and precise design development from the outset are essential for on-time project delivery, he opines, expressing his gratitude to the highly supportive senior management. “We just have to present our requirements, and equipment & manpower are allocated promptly, ensuring smooth project execution.”

Hailing from Odisha, Prabhakar is married to Anuradha Sahu, a homemaker who dabbles in stock trading; they are blessed with a son, Priyan Pulkit. He enjoys reading books, a hobby for which he allocates dedicated time. “The year 2020 is special for me, both personally and professionally,” he says earnestly. “In the midst of Covid, my son was born and our team handed over the Expo 2020 Road Project.”

Prabhakar has a strong sense of belonging to L&T. “The culture across all levels of the organization — from site teams to senior management — is supportive and inclusive. Over the course of my 15-plus-year tenure, each project has presented unique challenges and learning opportunities, and this continuous exposure has significantly contributed to my professional development and career growth.”

“I truly enjoy working in the solar industry and believe that when someone works in a field they are passionate about, they can contribute much more to the Company’s success, ” says Akhil T R, who has already worked on nearly 2 GW of solar projects. Though the DEWA VI Project is his first in L&T’s rolls, the company is not new to him, having been earlier involved with on solar projects with L&T in KSA.

At DEWA VI, Akhil is a lead for the Automatic Robot Cleaning System (ARCS). “With limited time available, we had to think quickly,” he says with vigour. “With a detailed execution plan, we ensured efficient manpower utilization and coordinated closely with stakeholders,” he shares. “I motivated the team, kept a friendly approach with in-house teams, and dealt firmly with stakeholders when needed, which helped us complete the installation on schedule.”

Another challenge the team encountered during tracker installation was when elevation differences exceeded the robotic OEM’s tolerance limits. He instantly flagged it off with the OEM, who then analysed the data, conducted mock-up tests, and based on the results, revised the tolerance range.

Large projects succeed due to strong teamwork, clear communication, and proper planning. “When all departments coordinate well and understand their responsibilities, even complex tasks can be completed efficiently without compromising safety.” Team motivation is equally important for Akhil. “Providing fair overtime, small rewards, and recognizing efforts are extremely morale-boosting, and when workers feel respected and valued, they stay committed and perform better.”

Akhil thrives on the guidance and support he has always received from his seniors, including the project head, deputy project director, and managers. “Their advice helps me make quick decisions and stay focused under pressure,” Akhil notes. “In fact, during the crucial ARCS activity, their support was key to completing the task on time.”

He would love some AI-powered tools to improve his work by automating routine tasks and providing clear, accurate data. “These can save time, reduce confusion, and increase overall productivity, allowing me to focus more on site work and contribute more effectively to the project.”

A native of Thrissur, Kerala, and still single, Akhil enjoys watching movies, listening to music, and playing cricket. “One of my life’s most cherished moments is being selected by L&T,” he says, smiling broadly. “Being a part of a team that’s transforming the region toward greener energy solutions makes me feel like I’m not just building infrastructure, I’m helping build a better tomorrow.”

EMPOWERMENT IS KEY

S Kathiresan

Senior Manager (T&C), Renewables IC

“The sense of empowerment I enjoy at L&T is what inspires me,” says S Kathiresan, “and the structured delegation of power that allows us to make immediate decisions.” At the tough Ar Rass Project, he is at his first in the Kingdom of Saudi Arabia, but Kathiresan carries with him the rich experience of having executed more than 4 GW renewable projects connected with STUs and CTUs in various States.

His area of focus at the 2 GWAr Rass 2 Project is the energization of ESF/PSS and all PV string and the combiner box feeding to IBR, prior to back charging from the grid, reducing the hot commissioning duration, avoiding the SMB and module failure due to polarity reverse.

Execution has been tough for Kathiresan and the project team, firstly because of the sheer expanse of the plant spread over 8,000 acres, a 37-Km-long boundary, with three plots and three pooling stations. “Our major challenge was to make the entire skilled workforce available upfront,” he says with a shake of his head. Other challenges included providing and receiving timely stage wise clearances from various stakeholders starting from engineering, SCM, construction, quality and commissioning. “A delay in one area could affect the area schedule leading to cumulative delays,” he remarks. “Therefore, the important lesson I learnt was to do things right the first time,” he says with a thumbs up.

“Hiring resources to complete the testing and commissioning is always a challenge, so I proactively developed an outsourced T&C agency and mobilized multiple other agencies to complete the cold commissioning on the agreed timeline,” he says, with an air of achievement. “It has gone a long way to help us meet our project target because once the grid received power, we energized the entire MVPS/PV area and the IBR in just 5 days, thereby reducing the time for hot commissioning.” In addition, the team carried out pre-checks, communication checks, tracker auto rotation, and Robet operations.

With the plant energized, Kathiresan can heave a huge sigh of relief, having delivered a huge project as per schedule and think about his family that comprise his wife, M Chitra, a professional in the software industry and his two children, K Tikshitha and K Kasini, whose birth are his life’s most precious moments. When away from work, he relaxes by reading.

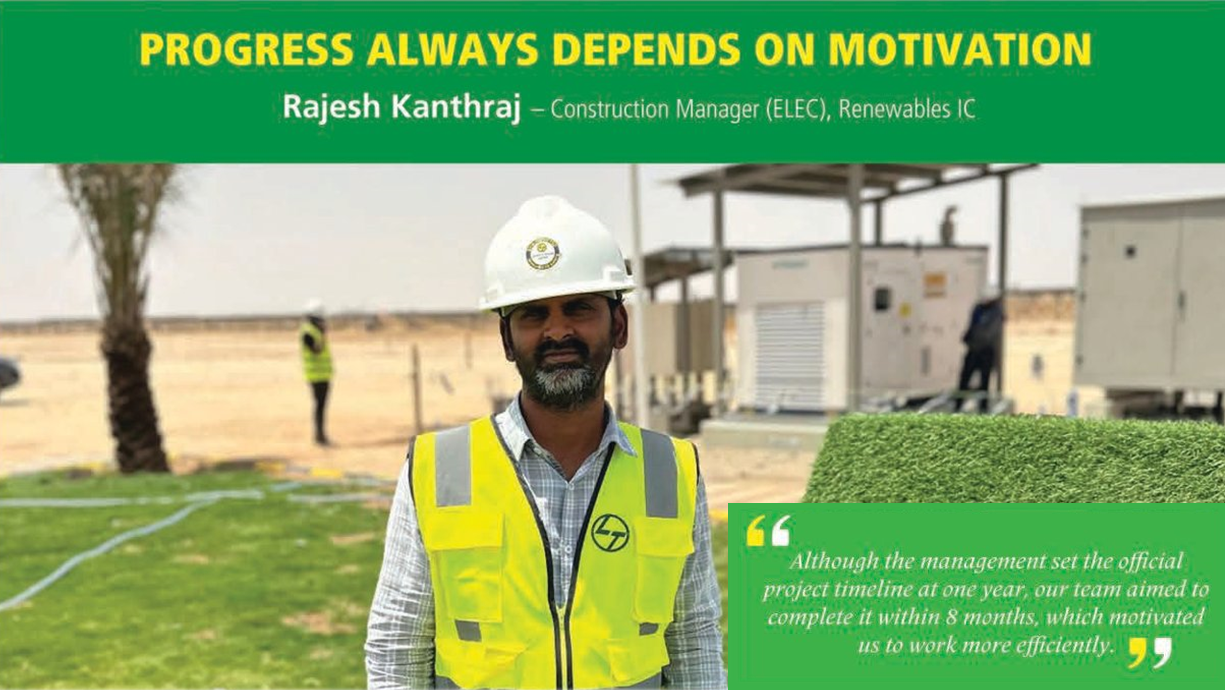

With a fair share of experience under his belt, Rajesh Kanthraj has worked at the Raigarh Thermal Power Plant, Tata Steel Plant KPО, DMRC Underground Metro, Saubhagya Cluster‑1 Project, and the NTPC Ettaiyapuram Solar Project. At the Ar Rass 2 Solar Project, his sixth in L&T, Rajesh is Construction Manager — PV, where he has utilized mobile-compatible platforms to track and update project progress, enabling real-time access and reporting from the field or remote locations.

Faced with tight timelines and limited availability of team members or tools, the project team was initially struggling to meet their project milestones, which threatened to hinder progress. However, with grit and determination, Rajesh & team prioritized tasks and created clear schedules to ensure that all all deadlines deadline were met. “I coordinated with my team members to allocate resources efficiently and leveraged available tools to maximize productivity,” he notes. “To ensure all stakeholders are aligned and to avoid potential misunderstandings, I organized regular meetings and used collaboration platforms to keep everyone on the same page.”

Rajesh is all for technology that accelerates progress. “Tools that reduce manual data entry, minimize errors, and provide instant, real-time updates directly from the site make our work so much simpler,” he states ardently. “Features like predictive analytics to anticipate delays or resource shortages will be invaluable, as will tools to enhance communication and coordination between field teams and the top management.”

Timely project delivery is, according to him, critical for project success, and when every team member takes responsibility and ownership, risks of delays are significantly reduced. At Ar Rass 2, Rajesh has learnt the value of setting ambitious internal goals. “Although the management set the official project timeline at one year, our team aimed to complete it within 8 months, which motivated us to work more efficiently and ensure that the project milestones were consistently met ahead of schedule,” he adds with a proud thumbs-up.

A Chennaiite, Rajesh is married to Amutha, a schoolteacher, and they are blessed with a son, Sushanth. His most memorable moments are those he spends with his close family and friends. “I enjoy listening to music,” he smiles, “and try to make time for it whenever possible because it helps me relax and stay motivated.”

L&T’s strong commitment to quality and innovation fills him with pride. “We consistently deliver high-standard projects while embracing new technologies, which inspires me to grow and contribute my best every day,” he says, signing off with a look of commitment.

Having worked on oil & gas and steel plant projects in India, UAE, and KSA, Aathikesavan Thangavelu was first stationed at the 300 MW Jeddah Solar Project and then the Ar Rass 1 Project. “The Ar Rass 2 Project is my third at L&T,” informs Aathi, “where I have grown from a construction manager to a project manager, all thanks to frequent training and opportunities provided to me by the Company,” he adds with a smile.

As a Project Manager at the 2,000 MW Ar Rass 2 Project, Aathi has completed off-grid commissioning up to the inverter prior to receiving grid power, while reducing the hot commissioning period. Thanking the senior management and his team for their cooperation and support, he adds, “My Project Director and BU Head always encourage us to adopt new technologies, giving our team more room to learn and grow.”

“To execute any large project smoothly, it is imperative that all major equipment and material like transformers, MV skids, PV modules, ramming posts, and torque tubes be delivered on time,” Aathi observes sharply. Due to political instability in the region, the Ar Rass 2 team faced issues with logistics, for the materials had to come from outside Saudi Arabia. “However, our team was always on top of things, closely following up with several logistics partners to make it happen!” Aathi acknowledges with a thumbs-up.

The challenges at site did not stop there, with frequent climate changes, sandstorms, extreme hot weather, and sudden heavy rainfall. “We had to think on our feet,” recalls Aathi, “and came up with alternate solutions like dyke wall and wadi (canal) construction to control & divert rainwater. We closely monitored weather forecasts and introduced midday breaks during the summer season to keep our workers well rested.”

“Every stakeholder involved in the project is provided with an RFID card and biometric entry,” Aathi reels off the digital initiatives at the Ar Rass 2 site. “In addition, all Material Received Reports (MRRs) have been digitalized, and calibration of equipment is monitored through an online platform.” He also mentions the SHEILD app for safety and QIR for quality, which have proven hugely useful for the team. Looking ahead, Aathi would love to see robots performing the installation of PV modules and torque tubes.

Hailing from Vaiayarendhal in Tamil Nadu, Aathi’s better half is Gomathi, a homemaker; they are blessed with two daughters, Mahima and Bharathi Kaviyarasi. The day Aathi became a father is his most memorable moment to date. “I try to make time for some music and books amid my busy schedule,” he says, signing off.

Abdel Raheem Abu Farhah, a Jordanian by birth, brings an international flavour to the 2,000 MWac Ar Rass 2 Solar PV Plant that he is executing along with the Renewables IC team in the Kingdom of Saudi Arabia. He is truly an international citizen, having executed several infrastructure projects in Qatar, Sudan, Morocco, and Egypt, apart from a slew of them in his native country of Jordan. His present assignment is a source of pride for Abdel Raheem on two counts: (1) He is part of a project that is a benchmark for the Renewables IC, exemplifying speed, scale, and technological innovation. (2) He is part of a company that, according to him, “stands as one family with a strong reputation in the market, bringing pride and honour when representing your workplace anywhere.”

On the tech front, Abdel Raheem is thrilled to be engaged in a project that is deploying several tech solutions to improve efficiencies including AI-based drones to monitor daily progress, timelapse cameras to document construction milestones and 15,000+ activities being monitored through dynamic bottleneck identification in Oracle P6 with Predictive Scheduling. Primavera presents the project team with weekly & monthly progress reports, look ahead plans, monitoring planned vs actual schedules, asking rates for productivity, client reporting, and much more. “It is my responsibility to follow up and update progress reporting by sheets which you can access from your mobile any time,” he highlights.

A veteran, Abdel Raheem certainly knows a thing or two about successfully delivering projects at speed and scale. “Executing large-scale projects essentially requires a strong sense of motivation and commitment to deliver project on time, and when every employee embraces his or her responsibility, project delays can be effectively eliminated,” he observes wisely. He is happy that he sees a lot of that happening at his site. “I engage effectively with the new team and have taken some key steps to solve my issues, like building teamwork with my team and working as one family to achieve project goals,” he says with a smile and a thumbs up.

A master of his own destiny, Abdel Raheem is single and treasures most the wonderful moments he gets to spend with his family and loved ones, and of course, “when playing cards,” he laughs.

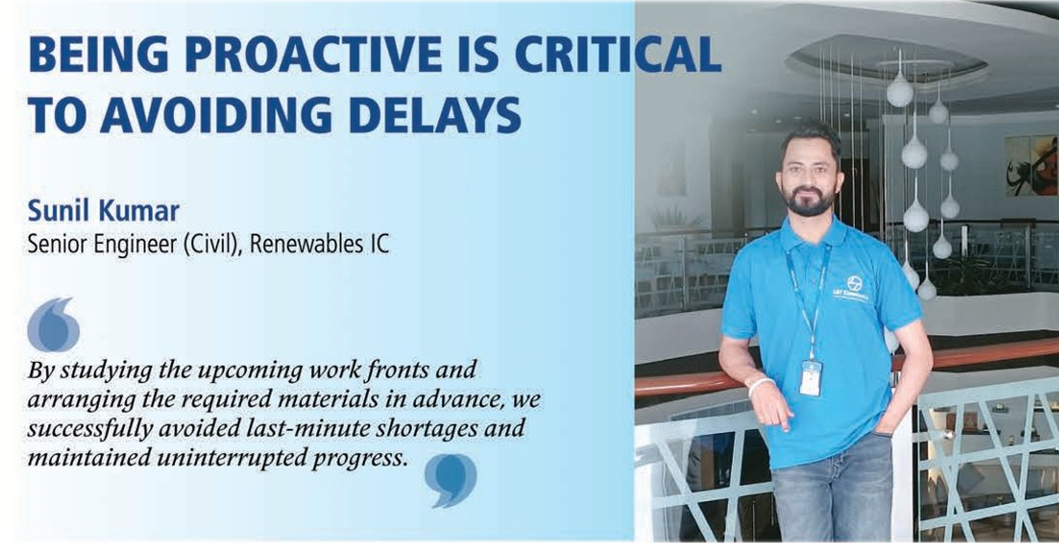

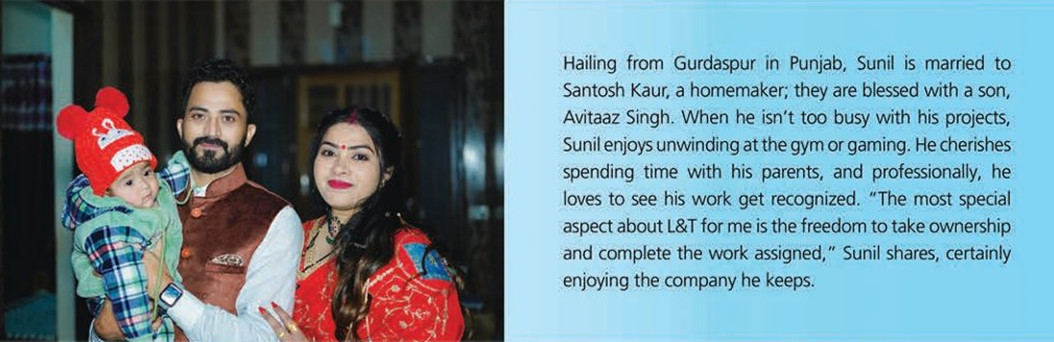

An important learning for Sunil Kumar is that proactive work is the most crucial aspect of executing large projects to avoid delays, a learning that he is religiously following at the Ar Rass 2 project, his first with L&T. “Along with proactiveness is proper planning,” he says firmly. “By studying the upcoming work fronts and arranging the required materials in advance, we successfully avoided last minute shortages and maintained uninterrupted progress.” At site, he was responsible for all civil works of the Pooling Substation PSS-03 as a part of the management team.

Another feature of his work is the timely communication he has with seniors, team members, and subcontractors to ensure alignment of all towards the same goal. “I find that it helps in quickly resolving issues and achieving better coordination at the site,” he says, adding that proper utilization of equipment and releasing subcontractor bills on time are critical to maintain steady cash flow and keeping subcontractors motivated to deliver faster.

“I truly value the guidance from my seniors, collaboration with my team members, encouragement & trust, and solving problems together,” Sunil shares earnestly. “With our experienced management, we had clear instructions and well-formed plans for how the work should be executed.” Thanks to their preparedness, Sunil & the project team overcame the recurring challenge of delays in material delivery by arranging all required material in advance for the PSS.

“In the civil field, almost 95% of structures up to the ground level are precast, which significantly reduces the overall construction time,” Sunil informs. “One improvement I would suggest is to extend the use of precast technology below ground level as well — for example, for pulpits, cable trenches, and light pole foundations. These activities, though small in nature, consume substantial time at site.”

As Project Manager, Amit Sundriyal found his 1.58 GWp ACWA Power Al Kahafah Solar PV Project in KSA an extremely challenging solar PV project, characterized by a highly undulated rocky terrain that required 100% grading. “The grading was a massive task, and critical to complete on schedule to avoid cascading project delays and ensure the timely and periodic release of work fronts for all subsequent activities,” he shares. “To address it, we mobilized a large fleet of P&M, which brought additional challenges in terms of HSE compliance and monitoring that were effectively mitigated by implementing strict HSE norms and rigorous monitoring.”

After an initial stint at the 1.8 GWp ACWA Power Sudair Solar PV Project also in KSA where he was Construction Manager — Electrical, Amit is at his second project with L&T, bringing with him rich experience, having played various roles, from Senior Engineer to Senior Construction Manager. Another challenge for Amit and team at site was to manage the disposal of the large quantity of debris generated from grading and trenching works, as well as sourcing soft soil for sand bedding and trench backfilling for which they deployed five crushers at the site to effectively manage the debris and convert the waste material into usable sand bedding and backfilling material, providing a sustainable and cost-effective solution too.

On the tech adoption front, Amit mentions the implementation of a smartwatch-based productivity monitoring system to track the daily performance of workers on key project activities. “The system monitors their location, work hours, idle time, and even health parameters that has enhanced productivity by minimizing idle time and significantly accelerated site progress,” he points out.

Amit attributes his success to the support from his seniors and team. “My seniors have guided me at every step, empowered me to take decisions, and trusted me with responsibilities, which has motivated me to deliver at speed and scale,” he says gratefully. “My team fully supports my decisions, proactively executes their tasks on time, and collaborates and ensures smooth project progress.”

Proper planning, proactively identifying, communicating, and resolving issues, quick decision-making, and aligning the team to a common project goal are according to Amit critical to execute large-scale projects. “Identifying and communicating project risks early with all stakeholders, preparing a clear mitigation plan, and ensuring continuous monitoring through regular reviews is the secret of success,” he emphasizes.

On his personal front, Amit’s life partner, Sonia, is a University professor and they are blessed with a son, Rudra. “Whenever I get time, I love to capture landscapes and unique moments,” he smiles, “and every time I am with my family and see their smiling faces, it creates new memorable moments for me.”

“By combining digital tools and people-centric coordination, we have created a project culture focused on agility and accountability,” says Murali P, referring to the culture at his 1.425 GW Al Kahafah Solar PV IPP Project in Saudi Arabia, where his is primarily involved in civil works for the Pooling Substation (PSS) and Temporary Site Facilities. He brings with him the experience of having been part of multiple large-scale infrastructure and renewable projects, including substation works and transmission line projects both in India and Africa. “My roles have spanned managing site execution, coordinating with multiple stakeholders, and ensuring timely delivery with quality and safety,” he apprises.

Several challenges arise in PSS construction due to tight timelines, multidisciplinary coordination, and remote site logistics. “We need to coordinating between multiple disciplines with civil, electrical, and mechanical works happening simultaneously within tight spaces,” Murali shares, “to manage which I introduced daily coordination meetings and a shared progress dashboard to ensure smooth communication and avoid clashes.”

Technology has been playing a key role in driving efficiencies. Murali mentions digitized concrete pour logs to maintain traceability, avoid overlaps, and optimize pour cycles for speed and quality, the involvement of all stakeholders — client, consultants, and internal departments — in weekly joint reviews for better alignment & faster approvals and WhatsApp groups & mobile-based photo tracking for daily progress reporting. “All these have helped us to micro-monitor our targets, speed up issue resolution, and drastically reduce delays in decision-making,” he notes. “We ensure the right technical and logistic support to subcontractors and simplify work fronts for uninterrupted progress, which has built mutual trust and motivated the teams to push for higher productivity.”

Murali points out that in projects of size & scale, micro-planning and front availability are key factors, and early coordination with inter-disciplinary teams (civil, mechanical, electrical) helps to avoid rework and achieve smooth workflow at site. He is glad that his project leadership has fostered a result-oriented culture, motivating the team to go beyond their comfort zones. “My seniors continuously guide me by setting clear priorities and empowering decision-making at the ground level while the proactiveness, coordination and ownership of the team smoothens and quickens execution,” he says encouragingly.

Hailing from Thottampatti, in Tamil Nadu’s Tuticorin district, Murali’s life partner is Brindha Devi M, a homemaker, and their family is complete with their two children, Dhruvan M and KaviSri M. Hе finds solace in Tamil music and long, solo walks. Some of his life’s precious moments include constructing a house for his parents, buying his own house and of course, the birth of his children.

POWERING PROGRESS ON DIGITAL WINGS

Saleh Salah Abu Najm

Senior Engineer (MECH), Renewables IC

Overseeing the drilling and casting of over 370,000 tracker posts in varying site conditions is no mean task, which is Saleh Salah Abu Najm’s responsibility at the Al Kahfah Solar Project. “I manage 79 drilling machines and 14 subcontractors, which has coordination and scheduling challenges,” he says, wiping sweat from his brow. “The differences in soil type, weather, and terrain between blocks results in inconsistent productivity, requiring frequent plan adjustments.”

But Saleh has managed it all with aplomb, thanks to his real-time digital productivity dashboard: “I initiated and managed a digital system for tracking daily productivity of drilling and casting operations, per contractor and per block, for early detection of delays and informed resource reallocation,” he notes proudly. In addition, Saleh & team have introduced GPS-based equipment, managed by 11 teams, to precisely define drilling points, ensuring accuracy in post alignment and significantly less rework.

The extent of Saleh’s digital interventions at the site doesn’t stop there; he led the development of digital measurement sheets based on actual quantities drilled and cast, to transparently track work progress and enable faster subcontractor invoice processing & reconciliation. “All installation manuals and drawings were validated digitally in coordination with the OEM and submitted as as-built packages, which streamlined material approvals and standardized installation across teams,” he adds.

“Daily front planning is everything,” he comments seriously. “Ensuring that the front work (survey data, material availability, area readiness) is always ahead of installation or execution teams has been the biggest driver of speed in our projects. It avoids idle time, reduces rework, and keeps subcontractors and manpower continuously engaged.”

Saleh’s technology wish list includes a fully integrated AI-based site coordination and productivity platform. “Using real-time data from all machines (like drilling rigs), GPS survey teams, material deliveries, and manpower deployment, it should automatically plan daily activities, redact potential delays, optimize resource allocation across zones, and generate instant reports for management and clients.”

A proud L&T‑ite, he is impressed by the company’s strong commitment to quality and innovation. “L&T consistently upholds high standards in project execution while embracing cutting-edge technologies, which not only drives industry leadership but also fosters a culture of continuous improvement and excellence.”

Hailing from Jordan, Saleh’s hobbies are swimming, football, and running. “I make sure to dedicate regular time for them to stay physically active and boost my mental and physical well-being,“he laughs, recalling a family reunion as a most unforgettable moment.

A Jordanian who is 2 years old in L&T, AbdAlrahman Ahmad Tahat believes that having a job isn’t just about saving money or building a career; it’s about creating a better future for others, making their lives easier, and helping develop societies. “Being a part of L&T helps me fulfil that purpose,” he begins with pride. “Contributing to meaningful large-scale projects that have a real impact on communities gives true value to my work.”

Currently at the Al Kahfah Solar Project, AbdAlrahman is responsible for implementing the Field Quality Assurance Plan (FQAP) and Project Quality Plan (PQP), conducting inspections and tests on civil works, and ensuring compliance with project specifications and international standards.

The most significant digital tool used in the project, according to AbdAlrahman, is the QIR app. “It efficiently records and tracks all quality observations and NCRS, ensuring they are properly addressed and closed timely. “He states, also mentioning the ‘Think Project’ tool, which manages and shares all project documents with the client for review and official approvals.

“At first, the idea of joining a new team and working with unfamiliar faces felt challenging,” AbdAlrahman recalls. However, he adds with a smile, “those feelings quickly disappeared after meeting my teammates. They welcomed me warmly and openly shared their knowledge and experience, treating me like a brother.”

One of AbdAlrahman’s main challenges was maintaining quality under tight schedules and high work volumes. “Aligning subcontractors of different ethnicities, backgrounds, and work cultures with our quality standards was another big task,” he remarks. “By staying organized, using the right tools, and fostering collaboration, I was able to overcome these while maintaining high quality standards.”

From a quality perspective, early and consistent engagement crucial for delivering large-scale projects with speed, AbdAlrahman reveals. “Aligning inspections & approvals with construction progress and following the ‘Do It Right the First Time’ approach prevents rework and ensures smoother, timely project delivery,” he says astutely.

In the future, AbdAlrahman would love to have an integrated digital platform that combines real-time material monitoring, quality management, and resource tracking into one system. “Specifically, for received materials, the system should highlight their current status & location of usage and include all relevant documentation such as manuals, FAT and SAT reports, material inspection requests, scheme drawings, and material test certificates.”

AbdAlrahman enjoys playing video games and watching anime & historical documentaries. “Despite a busy schedule, I always make time for these hobbies to relax and recharge,” he quips, adding that one of his most memorable moments was meeting his best friend after a long time. “We spent hours sharing stories, laughing, and creating new memories — it reminded me how valuable true friendship is.”