Though he has been a part of L&T for half a dozen years, Krishna Telikicherla is happy to have enjoyed the scope to grow and implement new digital solutions, more particularly at his present assignment at the CIDCO project. “I have been provided with all the required resources and support,” he affirms, “and my seniors and team members have helped me develop and even improve the scale of digitalization at my project.”

He quickly shares several of the digital solutions that the CIDCO team has deployed. “The digital scorecard is a compact metric monitoring system to monitor implementation and usage on a monthly basis,” he explains, quipping that it has created healthy competition amongst their sites. “Digicast tracks the lifecycle of precast elements right from mould preparation to final erection. We have piloted this App at the CIDCO Kharkopar precast yard and are planning to implement it at CIDCO Navade too.”

Internally developed Power BI dashboards like finishing trackers, procurement allocation trackers, procurement invoice plans and progress monitoring tools drive efficiency while QR Codes placed at strategical locations across sites make it easy for engineers & workers to scan & share their query/issue for quick resolution. “We use Power Automate too to send mail notifications to Quality In-charges about the expiry of mix designs for them to take necessary action.”

Internally developed Power BI dashboards like finishing trackers, procurement allocation trackers, procurement invoice plans and progress monitoring tools drive efficiency while QR Codes placed at strategical locations across sites make it easy for engineers & workers to scan & share their query/issue for quick resolution. “We use Power Automate too to send mail notifications to Quality In-charges about the expiry of mix designs for them to take necessary action.”

The road to digital adoption has not been without some initial teething issues of overcoming the resistance of engineers to transit from conventional methods to digital ways. “Incentivising the project, developing methods to compute and monitor the metric, recognizing engineers for their achievements in the digital domain, and conducting training sessions have been some of the few steps taken to overcome this issue,” Krishna points out.

The problem of having multiple applications for multiple domains is issues of storage, training and transitioning. “Having one App with domains pertaining to all the trades at a project, be it EHS or Quality or P&M, would be more feasible and user friendly for engineers to operate and be more digitally tuned,” Krishna says insightfully. He hopes for one App that can reconcile all data: fetching it from EIP pertaining to material brought at site, data from the Progress Monitoring Tool & physical stock updates. “This will be so useful to monitor wastage percentages and in turn reduce wastage,” he smiles.

On a personal note, Krishna hails from Jharsuguda, Odisha. Though single, his work schedule leaves little time for leisure, but he enjoys trekking and playing cricket. One of his most cherished memories is receiving his master’s degree from IIT Madras, with his proud parents capturing the moment on video.

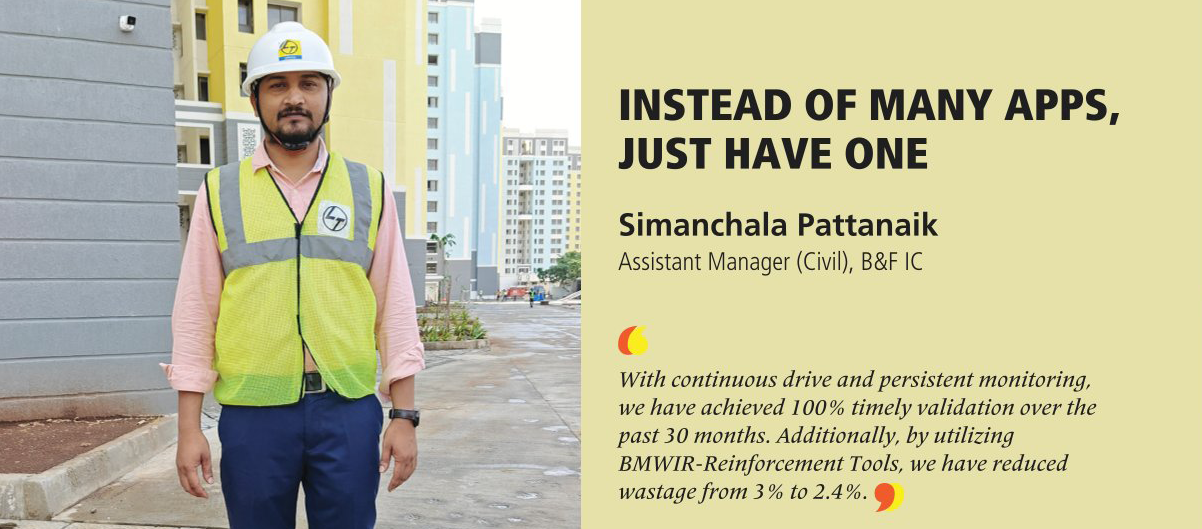

Simanchala Pattanaik brings a lot of passion to his current role at the CIDCO Bamandongri project, driving technology adoption with plenty of zeal. Convinced of its merits, he is already thinking of ways of how to improve adoption rates, and one method he advocates is to make it simpler. “Instead of using many different apps, it would be better if all the features were available in a single App like safety, conquer, BMWIR, WISA, etc.,” he says sagely. “I would also like to suggest that we develop a new App for material reconciliation covering the entire lifecycle from procurement to final consumption including payment to vendor and bill to client.” Regular workshops, hands-on training sessions, and real-time support will, he feels, bridge the knowledge gap and encourage more team members to embrace technology.

One digital initiative in which Simanchala has been deeply involved with and is happy with its success is the implementation of the BMWIR-Concrete & Reinforcement Tools. “Initially, our validation rate for BMWIR was less than 50%, posing a challenge to project timelines,” he points out. “We took it upon ourselves as a challenge, and with continuous drive and persistent monitoring, we have achieved 100% timely validation over the past 30 months,” he says, immensely pleased with their effort. “Additionally, by utilizing BMWIR-Reinforcement Tools, we have reduced wastage from 3% to 2.4%,” a testament to the power of technology in optimizing resources.

To address initial resistance to adopting & using the BMWIR application, the team started to monitor activities daily, discussing the tool at every monthly and weekly meeting, and highlighting the importance of its usage. “Our relentless focus paid off for we have achieved 100% adoption of the BMWIR tool,” he smiles at their success.

Reflecting on the support he receives from his seniors and team members, Simanchala says, “My seniors have been incredibly supportive, and their guidance and encouragement to take on new challenges have enhanced my skills and confidence in technology.” His team’s collaboration has been crucial too to implement digital solutions and maintain consistency across the board.

Beyond work, Simanchala hails from Balugaon, Odisha, and enjoys spending time with his family that comprises his wife, Arpita Pattanaik, a homemaker, and his son, ‘King’ Adrith Pattanaik. In his spare time, he plays cricket, reads, learns, and gardens.

A most cherished memory is being recognized with a BMWIR award during the IC Town Hall in Chennai on January 3, 2023, that was closely followed by the birth of his son.

Md Shadan Salik is most impressed with the professionalism that he has been experiencing in L&T that is also pushing him to grow and excel at his work. A GET, Shadan’s first assignment was at the AM Naik Tower project; 4 months later, he moved to the CIDCO Bamandongri project where he is busy with MEP planning and digital coordination.

“We are using the BIM Model for clash detection, quantity estimation and executing MEP works,” he mentions, sounding excited about his team’s technology adoption. “Our subcontractors are directly using the models to execute their work, resulting in minimal rework and more streamlined operations, and we use QR codes for digital feedback at site for real-time feedback and swift responses to any issues that arise, contributing to the overall efficiency and quality of the project,” he says, with a satisfied air.

If his project is one of the front runners in digitalization, it is because of several unique efforts like his Project Director’s initiative to earmark one day of the week as ‘Digital Day’. “On that day, we discuss digital applications, identify issues, explore improvements, and share new initiatives,” shares a charged Shadan. He is convinced that this regular, dedicated time has fostered a culture of continuous learning and innovation, with every Site In-charge playing a key role to drive the adoption and the use of digital tools and processes.

The initial reluctance of engineers to adopt the BIM model was one of the hurdles that Shadan had to overcome by organizing training sessions to educate the team on the benefits and applications of BIM such as minimizing rework and speeding up processes like quantity estimation and clash detection. “These sessions were crucial in shifting the team’s mindset and making them comfortable with technology,” he says, pleased with his efforts.

The initial reluctance of engineers to adopt the BIM model was one of the hurdles that Shadan had to overcome by organizing training sessions to educate the team on the benefits and applications of BIM such as minimizing rework and speeding up processes like quantity estimation and clash detection. “These sessions were crucial in shifting the team’s mindset and making them comfortable with technology,” he says, pleased with his efforts.

Looking ahead, Shadan sees room for improvement in the ‘Material NxT’ App and seeks new digital initiatives, like cost-effective sensors for material tracking, which could significantly improve the process of material reconciliation.

Outside of work, Shadan, who hails from Delhi and is still single, enjoys singing and sketching, assuring us that he finds very little time in his busy schedule to follow his passions. Among his most memorable achievements are receiving the BIM Excellence Award and the Digital Adoption Award for his project, accolades that underscore his commitment to innovation and excellence.

ON A STEEP DIGITAL LEARNING CURVE

Saranya C

Senior Engineer (Civil), B&F IC

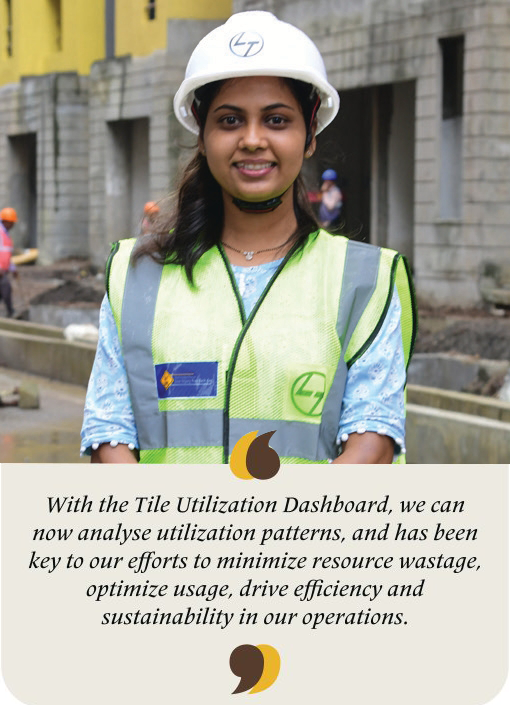

Her baptism, as it were, at her first project with L&T has been with digital solutions. “When I joined as a GET at the CIDCO site, I was introduced to various digital tools and their benefits through the experiences shared by my seniors,” recalls Saranya C. Since then there has been no looking back as she has immersed herself in leading technology adoption at her site in her capacity as a Digital Ambassador.

One of her earliest assignments was to introduce the pilot Tile Utilization Dashboard. “This innovative tool tracks utilization and wastage on a unit-by-unit basis throwing up comparative data on scope quantity versus issued quantity for site works,” she explains. “We can now analyse utilization patterns, and this dashboard has been key to our efforts to minimize resource wastage, optimize usage, drive efficiency and sustainability in our operations,” she rounds off with a sense of assurance.

It has not all been smooth sailing for Saranya for the team’s transition from Digital Store to Material-NxT did pose some significant challenges. “It was crucial to familiarize all users with the App modifications and address initial technical issues for which we organized training sessions for the site team and conducted kick-off meetings to identify and escalate issues to the BU digital team,” she informs.

On her rather steep learning curve, Saranya has been helped with valuable feedback from the senior management, including in areas for improvement, that have been instrumental in advancing the site’s digitalization efforts. “All my team members have fully adopted the digital tools used on-site,” smiles Saranya, happy with their support & involvement. “They actively participate in healthy competition to maintain their digital activeness scores, contributing to the overall site digitalization benchmarks.” She is of the opinion that proper pilot programs are essential before fully implementing any digital solution to minimize technical issues and to take on board user desirability.

Quickly learning her ropes, Saranya says insightfully, “Implementing automated workflows to draw approvals will be beneficial to ensure that the latest drawings are used by every stakeholder. When a drawing is updated, all relevant stakeholders should be automatically notified, and the approval process tracked digitally, to ensure accountability and reduce delays.”

Hailing from God’s own country, Kerala, Saranya’s is an engineering family: her husband, Abhinav Saxena, is a civil engineer too. She unwinds reading novels and listening to music.

As she grows in the company, Saranya is proud of L&T’s commitment to sustainability and social responsibility, working on projects that promote environmental conservation and community development.

He is a man of few words, a trait that is holding Aman Shrisath in good stead as he soaks in as much as knowledge about digitalization as he can. At the CIDCO Kharkopar project, his first with L&T, he finds himself at the right place at the right time being part of one of the most digitally active sites in L&T Construction.

“We are monitoring project progress on 4D BIM, that integrates time-related information into the traditional 3D model for accurate scheduling and project tracking,” he shares, elated at the opportunity to participate in the company’s journey of digital transformation. “Since we are now able to visualize project progress in real time, it is easier to identify potential delays and address them promptly.” Two other technology areas that he is involved with are using the BIM model to review the project along with the Consultant, Architect, PMC and EDRC prior to release of shop drawings and extracting quantities from the BIM model for procurement.

Aman credits his fast-track learning, among other things, to the opportunities he enjoys, and the networks he has been exposed to. “I am learning and developing also by attending conferences, working with tech experts, through training and on the strength of constructive feedback and recognition,” elaborates a resolute Aman.

It is critical for the technology being implemented to be user-friendly and aligned with the needs of end-users that Aman is acutely aware of. “It’s not just a matter of introducing new tools but also ensuring that they add value to the team’s work,” he notes, having gladly embraced the onus of communicating these concepts and even training team members on the new processes.

Looking ahead, Aman is keen on further integrating technology into his work, particularly in supply chain management, envisioning a system where IoT is used for real-time tracking, minimizing wastage and damages, and enhancing the efficiency of the entire process.

Hailing from Shirpur, in Maharashtra’s Dhule district, and still a bachelor, Aman enjoys travelling and music, finding solace in exploring new places and rhythms. His most memorable moment? A solo trip during which he found the space to connect deeply with himself and the world around him.

Reflecting on his short time with L&T and its role in nation-building, he says, “One aspect that I’m proud of is the positive impact that the organisation has on the nation’s progress.”

Reflecting on his short time with L&T and its role in nation-building, he says, “One aspect that I’m proud of is the positive impact that the organisation has on the nation’s progress.”

In his 13-year tenure with L&T till date, Suraj Takkar has worked at 6 projects including the celebrated Statue of Unity site where he recalls implementing several tech solutions. “We work in a fast-paced environment, where the project timelines are growing shorter day by day that we have even 3D-printed an entire post office in just 30 days,” he says with an immense sense of achievement.

Currently, at the Common Central Secretariat 1, 2 & 3, Suraj is implementing several tech solutions. “Asset Insight, Ib4U, the EHS App, IOT Analytics FLMS & FDMS (for fuel level sensing and dispensing), smart weighbridge solutions, MEHA Link (for all P&M audits and inspections), Asset NXT, WISA, Planning Saathi, Rise), Procube, Conquer and EDMS 4.0 are what we have deployed,” he elaborates.

Suraj is glad that he has been involved in developing several out-of-the-box solutions to help his project out of tricky situations like having to backfill basements with approximately 80,000 MT of sand without ramps for which the team identified a new mechanized solution, a LB40 Telebelt Conveyor to automate the whole process. Another was introducing a Concrete Recycling plant to filter out the coarse & fine aggregates from their slurry waste that was threatening to choke the city’s storm water drains according to the NDMC.

To meet the client’s special recommendation to use crystalline admixture powder in addition to chemical additives for better features of concrete, the team purchased a small silo, a loading hopper, conveyor, and batching accessories to programme batching of the crystalline powder from the batching plant.

Normally, sites construct huge underground tanks or use 50 KL or larger PVC Tanks to store water for construction. “At CCS, we installed Zinc-Alum modular tanks that are modular, can be assembled in any size, dismantled, re-used at the next site. It saved us costs,” explains Suraj, with a smile. “Covering the tanks with thermal insulation material and connecting them to 160 TR Chiller plants, we reduced the water temperature up to 7 degrees.”

Grateful to his seniors for their support in his efforts at digitalization, and for his timely training, he flags off M Pandian (P&M Head- CCS) & Sekaran S (TFL Head – CCS) for special mention.

Suraj has been recently married in April 2024 to Sugandha, who was earlier working at Kotak Bank in Chandigarh but now is seeking opportunities after shifting with him to New Delhi. “I like to do things focused on self-growth like reading books, pursing online tech courses on mechanical engineering, management, investing, future age technologies etc. and have completed my AMIE Graduation & MBA in Operations Management when working,” he shares proudly.

His journey at the Common Central Secretariat project is marked by a constant effort to integrate cutting-edge technologies into everyday operations. At his second project, that follows a successful tenure at the India International Convention Centre (IICC) project in Dwarka, New Delhi, where he was instrumental in executing the service gallery. That rewarding experience has significantly shaped his approach that he is now able to apply.

“The digitalized Safe to Start system through the SHEILD app is very useful, streamlining the entire process,” he explains. “We can update from our mobile phones without having to fill out paper forms or search for signatures.” He mentions using BIM (Building Information Modeling) and Trimble Connect Apps for 3D visualization. “These help us to resolve on-site issues between MEP (Mechanical, Electrical, and Plumbing) systems and the built structure while with the Procube platform, we can track project productivity, manage resources, and ensure timely delivery,” highlighting how technology is aiding to maintain efficiency and quality.

The elimination of hard copies has made life easier as also the introduction of digital solutions, but Deepak acknowledges the need for continuous improvement. “A special training programme involving all engineers would be very helpful,” he suggests, aiming to increase awareness and adoption of digital tools across the board. He envisions further advancements in technology integration and believes that equipping engineers with tablets for better viewing of drawings and BIM models could significantly enhance work efficiency and quality.

He credits much of his success to the support of his seniors and team members for their motivation and encouragement to adopt digital practices that have been pivotal in fostering a culture of innovation within his team.

Deepak’s story is not just about his professional achievements. Hailing from Bettiah in West Champaran, Bihar, he finds joy in simple pleasures like playing cricket and reading books, offering him a respite from his demanding job and helping him to maintain a balanced life. “After years of studying, when I got the job at one of India’s most reputed organizations, I was on cloud nine,” he shares with great excitement, a milestone that has marked the beginning of a journey filled with learning and growth. His dedication to embracing new technologies and his commitment to continuous improvement make him a true L&T ‘Tech Champ’.

STRIVING TO MAKE INNOVATION

A WAY OF LIFE!

Making significant strides in digital implementation at the Common Central Secretariat Project, Ajeet Singh is continuously learning and striving to make innovation a way of life. “Yes, this is my first project,” he confirms, but despite being new, he has taken things in his stride and is energetically implementing digital initiatives at site. “We introduced the Scope Award for top-performing site engineers and section in-charges that has proven to be a great motivator.”

Additionally, monthly refresher training sessions are keeping everyone on their toes on the digital front, which Ajeet feels are essential to keep everyone updated with the latest digital practices. He also highlights the importance of counseling low-performing site engineers and displaying the names of top performers on a wall of fame. “These not only motivate them to sustain their performance but also encourage others to strive for excellence.”

Daily monitoring of digital compliances is another key initiative. Ajeet elaborates, “This ensures that everyone is adhering to the digital protocols, leading to a more efficient and streamlined workflow.” He is extremely grateful for the incredible support, guidance, and teaching he has received from his seniors.

However, Ajeet’s journey has not been without challenges, like networking issues in the basement floors. “We have installed network boosters in the respective offices to improve connectivity,” he explains. Frequent change of staff has been another challenge, and the team is liaising with the digital team to resolve issues promptly. “Frequent training and monitoring have helped new staff to get familiar with our digital applications quickly,” he says, while third-party engineers have been on-boarded by creating dummy access with the digital team’s support to streamline processes. “To monitor digital compliance, the project head reviews the digital compliance status at all monthly EHS Committee meetings to keep the momentum,” Ajeet notes.

Hailing from Jaunpur, Uttar Pradesh, and currently unmarried, Ajeet enjoys reading books and listening to music in his free time. “Interacting with SNS Sir, participating in HR wellbeing programmes, and celebrating project achievements through various gatherings are some of my cherished memories,” he shares. He takes pride in the numerous awards the team has won too, including the BSC Five Star with Sword of Honor, the NSC Safety Award, the CIDC Vishwakarma Award, and client appreciation for achieving 35 million safe manhours.

Ajeet considers being part of L&T a great honour and finds diversity of work and exposure to different kinds of projects particularly enriching. “I have learned a lot and gained valuable experience from across various domains,” he concludes with a positive smile.

“One afternoon, I was at the IIT Madras, Building Science Block, sitting in front of 4 professors from different streams and possessing different expertise,” recalls Dhandapani M, with a sense of excitement. “I got a wonderful opportunity to explain the process and design aspects, and at the end we were enrolled and cleared to proceed to 3D concrete print the Post Office.” Although he has 18 years’ hands-on experience in high rise residential buildings structural design and coordination and is a consultant for water proofing, structural repair and a solutions provider for site execution challenges, there is no denying that he finds working on 3D concrete printing most exciting at his HAD Chandigarh project.

Naturally, all he talks of is 3D concrete printing. “It constructs concrete structures layer by layer using a special quick-setting concrete mix, with minimal human intervention, and eliminating the need for traditional formwork,” he explains, “relying on precise control of what I call the 3Ms – Material, Machines, and Methods – that need to work seamlessly together to ensure success.”

Being a new technology, it has required various brainstorming sessions and collaboration to arrive at the effective deployment of it in construction elements. “While not so much in smaller buildings like the post office, reinforcement detailing was a challenge in a larger project like HAD and the unique RC detailing has been painstakingly worked out to sync with 3D concrete printing,” says Dhandapani, seriously. HAD-Block 2 has a unique shape and every floor staggered to create the unique elegance, which meant a lot of structural challenges to achieve the curved beam connection, in execution and detailing. “My design and operation teams took the challenge as an opportunity and developed a suitable and workable solution to execute,” he shares triumphantly.

He is appreciative of the immense support from his seniors & team members for making such significant & successful in-roads into an entirely new territory. “We developed each step of the 3DCP process collaboratively, ensuring that every detail was carefully examined for strength and stability. Their motivation and encouragement empower me to achieve successful technology implementation.” Passionate about technology adoption, he believes that BIM (Revit) models can significantly enhance their workflow by seamlessly integrating all disciplines with the requirements of the 3D printer.

Originally from Mannargudi in Tamil Nadu, Dhandapani cherishes time spent with his wife, Bhuvaneswari, a homemaker and entrepreneur, and their two children, Harish Ragavendar and Sashtika. He enjoys long drives and listening to music during his free time, and proud to be contributing to nation building by implementing the latest technologies.

One of his favourite pass times is meditation and finding inner peace is certainly helping Ratnesh Tripathi to manage his work demands and the pressure of constructing to speed & scale. While, at one of his earlier assignments, at the DLF Crest project, the team implemented Prefab rebar cages on a large scale to reduce the cycle time to just 10 days, at his present project, the HAD project for BRO at Chandigarh, he and team are involved in 3D concrete printing at an unheard-of scale. “We are using 3D printing machines with all the necessary amenities for the very first time at such a large scale without any previous exposure and nowhere else in the world three 3D printers have been operated before with a single batching plant,” he flags off, with josh.

“We have been facing logistics issues during construction as the conditions are very dynamic and we have experienced some extreme weather conditions,” he points out. “Getting skilled workforce has been another huge problem,” he shakes his head. “We need to have production sector type of manpower to work in different shifts to achieve greater productivity and for this we have developed and formed a team of CSTI workmen at site to operate round the clock. And yes, we need to train them for some hands-on experience in technology, that is being used for first time on such a large scale.”

At site, Ratnesh is delighted with the support their team has been receiving from both the cluster & HQ levels through various in-depth discussions about logistics adjustments and understanding the technology to ensure smooth operations. “Our senior leaders have always supported us during some tense moments, which has helped us to think calmly and find solutions to overcome the various challenges, seen and unseen, in a timely manner,” he smiles, perhaps indicating that his meditation techniques are helping. He is convinced that BIM technology will significantly improve the working culture, in problem resolution for timely completion of projects. “BIM is also a better way to resolve clashes in activities during the work sequence,” he notes.

In addition to meditation, Ratnesh likes to read and write poetry and this native of Prayagraj, Uttar Pradesh, is married to Diksha, who is busy preparing for her Civil Services examination. Being a college topper, meeting MVS at the Grand Arch project site and meeting his wife are some of his life’s savoured moments.

“At L&T, your dedication and sweat will always be appreciated and considered by the top management without any biases,” he declares with conviction, “and every member of the L&T family will enjoy equal opportunities to grow.”

Engineers are normally forced to confine themselves to prescribed drawings but working with 3D printing technology, K Pradeep Kumar enjoys the license to dream, design & 3D print buildings of his thoughts. His journey with L&T has also been one with 3D printing having started at the first 3D concrete printed post office building project in Bengaluru. “It was a remarkable experience, not just because it was the first of its kind in the country, but we were entering into totally unchartered waters,” he grins. Presently, at his second project to 3D concrete print the HAD Campus in Chandigarh, he feels on top of the world as he looks at a new world of possibilities in construction.

In his role as Design Coordinator, Pradeep explains that the HAD Campus features robotic construction across six building blocks, five of which are being 3D concrete printed. “With this advanced technology, we can integrate the MEP services within 180 mm thick walls, optimized through solar studies and building simulations, and we have a neat, exposed surface without any need for plastering that is saving us cost and time significantly.”

Of course, working with such cutting-edge technology comes with its own set of challenges and Pradeep has had his fair share like placing lintels and windows on round-edged wall profiles requiring innovative solutions, such as creating a plaster band around openings to fit the window frames. “Careful coordination and planning are key to create structural beams with a 3D printed finish,” he observes and smilingly adds, “but with the guidance of my seniors and collaborative teamwork, we have been able to navigate these challenges successfully.”

Letting his imagination fly, Pradeep envisions precast 3D printing to play a bigger role in the construction industry of tomorrow. “Imagine structures being created in a factory setup and assembled on-site,” he says dreamily. “This will revolutionize the speed and efficiency of construction, allowing us to create far more complex designs.”

To unwind, Pradeep, a native of Tirunelveli, Tamil Nadu, and single, finds joy in painting and cooking. He cherishes the memory of organizing a farewell for his mother, who recently retired as a nurse, and for which he will be forever grateful to his L&T family.

“L&T is more than just a company; it’s a learning institution,” Pradeep reflects. “The emphasis on skill development and advanced technology training makes me proud to be a part of this organization.”

Not surprisingly, the highlight of Molli Simhachalam’s career with L&T is the successful delivery of India’s first 3D concrete printed Post Office in Bengaluru. “Receiving a message of appreciation from our Honourable Prime Minister Shri. Narendra Modi was exciting, as was meeting SNS Sir & MVS Sir at the first 3D printing project and interacting with them about the technology and process,” he enthuses. “Being appreciated by my IC Head for the very first 3D project was another highpoint,” he smiles broadly. Powered with that success, he is presently at the HAD 3D Concrete Printing Project for the Indian Army & the Border Roads Organisation at Chandigarh.

“As a part of P&M digitalization, with the support of the management and the project team, we fitted IoT devices in various construction equipment to monitor their performance data in real time,” he informs, “which has improved P&M performance and reduced fuel cost & other operational costs.”

Understandably, Molli has a lot to share about his 3D experience. “Since we were 3D printing in an open-to-sky environment, atmospheric variables like temperature variations could have caused difficulties, so we implemented a process to monitor the temperature and adjust the concrete rheology accordingly on a real-time basis,” he explains. Since the pumping rate of existing concrete pumps was much higher than the 3D printing output rate at 1–2 cum./hour, the team collaborated with the OEM to develop a custom pumping kit for 3D printing applications. A digital interface monitored from production to pumping to printing, to ensure seamless printing operations.

“We have been operating two printers simultaneously at HAD Chandigarh from a centralized batching plant, which is a first of its kind, after clearly analysing the process and implementing SOPs for trouble-free operations,” he elaborates. To address their challenge of the lack of experienced 3D operators, with CSTI – Delhi, they have identified a few CSTI electricians and trained them extensively on the job to engage them for 3D printer operations. “3D printing technology is currently limited to a maximum building height of 12 m, but we need to develop 3Ms (Machine, Material & Method) to print higher, for large-scale implementation.”

Molli appreciates the continuous support & valuable mentorship of his seniors, mentioning the trust that his IS, SLN Sir has reposed in him. “His collaborative spirit and encouragement foster a learning environment for me and my team, says Molli, who likes L&T supporting ‘upcomers’, investing time & money in youngsters.

On his home front, hailing from Paravada, Visakhapatnam in Andhra Pradesh, Molli is married to Mohini, a homemaker, and he reads to relax.