CREATING THE POWER TO LIGHT UP 132,000 HOMES

700 MW Ar Rass-1 Solar IPP Project, KSA

An area the size of 2500 football fields.

The length of cable laid is equivalent to 2/3rds of the Earth’s diameter.

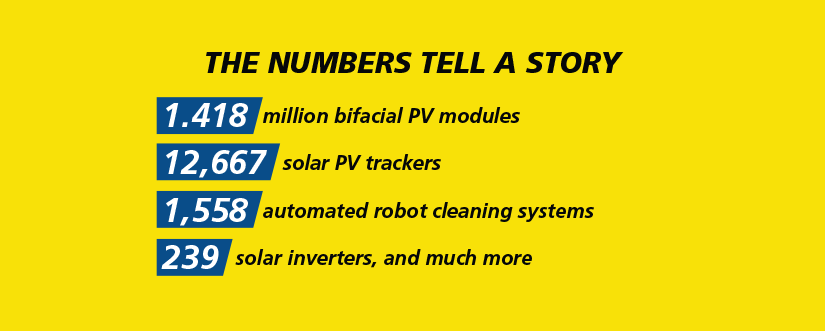

These are some startling facts that have gone into constructing the 700 MW Solar PV IPP Single-Axis Tracker Plant by a Renewables IC team at Ar Rass, that is the oldest and largest city in the Al-Qassim Province by area and third largest by population. The development of the plant is a part of the REPDO (Renewable Energy Project Development Office) Round 3 renewable projects with a combined capacity of powering 132,000 homes while offsetting nearly 1.5 million tons of emissions per year and a part of Saudi Arabia’s ambitious target to develop 130 GW of renewable energy capacity by 2030.

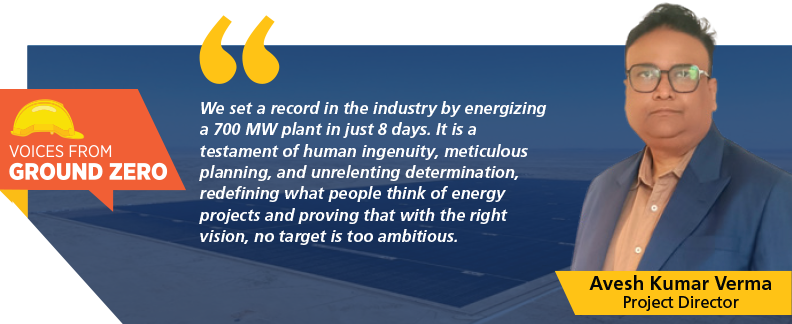

The scope of work for Project Director, Avesh Kumar Verma, and his team was to design, engineer, procure, construct, commission and test for 700 MW of solar-generated power. The project consists of PV plant works, and the plant will be connected electrically through a 33/132 kV substation, in turn connected to the Electrical Special Facility (ESF) via overhead transmission lines.

“We set a record in the industry by energizing a 700 MW plant in just 8 days,” exults Avesh, who is equally buoyed by the fact that his project has won L&T Construction’s Timely Delivery Award – 2024. “It is a testament of human ingenuity, meticulous planning, and unrelenting determination, redefining what people think of energy projects and proving that with the right vision, no target is too ambitious.”

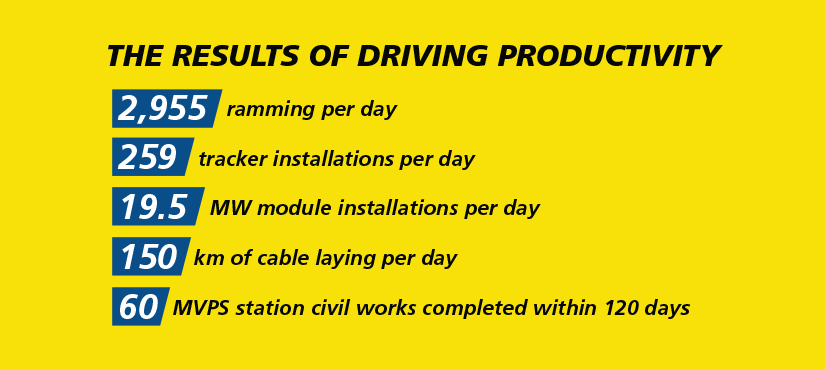

Never losing sight of the ball

With aggressive targets to achieve, not a moment was lost as the team got down to construct in real earnest. “We completed our project in time by focusing on the per day productivity that was achieved against per day asking rates as per the planned dates,” stresses Project Manager, Mithilesh Kumar Verma. Driving productivity was within the team’s control as majority of works in PV Electrical was inhouse, so dedicated teams for each activity were formed that synchronized with their successor activities to ensure that all teams got ready stock of fronts, avoided idling, and improved productivity and workflow, as the same workmen were involved in the same activity.

In the ever-evolving landscape of power systems, reducing inefficiencies and optimizing project timelines are paramount for which adopting innovative technologies to simplify installations and reduce resource consumption are critical.

“One such innovation that has had a transformative impact on our project execution is the SKID Inverter Station,” explains Project Control Manager, S N H Prasad. “By replacing traditional MVPS equipment, SKID Inverter Stations have revolutionized installations, particularly by minimizing the volume of civil work required and significantly shortening installation time.” He adds that this shift has been pivotal to ensure the timely completion of their project.

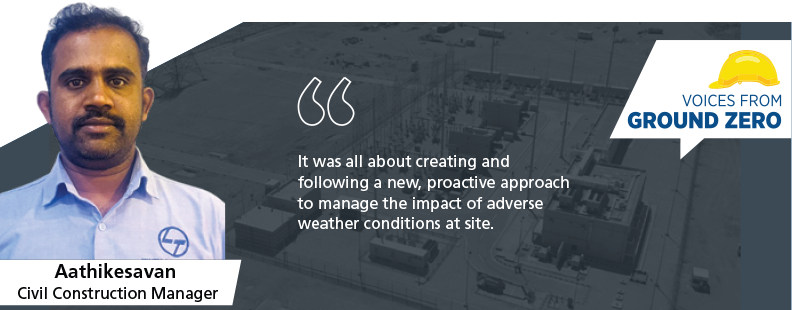

Combatting the weather and on-ground conditions

In the world of solar energy, as in any other construction field, unforeseen weather conditions can significantly disrupt progress. The trick is to anticipate and mitigate the impact of these weather changes to keep the project on track. Says Civil Construction Manager, Aathikesavan, “It was all about creating and following a new, proactive approach to manage the impact of adverse weather conditions at site.”

For their strategic planning, the team used weather forecast data in conjunction with local knowledge to be prepared for fluctuations before they occurred and adjust their workflows accordingly that not only safeguarded the integrity of the site but also helped to maintain the pace of construction. They faced abnormal rainfall for two months (March & April ’23), which was a rare occurrence in the area but a huge challenge, and the team had to be ready with adequate dewatering equipment to avoid any idle in electrical trenches and civil foundations.

Other steps to maintain progress included precast solutions for substation civil works, lighting & CCTV pole foundations, and PV communication tower foundations. “We used a slew of digital solutions at site,” says Avesh, reeling them off. “The QIR App for quality, SHEILD for safety, SharePoint for database management, timelapse cameras and drone surveys for geospatial, RFID cards, the WISA App for administration, Align for project monitoring, and BIM for engineering.”

Although resource mobilization was an uphill struggle, the team managed it and by constructing camps for the workforce, that solved the issue of non-availability of proper accommodation in the area.

Arranging material was another major challenge with the Russian aggression in Ukraine drying up supplies from Europe. New vendors were onboarded, with whom, the team continuously stayed in touch and with regular follow-ups, ensured timely delivery of materials, which in turn contributed to the timely execution of construction works.

Making Mission Zero Harm a reality

“On June 4, 2024, we were proud to announce that our team had successfully completed over 4 million safe working hours without any Lost Time Injuries (LTIs),” declares a delighted EHS In-charge, Mohamed Behery. “This achievement is a testament to the dedication, commitment, and constant vigilance of every team member in creating and maintaining a safe working environment.” A key factor in achieving this milestone was the 120,000 training hours conducted throughout the year. In addition to their internal safety efforts, the team also completed all external Environment & Safety (E&S) audits without any Non-Conformance Reports (NCRs) or major findings: another feather in Mohamed’s hat.

“It was a really tough project to execute with harsh timelines and even harsher conditions, but we succeeded thanks to our never say die attitude,” sums up an extremely satisfied Avesh. “I am sure in future many families will thank us for what we have created,” he concludes with elan.