Devika Rajesh is in seventh heaven, having just tied the knot with Jayakrishnan, who works as a structural engineer. “I am a newly married bride,” she exclaims, all ready to start dancing to a new tune that married life will start playing for her, for which she is well equipped. “Dancing is my passion,” she beams. “Iam currently learning Kathak, which helps me manage stress and gives me a huge feeling of self-satisfaction of successfully balancing the work and passion of my choice.”

Starting at the Coke Oven Battery project, Kalinganagar, Devika was transferred 8 months later to her present assignment at AMNS’s Blast Furnace #2 project. Although site life has been challenging, she is holding her own thanks to the guidance and wonderful management of R. Suresh Kumar (VP & TFL — AMNS), Krishna Nirmalya Sen (Head — EHS, M&M IC), and A. Dhanasekar (Project Director, Blast Furnace Projects). “They have never doubted my capabilities to perform in an otherwise male-dominated field,” she says earnestly. “My journey from a PGET in 2022 to Assistant Manager now has been closely monitored and moulded by my EHS In-charge, Mr. Satish Chandra Yadav, who has stood beside me as a pillar of strength, radiating positivity whenever l have felt like giving up. It is his confidence that has boosted me to attain speed and scale up my career,” she says gratefully.

Despite this support, Devika has had her share of challenges at site, especially with workforce management due to language barriers and gender discrimination since the workers were at first unfamiliar with female presence at site. “With consistent interaction and constant assurance, I have more friends among the workforce who are more ready to help me than the staff themselves,” her broad smile says it all.

She flags off their VR training as immensely useful, giving the workforce a real-time experience of various sites activities along with the hazards and risks involved. “I have realized that good planning and strict compliance to the SOPs, along with close monitoring and timely review of each activity, are crucial to precisely complete projects speedily and safely,” she remarks. “Technology can certainly enhance good material management, especially for PPE supply and other safety items, which will dramatically improve the quality of work.”

A native of Kollam, Kerala, one of Devika’s most memorable moments at L&T was when she was called up on stage at a client business partners’ meet. “Being the only female in a big team, I was asked to share my experience of being a part of L&T’s safety department,” she shares proudly, secure in the knowledge that the Company gives equal opportunity for all and urges ladies to take up site jobs without a second thought.

A GET from the 2022 batch, Somireddy Dorababu is taking rapid strides in building his young career at his first project, the 4.5 MTPA Blast Furnace #2 at M&M IC’s AMNS project. “I have been learning many things and the constant support from my Project Director, A Dhanasekar, has brought me up from zero to hero,” he says with an immense sense of gratitude. “Additionally,all my seniors have been very supportive, helping me out whenever I’m stuck, teaching me how to control and manage manpower and resources to be a Champion.”

“One of my life’s most memorable moments was the completion of hot stove erection from start to end,” he shares proudly. “It was a moment of personal and professional achievement that has left a lasting impact on me shaping me to who I am today.” He is inspired by L&T’s culture of teamwork and integrity, and the environment where everyone feels valued and empowered to give their best.

The constant pressure to meet tight deadlines while maintaining high-quality standards has been his biggest challenge considering the resource constraints and unplanned disruptions. However, together with the project team, Dorababu has been planning & implementing adequate measures to overcome these difficulties.

Proactively identifying potential risks and putting in place mitigation strategies, has been one step, closely collaborating with procurement teams to effectively address supply chain risks. Another step has been to optimize manpower and machinery usage by closely monitoring daily progress. “By opening and maintaining a transparent communication channel with all stakeholders has helped to flag off potential delays early and regular meetings and updates with the team keep everyone on the same page,” he shares.

Planning and coordination are, according to Dorababu, key to successful project delivery. “A detailed and well-structured project schedule allows teams to identify critical milestones and adjust resources accordingly to avoid delays,” he stresses, “apart from an agile project management approach that has scope for adjustments.” Speed and quality depend on a strong, reliable and driven team. “If the team is motivated, experienced, and well-supported, it becomes easier to meet deadlines without compromising the quality of work,” he says, gesturing towards his own site as a case in point. He would love an Al-based predictive analytics tool for resource optimization to forecast delays, track resource utilization, and predict potential risks.

Hailing from Vishakapatnam, a place known for its rich culture and history, Dorababu’s family comprise his parents and younger sister. When free, he does all those things that help him unwind and recharge.

She is at her first assignment with L&T at the challenging AMNS project having joined as a GET but Erothu Mani Deekshitha’s most memorable moment was something that happened at her site. “It was the successful completion and commissioning of a critical structure that I had been closely involved with from the foundation stage,” she shares excitedly. “Just seeing the planning, teamwork, and effort come to life was both professionally rewarding and personally fulfilling.”

Though there is the excitement of working for such a large organization on such a prestigious project, Deekshitha is quick to agree that as a civil engineer there are several challenges she must face including working within tight schedules, coordinating with multiple disciplines, managing work in congested areas alongside ongoing activities, and handling last-minute design changes at site. As she has learnt her ropes, she has evolved her own methods to address these challenges. “I focus on meticulous planning, daily progress monitoring, and effective manpower deployment,” she says, ticking them off, “and use digital tools for real-time tracking, conduct regular coordination meetings with subcontractors, and ensure quick resolution of site issues through proactive communication. The result: we have successfully maintained both quality and timelines,“ ‘she smiles triumphantly.

About the tech tools deployed at their site, Deekshitha mentions the Shield App, CONQURE (for quality), Wrench (for drawings, document control, and progress monitoring), along with 3D modelling/BIM and digital dashboards for real-time tracking. “These tools have enhancedd coordination, reduced delays, and accelerated site progress,” she stresses. She hopes for an integrated Al-powered project management platform that can combine real-time site monitoring through drones, automatically track progress, provide predictive analytics for potential delays, and instant coordination.

“In my short career, I understand that planning and seamless coordination between all stakeholders is key when delivering large projects like this one,” says Deekshitha, nodding, “apart from proactive problem-solving, identifying and addressing issues at an early stage to prevent delays and ensuring that the project stays on track without compromising quality.”

A new kid on the block, she soaks in the guidance she receives from her seniors. “They empower me to take decisions with confidence by setting clear priorities, ensuring that I have the right resources to get the job done,” she mentions gratefully, adding that the support and shared commitment with her team members enable them to deliver.

On her personal front, Deekshitha, who hails from Samalkot, in Kakinada District of Andhra Pradesh, is still single. While her father is a businessman, her mother is a homemaker. “To stay refreshed I love to read books, explore places and sketch,” she smiles.

REVELLING IN RESPONSIBILITIES, GROWING WITH OPPORTUNITIES

At her first project, Aisha Hussain is a proud civil engineer working in Planning at the AMNS Hazira, BF 2&3 projects. “I am extremely proud of my contribution to the meticulous planning to execute the fastest single and continuous pouring in the history of the Indian metals industry, of 5,083 cum. in 24 hours, executed at par with international safety, quality and project management standards,” she highlights excitedly.

On a steep learning curve, she is extremely grateful for the constant guidance and support from her seniors and mentors, including the Project Director, Project Manager, Task Force Leader, and IC Head. “Their experience, timely advice, and encouragement are helping me learn quickly, take ownership, and contribute to both MIS and site coordination,” she says confidently. “In fact, what inspires me most is the way they create opportunities for young engineers like me, entrusting us with responsibilities, encouraging cross-functional learning, and giving the confidence to showcase our capabilities.” Giving a shoutout to her team members too, she praises them for their cooperation and collaborative spirit that have created an environment where challenges are addressed collectively.

Tech solutions have improved coordination, minimized delays resulting in better project efficiencies. Aisha mentions a systematic approach for structural material to meet the erection requirements and modularization of structural erection that have both increased their pace of erection as well as enhanced resource utilization. “Despite coming from a civil background, I actively prepared and managed detailed planning schedules for mechanical activities, ensuring that they are achieved,” she says brightly, adding that the team has strengthened their MIS system (JCRs, MPCS, FDS, and site progress) for real-time tracking, analysis, and timely decision making, improving visibility and accountability.

“As a woman in the engineering field, I have always believed that true talent is not just about skills, it’s about the attitude of the mind that nurtures and amplifies those skills,” shares Aisha, with a composed expression. “After passing out from college as the Best Outgoing Student, having led two organizations — NSS & MUN — I never expected similar opportunities in the workplace, but L&T is different where I am being honoured to compère many events keeping the spirit of engagement and camaraderie alive.”

She is thankful to M&M IC for the wonderful opportunity to grow through the Executive MBA programme in ICM from NICMAR, Pune, in collaboration with L&T IPM. “As the youngest in the batch, sharing the classroom with many senior L&T‑ites is an incredible experience, enriching me with knowledge, wisdom, and new perspectives.”

Hailing from Alappuzha in God’s own country Kerala and single, Aisha’s immediate family is her father, Hussain M S, and mother, Ajitha R.

FRESH OFF THE BLOCKS, RARING TO FLY

Anuruddh Tiwari

Senior Engineer (MECH), M&M IC

Just a year old at L&T having joined with the 2024 batch of GETs, young Anuruddh Tiwari is already impressed with the company he keeps. “L&T’s commitment to quality, integrity, and innovation truly sets it apart and the organization gives its people the opportunity to work on some of the country’s most iconic projects, while fostering a culture of continuous learning and excellence.” He considers himself fortunate having got the opportunity to work at one of these iconic projects, the AMNS Blast Furnace #2 project in Hazira as part of the core execution team, where he is actively involved in site planning, coordination, and daily progress monitoring to ensure work with quality, safety and efficiency.

Several digital tools have been deployed at his site to improve site efficiency and maintain momentum across all fronts. “We are using BIM for clash detection, better etter planning, and visualization helping us streamline construction sequences and avoid rework,” shares Anuruddh. “We also have a QR Code-based real-time tracking system in place to monitor daily construction progress and quality inspections that have improved our speed and accountability of reporting.” On his wish list is access to an integrated mobile dashboard or app that integrates site progress data, material delivery status, safety alerts, and team assignments. “This will help speed up decision-making and reduce time spent on manual reporting,” he says with an assertive nod.

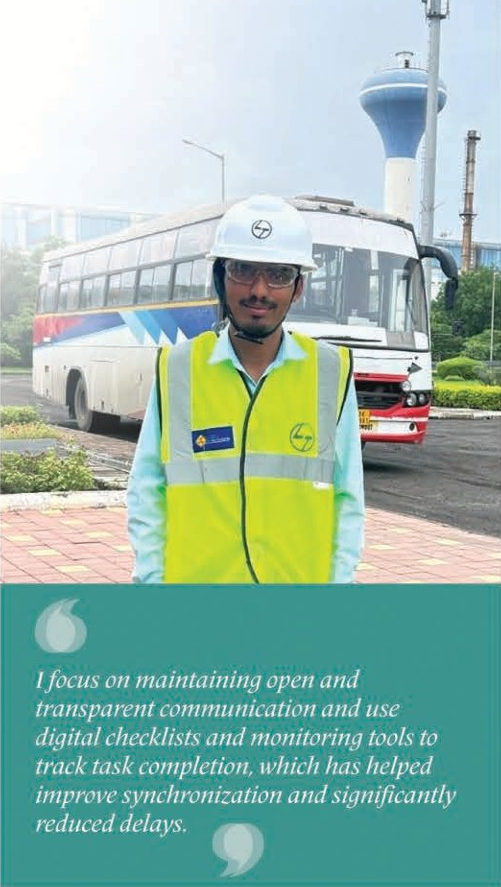

Challenges are part and parcel of site life and one of Anuruddh’s major concerns has been to ensure coordination across multiple teams working on tight schedules in a high-pressure environment. As mitigation measures, they started holding daily coordination meetings with all stakeholders. “I focus on maintaining open and transparent communication and use digital checklists and monitoring tools to track task completion, which has helped improve synchronization and significantly reduced delays.”

For someone learning the ropes at his first project, Anuruddh is enjoying the mentorship from his seniors and their frequent interactions to ensure his growth. “My team is very experienced, and collaborative and our positive team environment keeps me motivated and focused,” he says with purpose. Even a great plan fails without disciplined execution and therefore he puts a premium on proper planning, consistent on-ground follow-up, real-time monitoring and proactive issue resolution to deliver large projects.

On his personal front, Anuruddh, a native of Kanpur, Uttar Pradesh and still single, enjoys reading biographies, travelling and playing outdoor games making time for them despite his punishing work schedule. “My most memorable moment was being rewarded by an Education Minister (UP) in 2018 for getting AIR 19 Reso step exam in front of my family.”

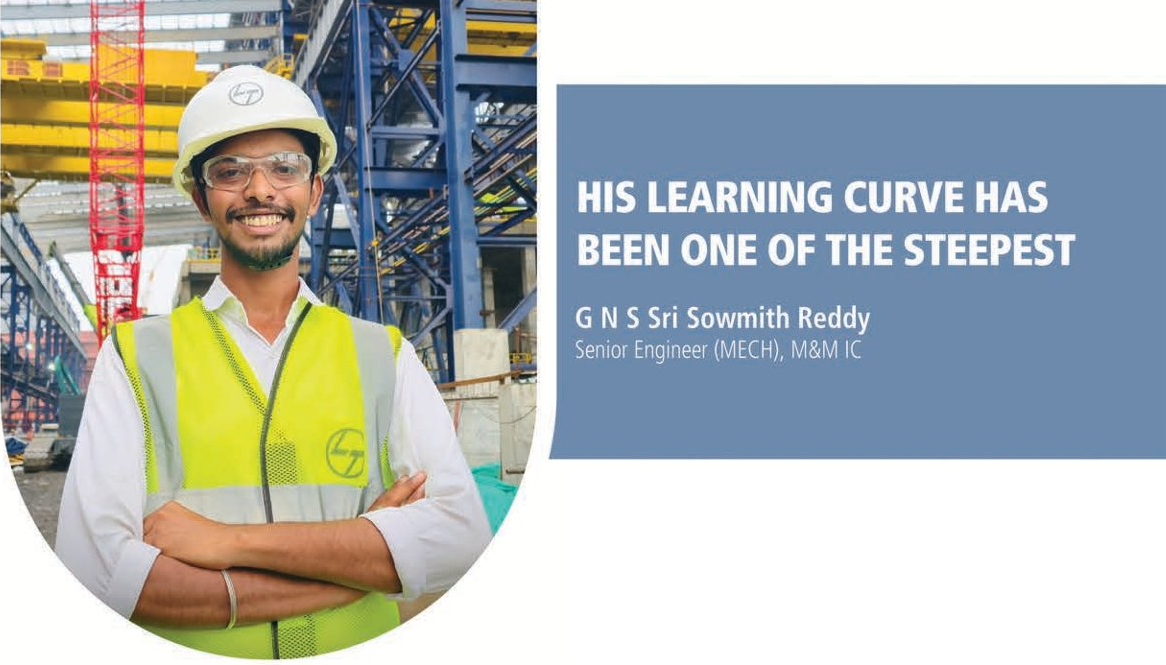

When I first came to site, I did not even know the basics of handling site work and today, I am leading the structural part of the caster area — one of the most critical zones of the project,” shares an elated G N S Sri Sowmith Reddy, from his first project with L&T at the challenging AM/NS site. “This was possible only because of my seniors, who encouraged me, gave me a platform to think innovatively, and guided me whenever I made mistakes. My team too has supported me throughout with safe and smooth execution,” he says, in gratitude for the support and cooperation he has received at site that has helped him describe a steep learning curve.

Quite unsurprisingly, he declares, “My most memorable moment was when the first EOT crane was commissioned in our project, where I led the structural part and was proud to see such large-scale machinery successfully lifting heavy loads.” Sowmith is quick to heap praise on the organization he is a part of. “In L&T, power comes with responsibility,” he says ays with newfound wisdom, “and the more responsibility you take, the more value and trust you earn.”

“We integrated modular erection methods to speed up work,” he says, sharing his responsibilities are site. “In fact, one erection was so unique that a senior client representative said he hadn’t seen such execution in his 25-year career!” One of the major challenges the site faced was to manage heavy and elevated erections in congested areas. “We overcame them by alternate sequencing, close coordination, training workmen, adopting modularisation and innovative erection methods,” ticks off Sowmith, who after a pause adds with a grin, “It’s all about imagineering!”

Front readiness, according to him, is the key to successful execution, ensuring that drawings, materials, manpower,and equipment are available on time. “With proper roper planning, coordination, communication, and quick decision-making, even large projects like our AM/NS project can be executed at speed,” he says with a vigorous nod.

He would love a real-time material tracking system to monitor the status of drawings, fabrication, dispatch, and delivery at site. “It will ensure front readiness, reduce delays, and greatly improve speed of execution,” he adds.

About his personal life, Sowmith shares that he is from Visakhapatnam. “My father, Gudimetla Suryanarayana Reddy, works at Vizag Steel Plant and my mother, Gudimetla Udaya Bhanu, has always been my pillar of strength.” Sowmith’s twin sister, G. N. R. Bruhathi, works in Mahindra & Mahindra’s automobile division. “Becoming a mechanical engineer like my father was my childhood dream, as I grew up watching his dedication and responsibility towards his work. His constant guidance that ‘if you work with sincerity and dedication, society will recognize you’ continues to inspire me. I strongly believe true recognition comes through consistent effort, integrity, and discipline,” he shares with a smile as he signs off.

Just into her second year with L&T and at her first project, the SMP#3 of the AMNS project, Vempada Sarvani’s main challenge was joining the project midway, which made it difficult for her to catch up with the pace and ongoing activities. One aspect that must have helped her is her army background, with her father being a retired Army officer, and she must be carrying that focus and discipline in her genes. From her part at site, she says, “I focused on understanding the existing workflows quickly and coordinated closely with different teams, paying special attention to detail while updating schedules and tracking progress.”

Helping Sarvani in her effort to bring herself up to speed is the collaborative and supportive environment that her seniors and team members have created in the planning department. “Their experience and encouragement have helped me learn quickly, work more efficiently, and contribute better to the team’s progress,” she says meaningfully.

Certainly, L&T’s culture of innovation and learning is helping her in a big way too, that she experiences keenly at her project. “It feels like a family,” she says proudly. “The support and collaboration I receive here motivate me every day to do my best and grow both personally and professionally,” and adds after a moment of thought, “I also appreciate how the company recognizes and values the work we do, giving us the confidence and opportunity to improve constantly.”

Being part of such a large & complex project has taught Sarvani that clear coordination and communication across all teams is critical for success. “Perfection at every level and contribution from every individual is vital to maintain quality and ensure tim progress,” she says insightfully. “It is important to be always proactive, identifying and addressing issues early helps prevent delays and keep projects on track.” On the tech front, she would love an Al-driven project planning and monitoring tool that integrates real-time site data with schedule forecasting to identify potential delays, optimize resource allocation, and automatically update schedules based on actual progress. “It will reduce manual follow-ups, improve accuracy, and allow planners to focus more on strategic decision-making,” she nods energetically.

The AMNS project is her first and Nellore Greashma Reddy considers herself fortunate to be associated with it from ground level. “It has been an enriching experience being exposed to the entire steel production value chain, right from iron ore collection to the final output of slabs, billets, and plate sections,” she shares, her eyes sparkling. “I have witnessed and learnt the entire process of constructing blast furnaces and steel melt shops, giving me not just technical expertise but also a sense of ownership and long-term vision.” Certainly, Greashma is making the most of being part of L&T or ‘Learning & Training’ as she describes the Company. “L&T’s focus is on nurturing talent, encouraging us to learn something new every day, keeping kee us motivated.”

Her short journey thus far has been smoothened by her seniors and teammates who have been her mentors and motivators. “Their willingness to share knowledge, guide me through technical complexities, and encourage me have been invaluable, be it in understanding project intricacies or supporting me in time-bound execution,” she says, adding with fervour, “Their belief in me has driven me to work faster and deliver at scale.”

To manage multiple deliverables concurrently, especially during peak phases, Greashma has a 3‑step strategy: “Clear prioritization, time blocking, and close coordination with stakeholders,” she ticks off on her fingers. “I created weekly and daily execution plans, adjusted priorities based on site requirements, and ensured seamless communication with cross-functional teams,” adding that tools like trackers and dashboards help visualize workloads and avoid delays. The implementation of smart digital tracking systems has accelerated reporting timelines and enhanced transparency across all project phases. “Our well-maintained progress trackers and Al-powered Excel tools, along with Power BI dashboards, help to visualize project data effectively.”

“Speed doesn’t come from rushing, but from readiness,” she points out insightfully and therefore effective planning backed by timely execution are critical to deliver large projects like hers. “Planning saves much more time than it takes, and I live by that,” she avers, “anticipating challenges, organizing tasks logically, and ensuring everyone is aligned with the plan makes all the difference.”

“My native place is Nellore in Andhra Pradesh, a town known for its natural beauty, agriculture, and cultural depth, where I learned the importance of relationships, patience, and resilience, qualities that continue to support me in my career today,” says Greashma, sharing her personal side. Single, she enjoys learning about technological advancements and financial management techniques. “Even with a hectic schedule, I don’t wait for the right time, I create it,” she smiles. Seeing the inside of a blast furnace was a professional moment to remember while she values quiet, heartfelt moments shared with her family.