A CULTURE OF CONTINUOUS IMPROVEMENT KEEPS QUALITY STANDARDS SUN-HIGH

112.5 MW WBSEDCL Solar Project, Goaltore, West Bengal

“Our secret to successfully maintain high quality standards has been to inculcate a culture of continuous improvement by encouraging detection, strict monitoring and addressing lead indicators for quality improvements, and our site has thus far reported 104 lead indicators,” says Project Manager, Narayana Panigrahy, sharing the prime reason for his 112.5 MW WBSEDCL Solar Project, at Goaltore in West Bengal, winning L&T Construction’s Quality Award for 2024. It also marks a first triumph for the mint-new Renewables IC.

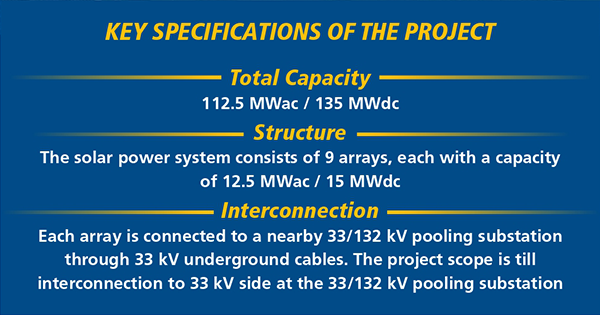

Narayana & his team are constructing one of the largest grid-connected ground-mounted photovoltaic (PV) systems near West Bengal’s Goaltore village for the West Bengal State Electricity Distribution Company Limited (WBSEDCL), designed to generate renewable energy to be distributed to customers and meet the renewable purchase obligations established by the West Bengal State Electricity Regulatory Commission.

In addition to design and engineering, the project team’s scope of work includes supply of modules, MMS, inverters, IDT, cables, HT panels, Automatic Robot Cleaning System & SCADA Systems, etc., the construction of the MCR & Auxiliary buildings, IR Platform, pilling, RO building for Module Cleaning, fencing, drains and roads, development, erection & installation at site, testing & commissioning and an O&M contract for 5 years.

Communication is key

“In our culture of continuous improvement, constant communication is critical and our regular team meetings with our Project Manager are primarily instrumental in maintaining the highest Safety and Quality standards,” says Assistant Manager – Planning, Arya Mondal, with a sense of purpose, “that enable effective and prompt decision making and effective resource mobilization that will go a long way in completing our project on schedule.” By consistently reinforcing quality control and safety standards, the team has successfully maintained exceptional project quality throughout the construction phase, fetching them a Quality Score of 976.

Daily discussions that focus on protocols to sustain a safe work environment provide the team with a platform to proactively identify and address potential hazards before they escalate, significantly reducing the risk of accidents. “Regular safety drills and clear communication ensure that all of us are wellprepared to respond quickly and appropriately in case of an emergency,” asserts Safety In-charge, Bijay Ketan Bhuyan. “Proactive identification and resolution of issues prevent delays and ensure smooth project execution.”

PEP Talks led by Jakir Hossain, Quality In-charge, and the site personnel have encouraged the staff and workers to meet higher quality and safety standards. “Our training programs are basically focused on technical skills, safety protocols and quality control,” adds Narayana, “that have resulted in superior quality & safety standards, increased productivity and reduced errors.”

External audit gives a clean chit

“Our site was selected for ISO 9001:2015 certification and the audit, conducted by M/s TUV NORD, did not throw up any NCRs or Observations and made only one point for opportunity for improvement,” beams Narayana, with good reason, attributing their good showing to the use of online tools to improve their project management and overall quality of their installations. The SANYOG App has enhanced workplace quality monitoring. “It streamlines quality assurance processes, quality training to workmen and staff, compliance checks, defect reporting,” Narayana continues, “and ensures that our installations meet the highest standards of quality, ultimately contributing to project success.”

Amongst the progress monitoring tools deployed, is the nPulse App to streamline progress monitoring, enhance project management efficiency and give the site leadership greater visibility and control over the entire process of construction & installation. “nPulse gives us real-time updates on project milestones, task completion, and activity wise progress status to accurately track project progress and facilitate timely decision-making,” Arya elaborates.

Quality is also dictated by the material one uses. The team’s rigorous inspection process conducted by the Quality & Store In-charges ensure that all materials meet the expected quality standards. “Upon receipt, every delivery is thoroughly inspected and constantly monitored to ensure material integrity throughout the project, preventing delays and defects,” highlights Jakir. “In addition, we have implemented a system of carefully timed and staged material deliveries, reducing the need for long-term storage and minimizing security risks.”

Key challenges and mitigation

Controlling a site spread across 420 acres: The solar site is widespread, distributed across multiple patches and surrounded by many villages with many approach roads within that plant area that presents some unique logistical and material security challenges, including the risk of theft & damage to their material. The project team’s response was to erect a robust fence around the entire 420 acres before commencing construction activities.

Rains threatened to spoil sport at the start of the project: The onset of the 2023 monsoon could have jeopardized the timely completion of the Main Control Room (MCR) works, particularly the foundation. Realizing the impending problem, the team convinced the client to finalize and approve the required drawings in advance, enabling the team to complete the foundation works well before the rains arrived.

Delighting the client: “Understanding the expectations and needs of our various stakeholders, especially our client and consultant, is an important step towards speedy and timely project completion,” remarks Narayana. Quality and Site Incharges facilitate ongoing client interaction during site inspections, ensuring alignment with project goals, transparent communication, and prompt issue resolution, “that are helping us to meet our client’s expectations at every milestone,” adds Narayana.

Recognition for a quality performance

The project was recognized as one of the Best Renewable Power Projects of the Year by Construction Times and won the WSO India (State) Level OHSE Silver Award, both in 2024. “We have been appreciated by our client, WBSEDCL, too” points out Arya. Appreciation certificates have been awarded for ‘Quality in execution activities and implementation of ISO 9001:2015 QMS requirements’ and for ‘Implementation of Best Environmental Health and Safety practices at site.” Internally, there were the Timely Project Delivery Award, Excellence in Construction Award, Health and Safety Excellence Award at Renewable IC Townhall 2024 for Domestic and Best Account Award for meritorious contribution.

Our site was selected for ISO 9001:2015 certification and the audit, conducted by M/s TUV NORD, did not throw up any NCRs or Observations and made only one point for opportunity for improvement.

Narayana Panigrahy

Project Manager

Certainly, the awards are reasons to celebrate, but Narayana finds true delight in seeing his team successfully complete and deliver a project on time with a good margin.