MAKING HIS MARK IN AN ENABLING CULTURE

Shidhalingappa Chanabasappa Bulla

Senior Manager (QA/QC), Heavy Civil Infra IC

What impresses Shidhalingappa Bulla most about L&T is the company’s “culture of innovation, digitalization and cost-effective practices.” He elaborates that his seniors are supportive and encourage the implementation of digital adoptions to achieve operational excellence, while his team members are collaborative, driven to achieve the desired goals of the project.

A lateral, who brings with him years of rich experience, CMRL-TU02 is his first project with L&T, and he finds himself on familiar territory implementing the ConEase App. “Back in 2008, our project had used digitalization for consumption of concrete including bill of materials (BOM) to monitor two batching plants at site in real time using the SAP Module and I was responsible for production and timely dispatches of concrete,” he recalls.

“We have been implementing ConEase from June 2022 to monitor requests created by Site Engineers, Planning Manager approvals, Quality approvals, concrete production, dispatches and receipts at site in real time,” he apprises, “and for FY2023–24, we have achieved 100% digital adoption and will continue to do so this financial year as well.” He mentions the Tunnel Segment Management System deployed at site, wherein RFID tags are inserted in the segment before concreting to capture the requisite data and monitor the segment tracking system.

“The key words to drive digitalization are Adoption and Implementation,” says Shidhalingappa, with a definite sense of purpose. “Initially, the number of people involved were lesser; however, with more people adopting and seeing its benefits and user-friendliness, there are more takers. I personally encourage my team and conduct weekly discussions on the same,” he affirms.

Is there something you would like to change? “Yes,” he nods, “like developing a software to optimize concrete mix designs for respective grades of concrete, by collecting the concrete ingredients’ material data from various projects and digitalizing incoming materials to inspect and validate (either by MTC or a third party) if the requisite property requirements meet the approval of the quality function.”

A native of Gadag, in the state of Karnataka, Shidhalingappa and his better half, Manjula, a homemaker, are blessed with, as he describes, “two lovely daughters, Sahana & Supriya, and some of my most enjoyable moments were my motorcycle rides with my elder daughter, Sahana, on Sundays during my stint in a highway project in Karnataka.” Another highlight was his younger daughter, Supriya, securing 97.4% marks in her XII CBSE exams this year. His other favourite pastimes are reading books and listening to music.

Although only 5‑years-old in L&T, Athira Sheeja is convinced that the Company’s success in its digital transformation lies in 100% implementation and one of the reasons why she loves L&T is because the Company encourages employees to come up with new technology/digital initiatives that will be productive at site to make processes easier.

Fortunately for her, Athira is getting ample opportunities to be a Tech Champ working in contract management for CMRL’s TU02 Project since 2023. “I joined CMRL TFL‑1’s Planning Department where I began my digital journey of adopting and implementing various digital solutions, along with my other planning responsibilities for both projects.” To ensure 100% implementation, she monitors daily, speaking to the end users to understand their difficulties during site visits.

A GET from the batch of 2019, she began her career in L&T Hydrocarbon (Offshore), working in the Marjan Increment Program Package‑2 Project as design engineer where she learnt and successfully contributed to the various analyses conducted for offshore oil platforms.

At CMRL TU02, Athira has been involved in the adoption & implementation of the Tunnel Segment Management System that uses passive IP-67 cast-in RFID tags and barcodes from which data can be read using a RFID reader/writer. “The scope of the Tunnel Segment Management System is to make available the entire lifecycle process data of the 18,000 precast tunnel rings segment-wise from casting to erection and keep the data alive for a span of 15 years,” she informs. Another remarkable innovation is the inhouse development of the Tunnel Inventory Management System which is in its initial phase of implementation. “It focuses on the consumption of tunnel consumables, its stock details, critical material, stock levels, etc., for 8 TBMs and their 32 drives and we intend to capture this data for further analyses as a record for future projects,” Athira shares.

She is happy that her seniors have been encouraging and promoting the adoption and implementation of digital initiatives by monitoring their concerned department juniors about implementation levels. “My team members enthusiastically attend training programs to understand, adopt, implement digital solutions, give feedback and even raise constraints or errors,” she adds with a smile. She is hopeful that soon there will be AI in Contracts to compare and summarize documents, assess risks, identify similar projects in the database, and suggest similar scenarios for present project details for reference through risk registers.

Hailing from Kerala, Athira loves to paint when free, aiming to be financially independent to support her family.

“AI IS THE EMERGING TECHNOLOGY.

LET’S PURSUE IT FURTHER.”

Bibek Kirtania

Engineer (Civil), Heavy Civil Infra IC

Bibek Kirtania

Engineer (Civil), Heavy Civil Infra IC

He may be at his first project with L&T at the CMRL TU 02 site, but Bibek Kirtania certainly has his fundas clear. “AI is the emerging technology, and we should definitely be pursuing it more by introducing AI-powered solutions at site,” he says with total conviction. In the area of technology adoption at site, he is excited about the many ‘firsts’ that his project is credited with.

“For the first time, we have installed RFID tags embedded into the concrete to retrieve entire details about the precast segments using a RFID reader/writer for the next 15 years,” he shares, additionally mentioning about the successful mobilization of the automatic concrete distribution technology for tunnel lining segment casting instead of using the traditional concrete transit mixer. “It is environment friendly, and reduces the casting time cycle,” he says with a thumbs up. “For the first time in India, we have adopted automation technology for tunnel lining segment rebar cage fabrication without any manual intervention. It is in the final stage of implementation.”

For the continued success of the digitalization efforts, Bibek feels that is important to foster an innovation driven culture where employees are encouraged to explore and experiment with new technologies. “Regular hackathons, innovation challenges and cross functional collaboration can promote this mindset,” he remarks. “We also need to invest in continuous training programs for employees, providing workshops, certifications and hands-on sessions to enhance their technical skills and empower them to adopt and adapt to emerging technologies.” His sound advice belies his experience.

Initially they did face challenges to implement new technologies at site due to the lack of knowledge about how to run the new technologies smoothly. “In the case of RFID, we took some key steps to ensure smooth operation, like dedicated and proper communication with the developer’s team and linking the entire barcode system with RFID tags to integrate it into the web portal. For the automated concrete distribution system, we made a few changes at site level during implementation along with the technology partner to enable smooth operation of new system.”

Hailing from Kolkata, West Bengal, Bibek is still single and when he has played his role enthusiastically at work, he expends his energies on other things that thrill him like cycling, playing cricket and listening to music.

A memorable moment? “Joining L&T, a dream come true,” he says simply.

HE’S A DOUBLE DELIGHT FOR HIS PARENTS

Sandeep Saini

Assistant Construction Manager (Civil), Heavy Civil Infra IC

“Being the son of a farmer, my parents always wanted me to excel in life,” recalls Sandeep Saini, earnestly. “They were very happy when I got selected in NIT Hamirpur for my graduation and overjoyed when I got selected by L&T through campus placement. Those have been some of my life’s most memorable moments,” he grins.

A GET of batch 2017, he started at the Punatsangchhu Hydroelectric Project 1 (1200 MW), Bhutan after which for the last four-and-a-half years, he has been at the RVNL Package 2 project, initially in the Planning Department and presently at ADIT‑2 site to execute the main & escape tunnels, laybys and cross passage lining activities. “I have supervised the erection of 2 main tunnels, 2 escape tunnels, 1 layby, and 1 cross passage gantry along with experts from M/s. TFI, Italy, and now looking after the lining activities.”

There are 48 laybys in the escape tunnel at distances varying from 100 m to 375 m, but since the cross-sectional area for the layby is more than that of the escape tunnel, it was not possible to shift the full-length layby gantry to cast the laybys. Re-erection and dismantling the gantry in each layby would have been costly & time-consuming. “After many discussions with various gantry manufacturers, we decided to have 3 panels of 3 m each that could rotate 360° along its centre with individual power pack and hydraulic systems,” shares Sandeep. “This ploy saved us both time and cost and we have successfully completed casting for 3 laybys. Other packages are replicating the same design and implementing the same procedure to cast laybys at their package,” he winks.

Explaining another challenge, Sandeep shares that as the lining for main and escape tunnels progressed and gantries completed more than 1 km of lining, the team started to notice undercuts and over breaks above the tolerance limit as specified in the Contract in some of the sections of the casted overt. “Normally, one side of the gantry overlaps with the previous casted pour and is aligned on the other side. To overcome this issue, we did 2nd checks by placing a profiler below the gantry to check the profile of the shutter plate from inside and have increased the frequency of gantry maintenance.”

“We share all our ideas/solutions with our seniors and management about issues being observed at site that are always taken positively and we are given a free hand to implement,” says a satisfied Sandeep.

Interestingly, his wife’s name is also Sandeep Saini! She looks after his home, and when free, he reads books & watches videos about trading & investing in the stock market.

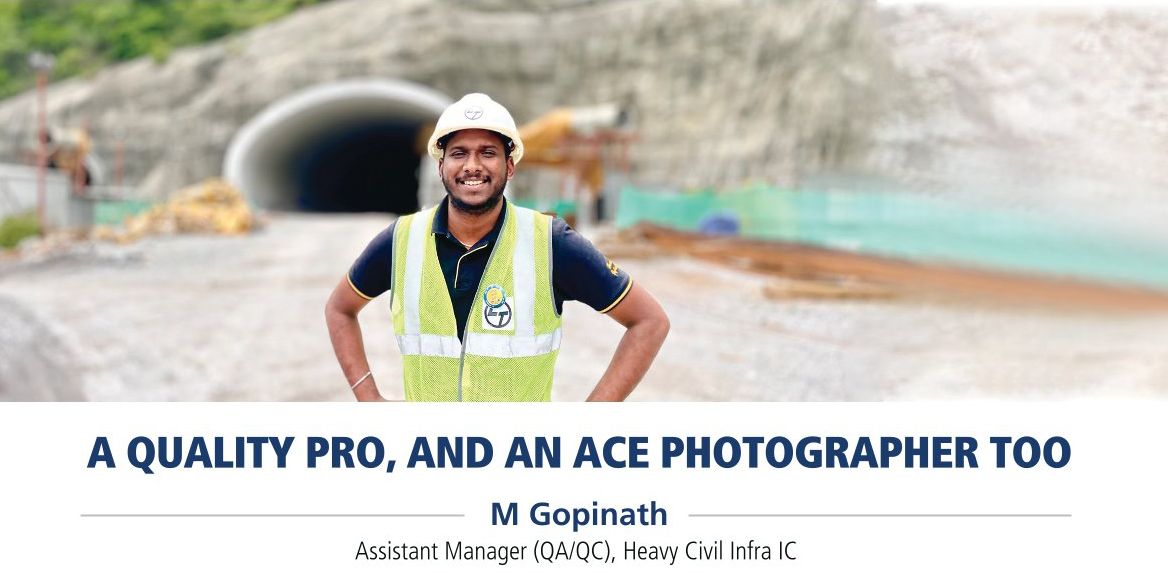

“I am an intermediate level photographer and love clicking landscapes, nature, wildlife but astrophotography is my all-time favourite,” shares M Gopinath, excitedly. Nominated among the ‘Top 40 Photographers from across New Delhi’ at the 9th Annual International Photography Contest 2023, his work is showcased in the 35 Awards Hall of Fame. He is equally passionate about his journey with L&T that began in 2013, which he describes as a dream come true.

At his present assignment at the RVNL Package 2 Project after stints at the Lata-Tapovan HEP (171 MW) & Singoli Bhatwari HEP (99 MW) Hydroelectric Projects, Gopinath is busy maintaining Quality Assurance & Quality Controls, ensuring lab functioning, testing incoming material, implementing PQP & QMS, establishing mix design, procuring source approvals, creating and following method statements. “I am also an Internal & ISO 9001 Lead Auditor, regularly submit data to client, identify and mitigate risks, conduct MRMs,” he waves his hand to signify a whole lot more.

Gopinath has been involved to implement Non-Destructive Testing (NDT) for concrete strength assessment and Energy Absorption testing on Poly Fibre Reinforced Shotcrete (PFRS) at RVNL. A passionate advocate for advanced technologies like the EV2 (Plate Load Test) for soil testing, he is part of various digital applications aimed to streamline quality control processes.

Combatting mindsets was Gopinath’s initial challenges to deploy the ConEase App. “However, with support from the project management and continuous awareness training along with regular microlevel monitoring, we have achieved 100% adoption, he declares victoriously. “We used to hold weekly meetings with section in-charges and engineers to address their challenges to adopt digital apps inside the tunnels that have yielded results with time.” Recently, HCI launched the ‘Equalizer-Quality Sanyog’ digital app to monitor project quality activities in real time. “I took responsibility to measure and evaluate the digital aspects and data transformation and digital working process of the app at my site.”

Joining the RVNL Project in February 2020 is a matter of pride for Gopinath. “It has significantly transformed my professional life,” he shares, “for apart from enhancing my technical skills in engineering, it has shaped me into a better team player, broadened my knowledge and thanks to this incredible project, I was honoured with the ‘Best Quality Engineer’ Award in 2021 and the ‘Best Quality’ Project Award in 2023, both in our annual Townhalls.” He is grateful to be working with a wonderful and energetic team, who eagerly adopt his concerns and wholeheartedly support him to effectively complete his tasks.

Hailing from Tiruchirappalli, Tamil Nadu, Gopinath admits that in addition to photography, he enjoys exploring adventurous places, traveling, and riding bikes too.

Although only two and a half years old with L&T at the RVNL Package 2 Project, having joined in 2022 as an Engineer Trainee, young Acshat Joshi is thrilled about the trust he has already won from his site leadership. “They have given me the opportunity to be a Digital Ambassador, are always open to discussions, and have always supported and encouraged me, providing valuable feedback by discussing the pros and cons about my ideas.” This kind of support has strengthened him to grow into his challenging assignment in Contracts Management.

What he has found most rewarding is his success in implementing a comprehensive Project Information Management System (PIMS) across five different site locations for real-time progress tracking, systematic documentation, and efficient communication among clients, engineers, and teams. It certainly was no walk in the park, as Acshat shares: “Initially, people were unaware of the benefits the platform could provide. It seemed to be an additional work for them and hence they were reluctant to adopt. But little did they know that this platform would help them to reduce redundancy. We organized training sessions to highlight its advantages, importance, and standard procedures of updating progress, communicating, monitoring, and analysing.”

He is equally delighted with the other digital initiatives implemented at site such as the tunnel communication system, video analytics, fuel management system and digitalization of key equipment like drill jumbos, shotcrete machines among others. “All these digital technological changes and initiatives have benefited the project in terms of productivity, cost, quality & safety,” he sums up with evident pride. Acshat’s responsibilities also include co-ordinating with the corporate digital team and a third-party developer to develop an app to optimise the use of explosives in tunnelling operations that should help future tunnelling projects using the NATM method.

He rues that had the employer been more flexible, the team could have adopted more digital technologies to streamline some of the processes such as billing, quality testing, etc. “However, we are still trying to hold the employer in confidence to introduce more digital initiatives with frequent meetings,” he grins.

According to him, L&T is an organization that fosters professional growth and innovation. “L&T’s commitment to promoting innovative ideas to solve business problems is inspiring. It is certainly a place where you can dream big and achieve great things,” he says with humility.

A Lucknowi by birth, and still single, Acshat’s hobbies include listening to music, reading books, travelling and clicking random pictures and is glad that after streamlining his work and with better time management, he manages to follow his hobbies.

FULL OF JOSH, READY TO TAKE ON THE WORLD

Samim Khan

Engineer (Elec), Heavy Civil Infra IC

He proudly exhibits a certificate of appreciation awarded in August 2022 recognizing Samim Khan’s impressive performance at his first site, the RVNL Package 2 Project that he describes as one of national importance. “I am always eager to introduce new initiatives to increase output and save costs,” he declares, mentioning the several technology initiatives introduced at his site including the installation of GPS devices across machinery, optimizing processes and enhancing the digital fuel monitoring system. “IoT connects both our batching plants and three weighbridges; with the ConPro App we track concrete and extensively use the IB4U App for P&M,” he reels off.

Considering the huge quantities of high-speed diesel consumed at large project sites, any saving directly impacts the bottom line. Samim shares the challenges they were facing with respect to receiving shortage of diesel from IOCL, pilferage, and the absence of any system to track consumption. “We have now integrated the entire fuel chain by connecting underground fuel tanks with sensors, static dispensers, and fuel bowsers with RFIDs and can now monitor the entire chain and analyse consumption, restrict pilferage, and have increased fuel mileage,” he says with a thumbs-up. To overcome some of the technical, operational, organizational and external challenges he encounters at site, he says, “I combine technical expertise with effective planning, communication, and problem-solving skills to minimize the challenges and maximize output.” Clear about his fundamentals, Samim says, “I am all for fostering a culture of continuous learning and upskilling my team members to accelerate technology adoption, for with more training and resources focused on emerging technologies, technology adoption will be smoother,” he points out with josh.

A good example of good work being rewarded at L&T, Samim’s most memorable moment was being recognized for his best P&M practice at the IC Town Hall in 2023. “I have been awarded for taking the initiative of installing Fuel Level Sensors and GPS devices in all machinery on the category of Process Improvement- Innovation in the Digital Fuel Monitoring System and was appreciated by the site for achieving the 1st Tunnel Breakthrough of RVNL Pkg-02.” His sense of accomplishment is so refreshing. “I am proud of L&T’s commitment to innovation and excellence in engineering and for contributing so significantly to the development of the nation and beyond,” he rounds off proudly.

Hailing from Howrah, West Bengal, Samim is still searching for hislife partner but in the meantime enjoys his various hobbies like readingscience fiction, playing cricket, and watching videos about unknown facts on YouTube.

MAKING HIS MARK AT AN ICONIC PROJECT

Neeraj Kumar

Senior Manager (QA/QC), Heavy Civil Infra IC

A lateral thinker, bringing with him years of rich experience, Neeraj Kumar is making his mark at India’s longest tunnel project, the RVNL Package 4 and his recognition as a Tech Champ is hardly surprising, considering the various technology solutions he is implementing. “We use the VMT System to measure precast moulds and segments in 3D,” he ticks off, “SDS or Segment Documentation System to track the casted pre-cast segments from casting to erection inside the tunnel eliminating paperwork, the ConEase App to track concrete production and control wastage, the Rebar Pro App to reconcile the reinforcements used in the different structures and the Equalizer (Quality Sanyog) App to improve project deliverables, raise QIRs, PIRs, site walk-downs, and training.”

Having tasted the benefits of technology, Neeraj is a strong advocate of driving technology adoption more effectively across L&T. “To drive implementation, we need more structured training programmes that highlight the benefits and practical applications of new technologies, and by doing so, we can ensure a smoother transition and greater acceptance of new technologies within our organization,” he notes astutely.

Working with TBM, using the NATM method and tunnelling in unforgiving Himalayan terrains, the team has been facing several uphill challenges like water seepage inside the tunnel which was addressed by introducing economical mix designs in backfill grouting for quicker setting to build the grout layer. “To measure moulds and segments, I arranged for the technicians to be trained to improve their competency levels to effectively use the 3D laser tracker,” he flags off. When the M‑60 grade mix design was inconsistent with the aggregate source, the team quickly experimented with various concrete mix trials with different proportions to establish the consistent and proven mix for segment casting.

Success in the construction industry is never a one-man show, and Neeraj readily acknowledges the guidance, mentorship, support, & constructive criticism from his seniors and team members that have strengthened him for his various battles at site. “Apart from helping me to refine my skills, they involve me in challenging projects that push me to learn and innovate. Their encouragement and collaborative spirit create a positive environment where I feel empowered to take the initiative and excel in my role,” says a charged Neeraj, who is proud to be part of a nation builder.

Hailing from Udhampur, Jammu and Kashmir, Neeraj’s family comprise his wife, Pooja Mahajan, a homemaker, and his two lovely children, Tanishka & Tashvi. Neeraj likes playing cricket & travelling, and a most cherished memory is a family trip to the Nubra Valley in Leh Ladakh.

Hailing from Udhampur, Jammu and Kashmir, Neeraj’s family comprise his wife, Pooja Mahajan, a homemaker, and his two lovely children, Tanishka & Tashvi. Neeraj likes playing cricket & travelling, and a most cherished memory is a family trip to the Nubra Valley in Leh Ladakh.

Having joined L&T as a DET, Manu Prasad has had the opportunity to work at some key projects like the 520 MW Parbati Hydro Power Project, Himachal Pradesh; the 1,020 MW Punatsangchhu Hydro Power Project, Bhutan; and presently at the RVNL Package‑4, India’s longest railway tunnel project with NATM and TBM. With his overall experience, Manu has started to appreciate what imagineering is all about.

He is excited about the Korean-made automatic carousel plant the team has installed at the casting yard for TBM tunnel segment production. “The Korean-made automatic carousel plant has a PLC operated control system, and with its proximity sensors and limit switches, it helps to move moulds on the rail tracks to speed up segment casting,” he explains. Other tech interventions include IoTs (GPS, fuel level sensors, RFID tags) in P&M equipment, fuel level sensors for effective fuel management, operational efficiency, and cost savings. “With accurate real-time data, we can prevent fuel theft, ensure timely refuelling, maintain smooth operations, and maximize productivity.”

GPS devices are acting as powerful tools to improve project management, improve security, and operational efficiency. “With GPS-enabled IoT devices, we are easily tracking the location of assets, providing insights into equipment utilization, and ensuring that assets are not lost or stolen,” he adds with a thumbs up.

A tough project being executed in tough conditions call for innovations and Manu shares a few examples of the team’s clever thinking like installing a water treatment plant to supply pure water for the steam boilers and an automated polyfibre weighment system at the batching plants to show the quantities of polyfibres in the batch sheets. In his wish list, is AI powered predictive maintenance in plant and machinery and to drive tech adoption, he recommends training, resources, workshops, rewards & recognition.

“During monsoon, cement bulkers were unable to reach our project due to landslides, so we installed additional cement silos (2 × 200 T) at the batching plants to operate them like secondary cement feeding sources and ensure unhindered segment casting,” says Manu, who is grateful to his seniors and team members for their valuable mentorship, constructive feedback to identify areas for improvement and develop new skills and for sharing their experience. “Their support boosts my confidence and motivates me to excel,” he says with josh. “My team members help me analyse mistakes and develop improvement strategies.”

From Calicut, Kerala, Manu’s small family is his wife, Neenu, a homemaker, and their son, Rishvedh. Cricket & travelling help him chill, and he fondly recalls a family trip to Badrinath.

EMPOWERING INNOVATION, TRANSFORMING IDEAS INTO DIGITAL REALITY

Ankur Jain

Manager (Systems), Heavy Civil Infra IC

Having started his innings with L&T in 2012 as an Assistant – ISD Systems at the CC-27 Delhi Metro Project, Ankur Jain has since had several reasons to celebrate with a company that he prides for its dedication to exploring imagination and fostering innovation. “I have been recognized with several awards,” he says excitedly, “including the Best Project ISD – 2023, Best Digital Ambassador – 2023, and Best Digitally Savvy Project – 2023 in the MEGA category.” Currently at the prestigious RVNL PKG‑4 Project, he is involved in constructing Asia’s longest railway tunnel.

Implementing the advanced Tunnel Communication Technology is a tech innovation that Ankur is particularly proud of, which improves real-time monitoring, ensures seamless connectivity, and enhances their ability to manage activities inside the tunnel. He proceeds to list out several other digital solutions deployed at site that include RFID systems to track assets; ConPro to manage concrete, reduce wastage, and improve tracking; Material NxT that streamlines material management; Weigh Bridge Systems (WBS) tamper-proof with secure data storage to prevent unauthorized access; the Leaky Feeder solution to enable critical communications for emergency services in challenging environments.

“We deploy video analytics to increase security and gather operational insights, HK Connect that integrates site reporting and management reviews, VMT (Vehicle Monitoring Technology) to track and manage construction vehicles, and WAS (Workmen Attendance System) to digitally track attendance and monitor productivity,” he elaborates.

Operating in a hydel location, a major hurdle was the lack of data connectivity and mobility. “I implemented RF devices with an air distance of 5 km to create a single dashboard to monitor project progress across all locations,” Ankur shares his initiative. “This solution has greatly enhanced our ability to track and manage the project effectively.” He would like to improve the procurement process to track materials from Purchase Request Creation (PRC) to Material Receipt Note (MRN) at each location for better visibility and control over material management.

Ankur is extremely thankful to his seniors and team members for the pivotal role they have played in his success story. “Their guidance provides valuable insights that enhance my contributions and foster a collaborative environment to make my work more fruitful and meaningful,” he says with ardour. “Pride here is not just about grand achievements but also about the small, everyday moments and qualities that make us unique and valuable contributors.”

A native of New Delhi, Ankur’s better half is Rupali, a homemaker, and he admits that his life’s best moment was his marriage to start a new chapter. They are blessed with a son, Mridul, and a daughter, Urshita. Ankur’s other loves are traveling and exploring new places.

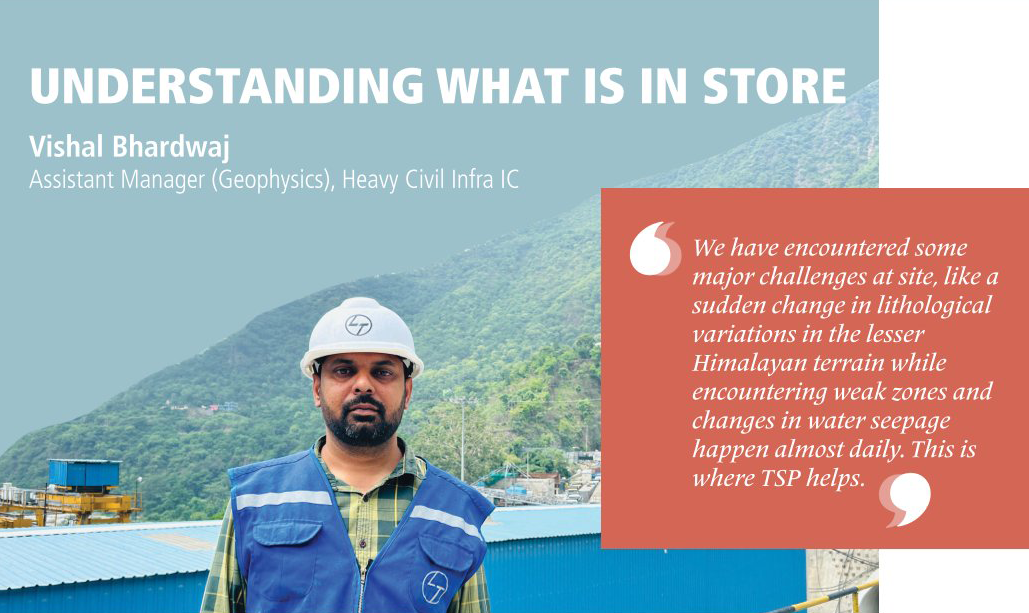

At the challenging RVNL Package 4 project, where the team is tunnelling into the Himalayas in entirely unchartered territory, it would help them greatly if they had some idea what is awaiting them as they dig deeper and geophysicists like Vishal Bhardwaj can help with techniques like the tunnel seismic predictor. “TSP is used in railways, highways and various types of hydro power underground tunnelling systems to anticipate the geological conditions that could be encountered during tunnel construction, relying on seismic methods to gather information about the subsurface conditions before and during the excavation of a tunnel,” he explains, sounding almost professorial.

TSP helps in geological mapping to predict the types of rock or soil that will be encountered, including their strength, weak zones, & water content and to manage risk by identifying potential hazards such as fault lines, water-bearing strata, or unstable rock formations. He explains that work at RVNL involves both acquisition & processing work. “As part of acquisition work, we measure the seismic waves generated by the impact hammer inside a tunnel, acquire accurate data without disturbance, marking the position for testing and coordination with the tunnel team, check the quality of the raw data, edit the geometry of the layout, if required, and perform tests with the good quality data,” he explains.

Processing work involves getting & processing the raw data either from the Cloud or file, generating results in about 6–8 hours, computing the geo-mechanical parameters like P & S‑wave velocities, Poisson, Young’s, shear, bulk modulus, and submitting reports.

“We have encountered some major challenges at site,” he says gravely, “like a sudden change in lithological variations in the lesser Himalayan terrain while encountering weak zones and changes in water seepage happen almost daily. This is where TSP helps,” he smiles tightly, “by continuing to analyse rock mass conditions and taking remedial measures before proceeding.”

In terms of improvements, Vishal recommends the introduction of seismic and well data software QA/Testing/Scrum MASTERLandmark decision space Geoscience for seismic analysis, velocity modelling, lithology interpretation, AWS & Azure DevOps.

A lateral, having joined L&T with years of experience in other companies where he has worked on Mesa 3D, NDT (Ground Penetrating Radar), & Shallow Seismic Refraction Method, Vishal is impressed by the opportunity here for every employee to explore his/her potential.

Hailing from village Siwan, in Haryana’s Kaithal district, Vishal is married to Rubi Rani, a homemaker, and blessed with a son, Dhanjot, whose birth “made me happier and more joyful and that feeling is still with me,” he says lovingly. He reads newspapers when free.

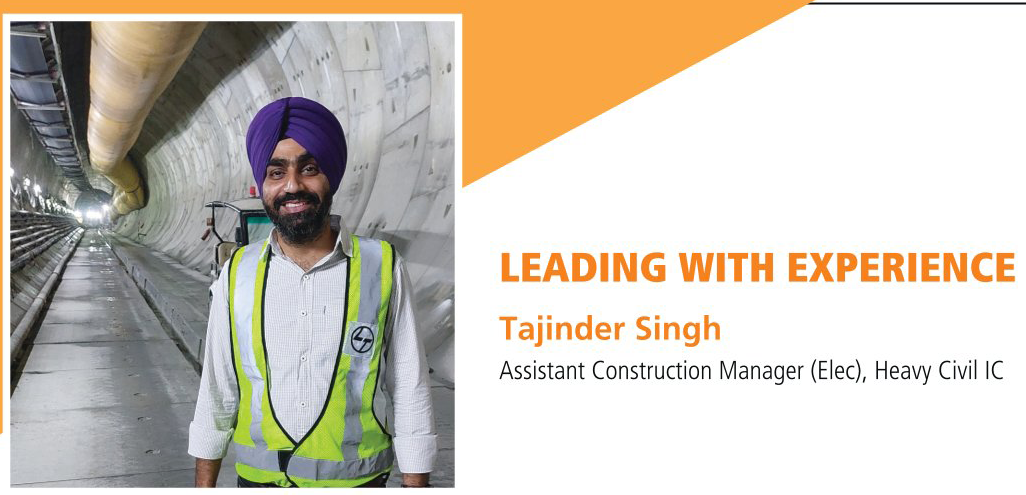

“Having successfully assembled 18 TBMs and achieved 13 successful TBM breakthroughs, I am able to guide and lead my team through the ups and downs encountered during TBM operations,” shares Tajinder Singh, referring to his previous experience with other companies before joining L&T, that includes overseas stints in Singapore & Qatar.

Presently Tajinder is busy at the RVNL Package 4, constructing a twin tube tunnel with hard rock single shield TBM in the Himalayas, and considers himself fortunate to be working with some “great and innovative minds” helping him to develop critical thinking, evolve strategies for unforeseen circumstances and find definitive approaches to minimise/ alleviate such events. “My seniors and team members are highly skilled and qualified, creating an environment of zeal towards work and challenges to keep us motivated as a united working front,” he says passionately. “Their support invigorates me to pursue excellence,” adding that being entrusted with the responsibility and freedom to execute ideas at site, is helping him build excellence in learning and development.

TBMs are at the centre of Tajinder’s life. His initial challenge was to transport the two overweight and over dimensional TBM parts & equipment through the narrow & challenging Himalayan terrain, for which special self-propelled modular vehicles were used. “We transported them using 8/12 hydraulic axles trailers with the cargo laid horizontally and at the orientation change point, a tower stand jack system was set up,” he explains. Their next challenge was to assemble the TBM machine in 8 weeks.

“We did it in 6 weeks,” he laughs delightedly. “Our last major problem was to push the TBM about 600–700 m to the launching point which we achieved with an innovative skid jack system.”

While Tajinder has had opportunities earlier to adopt tech, he is keen to implement such innovations at L&T too by organizing training programmes to create awareness and critical thinking amongst his peers and professionals. “This will help us to have better innovators and thinkers amongst us to lead the future of L&T,” he says zealously. Towards improvements, he recommends the creation of an innovative power backup system with no lag/ buffer/ kick in time without loss of power, to eliminate stopping and interventions to the TBM during the drive.

A native of Punjab’s Hoshiarpur district, Tajinder is married to Harjot, a homemaker, and their family is complete with their two children, Namreen & Nehmat. While becoming a father is what he cherishes, he enjoys playing badminton, working out and watching sci-fi & adventure movies.

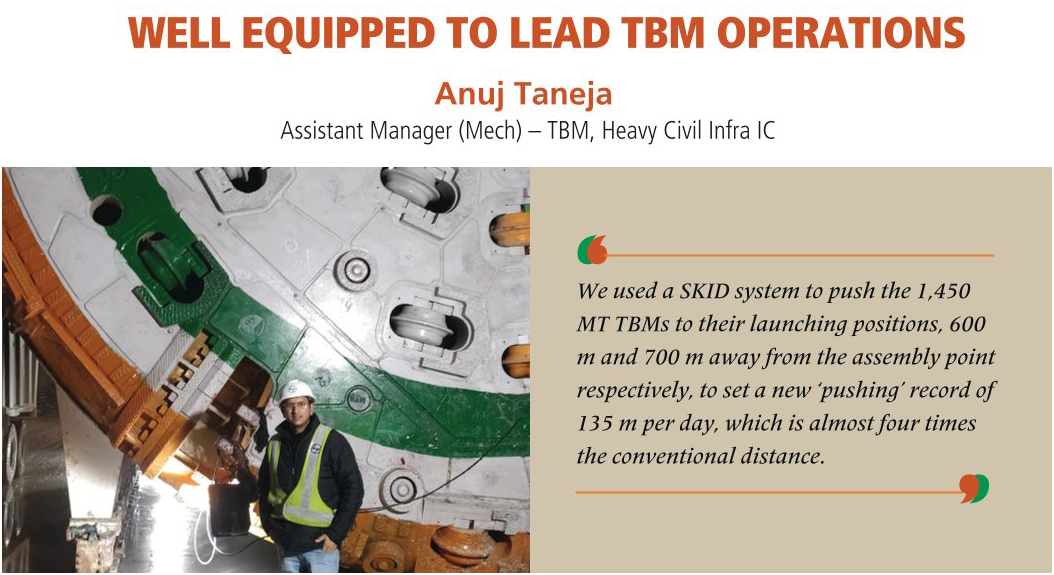

“Throughout my experience, I have worked with 4 Slurry, 1 EPB, and 2 Hard Rock TBMs, as well as in a manufacturing unit and this diverse experience has equipped me to guide and lead my team through the challenges encountered during TBM operations and manufacturing, successfully navigating any issues that may arise,” says a confident Anuj Taneja, from his RVNL Package 4 project. Although his first with L&T, Anuj brings with him the experience of having worked at other challenging projects for other construction companies.

Being a TBM expert, TBM is Anuj’s favourite subject. “We used a SKID system to push the 1,450 MT TBMs to their launching positions, 600 m and 700 m away from the assembly point respectively, to set a new ‘pushing’ record of 135 m per day, which is almost four times the conventional distance,” he shares proudly. “We utilize HK Connect to monitor all the working equipment established in the TBM, to ensure optimal working parameters and conditions.” A 10 km long tunnel conveyor belt (Make H+E Power 315 X 3 KW) and booster for the tunnel belt are connected to the TBM via an optical fiber cable, he notes too.

Referring to the team’s initial challenges of transporting the overweight and over-dimensioned TBM parts and equipment through the narrow and challenging Himalayan terrain, Anuj mentions using Self-Propelled Modular Transporters (SPMT), after conducting prior route surveys and live testing the bridges, and 8/12 hydraulic axle trailers, with the cargo laid horizontally. A tower stand jack system was set up at the orientation change points. Faced with the challenge to assemble the TBM machine in 8 weeks, the team did in 6 weeks handling some major heavy-weight consignments, such as the Main Drive, Cutter Head, TBM Shield, Tail Skin, and Erector. “Our technical team brainstormed to come up with a solution involving a 1000 MT gantry, a method never before attempted in India, particularly in the challenging Himalayan region,” highlights Anuj.

“Constructive criticism has helped me build a great approach towards excellence in learning and development, which is why I am a proud L&T‑ite,” shares an enthusiastic Anuj. “And yes,” he nods, “I would like to see more frequent implementation of innovative technologies and training programmes to create awareness and foster critical thinking among my peers and professionals,” which he believes will develop better innovators and thinkers within L&T, driving the future of the organization.

Hailing from Nahan, Distt. Sirmaur, in Himachal Pradesh, Anuj is single and finds ample time and opportunities to follow his passions, playing badminton, engaging in adventure sports, and watching sci-fi and adventure movies. His first international trip is one of his most memorable moments.

She is at her first assignment with L&T at the RVNL Package 4 Project, but Mahima Rajput is focussed to ensure 100% implementation of all the digital Apps deployed at site, address and overcome user resistance, and maintain accurate data tracking. “Ours is a very digitally active site,” she smiles, “implementing various digital initiatives such as Rebar Pro, ConPro, the Workmen Management App, HK Connect, timelapse and 3D videos.”

Elaborating on a couple, she mentions that Rebar Pro is helping the site to manage rebar usage efficiently. “With training, we have achieved 100% implementation by reconciling application and site data and streamlining the processes from store management to rebar receipt, for transparency and efficiency for reinforcement.” ConPro, on the other hand, has significantly reduced wastage, and improved tracking with 100% implementation. “We have reduced concrete consumption from 2.5% to 1.64% and saved crores, while contributing to environmental sustainability,” Mahima adds triumphantly.

Eager to cover more ground in the digital space, Mahima is keen to enhance the integration of data analytics tools for deeper insights into project performance and efficiency. “I believe that we should improve the user interface of our Apps to make them more intuitive and user-friendly that could further drive technology adoption,” she points out insightfully. “Of course, implementing an advanced predictive analytics tool could significantly enhance project planning and execution by providing real-time insights and forecasts, enabling proactive decision-making and resource optimization,” she nods.

L&T has been a great proving ground for Mahima with its unwavering commitment to innovation and excellence, fostering a culture of continuous improvement that empowers employees to lead impactful projects. She has found her seniors guiding and supporting her while her team members are ever ready to adopt, implement, and troubleshoot. “Their collaboration and feedback are invaluable to overcome challenges and achieve project goals,” she notes meaningfully.

A native of Kanpur, Uttar Pradesh and single, Mahima’s family comprises her father, Akshay Kumar; mother Javitri Devi, brother Aditya, and sister Gauri. Her secret to maintaining work–life balance is to spend her free time studying Indian history, cooking, and reading spiritual books. “One of my most memorable moments was a visit to Mahakal, Ujjain, with my family, which was a significant milestone for us,” she recalls happily.