A life-enhancing event in his life was Mohd Arshun’s pivotal role in the Meerut Aligarh Ghaziabad Road Project, achieving the world record of laying 112.5 lane-km in 100 hours (Mission-100 in 100). “Digital initiatives were crucial to our success,” he points out like using a Power BI-based mobile app to monitor material production and transportation, advanced GPS technology to track equipment, introducing fuel sensors for diesel management, apart from live CCTV monitoring of production plants. “Along with the team, I helped integrate all these digital technologies and coordinated the efforts from our central control room, the WAR room,” he notes with a sense of accomplishment.

Appreciating the potential of digital technology to enhance project management, he strongly believes that workshops and training can help users better understand the benefits of digital tools, reducing their effort and benefiting the organization as well. “I see Power BI tools as a significant improvement for site monitoring and data analysis,” he adds.

Crediting his seniors for their support that has won him the tag of a Tech Champion, he flags off Operation Head, Manish Kumar Agarwal, and Project Manager, Neeraj Kumar Garg for special mention. “I am grateful for their confidence in me. They have guided me in areas like integrating various digital tools for monitoring and budget allocation,” he shares.

A GET from the batch of 2015, Arshun started at the Unnao Lucknow Project (ULEP), where he quickly took on the role of Subcontractor Billing & QS Engineer in the Planning Department, continuing his journey thereafter at the Pragati Maidan Project as a Planning and Costing Engineer. Currently, he is at MAGRP in Planning and Cost Control. Looking back at his tenure at L&T, Arshun says, “Promoting innovative ideas to solve business problems is one of the aspects about L&T that makes me proud of being part of this organisation.”

Hailing from the ‘City of Brass’ – Moradabad, Uttar Pradesh – Arshun enjoys playing badminton on weekends to unwind and cherishes his family life with his wife, Nikhat Jahan, a homemaker. Reflecting on his journey, he fondly recalls that another memorable moment in his life was receiving the on-campus selection mail from L&T.

STILL ENJOYING THE FEELING OF

SETTING A WORLD RECORD

Yuvraj Yaduvanshi

Assistant Construction Manager (Civil), TI IC

For all who have been associated with the Meerut–Aligarh–Ghaziabad Road Project, the highlight is certainly setting the world record of laying 112.5 lane km of road in 100 hours. It is no different for Yuvraj Yaduvanshi for whom being part of the record-setting team is his life’s most precious moment.

On the tech adoption front, Yuvraj assures that he is making full use of the mobile app specially developed to monitor logistics for improved operational efficiency. “The App helped us to achieve the remarkable milestone of setting the twin world records of laying maximum lane-km of asphalt and maximum quantity of asphalt produced,” he says with obvious pride. Internal training and workshops were organized at site level and a central coordinator appointed to support during the implementation phase. “This helped us to understand all the hidden benefits of using this App and how it could be a breakthrough in time and data management,” he says, adding that it was all thanks to the Project Manager and the Section In-charge.

Some tough challenges for Yuvraj during execution were logistics and traffic management. “We had to, on one hand, guard the safety of the existing road users and, on the other, ensure that the project was completed within the stringent timelines,” he shares. On the safety front, workmen were engaged only after thorough safety inductions using VR technology. Logistics were managed using GPS technology and mobile Apps developed for the project site.

Yuvraj is of the view that the Company should mandatorily induct new joinees and freshers from academics into digital technology and make them aware of its potential benefits to enhance operational efficiency and product quality. “Advanced machine control systems can be implemented in all the paving equipment to communicate with the GPS satellite and digital data input by the Site Engineer to profile the pavement layers with precision to increase efficiency and reduce the chances of re-work,” he smiles.

Providing growth opportunities to employees by upskilling them through an engrossed culture of learning at L&T is one of the reasons that makes him proud to be a part of this organization.

Hailing from Kumher in Rajasthan’s Deeg District, Yuvraj is married to Anjali, who works at the Indian Bank at Mathura as a customer service associate. His daughter, Aarya, is certainly the apple of his eye, and his best moments are spent playing with her. His other hobbies are playing badminton, volleyball, and more.

FROM CAMPUS TO CORPORATE WITH THE URGE TO LEARN

Akash Rao

Senior Engineer (Elec), TI IC

Fresh off his graduation, Akash Rao landed up at L&T’s Meerut–Aligarh–Ghaziabad Road Project at its initial stages itself. “Entering the corporate world was challenging because our project office was just being set up and there was not much scope for training then,” he recalls. But fuelled by a fire in his belly, Akash proactively sought opportunities from his manager and in-charge to learn, and they promptly provided him with facilities to train across departments like EHS, P&M, QA/QC lab, and execution.

“With most things being digitalized, I focus on modern technologies implemented in our project and adopt them to improve the productivity and quality of my work,” remarks Akash, smartly, who is most interested in digital process automation, which will give him all-round visibility of his work progress.

Speaking of driving digital, Akash and team have deployed an RFID-controlled fuel dispensing system with mobile automation (MOBA) and fuel level sensors in machinery to monitor levels and prevent diesel theft. “Furthermore, we have implemented 100% digital connectivity in assets at our site to record performance,” he adds with pride. “Thanks to these measures, the machinery runs without interruption and the fuel sensor has reduced costs.”

Akash thanks his seniors and team members for their support and drive to implement technology for better performance of plant & machinery. “Every week, my in-charge sits with me, and I present my new learnings to him,” he informs.

Hailing from Bhadohi in Uttar Pradesh, Akash is part of a joint family including his grandparents, three uncles & aunts, twelve cousins, his parents, and three brothers. “We all live together under one roof but on different floors. My father is a farmer, my mother a homemaker, and I am extremely grateful for their love & support,” he says smiling. While Akash doesn’t get time to play cricket these days, he spends his free time reading books and listening to music.

“My most memorable moment is joining L&T; when I sent my first salary to my parents, they were over the moon. Just like I was when our project created the world record for completing 100 lane km in 100 hours and for laying the highest quantity of bituminous concrete!” he notes, proudly signing off.

Constructing the greenfield Navi Mumbai International Airport project with concurrent land development calls for seamless integration across multiple domains and that is one of Prathamesh Dingorkar’s primary objectives. “As part of the Planning team, I oversee Contracts Management and drive the implementation of digital initiatives on-site, to ensure that the project stays at the forefront of innovation and efficiency,” he says engagingly.

What is helping him, and his team stay in touch with their asking rate is technology. “Identifying gaps and proposing digital solutions to address them demands significant effort for approval,” informs Prathamesh and therefore the fact that they have introduced several of them is praise-worthy. “We use BIM-based 3D modelling for improved planning, server-based Primavera P6 for scheduling, mobile software for dynamic progress reporting, and drones to conduct aerial surveys for efficient progress monitoring. Cloud-based platforms enable secure data sharing and remote collaboration, ensuring that all stakeholders have real-time access to the latest project information.”

Monitoring progress with inputs from multiple domains requires dedicated, user-friendly Apps, although encouraging their adoption was initially challenging, that required emphasizing their benefits and broader impact. “Utilizing a server-based platform for schedule updates and a mobile App for progress monitoring has proved to be an efficient, streamlined approach and, overall, a lean practice,” he remarks with purpose. “It is also essential to streamline the integration of various tools to minimize compatibility issues and ensure smoother transition,” he adds.

Prathamesh firmly believes that once a digital tool is adopted for a specific purpose, all traditional reporting systems for the same activity should be immediately eliminated, as maintaining both methods is inefficient and goes against lean work practices. “A visual tracker for project progress will significantly benefit the project for when a site engineer updates the progress in the monitoring App, the visual model of the project should automatically update on the cloud, making it accessible to all users and reviewers,” he says forcefully. “With this visual tracker, progress reporting can be cross-checked with the updated model; it is an excellent tool for management and client reviews and the model can be configured to highlight obstacles that may hinder further execution.”

Prathamesh is thankful to his seniors & team members for their on-going mentorship, encouragement & constructive feedback that are key to his success.

A native of Panvel, Maharashtra, Prathamesh’s better half is Dr Anushree, an M.B.B.S doctor pursuing her M.D. from Sir J.J. Hospital, Mumbai. Playing badminton is what relaxes him, and he is particularly proud of having won the Delta Award (2.0) for Execution Excellence with Innovation.

A strong proponent of technology at work, Harikrishnan G believes that people initially resist new technology because it feels complicated but if the adoption process is intuitive and user-friendly, there will certainly be more takers. He is seeing it in action at his current Navi Mumbai International Airport project. “At first, it was challenging to monitor new workers and effectively educate them about their tasks and that lack of guidance were resulting in a noticeably adverse impact on both our processes and the quality of our products,” he says with a worried expression. “However, once we implemented a structured approach, there has been a significant improvement,” he says with relief.

While Power Apps have improved the team’s ability to monitor awareness among the workers, Frontline Supervisors and Engineers by keeping them well-informed and aligned with operational standards, the Apps are a robust platform too to track DRIFTS (Do Right In First Time), external/internal NCs and walkdown findings enabling them to closely monitor and manage deviations in both processes and products. “With this proactive approach, we can identify any major/minor discrepancies and address them promptly, effectively to keep our operations on track maintaining high-quality standards,” says Harikrishnan with fervour.

Convinced of its success, Harikrishnan advocates tailored training and supporting individual users’ needs and skill levels to drive greater adoption. “Having influential leaders or peers to adopt and endorse technology can also help drive adoption for people often follow the lead of those they trust or admire, so encouraging leadership buy-in would be vital,” he says. Apart from clear and transparent communication about the benefits of the new technologies, he proposes a strong feedback loop where users can voice their concerns, suggestions, and difficulties for both buy-in & continuous improvements and incentives for early adoption or consistent use of the technology like recognition, rewards, and demonstrating clear personal or professional benefits.

He is keen to have an App that incorporates well-timed and contextually relevant notifications to enhance user engagement and prompt timely responses. “The current product quality ratings are manual, tedious, and not very effective to capture realistic product quality, but digital Apps can make them more frequent conducted by a broader group of peers and cross-functional teams, for better implementation and accuracy.”

A native of Thiruvarur, Tamil Nadu, Harikrishnan is married to Vishnupriya G, a homemaker and preparing for her Civil Services exam, and they are blessed with 2‑and-a-half-year-old son, Pranavkrishnan V. H, who’s first birthday is his life’s sweetest moment. He loves to play cricket when not driving tech adoption.

At the Navi Mumbai International Airport project, Raj Nandini Saxena is still at her first with L&T but there is no denying that she is extremely proud of the company she keeps. “L&T is truly a nation builder and no matter how complex our projects are, the world knows that “if not L&T, then who?” And even as she plays her challenging role at site, Nandini is realizing that at L&T, you enjoy all-round development to be a complete professional.

“As I am responsible for progress monitoring and scheduling, I realized that gathering data from every corner of such a massive site was a hugely robust task relying on conventional methods, that could also result in mishandling of data,” she observes. “Therefore, I streamlined data collection by creating a user-friendly format on OneDrive for daily updates,” she smiles, adding that later she contributed to the development of L&T TI IC’s Daily Progress Input App and even trained site engineers to use it. “This initiative enhanced efficiency and standardized our project control processes,” she assures.

Streamlining App usage had its hiccups like resistance to change, network issues, frequent user changes, and mapping activities. To overcome these the team held trainings, weekly reviews, and ensured that the Section In-charges monitored progress through the app.

“I acted as the single point of contact for app-related queries, with prompt user feedback to update the backend on a monthly basis and keep the project on track,” she shares. Of course, she nods, everyone should embrace technological advancements, by being open to new ideas and investing time to understand them.

She smiles that she would love a comprehensive App that digitalizes all reports and eliminates paperwork. “Ideally, it should integrate scope, schedule, invoice, cost, and wastage tracking on to a single platform that will significantly save time, reduce man-hours, and streamline project closeout claims with time-stamped data.”

Nandini attributes her success in good measure to her seniors and team members. “Their involvement made it easier for me to coordinate with the site team, ensuring steady app development and smoother implementation.”

From Bhopal, Madhya Pradesh, Nandini’s family comprises her father, Mr. Rajeev, mother, Mrs. Anamika, and brother, Jai. “We share a strong bond and support each other in everything,” she says with feeling. “I love sports and am a national medallist in speed skating,” she beams. She also enjoys badminton, dancing & reading. She involves herself in essay writing, debates, extempore speaking and marathoning. Her parents’ pride at her joining L&T and winning her first national medal are special moments, she savours.

After opening stints at the Yadagiri Warangal Road & Mumbai Nagpur Expressway projects, K S S Krishna has found his true calling at his present Navi Mumbai International Airport Project. “I have been nominated as the P&M Digital Champion for the site, which is motivating me to take up new digital initiatives and provide a supportive environment and the resources to implement digital solutions at site,” he shares with vigour.

Krishna is certainly lucky for several digital solutions are being implemented at his project like the Trimble 3D Grade Controller System on motor graders to reduce material wastage, gain accuracy and ensure lesser cycle time, cost & manpower. He is particularly impressed with the Fuel Dispensing Monitoring System. “Working on the RFID principle, this technology is helping us to stop fuel theft and with real time, asset wise data of fuel dispensing stored in the MOBA FDMS Portal, we can easily monitor the fuel consumption of the assets,” he mentions with a broad smile.

While the GPS-based SPOTRACK tracks vehicles & is a useful tool to monitor vehicle working hours, idle hours, & working kilometres, the Fuel Sensor monitors individual vehicles with the help of a fuel sensor & GPS device, to show in real time the fuel level in the tank, fuel filling, fuel removal and fuel consumption details, all digitally. “We monitor the production of our batching plants too with IoT-based sensors that provide real-time data about production, production design, consumption of material, wastage details, and transit mixer trips,” Krishna details out.

One of the team’s biggest challenges to implement digital solutions was network connectivity with not a single telecom tower in a radius of 10 km, forcing them to purchase an additional device to boost connectivity.

A fully charged Krishna is keen to have a special team at site to drive digital activities, a special room to conduct digital analysis and all-out efforts to improve the awareness of both the employees and the workers about the benefits of digitalization.

A proud L&T‑ite for the kind of iconic projects that L&T is involved in like the Statue of Unity, the Atul Setu Bridge, and the High-Speed Rail, Krishna says, with his eyes glowing, “These not only highlight our expertise but also contribute significantly to India’s growth and infrastructure.”

Hailing from Tanuku, Andhra Pradesh, Krishna is a bachelor and loves to travel & explore new places, dance and, quite predictably, learn about new technologies during his free time. Surprising his mom at home on a Mother’s Day is a much-cherished moment.

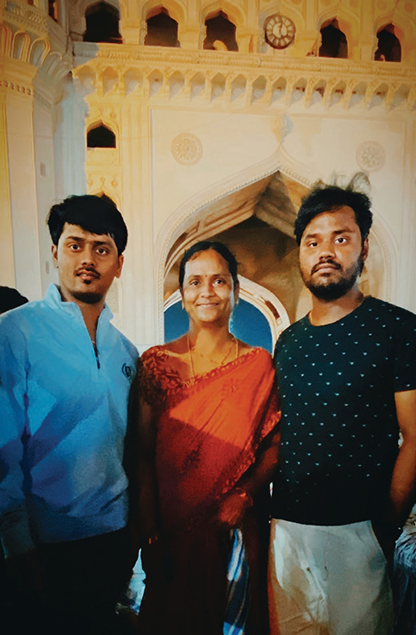

She is a GET, and the greenfield Navi Mumbai International Airport project is her first with L&T. Yet young Maheswari Mohanty is convinced that people make all the difference, and she is very impressed that L&T prioritizes employee safety, health, and work-life balance. “The success of the organization is closely tied to the well-being of its people and this focus on empowering employees and nurturing their potential makes L&T not just a place to work, but a place to grow and thrive professionally and personally.”

She brings this passion & commitment to her challenging task of keeping workforce, material, and equipment safe at her site for which technology is helping her big time. “With SHEILD, we actively monitor various safety checklists against the activities being executed apart from capturing unsafe acts and conditions, work permits and incident notifications, if any,” she shares. “This is helping us achieve our Mission Zero Harm and inculcate a safety culture.” Maheswari takes care of the data analytics to ensure & verify the Reverse the Risk (RTR) checklists and UA/UC compliances daily. “I prepare detailed RTR/UA-UC analysis of all site activities using BI Apps to identify trends of unsafe acts and conditions, lagging areas and improvements required that has improved our EHS performance and reduced risk levels.”

She mentions AR – SPARSH for training that is working very well in this greenfield project with retention levels as high as 80%; it covers more workers and saves time & resources. “Additionally, we are using Power BI and Advance Excel to automatically track changes in EHS regulations and standards, to ensure compliance, and the cloud-based EHS Management System is a centralized platform that stores all EHS data (incident reports, inspections, audits) that is easily accessible to the team,” she apprises.

Even as she drives tech adoption, Maheswari has lots of ideas to quicken the process. “We must encourage collaboration and peer support, streamline implementation processes by reducing complexity, and foster a culture of innovation,” she says seriously. However, she is happy with the support she has enjoyed from the department heads of EHS (HQ & Project), Digital (HQ) and the site execution team. “Our leaders share their experience and knowledge, ensure access to the latest tools, technologies, and training programmes so that we are equipped with the necessary knowledge to implement and successfully execute.”

“I belong to Odisha, and currently reside in Rourkela, District at Sundargarh, also known as the Steel City and live with my parents,” she says, with a smile. Her family comprises her father Niranjan, mother Jyochana, sister Lipun & brother Bhanu Prakash. Maheswari’s hobbies are outdoor games, mainly badminton & cricket.

“I love to write and read books on philosophy, as I find them intellectually stimulating,” shares G T Dhanush, who is not just a budding engineer but also an avid writer and BIS scholar, with an M.Tech. in Construction Technology and Management from NIT‑K, Surathkal. His passion for writing extends to daily journals, short poems, and various write-ups, showcasing his diverse talents beyond his professional endeavours.

Dhanush has already made significant contributions to two major projects: the NSPR-BIAL Project, where he began his career as a Graduate Engineer Trainee (GET), and the MGEP, where he currently excels.

Dhanush takes great pride in his role of driving technology adoption at these projects. “At the NSPR-BIAL Project, I played a pivotal role in implementing a grade control system in collaboration with Trimble, Leica, PMO, and the site team. This initiative was crucial for the successful execution of the apron and taxiway area earthworks,” he shares. “Additionally, I led the successful implementation of PROCUBE, enhancing progress monitoring and data capture.”

At MGEP, the team has successfully adopted SHEILD for safety monitoring, achieving 100% utilization by raising awareness and highlighting its benefits. “We have connected all external and internal assets through GPS to track usage, enhance productivity, and monitor HSD consumption to control costs,” he explains.

Dhanush is pragmatic about the challenges of digital adoption. He recalls the initial hesitancy at NSPR-BIAL to adopt grade control graders due to calibration issues affecting productivity. “We used the graders only in the final layer to minimize the impact on productivity while calibrating the system. This approach gradually built confidence and led to active usage,” he remarks.

He emphasizes the importance of demonstrating how digital data capture can streamline processes and eliminate redundant tasks like manual progress reporting. “This clarity encourages widespread adoption,” he says, underscoring his role as a digital ambassador. He advocates for greater adoption of BIM from the project’s initiation stage to significantly enhance planning, control, and monitoring.

Hailing from K M Doddi in Karnataka’s Mandya District, Dhanush reflects on a memorable moment when he convinced his parents to allow him to pursue a Diploma in Civil Engineering instead of medicine, as they had initially desired. “This decision,” he notes, “always calms me during stressful times, reminding me of my determination and independence.”

“At L&T, I am proud to be part of a team that builds the longest, tallest, and biggest structures,” Dhanush concludes, embodying the spirit of innovation and excellence that defines his career and contributions.

At his second project, the Meerut–Hapur–Ganga Expressway – where he has been assigned after an initial stint at the Mumbai Nagpur Expressway Project, young Manoj Vishwakarma is taking care of Package 2 and managing roughly 1,200 personnel.

Elaborating on the technology solutions adopted at his site, Manoj says, “As a part of digitalization, we are implementing WMS or Workmen Management System to manage the workers, have installed GPS on the vehicles, and use the SHEILD App to drive Safety.”

Manoj’s major challenge, since he is dealing with labour, is to enrol and capture the attendance of all the workers at his site. “We are co-ordinating with the site team on a daily basis to get this done timely,” he remarks. Another challenge that he faces is his inability to print the experience of the workers during the screening process in the system. “While it is showing up on the screen, it is not getting printed in the hard form and that needs to be rectified,” he says.

Acknowledging the role of his seniors to prepare him for his role at L&T, he says gratefully, “My seniors have been guiding me from time to time to make me thorough in the use of the digital platforms and I have also been involving my junior team mates to ensure that they also know about our various digital solutions for use in the near future.”

“One of my most memorable moments is the day when I joined L&T,” says Manoj, adding that he is proud to be an L&T‑ite. “L&T has such a huge brand name that on occasions when I say that I belong to the L&T family, there is no need to say anything else. People know us that well. Further I really don’t have words to express what kind of respect people give me when they come to know that I’m from the L&T family,” he says. his eyes shining.

“One of my most memorable moments is the day when I joined L&T,” says Manoj, adding that he is proud to be an L&T‑ite. “L&T has such a huge brand name that on occasions when I say that I belong to the L&T family, there is no need to say anything else. People know us that well. Further I really don’t have words to express what kind of respect people give me when they come to know that I’m from the L&T family,” he says. his eyes shining.

On his home front, Manoj, a native of Madhya Pradesh, is married to Saroj, a homemaker, and they are blessed with two children: son, Sanvardhan and daughter, Sanskruti. Playing cricket is his favourite pastime and he mentions with delight playing in the annual cricket tournament organized in January every year as part of the Safety Month celebrations.

On his home front, Manoj, a native of Madhya Pradesh, is married to Saroj, a homemaker, and they are blessed with two children: son, Sanvardhan and daughter, Sanskruti. Playing cricket is his favourite pastime and he mentions with delight playing in the annual cricket tournament organized in January every year as part of the Safety Month celebrations.

FINDING OPPORTUNITIES IN CHALLENGES

After stints at three projects where he was responsible for MIS, Ajay Chouhan’s first project, the Unnao–Lucknow Expressway Project, still finds a special place in his heart. “Joining as a DET, I learnt all my skills and built self-confidence, fully supported by my in-charge Mr. Anil Kumar Sharma,” he says with feeling. “I was given training & responsibility from MIS to overall P&M operations.”

Currently at the Meerut–Hapur–Ganga Expressway Project, Ajay has spearheaded several tech initiatives such as a RFID-controlled fuel dispensing system and the fuel level sensors for machinery, which have drastically reduced fuel theft, and 100% digital connectivity to monitor asset performance, all aimed to maintain operational efficiency, minimize losses, and ensure timely delivery.

“Yes,” he nods that there have been hurdles to implementing the tech-driven initiatives at his project sites, “but,” he adds with a smile, “these challenges also presented opportunities for growth and innovation,” ear-marking resistance to technological change and integration of new technologies with existing systems as two of the biggest hurdles. Training, learning programmes, stronger collaboration with technology providers, and increased involvement of stakeholders in the adoption process, he believes, will reduce resistance to new tech and ensure that solutions meet the practical needs of all users.

“One new technology that could significantly improve project efficiency and resource management is the implementation of IoT-enabled predictive maintenance systems for our machinery and equipment,” shares Ajay thoughtfully. “With sensors embedded in machinery, we can continuously monitor condition & performance and collect real-time data on various parameters, which can then be analysed using machine learning algorithms to predict potential failures before they occur.” He is convinced that data-driven decision-making will minimize unplanned downtime, optimize maintenance schedules, and improve asset utilization, safety, & reliability.

Ajay hails from Bhopal, Madhya Pradesh, and his hobbies are playing volleyball and reading tech updates. “I make it a point to spend at least half an hour every day to stay up to date on fast-evolving technology,” he says with a thumbs-up. Being selected at L&T is his most memorable moment, with his sister’s wedding a close second. The Company’s unwavering commitment to innovation and technological excellence is what makes Ajay most proud to be an L&T‑ite. “L&T has always been at the forefront of embracing cutting-edge technologies and integrating them in its projects, setting industry benchmarks for quality, efficiency, and sustainability.”

In January 2024 at his second project, the Meerut-Hapur Ganga Expressway Project, young Deepak Mishra participated and won a UA/UC contest organized by HQ. “It was great to be recognized by the Company and I was hugely motivated to continue reporting UA/UC at all sites that I visit,” he says with energy. “Although our EHS team reports UA/UC count daily, I also do and have maintained my position at the top of the score card. In fact, I was recognized at site for being the top performer for UA/UC reporting for the last 4 months,” he shares with pride of being a part of L&T that he describes as “a platform to make a miracle.” Although his first project was the MPEP (Package 22), Ratlam, he has undergone training at MVEP, Vadodara, & Pragati Maidan, Delhi.

Tracing his exciting journey as a Tech Champ, Deepak admits that he at first did not know much about digitalization. “My training on the SHEILD App at site conducted by the EHS department in September 2023 was my first step onto the digital platform.” Thereafter, he has continued to diligently use the SHEILD App and started conducting early morning safety TBTs & quality PEP talks, fill RTRs and enter data on quality into the Quality App daily.

For someone just making his career at L&T, Deepak is grateful to his seniors for supporting, guiding, correcting and encouraging him to use digital solutions. “Mr. Biplab Kumar Ghosh sir has supported me while my site safety in-charge Mr. Suraj Eknath Kolhatkar sir has supported me like a mentor, always standing behind me whatever the situation and helping me to sort out the problem. To be honest he is an integral part of my success story,” he says emotionally. “Needless to say, our site project director Mr. Shashikant Tripathy sir has always rewarded me and recognized my work.”

Deepak points out that to address the challenge of machinery breaking down during work, it is important to have a backup plan, otherwise arranging alternative sources is difficult. “I feel that in the SHEILD App, the time to close UA/UC compliance should be more before carrying over to the next level,” he suggests, emphasizing the need for more training programmes and says that giving participation certificates is great motivation.

A native of Rewa, Madhya Pradesh, Deepak is still single and loves playing cricket and watching movies in his free time. “My most memorable moment was doing the major pouring concrete at night with no one to control me as I execute my work as per our plan,” he signs off happily.