S. Arunkumar

Senior Construction Manager, B&F IC

At the Chennai Airport Project, the unlock opened to a flurry of activity and several challenges that the team, including S. Arunkumar, prepared to face with resilience and strength. “Workmen mobilization was our biggest challenge,” he shares. “We liaised with the district government officials for e-passes for vehicles and with the support of a travel agency brought back some workmen. Our next challenge was to identify their skills and engage them appropriately as half of them were new to the site and had not worked at an airport project previously,” he says with a frown.

Never the ones to give up, the team began to aggressively train the new workmen supported by all other departments and CSTI. “We had work-based training for the lesser skilled workmen and within a week to ten days, we began to engage them in areas less prone to risks till they were qualified enough to work at heights.” Arunkumar mentions the WISA App that helped them enormously to engage the right person for the right job from the start. “Our efforts have paid off as we have completed the concrete basement retaining wall,” he says with an air of success.

Arunkumar acknowledges the support from the client and other local bodies to manage the new normal at the Chennai airport site. As chartered flights had resumed, passenger movement could have posed a threat of infections. “With the client’s support we were able to divert their movement that enabled us to start concrete production from June.” He credits his enthusiasm and consistent performance to his Project Manager, Anup Chulliyil’s guidance and the support of his colleagues, Ravishankar, Karthikeyan and Pradeep. “My team has always stood by me,” he says albeit a little emotionally.

Having joined L&T in 2006 as an Assistant Engineer at the Sainath Education Project, Anekal, Arunkumar has worked at the Trident Hotel, Cognizant Software Technologies, HCL Technologies, US Client Safron CENCO and TOD Musarambagh projects before taking over as Senior Construction Manager at the Chennai Airport Project.

Hailing from Chennai, Arunkumar is married to Sujatha, a homemaker and they are blessed with two children, son, Shyam, and daughter, Dharshini. A voracious reader with a penchant for autobiographical and history books, he also loves listening to music and is a hard-core fan of the legendary singer SPB. He recalls with pride receiving an appreciation from the late AR for completing the Puttaparthi project in a record 50 days. His first meeting with his wife and the birth of his children are some of his other

memorable moments.

“L&T has given me the opportunity to work with diverse multi-cultural teams that has helped me immensely as a professional. My organization is building nations and I could not be prouder,” leaving no doubt how much he values his Company.

A BLACK BELT CONSTRUCTION MAN

Rana Dhar

Construction Manager (Civil), B&F IC

Assam normally has an extended monsoon from April all the way to October and since the project is located in a low-lying area that was originally a pond, the slightest rain floods the place and dewatering is the only way out.

He is a 2nd Dan Black Belt in karate. “My hobby is to practice karate,” shares Rana Dhar, “I manage some time for it on Sundays. Sometimes I even teach karate,” and Rana should certainly be drawing on some of the positive aspects of karate like balance, confidence, timing, situational awareness as he performs at his Assam Cancer Care Foundation project at Dibrugarh, Assam. “Working in such a remote location, workmen mobilization and retention was a massive challenge for us right from the beginning of the project,” he points out. “Dibrugarh is known as the Tea City of India that attracts local manpower to its magnificent tea estates but due to scarcity of resources, cost of living is very high so to mobilize and retain manpower from other states is a huge task. We had mobilized 120 workmen from Bihar, West Bengal and Jharkhand just before the lockdown and retaining them during and after the lockdown was a major task.”

The project had planned to complete casting the hospital raft before the monsoons, but COVID-19 put paid to all their well-laid plans. “It was critical to complete the raft before the monsoon or else we would have lost a good 3-4 months in dewatering alone,” says a serious looking Rana. They thus approached the client and received permission from the District Collector to resume minor construction works like shuttering and reinforcement from April 2nd. “We resumed the work with a reduced manpower scattered across the site strictly adhering to all the SOPs,” he shares. “Initially it was difficult to manage the workmen, but we supported them and they in turn reciprocated. The district administration also supported us by arranging passes for vehicles to deliver cement, steel and bulk material.” Ultimately, they completed casting the raft on 13th May signalling a huge triumph for the team.

Rana joined L&T on 5th June 2005 as a Junior Engineer at the Rajiv Gandhi Indoor stadium project after which he has worked at the Games Village, Godrej Water Side, ESIC Joka and NEIGRHIMS projects before taking over as Project Head at the ACCF project.

Ranganathan E

Manager (Mech), B&F IC

The pandemic was a huge damper for E Ranganathan, Project Head of Assam Cancer Care Hospital Project at Kokrajhar, having been in the thick of action across several prestigious L&T projects for over a decade and a half. “Remobilization of our workforce and adhering to COVID-19 precautionary norms was an entirely new challenge,” he shares. “Our project was at a very early stage, so it was very critical that we complete the temporary infrastructure before the monsoon as soon as we received the green signal to re-start operations on May 4th.” Since labour had gone, the team decided to engage local labour for the immediate execution of works. “Getting them to match L&T standards of safety and quality has been tough,” remarks Ranganathan.

Their remote location some 240 km from Guwahati proved to be a big roadblock for material procurement, and since they depended on the metro cities to a large extent for many consumables, the lockdown had veritably cut them off. “However, we took all these challenges in our stride and moved forward,” says a determined Ranganathan and success was just round the corner. “We enjoyed the first fruits of our labour when despite all the hurdles we managed to initiate and complete a total excavation of approximately 12,000 cum within 10 days of resuming work.” Ranganathan’s excitement is obvious.

Our client, Assam Cancer Care Foundation, has been a tower of strength for us during these tough and testing days, he acknowledges. “They helped us with the basic medical facilities, their medical staff regularly visited and checked on our workmen and they even helped us to arrange for rapid COVID-19 testing at site.”

He attributes his performance to the support he has received from Sudipta Kumar Basu (KKCL CPM), Anjan Mahapatra, Project Director, Manish Kumar, Central Project Manager, Dilip Kumar Bera, Project Manager and Mr Prasenjit Mukherjee, Accounts Head. “Bapi Mitra Chowdhury and Anirban Saha also stood by me unfazed as we braved the challenges together posed by a common enemy,” says a thankful Ranganathan.

“I am extremely happy to be a part of an organization that takes care of its employees and builds landmark monuments like the Statue of Unity. I stand tall with pride and will continue to give my best for the organization,” he signs off positively.

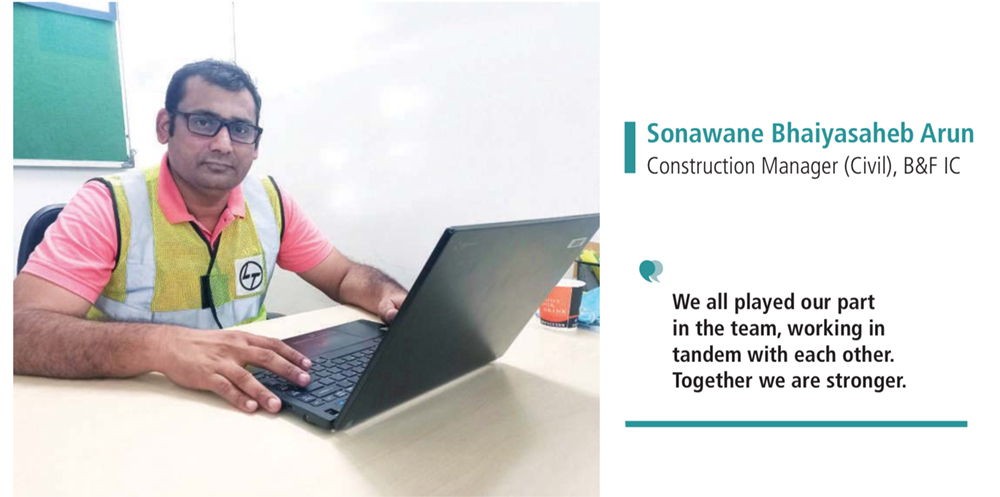

UNFAZED AND ARMED WITH SOLUTIONS

Even as the challenges posed by the pandemic loomed large, Sonawane Bhaiyasaheb Arun, known for his generous heart and easy smile, stood unfazed armed with a solution-oriented mind-set. In quick time, the team had to create a workman habitat inside the site premises and work to bring back workmen to reach their pre-lockdown strength of 1300. “The issue was that because of Mumbai’s rising number of positive cases, no one was willing to travel so convincing them required excellent interpersonal skills,” says Sonawane. A critical task was to make the site ready for restart following the new safety, health and hygiene norms and fresh SOPS. “Another hurdle was that we had to take several new permissions to restart work that the government authorities had newly imposed and of course,” he sighs, “there were so many restrictions on movements, on timings that we had to take into consideration.”

Approaching the issues systematically, Sonawane shares about the various teams that were formed to address specific issues of procurement, workmen mobilization, site facility, approvals, safety, NSC coordination and such like. “At the same time, we had to create confidence among the workmen to return to work on one hand while on the other, extend facilities to our nominated subcontractors to help them get back to work. We even helped them mobilize workmen,” says Sonawane with the air of a man who has worked hard for his success. “Our vendors joined hands with us while our client supported us to implement our SOPs by coordinating with the Government officials for permissions.”

He is all praise for his seniors crediting his stellar performance to their bird’s eye view of the overall situation and constant guidance. “We all played our part in the team, working in tandem with each other. Together we are stronger,” he says with great conviction.

Sonawane joined L&T in 2007 as a senior engineer at the DIAL Terminal-3 project after which he has worked at the Cognizant Phase II, Reliance Jio Garden, Capgemini IT Park Airoli, BARC, Wipro Pune projects before taking over as the Finishing Head of the L&T Business Tower Project in Powai, Mumbai.

Hailing from Chalisgaon, Maharashtra, Sonawane is married to Swapna, a homemaker and they are blessed with two children, son, Jai, and daughter, Maitryi. An altruistic at heart, he spends his free time to give back to society by actively participating in clean-up drives and recycling waste into fertilizer. Coming from a humble background, Sonawane in all modesty says that the joy he saw in his parents’ eyes when he became an engineer is the most memorable moment of his life.

About his association with L&T, Sonawane says, “We, as an organization, are building this great nation and that makes me very proud!”

STRIVING TO DELIVER IN A CRISIS

Munjeti Gopala Krishna

Construction Manager (Mech), B&F IC

A major challenge confronting Munjeti Gopalakrishna (or MGK, as he likes to refer to himself) at the RAMCO Line-III, Cement Plant project in Jayanthipuram, was to mobilize adequate skilled manpower after the unlock by whatever means possible to meet the project completion deadlines. He is delighted that by achieving his objective, they have successfully achieved some important project milestones. “We have handed over the process requirement to the client for the preheater, kiln, clinker cooler and ESP buildings,” he shares with a huge sense of satisfaction. “We completed the pre-assembly of critical erection works in the elevated structure that ensured that we not only saved time but we are in a much better position to achieve our targets and hand over the building to the client in time.”

While MGK and his colleagues had to rely on their vendors and subcontractors to identify and mobilize enough manpower, they were careful to search for and find skilled manpower for the critical erection works of the preheater. He is extremely thankful to his seniors and colleagues for having made this possible. “It has been a huge collective effort to mobilize manpower,” he shares with great fervour, “all our teams from planning, admin and other support functions worked very hard and in a well-coordinated way to ensure that we had adequate manpower to start operations at site as soon as the lockdown was lifted.”

Working on the RAMCO cement plant project, MGK finds himself on familiar ground because he has worked on a sting of cement plant projects before. Although after joining L&T in 2009, his first project was ICICI Bank Gachibowli and another stint at Hyderabad Metro Rail, the rest have all been cement plant projects: 6,000 TPD Zuari Cement Plant, 6000 TPD Heidelberg Cement Plant, 3500 TPD Prism Cement Plant, 6500 TPD Orient Cement Plant and the 4500 TPD KCP Line-II Cement Plant. “You can call me a bit of an expert on cement plants,” laughs MGK, who hails from the village of Loharijola in Andhra Pradesh’s district of Srikakulam.

He is married to Sudharani, a homemaker, and they are blessed with two children: Akshini and Keerthi Krishna. His favourite hobby is cricket.

In conclusion, he says, “Our organization took on a very big challenge to mobilize manpower during the lockdown by using various modes of transport which has gone a long way to help us complete our project within the stipulated time.”

SEEKING QUALITY IN EVERYTHING

Suman Kumar Sourabh

Manager (QA/QC), B&F IC

An attribute that Suman Saurabh gives greatest importance to is ‘honesty in quality product delivery and EHS’ and as a professional with the responsibility of driving quality at his project, it is a very relevant attribute to have. Having joined L&T in 2010, Suman is presently working at RAMCO’s Jajpur Cement Grinding Unit, Haridaspur, in the Jajpur district of Odisha. “During and after the lockdown, most of our old workmen left our site,” he shares his challenges, “and we had no proper communication of how workmen from other states could travel to our site after the unlock. It was very difficult to find skilled manpower locally, but we had no other option but to get maximum labour locally. On top of this, we were facing huge pressure from the client to commission the plant in time.”

For Suman and his colleagues, arranging for local subcontractors and introducing new, small vendors were the only solutions to increase manpower. “We depended on their (the local subcontractors) networking to source labour and we even sent vendor supervisor teams to the nearby villages to identify, motivate and convince workmen to come and work at our site.” The vendors also helped by providing the history of new workmen that made it easier for the team to screen them before engaging at site. “The client supported us to implement our SOPs,” adds Suman, “they made arrangements to quarantine the new workmen and coordinated with our admin team and the local administration to arrange for new labour.” Suman points out that they sourced new workmen only from green and orange zones and “we started evaluating workmen through video calls before calling them to site.” Suman also acknowledges the help and support from his seniors to address his site-based issues.

Although COVID-19 has thrown up several unique challenges, Suman has been able to hold his own thanks to his 10-year experience with L&T that began at the Lafarge Cement Grinding Unit project after which he was involved in the ‘Atmosphere’ project in Kolkata. “It was an iconic project,” he shares with pride, “and I was responsible for 4000 MT of structural steel fabrication and erection.” Suman’s 3rd project was the Tata Housing Avenida project, again in Kolkata, where he was looking after MEP works, after which he has landed at Jajpur.

Suman’s native place is Katihar in Bihar. He is married to Nutan Kumari, a homemaker, and the birth of his angel, daughter Anika, has been Suman’s most memorable moment. “I like to listen to music in my free time,” he says, nodding that he does find time for it.

EVOLVING CATCH-UP PLANS TO STAY

ON TRACK

Ravi Pattem

Construction Manager (Mech), B&F IC

With the amount of time lost due to the lockdowns and delays in mobilizing adequate labour to bring site operations back on track, several managers like Ravi Pattem across L&T Construction are evolving catch-up plans with their respective teams. The labour exodus with the Unlock has left several sites including Ravi’s RAMCO Kolimigundala project site searching for skilled workmen which is why he triumphantly claims, “I explored and mobilized 387 relevant workmen for mechanical works and then trained them to reach L&T quality and safety standards.” Apart from having to arrange transportation to mobilize fresh labour, Ravi’s other challenges at site have been to offset the shortfall of oxygen and carbon dioxide cylinders and welding rods. “Of course, the rising number of COVID infections to our staff has been another headache,” he adds with a pained smile.

His mobilization of workmen has been most helpful for the site because as he shares, “the kiln erection was completed as per schedule with trained workmen and we also completed the erection of the preheater top structure.” Ravi is equally proud of another piece of his out-of-the-box thinking. “To overcome the shortage of O2 cylinders, I replaced the gas cutting machine that involves the usage of O2 with a plasma arc cutting machine that does not require O2.”

On ground, Ravi and his team have been busy creating a healthy work environment. “We are constantly monitoring and motivating our people to achieve our committed targets,” he emphasizes. “We have helped to provide transportation facilities for manpower mobilization by seeking prompt approvals from the cluster, convincing the local government officials to conduct COVID-19 tests for the newly mobilized workmen and are using the Spandana Android app to update workmen details prior to seeking permissions from government officials for inter-state mobilization.”

In this fight to overcome the disruption caused by the pandemic, Ravi is bringing to play all his experience gained from having worked at eight projects at L&T with RAMCO being his 9th. Hailing from the village of Puttur in the Chittoor district of Andhra Pradesh, Ravi is married to M Monika, a homemaker and they are blessed with one child, Yuva Sai. “I love watching movies over weekends,” he smiles.

Ravi is proud of L&T for having taken on challenging projects like the Navi Mumbai Airport and the Statue of Unity and for taking care of its employees during the COVID-19 crisis despite facing a severe monetary strain.

Two aspects that make Parwez Ahmad proud of being a part of L&T are the freedom to operate and take decisions. “Further, the confidence that my seniors reposed in me has always been a morale booster especially during these difficult and testing times,” he says earnestly. “These factors together have always inspired me to work harder and achieve higher standards in my field of work.”

Parwez’s contribution has been inspirational at his present project, the India International Convention & Expo Centre at Dwarka in New Delhi, to combat the pandemic. Oh yes, he nods, “We have had to face many challenges since the lockdown. One of which has been to network with subcontractors and tap new and different sources to mobilise labour. Though the prevailing travel restrictions were big hurdles, we overcame these by closely coordinating with subcontractors located in various states to arrange buses, train tickets for workmen followed by the due diligence of identity verification.” He mentions about the separate isolated blocks that were maintained to house the fresh inflow of new workmen to ensure quarantine norms along with round-the-clock medical check-ups. “Perhaps the biggest challenge,” Parwez says, “was to establish an emotional connect with the workmen by extending to them a comfortable and safe working environment since they were risking themselves by working in such harsh times.”

Apart from revamping the labour camp and setting up quarantine blocks, Parwez was involved in revisiting the SOPs for camp operation and maintenance, realign them with the Health Ministry guidelines and formulate new rules for the new, incoming workmen. He mentions the introduction of a Public Address System in the labour camp to frequently broadcast the precautions and care to be taken to prevent infections adding that the introduction of additional features in the WISA App made workmen induction far easier. “The support extended to me by my seniors and team members has been quite extraordinary,” says a grateful Parwez, “and they will remain a guiding influence to deal with such situations.”

Before IICC, Parwez has a host of other projects with L&T in his track record. “My first project was VGS Dulhera Project,” he recalls, “followed by HCL, the Convention Centre in Aero city and the BJP Headquarters project before moving here to Dwarka.”

“I like to spend my spare time bonding with my family members,” he says with a glow to his face and his family members include, his wife, Kamila, who is a homemaker and two sons, Aayan and Arhaan. Parwez hails from the village of Mania in the district of Ghazipur in Uttar Pradesh.

AIMING TO ACHIEVE HIS GOALS!

Boopathi C

Senior Engineer (Civil), B&F IC

As the MVDC Test Track Project reopened from the shutdown, Boopathi C and team faced challenges to operate in new ways. “As majority of our workmen had left, to resume site activities with a negligible workforce was our greatest challenge,” shares Boopathi, “along with mobilising fresh workmen, ensuring their health, safety and strictly following all the COVID-19 restrictions.” Diving right in, the team began by first boosting the morale of the subcontractors and workmen. “Thanks to our dedicated effort to re-mobilize and continuously follow-up, we have efficiently restarted site activities,” he shares proudly.

“After creating confidence among the workmen, we trained and offered them incentives,” Boopathi shares. Their strategy was simple but effective. “To overcome the shortage of labour, we focussed on engaging local workmen to carry out site activities. All manpower driven activities such as stone pitching that had come to a standstill due to the pandemic, were kick-started.”

Though productivity was suffering due to reduced work hours and moderately low level of local skilled workforce, digital solutions helped to perk up progress for Boopathi and team. “Through Procube, I enter the required data, monitor lapses, identify shortcomings and thereby improve productivity,” he says with quiet determination.

Boopathi acknowledges his Project Manager, Construction Manager, Project Administrator and Time Office In-charge for their unstinted support to mobilise workmen during the strict travel restrictions in Tamil Nadu. “It is only due to their support that we could arrange buses and train tickets to safely bring workmen back from all parts of the state,” he points out.

Boopathi has rich experience in working on factory projects such as Saint Gobain Phase – III – Sriperumpudur, Natrip Test Track – Oragadam, JK Cement Plant – Chittorgarh, Maruti B&C Line – Manesar before taking over as Senior Engineer at MVDC Test Track Project.

Hailing from Manapparai in Trichy, Boopathi is married to Carmila Devi B who works as a Computer teacher in a private school. They are blessed with a daughter, Venmugil B, whose birth is Boopathi’s life’s most memorable moment. He spends his free time listening to music, reading news and cooking. Though he admits that he does not have much time on hand to actively pursue his hobbies, he utilises his daily travel time to the site to catch up on music and news.

“It is great to work for L&T as the organization has supported me in all my endeavours. My seniors and colleagues have always motivated me to aim and work towards my goals. L&T supports various CSR activities that I am part of, which makes me proud!”