“L&T HAS CARVED

A SPECIAL NICHE IN

MY LIFE!”

Arijit Mukherjee

Construction Manager (Civil), WET IC

Arijit Mukherjee has been with L&T for more than two decades, since July 2002. “Apart from my parents, L&T has carved a niche in my life,” he shares passionately. “Wherever L&T-ites go or whomever they meet, even someone not associated with the construction industry, we are always seen respectfully,” he says with a sense of pride. “Our clients and all the stakeholders have confidence that we will never let them down and those expectations pump our adrenaline to convert the impossible to possible!” He reminisces his parent’s joy when he joined L&T as a moment he cherishes.

The Coimbatore STP project is Arijit’s 10th project with L&T. “My primary responsibility is its timely completion within the estimated cost through proper planning, monitoring and co-ordination with subordinates’ agencies, clients and local agencies,” his focus is clear. His mandate also includes maintaining measurements of work done for subcontractor billing, following up with the billing engineer, PMC & Clients for easy processing of client invoicing, planning & scheduling work breakdown structure for different site activities, resolving site related issues taking the PMC & Clients into confidence, continuously following up with stores and planning for ready material availability to site.

“Yes, it has been a challenging project,” he nods, “The first was to clear a huge dump of waste of more than 6 m in height over a 50,000 sqm area as we were constructing on a municipal dumping yard that was emitting an obnoxious smell that people residing even 4 km away could not bear,” he winces at the memory. Another challenge was the pandemic.

Arijit mentions the erection of a 7.2 m wall that was new to the team and to the workmen. “We tackled it with exclusive planning, work methodology, proper sequencing of activities and engaging a formwork specialist for regular inputs and training.” A 60 MT tyre mounted crane was arranged to facilitate 1.4 MT special shuttering assembly for the 7.2 m wall height. They adopted an unconventional single pour concreting method using specially designed free flow concrete mix. It was successfully executed after a mock up trial convincing the client.

Thankful to the senior management for entrusting the project to him and the tremendous support from the EDRC Team, he appreciates the support the execution team enjoyed. “Our Project Head, Planning and Quality personnel have played pivotal roles in our success,” he says with a thumbs up.

Arijit is married to Pompa who is a homemaker and an amateurish Kathak dancer and their son Avrojit, are both very supportive of his professional life. Reading story books, playing cricket, and listening to music are what relaxes him.

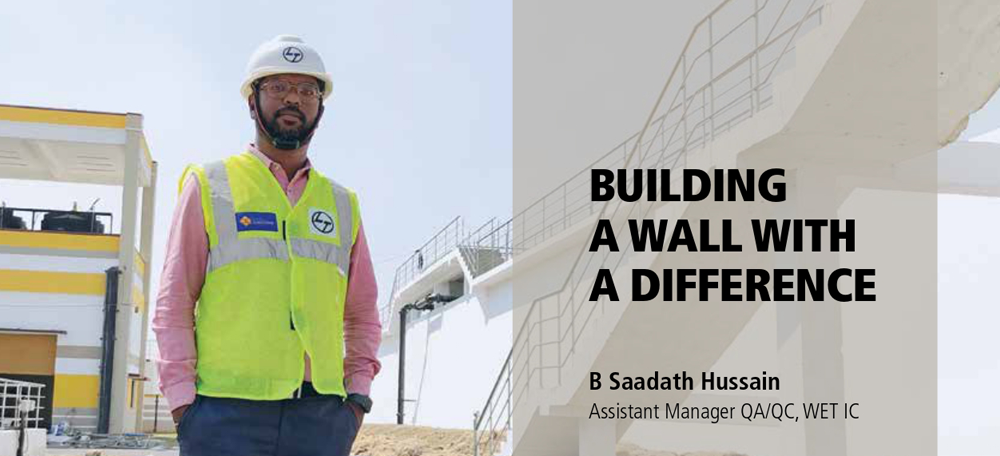

For Saadath Hussain, the Coimbatore STP project that won a mention from the awards committee for its quality was primarily about pouring concrete for a 7.2 m wall in a single lift against the standard practice of constructing 1.2 m walls. “A 7.2 m wall would involve multiple lifts and joints that is not ideal for a water retaining structure,” points out Saadath. “After discussions with the client, the Tamil Nadu Water Supply & Drainage Board, we presented a mock-up of the proposed 2 m x 7.2 m wall.” Once the client was convinced, the team casted the walls of the entire structure, panel wise in a single lift right from 6 m to 7.2 m walls.

“This was the first successful tallest single concrete lift in WET IC,” says a proud Saadath, “and the initiative fetched us a lot of tangible and intangible benefits: an improved surface finish with minimal joints, simplification of the process, time saving, better workmanship, improved productivity and enhanced customer satisfaction.”

Most of the project team’s challenges were pertaining to this wall. “The formwork for the 7.2 m wall was new to us so we brought in an exclusive formwork specialist into our team,” ticks off Saadath. “We had to use free flow concrete, the right mix arrived at after multiple trials.” The maximum length of the available vibrator needle was 3 m whereas concrete had to be compacted from 7.2 m. A high performing vibrator with a 10 m long needle was sourced by experts and procured exclusively for wall concreting. “Another challenge was that the top width of the wall was 200 mm, whereas our boom placer mouth was 230 mm,” shares Saadath. “We tackled the issue by using a tremie like assembly exclusively fabricated at different heights with PVC and MS materials for concreting.”

He is happy that his seniors and team members were with him every step of the way helping him out at all stages like design and execution of formwork, design of concrete and safe execution. “Digital solutions like QIR with inbuilt SOP modules have helped us all to address and rectify issues and to execute the job as per requirements,” he stresses.

Saadath is at his 3rd project with L&T after having joined the ranks in 2015. Hailing from Chennai, Saadath and his wife, Razabunisha, a homemaker, have two lovely daughters, Ziya Saasha and Zaila Saasha. During his free time, he reads. Memorable moments? “When I held the hand of my better half and the birth of my daughters,” he smiles delightedly.

A BIS SCHOLAR WITH

BIG DREAMS

A Ramachandran

Assistant Construction Manager

(Instrumentation), WET IC

After joining L&T in 2016 as a GET, A Ramachandran worked on two projects, the Bengaluru UFW and the BDA NPKL Package 2 project, again in Bengaluru, before taking a break for the company’s Build India Scholarship programme that was an invigorating experience for the youngster. “Pursuing a M Tech at NIT, Trichy gave me with a deep understanding of construction planning and control, construction economics and finance, contracts and specifications, personnel management, construction methods and equipment, quality, safety management, and how to manage real-time projects.”

Sufficiently invigorated, he rejoined WET IC, WW BU at the Coimbatore UGSS and STP project that won a mention by the awards committee for its Quality performance. “I am playing an instrumental role in planning, estimation, and job-cost reports, having succeeded to improve the project’s margins by implementing cost optimization initiatives, such as the 7.2 m single lift concrete wall,” shares Ramachandran. “Guided by our Project Manager and Cluster Head, we clearly worked out a sequence of activities and planned accordingly with time and cost optimizations.” He acknowledges the support of the Quality Manager and the site engineer team for their success.

He is mindful that digital solutions have enhanced the efficiency of their performance. “We have implemented EIP Pragati for progress monitoring, View EHS to ensure EHS implementation, the WISA App for workmen induction and screening, and the QIR app (Quality Incident Reporting) for quality checks and reporting of quality incidents,” he ticks off. “We have also tried BIM models for structures for better execution.”

Proud to be an L&T-ite, Ramachandran enjoys opportunities for continuous learning and development that the company offers. “L&T believes in investing in employee development which is crucial to maintain a skilled and motivated workforce and achieve business success,” he remarks wisely.

Ramachandran, who hails from Kodumudi in Erode, Tamil Nadu, is married to Vineya S R, who is currently pursuing her MBA. “Reading books, listening to and singing Carnatic music and songs are my hobbies,” he says. About his most memorable moment, he mentions a trekking trip in Meesapulimala, near Munnar, during a vacation with his post graduate friends. “We laughed, talked, and bonded over the shared experience of exploring a new place together. When I look back, that was a moment of pure joy and connection that I will always treasure,” he says nostalgically.

OVERCOMING ‘TALL’ CHALLENGES TO

DELIVER A QUALITY PROJECT

Mohan Raj S

Assistant Construction Manager, WET IC

For all engineers who are working to construct the Coimbatore UGSS & STP project that won a mention from the Awards Committee for its Quality performance, their ‘tallest’ challenge was to complete a 7.2 m wall, cast and concreted for the first time by the Waste Water BU of WET IC. S Mohan Raj also refers to the same wall and the specific challenges involved in casting the wall like concreting at a height of 7.2 m and the use of special, high frequency vibrators. In addition, his responsibilities at site included public management that involved finalization of the land and location for the lifting and pumping station and road restoration work that was tough, and back breaking, especially during the rainy season amid dense traffic.

“We completed the SBR civil works within 6 months,” he shares triumphantly, “and the sewer network of some 200 km in an extremely short period of time. In fact, we reduced two-layer pouring into one in the road restoration work that saved us both cost and time.”

Mohan Raj is thankful for the all-round support he has enjoyed especially from the planning, safety, quality, and admin & IR teams. “Digitalization has made us a lot more efficient,” he agrees, mentioning digital solutions like QIR, View EHS, e-Pragati and M-Flow with inbuilt SOP modules that have helped everyone to address site-based issues, rectify them and thereby execute the job as per the contractual requirements.

Having joined L&T in July 2013, which he describes as one of the world’s top organizations, giving all employees the opportunity to learn, grow and enhance their skill and knowledge, Mohan Raj’s first assignment was the water supply project at Kalaypattinam Municipality, Tuticorin. “We constructed a 10 lakh litre capacity overhead tank,” he explains, “and my responsibilities were cost estimation, scheduling and finishing works for the entire DI network.” His second was a rural water supply project, again at Tuticorin.

Mohan Raj is from the village of Sankari, Salem, Tamil Nadu and is married to T Manjula. They are blessed with a son, M Nithish. “My hobbies are photography and running,” he laughs and says that his life’s most memorable period was when he was recognized as the overall champion in athletics during his college days.

At the Coimbatore UGSS & STP Projects, as Senior Engineer – EHS, A Mohan Pandi is striving to ensure a streamlined site. “In the STP, we planned a 7.2 m single-pour concrete wall,” Mohan begins. “With the help of the carpentry team, we made 7.2 m shutters, but it is difficult to lift them because of the length, width, and wind speeds in the area. We evolved a design plan with the EDRC team with proper approvals for the lifting procedure by creating shutterspecific spreader beams, which ensured safe lifting.”

Thankfully, the team had received all project-specific formwork drawings for critical structures before execution, to carry out their work at height without risk. “We prepared height pass structures and periodically held health check-up camps,” Mohan notes. “The workmen are well taken care of with a separate shed and given periodical rest times.” The STP, located in the middle of a garbage yard, emitted a bad odour that was causing health problems. “We distributed bananas and health drinks to the workmen, taught them breathing exercises and conducted regular lung function tests.”

Speaking about waste management at the project, Mohan lists out his team’s initiatives: “We have repurposed scrap plywood for the banner frames, hangars, material stacking boxes, and more. Around 40 kg of steel water has been reused, and we have collected 7 kg of used nails for shutter work.” For the curing process, Mohan and team implemented a drip system in the hose to save water, while ensuring 100% coverage of the curing.

“It is a matter of pride that our project has won several safety awards,” Mohan states. “We achieved a 4-star rating and 2nd place in the construction sector at the CII-SR EHS Excellence Awards. Other major awards include the RoSPA Gold, British Safety Council Award, and Prashansa Patra from the National Safety Council of India.” Within WET IC, the project has received the Annual EHS Trophy, the NEER Trophy, and the GO Green Champion Award, while achieving 2.8 safe million manhours.

Hailing from Bodinayakanur, Theni in Tamil Nadu, Mohan loves learning new technologies and likes to play cricket and football in his spare time. He is proud to be a part of one of the world’s top organizations: “L&T provides ample opportunity to learn, grow, and enhance our skills and knowledge. I will never forget the day I got the job here and my family’s reaction to it!” he signs off, shaking his head in wonder.

Apurba Mondal

Engineer (Civil), WET IC

Apurba Mondal is a very proud and happy man. He has always been proud to be an L&T-ite for, as he says, “L&T is among the world’s top organizations that gives us the opportunity to learn, grow and enhance our skill and knowledge.” He is now doubly happy because his project, the 30.53 MLD STP they built for the Tamil Nadu Water Supply and Drainage Board in Coimbatore won a mention from the Awards Committee for its quality, reaffirming that Quality is top priority at L&T.

While the main task was to clear about 30,000 cum of garbage dumped to a height of 6 m, Apurba was a busy man involved in a variety of activities including planning, estimation & scheduling of the STP construction works, resource planning and manpower mobilization.

“For the first time we implemented the L&T formwork system to complete a 7.2 m tall wall concrete in a single pour,” he says, flagging off an achievement. The result was a smooth surface to the wall without any cracks, cold joints, or leakages, with uniform thickness and construction joints, saving a lot on construction time in the process. “We used specialized construction technology like special 10 m long high frequency vibrators and Tremie pipes for concreting at height,” he informs, “and completed the SBR civil works within 6 months during the time of the pandemic.”

However, Apurba faced several issues when pouring concrete for the 7.2 m tall wall that had a bottom thickness of 1,050 mm and top thickness of 200 mm. “Fixing the tie rod with the water barrier and in the wall shuttering were challenges as was vibrating concrete at a height of 7.2m or fixing the wall shuttering as the panel weight was more than 1.5 T.” Not to be deterred, the team prepared a mock-up of the wall to convince the client and once they gave them the go ahead, the team got cracking and succeeded handsomely. Digital solutions such as View EHS, QIR, WISA, and virtual reality made it easier to visualize the understand structures to resolve problems. BIM models clarified the subcontractor’s engineering concerns during construction and he mentions that the workers were trained through the BIM Model to understand their work and execute it efficiently.

Hailing from Aranghata, Nadia, Apurba is single and lives with his mother and elder brother. He is passionate about technology and photography and fondly recalls the day when he bagged the job at L&T and the joy his parents felt.