BELIEVING STRONGLY IN TEAMWORK & PROBLEM SOLVING

Dommalapati Udaya Kumar

Construction Manager (Civil), WET IC

“One of my career’s most memorable moments was the successful commissioning of the pipeline at the Kundaliya Irrigation Project — Left Bank,” says Dommalapati Udaya Kumar, with the ardour of a true construction professional. “It was a challenging task requiring careful planning, teamwork, and strict safety measures and commissioning the line smoothly gave me immense pride and reinforced my confidence in teamwork and problem-solving.” Currently working on the Hatpipaliya Micro Lift Irrigation Project, which covers a vast 164,000 hectares, he reflects on the initiatives he led at the Kundaliya project, where he was instrumental executing complete pipeline works for a 63,000-hectare command area and commissioning 12,000 hectares.

An advocate of digital solutions to drive efficiency, Udaya mentions introducing digital mapping Apps (Map INR) to streamline pipeline routing, identify land ownership in advance, and resolve land clearance issues faster. “It minimized delays and speeded up site progress,” he notes. At the same project, he faced challenges of managing high water pressure and ensuring that valves, joints, and pipelines remained leak-free during OMS testing, apart from coordinating with multiple teams for simultaneous testing. “To address these challenges, I ensured proper pre-checks of valves and fittings, strictly adhering to safety procedures, proceeding with the pressurization step-by-step, and maintaining clear communication among teams,” he says, adding after a pause, “All these measures helped us complete the testing smoothly and on time,” he smiles triumphantly.

Speaking from experience, Udaya shares that in irrigation projects, delivering work with speed depends on proper planning of pipeline routing, timely availability of materials, and close coordination among site teams. “It is important to resolve issues such as land clearances, joint testing, and valve commissioning as early as possible to avoid delays and ensure timely completion,” he says assertively. Looking ahead, he is keen to adopt loT-based pipeline monitoring systems for real-time detection of pressure drops or leakages. He believes that such a technology could significantly improve safety, reduce water loss, and enhance efficiency irrigation projects.

“Yes,” he acknowledges, “my work comes with a lot of challenges, but I am glad to have the right guidance from my seniors with their valuable experience and the coordination and support from my team,” adding that this teamwork helps him to complete his work faster, on a larger scale, and with high quality.

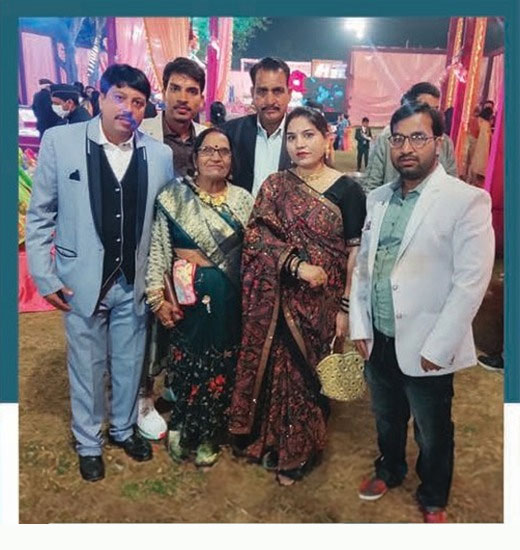

Udaya comes from Gaddamavari Palli village in Andhra Pradesh’s Tirupati District. His family includes his retired father, his mother, wife (Naga Jyothi, a homemaker, who manages his home and supports him), and his young son, Nayanesh. In his free time, he enjoys playing cricket and learning new skills through online courses.

PROVIDING WATER IS A DEEPLY FULFILLING EXPERIENCE

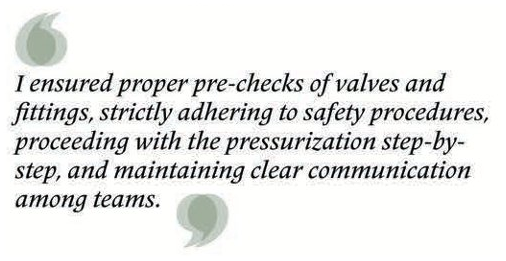

“Among the many milestones in my career, the commissioning of the Kundalia Irrigation Project — Left Bank stands out as the most memorable,” says Nesakumar Kalaiarasan, with stars in his eyes. “The first pumping operation began at 3:00 am, in the quiet stillness of the early morning, and standing at the pump house, watching the system come alive with the water beginning its journey towards thousands of hectares of farmland, was a deeply fulfilling experience.” The project has special relevance for him as it was his first with L&T followed by a stint with the LWMS Operations team where he was involved in the in-house development of the Outlet Management Systems (OMS). “I played a key part in the assembly and testing of the OMS modules at the ISP-Parwati Phases I & II and ISP-Kalisindh Phase I MLIS projects, my current assignment,” he shares with barely suppressed excitement.

Certainly, developing the OMS initiative is closest to his heart, being strategically important to tackle several challenges including the team’s dependence on a single OMS supplier, delays in OMS installation that were adversely affecting project timelines, poor integration with Web SCADA and customer dissatisfaction due to the unreliability of the system. “By designing a customized, scalable, and cost-effective OMS model, we were able to implement parallel activities, improving interdepartmental coordination and reducing delays. In addition, it improved communication systems and deployed IT teams to enhance online performance,” he says, adding, “Most importantly, it gave us control over activities in the critical path.”

Acknowledging the merits of collaboration, Nesakumar is all praise for the strategic direction of his seniors and the support from the top management, EDRC, F&A, EHS, and Quality teams across HQ, BU, and the Cluster. “Their strategic involvement ensured cross functional coordination for faster issue resolution and empowered the site teams through training, resources, and leadership.” He is equally moved by L&T’s commitment to empowering employee with ownership and innovation. “Whether it is developing inhouse systems like the OMS or driving productivity through collaborative execution, L&T fosters a culture where ideas are valued and excellence is expected, trusting its employees and creating an environment where speed, scale, and quality are not just goals but shared achievements.” His commitment to the Company he keeps shines through.

A native of Karur, Tamil Nadu, Nesakumar’s life partner is Brilly, a devoted homemaker, and they are blessed with two children: son, Titus, and daughter, Menorah. In his free time, he loves playing cricket, reading historic novels, watching movies, and traveling to hill stations whenever he gets the chance.

“One of my life’s most memorable moments was at one of my previous projects where we successfully commissioned the OMS system up to the 1‑hectare point and seeing the smiles on the farmers’ faces was truly rewarding, reminding me of the real impact of our work on people’s lives,” says a passionate Manivannan Sekar.

Currently, he is at the Hatpipaliya Micro Lift Irrigation Project, a large-scale initiative covering 1,64,000 ha CCA with around 8,300 OMS across the districts of Dewas and Ujjain in Madhya Pradesh. “Previously, I was part of the Kundalia Irrigation Project (Left Bank) with a CCA of 63,000 ha and 2,800 OMS in the Agar Malwa district. In both projects, I have been involved in executing and coordinating to ensure timely progress and quality delivery,” he says purposefully.

A proud L&T‑ite at heart, Manivannan says, “I have personally experienced how L&T empowers its employees through continuous learning, strong teamwork, and real responsibility, even in challenging environments. That sense of trust and impact is something I value deeply.” The strong bond he feels with his Company is strengthened by the clear direction and timely support he receives from his seniors, empowering him to take quick decisions. “They empower me to take ownership, which drives accountability and efficiency while I coordinate and openly communicate with my team members, working together to resolve challenges quickly and keep the workflow smooth. This collaborative environment helps me deliver with both speed and scale.”

About driving efficiency at the site, Manivannan mentions implementing the GIS-based MAPinr app for pipelaying work and daily progress reporting from junction to junction (DPR to Planning). “We introduced online indent posting for digital material tracking for real-time monitoring, reducing errors and minimizing material shortages,” he says, mentioning some of their tech solutions. Drone-based progress monitoring provides real-time insights for faster decision-making, while mobile-based daily WhatsApp-based reporting has replaced paper logs, improving data accuracy and coordination. “These digital initiatives have collectively enhanced our planning, reduced rework, and accelerated site progress,” he says, nodding encouragingly.

Strong planning, coordination, alignment amongst all stakeholders, and proactively resolving site issues are, according to Manivannan, the ingredients to a successful project. “Daily tracking and quick decision-making at the field level are essential to stay on schedule and working smarter with clarity and accountability,” he emphasizes.

Manivannan hails from Muthandikuppam village in Cuddalore, Tamil Nadu. “I come from a supportive family who have always encouraged me in both my personal and professional life,” he shares with feeling. Married to Jayasri, a homemaker, they are blessed with one son, Koshik. “I enjoy reading, listening to music, and making reels, which helps me recharge and maintain a healthy balance between work and personal life.”

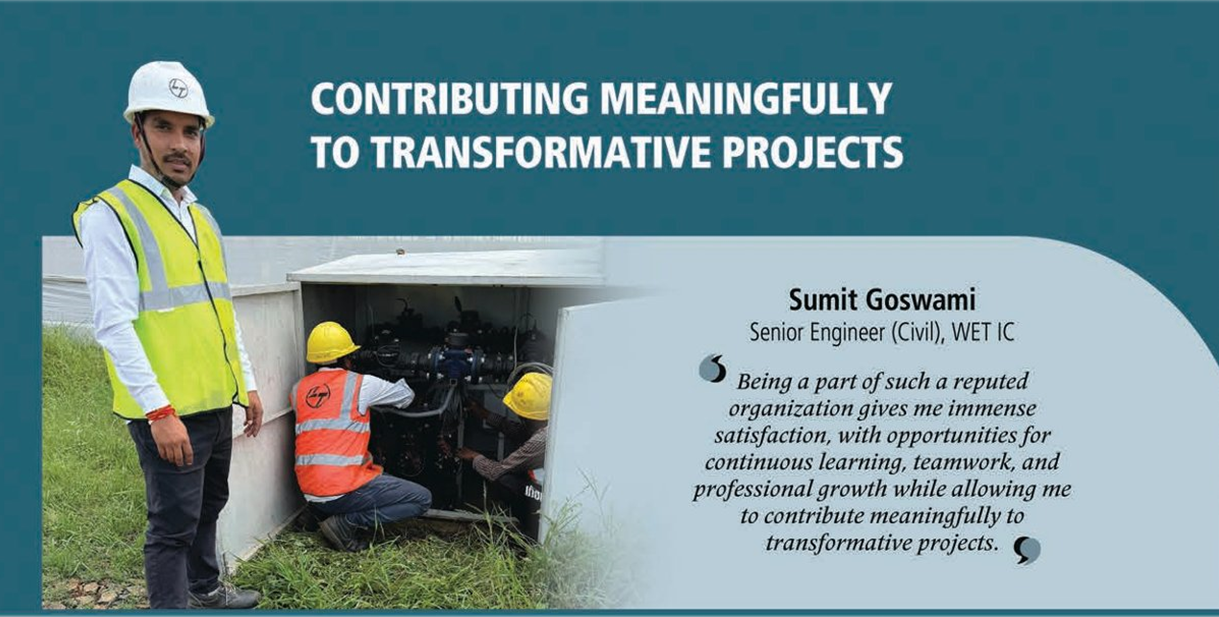

Just two years with L&T and yet Sumit Goswami, a GET of the 2023 batch, has already worked across five project sites at different locations: Hatpipaliya Micro Lift Irrigation Project, Chhaigaonmakhan Lift Irrigation Scheme, Alirajpur Lift Irrigation Scheme, Narmada Kshipra Multipurpose Project, and currently ISP Kalisindh, where he has been part of the team implementing the in-house OMS box, apart from material procurement; mechanical assembly & testing; site foundation; mechanical, electrical, & instrumental installation; and cabinet enclosure works. “Implementing precast pile/footing foundations (at 1.5–2.0 m depth) based on soil conditions, reducing settlement issues, and eliminating rework have enhanced the structural stability of the OMS boxes and improved the lifecycle performance,” he explains.

The project team has installed an advanced valve & filtration system by upgrading plunger-based solenoid valves to diaphragm-based ones, which have a longer service life as they minimize rusting and reduce maintenance requirements. “We have adopted LoRaWAN communication for real-time monitoring and control by configuring a fixed connectivity model of 20 OMS boxes per gateway, with a range of 2–3 km, improving reliability and scalability, and by integrating gateways directly into OMS boxes, we optimized the cost,” he adds.

“Never start execution without 100% verified dimensions, levels, availability of required resources, and skilled manpower, “cautions Sumit. “Speed is achieved when every stage is executed right the first time — precision and preparation are the true accelerators,” he says, adding that teamwork, quality of work, and skilled manpower are essential for maintaining speed & scale. “If quality is compromised, rework is inevitable, resulting in loss of both time and money.” At the top of his tech wish list is an AR tool to overlay design drawings onto live site conditions for real-time accuracy checks to reduce errors and improve installation speed.

A native of Bhind, Madhya Pradesh, Sumit’s cultural roots have kept him grounded and motivated. “I come from a supportive and value-driven family that has always emphasized discipline, integrity, and continuous learning,” he says. He enjoys playing cricket & badminton and going to the gym. “These hobbies keep me physically active and help me develop focus, teamwork, and resilience. However, my projects keep me busy on most days,” he adds with a rueful smile.

What inspires Sumit the most about being an L&T‑ite is the Company’s focus on digitalization and modern construction practices that not only enhance productivity but also set new industry benchmarks. “Being a part of such a reputed organization gives me immense satisfaction, with opportunities for continuous learning, teamwork, and professional growth while allowing me to contribute meaningfully to transformative projects,” he concludes.

“My most memorable moment in the two years I have spent with L&T at the ISP Parwati Phases 1 & 2 project, my first, was to see the pump start the commissioning activity,” says an excited of Surajbhan. “It gave me both a huge sense of achievement and completion.”

For him, the most important initiative by the project team at this micro irrigation project was the development of an in-house Outlet Management System (OMS). “We were struggling with high dependency on a single OMS supplier that were causing delays in the OMS installation that were in turn affecting project timelines,” he points out. “Our answer was the OMS, an internally developed system that empowers us to manage design, procurement, and installation more efficiently, and thereby accelerate execution.”

Elaborating on the OMS, Surajbhan explains that they utilized open-source EOFCV valves and LORA-based communication, eliminating the need for proprietary servers, thereby reducing the system’s complexity and power consumption. “The OMS was seamlessly integrated with Web SCADA, enabling real-time monitoring and control for improved operational performance,” he adds, with a thumbs up.

He attributes their success to the strategic direction from his seniors, who critically supported the shift from vendor dependency to in-house development. “We succeeded thanks to the support from the top management, and the teams from EDRC, F&A, EHS, and Quality,” says Surajbhan with gratitude. “Their strategic involvement ensured cross-functional coordination for faster issue resolution, and we empowered the teams through training, resources, and leadership.”

Sharing his insights collected during his 2‑year career, Surajbhan mentions that they have always been hindered by shortages in material supply leading to delays because some vendors did not supply material on time. “To speed up a project, it is very important to plan the P&M, material and manpower required before starting work and then monitoring it regularly,” he says wisely. Looking ahead, he hopes, that the Company will soon introduce automation in pipeline welding and improve decision-making through Al-driven insights.

“What impresses me most about L&T is importance give to the safety of the employees and workers with top priority to the quality of work,” he says, adding proudly, “In two years, I have won the Safety Award three times!”

Hailing from the holy town of Ayodhya, Uttar Pradesh, Surajbhan is still single and loves to play cricket, read historic novels, and watch movies when he is not busy driving progress at his micro irrigation project.

SKETCHING THE BIG PICTURE

Gautam Arun Jaday

Construction Manager (Civil — NRW), WET IC

Pencil sketching (shading) and photography are Gautam Jaday’s favourite hobbies, and he will agree that by bringing his decade and a half of rich experience of handling water projects to L&T’s Pune-PKG03 water supply project, he is certainly sketching his career’s next level of growth. Apart from overseeing critical components of the Non-Revenue Water (NRW) management strategy, he is responsible for identifying and curbing water losses. “Reduction and maintenance of NRW levels is a continuous process that demands constant innovation, persistence, and above all, a collaborative team spirit,” he stresses.

At the heart of Gautam’s approach is the seamless integration of digital technologies to improve speed, scale, and accuracy, and he considers himself fortunate to be part of the team that developed a Proof of Concept on water loss detection using Digital Twin Technology. Winning the CIl National Award for Excellence in Water Management in 2024 and the internal Innovation Award 2024–25 for UFW Reduction using Digital Twin and receiving a Letter of Appreciation from the Pune Municipal Corporation (PMC) for the team’s efforts in commissioning and reducing the NRW levels by 19% in two zones, serving a population of approximately 51,000 residents, are among Gautam’s most cherished memories. “With the Water Technology Centre, we have developed and deployed a hydraulic model integrated with a machine learning-based predictive system to detect segment-level loss hotspots in the Panchwati Zone, which has reduced NRW from 53% to 29%,” he announces triumphantly.

He is proud of his association with L&T too for he has found to his delight that the values of the organisation resonate with his own. “This is a place where passion meets purpose and technology is used not just to build systems, but a better future,” says Gautam.

All major infrastructure projects bring their unique brand of challenges and Gautam has had his fair share like identifying illegal connections and tackling leakages from aging pipelines. “By leveraging GIS mapping, digital twins, and Al-powered water audit tools, we proactively detected and addressed issues in the network,” he explains. “Illegal connections were metered or disconnected in coordination with PMC’s staff, helping bring unaccounted water under control.”

Gautam’s success is attributable to the timely decision-making of his seniors and the collaboration of this team that he describes as the synergy that drives real impact on ground. Technology integration, strong teamwork and timely decision-making are what win the day in project execution. “I have learnt that early detection and proactive resolution of water losses significantly reduce rework and project delays,” he avers.

On his personal side, Gautam hails from Satara, Maharashtra, is married to Neha, an interior designer, and they are blessed with a daughter, Ruhee.

DRIVEN BY FOCUS; DEFINED BY RESULTS

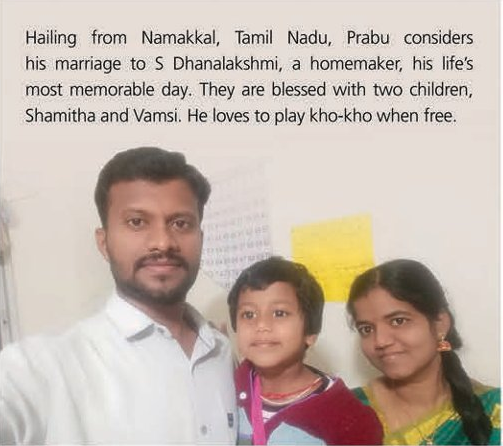

He has learnt that effective coordination, communication, timely identification and resolution of issues are key to successfully delivering large projects at L&T, an organization he holds in the highest esteem. “L&T values integrity, teamwork, and continuous improvement that motivate me to contribute my best every day.”

At his present assignment at the Pune Package 2, Prabu and the project team encountered two major roadblocks. The first was the lack of accurate information about the existing water pipe networks; the other was the lack of consumer awareness about the benefits of Water AMR (Automated Meter Reading) meters. While the first called fora thorough survey requiring additional time & resources impacting project schedules, the second was causing resistance at ground zero and slow adoption. “I believe that by proactively addressing challenges as soon as they arise, rather than waiting for them to escalate, we can keep projects on track and maintain momentum,” he says insightfully.

By putting his belief into action, Prabu led the efforts to streamline the survey by organizing focused teams, using digital tools for faster data collection, and mapping to create and sustain consumer awareness. “We initiated targeted communication campaigns and conducted community engagement sessions to educate consumers about the advantages of AMR meters, which gradually improved acceptance and cooperation,” Prabu adds.

The introduction of acoustic leak technology to detect invisible water leaks in underground pipes is something Prabu is extremely pleased about. “This non-invasive method eliminates extensive digging to locate leaks, saving time, reducing site disruption, enabling quicker repairs and reducing water loss,” he shares. Another improvement at site was integrating real-time monitoring systems for both flow and domestic water meter data. “With this digitalization effort, we can immediately detect anomalies and efficiently manage water while the continuous data flow for proactive maintenance and rapid response to any irregularities, ultimately improving operational efficiency and site progress,” states Prabu, with a definite sense of purpose.

By supporting him, providing essential resources, developing baseline infrastructure, and ensuring timely resolution of reported issues, Prabu’s seniors has been empowering him to perform while the collaboration and prompt action of his team members are helping him to maintain momentum and deliver results. He would dearly love an advanced IoT-enabled predictive maintenance system for water infrastructure, using real-time sensors and AI analytics to predict potential pipe failures or leaks before they occur.

What thrills Adarsh Gaonkar most is getting his works sanctioned for execution and successfully commissioning his projects for operation. Having started with L&T as an Assistant Engineer, he is currently working in Pune as a Central Coordinator for all water management-related activities in the Pune Packages, which has exposed him to both the technical and strategic facets of constructing water infrastructure.

Recognized as a Tech Champ, Adarsh is proud of the tech solutions implemented at his project. “We monitor in real time the flow of data from domestic water meters, having developed a Digital Twin to collect and analyse raw data that we share with the management for decisions,” he points out. These digital interventions are empowering the team to detect issues like leakages, backflows, meter tampering, and other abnormal consumption patterns resulting, resulting in less water loss, reduced downtime, better resource efficiency & service reliability across the entire network. To further increase the efficacy of his tech solutions, Adarsh would like to see Al & ML integrated with data channels to deliver real-time, geography-aware insights to help proactively troubleshoot, plan sustainably, and maintain peak performance across the board.

Acknowledging that these were not easy to implement, Adarsh’s determination shines through in the way he has overcome several challenges to succeed. Resistance from local authorities to installing digital tools, multiple inter-departmental dependencies, the need for permissions from external agencies were roadblocks, slowing down pace of execution. “By maintaining transparency in communication and actively involving the client, we have been able to fast-track approvals and keep the project moving forward,” he shares, with gusto.

Adarsh’s experience has taught him that delivering projects like his hinges on the ready availability of resources in-line with work fronts for execution, ensuring permissions from all stakeholders involved and carefully considering on-site factors like strata, utilities, access to fronts, etc. for smooth operations. A proud L&T‑ite, he says, “Access to L&T’s vast experience as well as the willingness of vendors and service providers to partner us to complete and improve our projects under execution is great,” he smiles broadly. Ensuring the availability of material and resources for baseline infrastructure development and timely resolution of reported interventions are how his seniors are helping him succeed.

On the personal front, born and raised in Thane, Maharashtra, Adarsh lives with his wife, Priyanka, a teacher. Though work leaves little room for hobbies, bbies, cricket remains his passion.

WATER CONSERVATION IS HIS MOTTO

Rajshekhar Kshirsagar

Engineer (MECH), WET IC

At his first project with L&T, the Pune-PKG03 Water Supply Project where he is overseeing non-revenue water (NRW) works, Rajshekhar Kshirsagar is proud to be contributing to impactful projects that shape infrastructure and society, giving real meaning to his work. He is equally excited about the recognition his team has won for their efforts in controlling NRW, which includes the CII National Award for Excellence in Water Management — 2024 and the Innovation Award 2024–25 for UFW Reduction using a Digital Twin.

“We successfully executed a Proof of Concept on water loss detection by implementing Digital Twin technology, in collaboration with our international partners, Status 4, Brazil, and Smarterra,” he shares. “Further, we deployed an integrated hydraulic model and ML-based predictive analytics system at the Panchwati Zone, developed by the Water Technology Centre team for hotspot detection, which has reduced NRW from 53% to 29%.” A Water Audit Software developed in-house and implemented at the Pune Municipal Corporation has improved data-driven decision-making and network performance monitoring and Rajshekhar is delighted that NRW has reduced from 65% to 19% in Baner Gaon Zone 2 & Ahiregaon Zone (DMA 1).

“My responsibilities include conducting detailed water audits, analysing flow data to detect network losses using advanced leak detection instruments, and overseeing the installation and monitoring of Automatic Meter Reading (AMR) and bulk meters, for accurate data collection and validation,” he shares. In addition, he monitors key instruments like the electromagnetic flow meters, pressure transmitters, and isolation valves to ensure effective zone isolation, flow regulation, and overall control across the water distribution network.

“Reducing and maintaining NRW levels is a continuous and challenging task that demands consistent effort, detailed analysis, and timely execution,” he states purposefully, “and my seniors’ guidance and strategic direction along with the dedication and on-ground support from team members have accelerated the entire process.”

Seamless integration of technology with strong teamwork and timely decision-making are the key ingredients to successful delivery of large projects, he opines. “However, the real impact comes when this technology is combined with effective coordination across departments and swift execution on the ground,” he says with an assertive nod. Returning to familiar territory, he adds that early detection and proactive resolution of water losses minimize rework and prevent delays to keep the project on track. He would love an Al-driven autonomous drone and robotic inspection system to manage NRW and an Al-powered loT leak detection system.

A native of Solapur, Maharashtra, Rajshekhar is the son Govind, a businessman, and Geeta, a homemaker. His brother, Chandrashekhar, is currently working as a Project Engineer at C DAC, and his sister, Sanjeevani, is married. Rajshekhar enjoys playing cricket and travelling.

Already at his 9th project after joining L&T in 2008, Parthasarathi T is convinced that efficient project delivery lies in smart planning and reliable machinery, having independently handled multiple M&M projects. With six years of invaluable international exposure, he has been managing P&M operations as CPLM for the last five years for the Southern Cluster sites in WET IC.

He is particularly delighted with the automatic trencher that he and his team have deployed at the Mandya project site to lay HDPE pipes, which not only has improved their efficiency but has also been pivotal in helping them complete their activities on time as planned Parthasarathi agrees that it was not all smooth sailing, for the initial trials of the trencher revealed technical issues. The project team was, however, on a mission. “With the support of our seniors and OEM experts, we identified the issues and carried out the necessary modifications to ensure reliability,” he says with the expression of a mission accomplished. “Today, the trencher is running smoothly and contributing significantly to our project’s speedy progress.”

Delivering large projects, according to him, involves proper planning, quick decision-making,adoption of technology, and teamwork. “The early identification and resolution of issues make all the difference,” he points out astutely. “Even small problems, if left unattended, can escalate into major delays,” he shares from experience. On the tech front, Parthasarathi sees huge potential in Al-based predictive maintenance and real-time equipment monitoring tools, to further enhance reliability and minimize downtime.

Hailing from Nagercoil, Tamil Nadu, Parthasarathi is married to Sujatha, a homemaker. They are blessed with a son, Aswin. Listening to music and watching cricket are his favourite pastimes, which he takes time out for whenever he can. “Some of my most memorable moments was when I was working abroad and I got to learn a lot from the client team from Bechtel,” he recalls with a glint in his eye. “It was great that our team successfully completed the project ahead of schedule with 100% safety.”

“L&T’s focus on innovation and commitment to delivering worldclass projects with excellence and safety make me proud to be a part of this organization,” he says, recognizing the vision and values of the company he loves.

After a decade with L&T, Tabish Jamal Hashmi has learnt that a balance of foresight and flexibility is critical to executing large projects, apart from detailed planning, adaptability, and open communication. “I believe in the ‘First Time Right’ approach and know that speed is not about rushing but about anticipating challenges, staying prepared for setbacks, and making timely, well-informed decisions to keep a project moving without losing quality and safety,” he says with wisdom. He is therefore certainly well armed to be executing his current assignment as Deputy Project Manager at the Jodhpur Water Supply Project, Rajasthan.

As a standout effort, Tabish flags off leveraging drone-based aerial monitoring and 3D mapping at their 200-km-long project that shows elevation-based heat map & real time views. “These have significantly improved the accuracy of our planning, work sequencing, early identification of bottlenecks, accelerated decision-making and improved coordination between client, design, and execution teams,” he says with a flourish. “We already use Virtual Reality (VR) in the form of 3D modelling walkthroughs for visualising water treatment plants and associated infrastructure before construction, but I would like to see this technology become more refined and interactive.” Tabish wishes for a next-generation VR platform f tot simulate real-time construction sequences, test different erection methodologies, and virtually coordinate between civil, mechanical, and electrical works. “This can help detect and resolve interface issues earlier, optimize work fronts and significantly reduce delays and rework,” he says, gazing into the future.

The team’s biggest challenges have been to execute civil and pipeline works in a desert region under extreme weather conditions and tight timelines. “To address these, we have optimized our work schedules to make the best use of manpower and equipment during high-temperature periods and focused on workforce welfare, actively promoting a ‘We Care’ culture to ensure safety, comfort, and high morale among our teams,” he nods.

Tabish revels in his seniors’ trust and confidence in him that have empowered him with the autonomy to take swift decisions and share timely guidance in critical situations. “My team has been my greatest asset,” he states unequivocally, “their dedication, adaptability, and problem-solving mindset have been instrumental in driving progress and delivering impactful results.”

A mentor at work, there is another endearing side to Tabish. “I enjoy mentoring young minds, especially students from my alma mater, Jamia Millia Islamia, helping them make informed career choices,” he shares passionately. An avid follower of club football, this native of Bhopal, Madhya Pradesh, is married to Tooba Iqbal Farooqui and they are blessed with a son, Nuaym Jamal Hashmi, whose birth has been a life-defining moment for Tabish. He concludes by expressing heartfelt gratitude to his mother, Shama Parveen, for her constant support and inspiration.

Although the RGLC Phase III Jodhpur project is Surender Kumar’s first with WET IC, he is already a seasoned hand at L&T having been associated with five projects with M&M IC, where he was responsible for structural and equipment installation including commissioning and handover. His experience with L&T has convinced him that the Company is extremely system oriented. “Everyone has defined roles and responsibilities and the systems and processes that not only makes this organization but also sustains it to grow, conquering all the challenges and competitions,” he says with passion.

“My seniors set clear priorities, align me with the project vision, and empower me to make on-the-spot decisions without unnecessary bottlenecks and their regular feedback helps me refine my approach and stay focused on outcomes,” he says purposefully. Surender praises his teammates for their ‘solution first’ mindset. “When challenges arise, everyone contributes with ideas and resources to resolve them quickly instead of getting stuck on problems,” he highlights the reason for their collective success.

At the RGLC project, Surender mentions their fortnightly drone surveys that have provided the team high-resolution aerial images and 3D site maps. “This survey has not only given us accurate measurements of executed works but also the exact locations and tracking of hindrances without the need for manual surveys or visits to the location. It has saved us a lot of time and empowered us to take decisions well in advance to remove the hindrances or change the alignment of the pipeline,” he shares.

Surender’s focus is to maintain speed of execution without compromising on quality & safety for which he uses checklists and mobile-based reporting to ensure compliance in real time. “By closely monitoring progress and talking regularly with the workers about the importance of Safety & Quality, we encourage them to follow our SOPs,” he points out. “In my view, and with my experience of having worked on this type of a large-scale project that is spread over more than 250 km, the key factor is close monitoring using digital platforms like the drone-based survey we are conducting.” Looking forward, he says he would like some automatic and reliable welding system that can significantly improve the quality and progress in MS pipe laying work.

On his personal front, a native of Sirsa, Haryana, Surender’s life partner is Priyanka, a homemaker, and they are blessed with a daughter, Yashvi, whose birth is his life’s most cherished moment. His main hobby is playing cricket, especially on weekends.

“I believe my uniqueness is my ability to learn from the past,” says Harisankar R, “and maintaining good relations with all, especially our clients and workers,” and he brings this self-understanding to play at his RGLC Phase 3 project in Rajasthan where, as Construction Manager, he is leading the civil execution works in the IPS 3 Pump House, ESR, and others. Not his first project with L&T, Harisankar’s focus is on completing the project with its 216 km of MS pipeline, four pump houses & nine surge tanks by 31 January 2026.

Drone-based aerial surveys have helped the team capture highresolution site images for real time 3D mapping and progress tracking, reducing manual supervision time, improving reporting accuracy and helping identify bottlenecks early. “With BIM integration, we are using 3D images to identify design clashes before execution,” he says. “With these digital initiatives, we have significantly reduced manual effort, improved communication, and most importantly, accelerated site progress,” he says with a definite sense of purpose.

The extreme Rajasthan weather is one of the site’s major challenges with summer temperatures soaring past 50°C. “To beat the heat, we planned our shift time from 7 am to 12 pm and from 4 pm to 10 pm, which has been one of the prime reasons we have kept to our asking rate,” he says with a punched fist. “In my experience, delivering large projects quickly and on time depends on clarity and alignment from the start to end especially around scope, priorities, ownership, and responsibilities.” Harisankar believes that only experience gives clarity, and it is important to know what one is seeking. “If I want to make a sculpture from stone, instead of focusing on the making, just cut out the unwanted parts of the stone and, in the end, Iwill get the sculpture I need,” he explains.

Attributing a lot of his success to the support and cooperation from his colleagues, he says, “My seniors provide clear direction, timely guidance, and quick decision-making support while my team members actively collaborate, share responsibilities, and maintain transparent communication ensuring alignment with our project goals.”

Hailing from Nagapattinam in Tamil Nadu, Harisankar is still in seventh heaven having been married to Suvetha just a couple of months ago. Singing her praises, he says that she possesses exceptional academic ability, a strong intellect, passion for learning and impressive artistic skills. Cricket, for him, is not a hobby but a passion. To stay fit, he wakes up at 4.30 am to go horse riding. “I particularly cherish memories created with my mother filled with love, strength, and care that have deeply impacted me,” he shares with feeling.

DIGITALLY ORIENTED, AND LOVING THE CHANCE TO DO MORE

“I’m digitally oriented and love exploring new technologies and implementing digital solutions at various projects that helps me stay updated with digital trends to bring efficiency and creativity into my work,” says an excited Prachi Khawse. “In fact, I even work on small personal or academic projects where I can apply new digital skills.” This mindset is certainly helping her take positive strides forward in her career that began with L&T in 2022 as a DET at the 477 MLD WTP Chandrawal project in Delhi where she worked in the planning department. “On 2nd June 2024 1 was transferred to the RGLC Phase-III Jodhpur project as a planning engineer and with my other responsibilities, I am a digital leader too,” she says with immense satisfaction.

Prachi flags off the drone survey conducted at her site as a tech solution that has enormously helped the team with accurate site mapping, faster data collection, progress monitoring and substantial savings in cost & time thanks to the minimal manpower required. “We have implemented 4D Design (Time-integrated BIM modelling) to enhance planning, monitoring, and execution efficiency,” she shares, ticking off the several advantages of enhanced visualization by linking the 3D model with the construction schedule, quicker decision making, improved coordination between the site teams, consultants, and contractors and reduced rework by detecting conflicts between design and schedule early. “By integrating BIM and conducting drone surveys, I’ve learned that early detection of issues, clear visualization, and real-time monitoring are key to keeping execution on track and ensuring timely delivery of large projects,” she emphasizes.

The supportive role played by her seniors and team members has been crucial in driving her digital intent at site. Yes, she nods, that there was some initial resistance but overcame it by conducting awareness sessions and demonstrations to build the team’s confidence. “My seniors have guided me with their strategic vision, timely feedback, and encouragement while my team members have collaborated actively by sharing inputs from the site, assisting in data collection, and ensuring smooth adoption of these technologies.” She is thankful for their trust, and teamwork that have motivated Prachi to deliver better, faster, more accurate, and scalable solutions. She longs for an Al-powered predictive analytics tool integrated with BIM and project data.

Hailing from Ramthi in Maharashtra’s Nagpur district, Prachi’s family is her mother, a homemaker, and her brother who is a structural engineer. “I enjoy travelling and exploring new places, as it allows me to experience different cultures and perspectives,” she smiles. At L&T, she is proud and thrilled to be working on iconic large-scale projects, guided by experienced leaders and supported by a collaborative team.