SAFETY IS ALWAYS BY CHOICE,

NEVER BY CHANCE

Chandra Sekhara Rao, Head – EHS, DIAL Project, Phase 3A has been finetuning the art of EHS ever since joining L&T in 2006 at the HIAL Project. His mandate to ensure safety at this brownfield and unique DIAL project has been demanding. “The quantum of work involved is huge so managing safety at every work location is hugely challenging, but we are managing it effectively, and I felt on top of the world when I received the Best Safety Award 2022 from SNS Sir,” he beams, mentioning it as one of his life’s most precious moments.

“My principal work is to identify the critical areas of improvement in terms of EHS, the training needs, review EHS risk level and appraise the risk with remedial measures, coordinate with the client, and other stakeholders including DPCC, BCAS, AAI, CAQM, CPCB, Project Interface Team, BOCW Team, Labour Commissioner’s Department for the smooth and safe execution.”

One of Chandra’s first concerns at the site was identifying a web of underground utilities directly and indirectly connected with airport operations and re-routing them prior to starting work. Ground Penetration Radar to correctly map the underground utilities, CAT (Cable Avoidance Tool) and strictly implementing work permits both safeguarded the utilities and expedited progress. “Working close to the airport’s operational and sensitive zones, we had to be aware of and keep equipment and the workforce safe without hindering airport operations.”

Focused not to add to an already extremely polluted city, the team adopted a systematic and well-planned approach by strictly using natural gases like PNG and CNG for most of their vehicles and equipment, making a PUC Certificate compulsory for every vehicle and equipment, using solar power and effectively controlling dust.

‘Safety is always by choice; never by chance’ is Chandra’s motto. He is glad that the project’s leadership is committed to maintaining high EHS standards. “Every meeting starts with EHS denoting the Safety First culture at the project,” says a satisfied Chandra. “Innovative ideas and practices are duly recognized by the management to promote safety culture.” He adds that digitalization is now an integral part of EHS with most of the EHS inspections, work permits, EHS checklists being carried out on digital platforms like RTR, SHEILD & IB4U Apps among others.

Chandra is a proud L&T-ite too. “L&T provides an excellent platform to excel in your professional career through various learning and development programs that are industry benchmarks.”

“I am native of Burja, Vizianagaram, Andhra Pradesh and my better half is Swathi, a homemaker, doing a selfless job of looking after our family,” he says with feeling. Their children are daughter, Pranathi, and son, Prabhas, studying in 8th & 4th standards respectively. “I love to learn and adopt new things, watch movies and explore new places when free,” he smiles.

LOOK BEFORE YOU LEAP;

PLAN BEFORE YOUR EXECUTE

At the DIAL project, Srinivasarao Vaskuri is executing his 4th project with L&T after stints at the Kothakota Jadcherla, the Halol Godhra Shamlaji and the Delhi Agra Road Projects. The most important lesson he has learnt from this experience is that it is imperative to plan before executing. “Planning that precedes execution work must involve all the team members including the sub-contractors and all interested parties for everyone to be on the same page,” he says wisely. “Team meetings and workshops are important too to assess risks involved in the activities and to implement mitigation measures.”

EHS cannot be driven by a single individual alone; it must be a collective responsibility to be successful. Against that backdrop, Srinivasarao’s assertion that, “Even though I’m an execution personnel, I always consider myself as an EHS personnel,” is extremely encouraging. To address the issue of frequent change in the workforce, the team developed and trained the workforce to effectively implement EHS to cultivate a safe culture at the project. Working next to ‘live’ traffic and ensuring that construction activities do not hinder passenger and vehicular movement is a perennial headache for road construction project teams. “When working on the connecting road towards the airport (City to Airport) we executed without hampering the heavy, dense traffic and ensured the safety of passengers and public too,” emphasizes Srinivasarao.

He attributes teamwork as the primary reason for DIAL winning the Safety Award. About support, he is appreciative of the guidance from his seniors. “Our team members too were involved in all activities and have put in their best for the project to succeed,” he says with a broad smile. He is proud of being an L&T-ite especially when he hears people refer to the company as the best in construction during his travels or site investigation trips.

A native of Bhimavaram in the West Godavari district of Andhra Pradesh, Srinivasarao’s better half is Neeraja, a homemaker, and they are blessed with two daughters, Tejeswari, who is in the 5th standard and little Poojita who is in Nursery. Listening to songs, singing and crafting are what he indulges in during his free time. Being an academic topper in B. Tech in 2004 is certainly a cherished moment as is the completion of the girder erection and piling operations (600 piles) in the densely populated Palwal area without any damage to utilities. “Another memorable moment was when I received the Best EHS and Quality Awards for two consecutive years for my package,” says a charged Srinivasarao.

PAVING THE WAY FOR NATION BUILDING!

Adnan Ahamad

Construction Manager (Civil), TI IC

After joining L&T as a DET in 2008, Adnan Ahamad has been a part of multiple road and runway projects, and credits two overseas projects in particular for some crucial learnings: “I was fortunate to work as Senior Engineer at the Abu Dhabi Airport Project and as Assistant Construction Manager at the Al Wakrah Bypass Expressway and LRDP in Qatar and what I learnt at those two projects, have helped me enormously at the DIAL Project.”

At the DIAL Phase 3A Project, Adnan is part of the execution team, following a focused and safety first approach that has won them the coveted Safety Award in L&T Construction. “I was actively involved in the HIRA and SWM workshops to identify hazards and risks, with requisite safety measures to be implemented prior to commencement.” Adnan and team conduct mock drills, demonstrations, pre-start inspections, kick off meetings, and various safety-related trainings. “Activity-based daily verification of EHS was easy thanks to the SHEILD app,” he says.

Speaking about operational challenges at DIAL, Adnan informs that one of the major issues is the movement of equipment in live TXY/ operational area. “Another difficulty is when pilots are misguided due to the improper handling/installation of MAGS. Given the importance of the airport, frequent VVIP movements interrupt routine activities and workforce movement, which in turn keeps resources idle.”

Despite these challenges, Adnan is incredibly proud of working day and night to deliver a great infrastructure to the nation. “We are nation builders, and that’s what makes me most proud of being an L&T-ite. Recently, we handed over the runway and apron area to the operations team. I am thrilled to see an aircraft take off, land, and park at stands built by us!” he is positively beaming.

In addition to the SHEILD app, the DIAL project team has extensively adopted digital technologies to manage and track EHS performance. Adnan throws light on one such initiative, the GPR survey for UG utilities: “We use the Google Earth map to identify UG utilities in real time during excavation and have successfully mapped the entire underground utilities of the airport onto Google Earth through GPR survey coordinates, and protected or rerouted them safely.” GPS and speed governors track assets and speed limit violations on the dashboard.

A native of Lucknow, Uttar Pradesh, Adnan is married to Sana Shaheen, a home maker, and they are blessed with a son, Azlan Ahamad. When he is not busy executing runway projects, Adnan likes to watch movies and read books.

EFFICIENTLY MANAGING

MAN-MACHINE INTERFACE

Manish Agarwala

Manager (P&M), TI IC

Manish Agarwala’s focus at the Safety Award-winning DIAL Phase 3A project is to efficiently manage man-machine interface and adopt new era technology to ensure safety and enhance productivity. “We have introduced 3D technology into versatile construction equipment like motor graders and excavators by mapping their coordinates to safeguard utilities during excavation and grading operations,” he informs. These have eliminated the risks of man-machine interface to achieve mission zero harm.

Starting his journey with L&T at the Delhi Agra Road project, Manish’s initial responsibility was MIS, then as Resource Coordinator and thereafter as P&M In-charge of one of the project’s packages. On familiar territory at DIAL managing P&M, he flags off the in-house design and fabrication of mobile fog canons, developed on a waste to wealth model, to control dust. “We use Runway Closure Markers (RCM) during runway marking and repair works which are lighted visual aids that warn pilots of closed airport runways and taxiways to protect the maintenance crews working in these areas.”

Other safety measures adopted by the team include cameras fixed on gantry cranes for better visibility along the tracks on either side, reverse cameras to eliminate risk when reversing, well trained APSOs (Accident Prone Spot Owners) to identify possible hazards & risks associated with activities and alert the concerned people for corrective actions. “Another important step was to partner with the client and other competent faculties to impart training on airside safety requirements to all staff and workforce,” adds Manish.

Working in Delhi, one of the most polluted cities, put pressure on the team not to add to it. The hot mix plant was set up on the airport premises considering all the environmental strictures. “Replacing conventional fuel with PNG (Piped Natural Gas) was our first step to go green,” says Manish, “then controlling dust and setting up stations to monitor air quality in real time.”

Manish is all praise for the support of his seniors and team members. “Seniors have always encouraged and motivated us to achieve our milestones with utmost safety and zero harm to workers while our teammates have always followed the SOPs to be on right path towards safety, quality and progress,” he says earnestly, specially mentioning RKJ Sir, SPR Sir, PGAG Sir and CS Rao Sir. About his company, Manish proudly states, “L&T is the best construction company in India, known for its excellent safety and quality records, providing all possible facilities to its employees for better living.”

Manish is married to Komal, a homemaker, and their family is complete with their son, Rishant. He belongs to Guwahati, Assam, where his parents reside with his brothers. “I like listening to music and playing cricket,” he says. His memorable moments are when he became a father and “when I was recognized as the best performer at DIAL and received the trophy from KVP sir.”

SAFETY IS ALL ABOUT EMBRACING CHALLENGES!

Amit Dey

Assistant Manager – EHS, TI IC

Being stationed at the DIAL project site was a dream come true for Amit Dey, his first full-fledged deployment after joining L&T as a GET, in 2019 and he is over the moon that his project won the Safety Award 2022.

The DIAL site is both special as well as challenging from a safety preparedness standpoint, he observes. “It is almost like working next to a live wire having to coexist with a fully operational airport close by,” warns Amit, “yet with the cooperation of several stakeholders, we have been working in synergy, causing minimal disturbance, and strictly following all the international guidelines.”

“We believe awareness, enhanced skill, and behaviour as per project criteria are key to our success,” he declares. “We have sincerely worked on root causes of violations and based on specific inputs, have initiated training programs as per the specific needs. The DIAL operational and EHS teams worked together to create awareness, enhance skill and behavioural aspects to meet our objectives.” Apart from specialized trainings for poor visibility procedures, “we had tied up with industry expert faculties for defensive driving training programs and behavioural based safety to impart training to drivers and operators and improve their competencies.”

On the digital front, Amit and his team used advanced learning tools like AR to improve safety learning and situational awareness of DIAL site workers. Besides this, a specialized VR module for airside safety has contributed significantly to improve safety orientation, project risk management and workmen productivity. L&T-developed apps such as RtR, SHEILD, and WISA are also being used.

“Always do the right thing and do not settle for anything less is my mantra,” shares Amit. With gratitude to his mentors, Amit says “nurturing, mentoring through tough times, exposure to new concepts, digital initiatives, and constant encouragement from experienced members of the team have shaped my professional capabilities.” He credits his success to his team, working with them every day on airside safety manuals, to achieve 40 million safe man hours, and several other milestones achieved along the way.

A native of Sundargarh, Orissa, the second largest district in the state known for its industrial density and rich mineral deposits, Amit is single and an avid keyboard player.

“In the few years I have spent with L&T, I already feel empowered,” he says with passion. “All thanks to L&T, a home of continuous learning and professional development where safety is in our DNA,” he signs off already a true L&T-ite at heart.

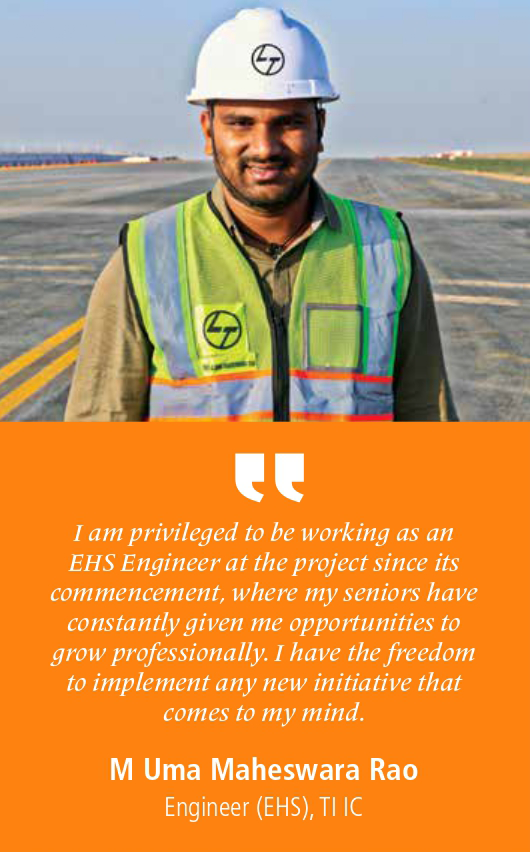

EXECUTING WORK SAFELY

AT INDIA’S BUSIEST AIRPORT

At his first brownfield airport project, M Uma Maheswara Rao – or Mahesh, as he is popularly known – has witnessed several new initiatives and practices contributing to the DIAL Phase 3A Project winning L&T Construction’s Safety Award 2022. “I am privileged to be working as an EHS Engineer at the project since its commencement, where my seniors have constantly given me opportunities to grow professionally,” he remarks. “I have the freedom to implement any new initiative that comes to my mind.”

One of the critical tasks at the project was to construct the first-ofits-kind Elevated Cross Taxiway (ECT) Spine Bridge over the existing airport’s busiest road. “Apart from safe and smooth take-offs and landings, the ECT reduces taxiing time and thus saves fuel,” explains Mahesh. A major safety concern during its construction was the transportation and erection of PSC girders. Mahesh and his team formulated a comprehensive EHS Management Plan in consultation with all the stakeholders to execute the work safely. “We have accomplished 590 girder erections and completed the ECT without any incident,” he smiles.

The DIAL Project has won various national and international-level safety awards, and Mahesh has actively contributed to the entry submissions. “My most memorable moment is winning NSCI’s Sarvashrestra Puraskar Award (Gold), India’s highest Safety Award and I am very happy to be a part of that achievement!” he beams.

A common issue in RREC projects is tracing relevant test certificates for inspected equipment. “Inspecting and tracking tools and tackles is tedious as the inspection tag erodes or gets detached from the surface,” Mahesh rues. “To counter this, we developed an application called UNIQUO to track TPI certificates. We receive alerts from the app notifying the expiry of certifications 30 days in advance, to help us maintain active inventories.”

On the digital front, the EHS risk has been maintained at ALARP levels thanks to applications like IB4U, SHEILD, AR and VR modules, WISA, and Google Earth. “The mobile apps monitor, register, manage, and report EHS performance effectively, and the data generated provides significant insights about strengths, weaknesses and help us shift focus appropriately,” Mahesh notes insightfully. Periodical needbased training on focus areas of improvement has improved the safety culture at site.

A native of Tanuku in the West Godavari district of Andhra Pradesh, Mahesh is married to Ellari, a homemaker, and they are blessed with a baby boy, Shreyansh. Mahesh likes playing cricket and badminton, and enjoys travelling with friends and family.

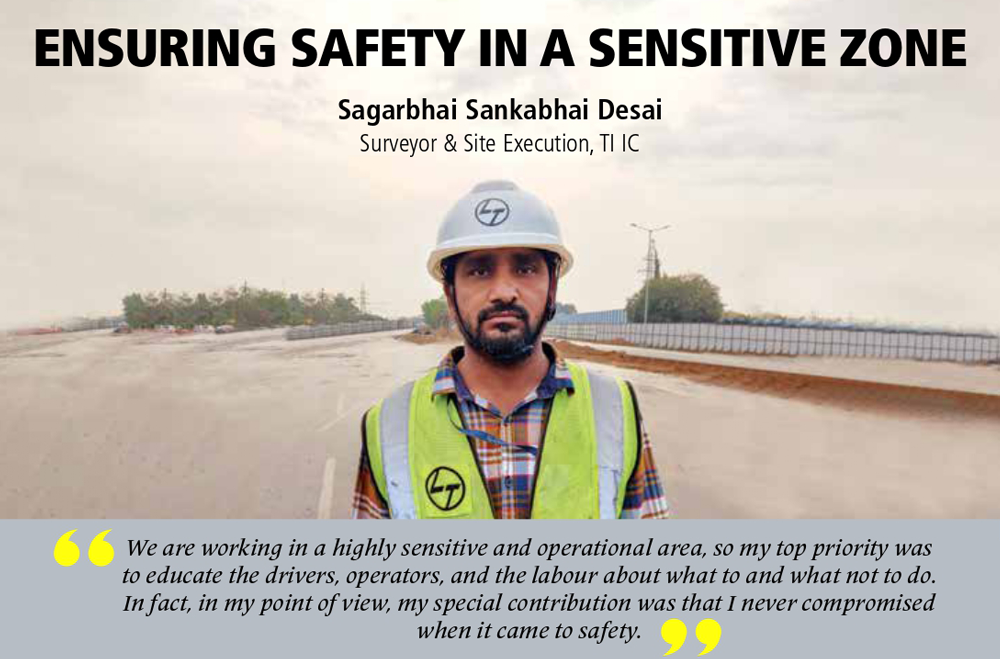

Several people and factors contributed to the Delhi International Airport project winning the Safety Award 2022, like Sagarbhai Desai, who takes care of earthwork activities and ensures safety when working in a sensitive zone. “Working at DIAL has really been a very good experience and a challenging one too in all aspects, especially safety,” begins Sagar, “for we are working in a highly sensitive and operational area, so my top priority was to educate the drivers, operators, and the labour about what to and what not to do. In fact, in my point of view, my special contribution was that I never compromised when it came to safety,” his says resolutely.

Dealing with labour is no easy task and Sagar had to be always on his toes to control and ensure that they always followed safety practices. “I had to make them understand the little things of working on a ‘live’ airport and runway like not creating or spreading FOD, only working in designated areas and that they could not go or wander anywhere they wished,” he points out.

Safety is never the sole responsibility of an individual; it is a shared responsibility that Sagar agrees totally. “100% Safety can only be achieved with team effort and all my team members helped me greatly to maintain safety standards,” he says, acknowledging teamwork. “There was very good coordination regarding work and safety and the management was always supportive, providing the required resources, wherever and whenever required.”

Sagar has worked at many locations but his first assignment at DIAL was to construct the S-2 Taxiway. “After its construction, seeing the first flight go over the taxiway gave me a wonderful feeling and is certainly one of my life’s most memorable moments,” he says, eyes alight. Onto his 3rd project, Sagar is proud about working with L&T. “The most beautiful thing is that the company treats its employee as well as its labour which is why all of us give our best to the organisation,” he says with conviction.

Sagar’s native place is Hirpura, Vijapur, in Gujarat’s Mehsana district. He is married to Sejal, a homemaker, and they have two children, daughter, Prachi and son, Vishal. “Listening to music and cricket are my hobbies,” he smiles.

WHEN IT COME TO SAFETY,

WE APPROACH EVERY DAY’S WORK

WITH A FRESH PERSPECTIVE

Mohammad Mehraj Azam

Engineer (Civil), TI IC

Md Mehraj Azam, Site Engineer at the Safety Awarding winning DIAL Project is elated for being recognized as a ‘Safety Champion’ by the project leadership team. Crediting his team and the company culture for winning the award, he feels that process is the key. “At L&T, we work as safety professionals to help develop and sustain a safe workplace, driven by values and not regulatory consequences.”

Mehraj does not believe his job is only about regulatory compliance. “Our role involves training, hazard and risk identification, audits, inspections, communications, motivation, training, drills, utilizing mitigation tools, investigating incidents and near incidents,” he elaborates about the efforts undertaken for the project and thanks the Project EHS team for mentoring him and helping to shape his thoughts and approach.

“When working in close vicinity to one of the busiest airport roads, the workforce crossing it becomes the most critical risk,” he points out. “To mitigate it, I have planned activities in such a way that the workforce and other resources are engaged separately with restricted movement.” Having a 24×7 monitoring team helps, as does upskilling the existing workforce to meet the project requirements of safety & quality.

He is all praise for his seniors who stood by him and allowed him to take independent decisions. On the digital front, he mentions the Safety Mobile App. “Access to modules on safe work methods and other safety data in the App have tremendously improved the safety culture at the project site,” he notes triumphantly.

After joining L&T as a DET in 2018, Mehraj was previously at the Pragati Maidan Project and credits the experience of working with various departments and his familiarity with day-to-day functions in quality, safety, planning and execution teams as the bedrock for his career growth.

A native of the national capital, Mehraj likes watching movies, listening to music, and reading books when he has time.

Handing over of the DIAL Taxiway and Hangar to the BSF team was his proudest moment. “After giving your everything to a project and finally witnessing the facility being dedicated to the nation is a moment to cherish for a lifetime,” he says with his eyes gleaming. “Working with L&T always makes me feel great for we contribute to nation building in whatever we do,” he signs off with a deep sense of pride.