PUTTING PEOPLE AT THE CENTRE OF THINGS

Paramjit Singh

Deputy General Manager – Civil, TI IC

Paramjit Singh is on his first assignment with L&T at the Mauritius Metro Express project but brings with him years of rich experience, although it seems that L&T was his destination. “Every civil engineer in India dreams to join L&T, one of the finest construction companies, and I am proud to be a part of this lovely organisation and thankful to have been posted at an international project with the opportunity to make my country proud,” he says with genuine passion, adding that L&T exemplifies the sterling qualities of values, virtue, fairness, respect, care, and honesty.

At the Mauritius project, Paramjit’s ambit of responsibilities included anchoring on-site activities to ensure project completion within the time and cost parameters, effective planning & resource utilisation and directing, leading, & motivating the workforce. “We strove to be more effective and efficient in our operations by micro-planning our various activities, building trust within the team to be one cohesive unit and, most importantly,” he smiles, “maintain good relations with the local contractor, client, and consultant.”

On site the team had to contend with the unpredictable, tropical maritime climate of the island where it could rain without warning anytime leaving moisture in the beds creating compaction issues. “To address it, we adopted a method of covering the bed with 100 m long polythene sheets to be put as soon as it started to rain with a small edge drain to drain off excess water, much like what they do on cricket pitches,” he shares. Of course, ready availability of material was always a tough nut to crack for the team.

“Digitization puts the operators and the workers at the centre instead of operations,” he remarks, sharing a new take on deploying digital solutions. “It vastly minimizes operational uncertainty, eases the burden on the safety engineer to identify potential risks and finally ensures that the equipment itself is working within healthy and safe limits.”

“Whenever we needed help to achieve our target, my boss and team members were ever ready to support,” says Paramjit, acknowledging excellent teamwork. “Without proper support, we could have lost track of progress and would not have been able to complete the project in the desired time.”

“I am from the paradise on earth namely Baramulla in Jammu and Kashmir, that sits in a breath-taking valley,” though presently enjoying with his family in Mauritius. “I have two lovely daughters, Sargamjeet Kour and AmyJeet Kour and my wife, Baljeet Kour has a Diploma in Secretarial Management, is a Bachelor and Masters in Commerce and Bachelor in Education.” His most cherished moment is when he held his first daughter for the first time.

FINDING THE

RIGHT NOTES TO A

DESIGN SUCCESS

Sukanta Kumar Saha

Principal Architect (Sr. Manager), TI IC

He is an artist by profession. At work, an architect; in his personal space, a musician and an art lover. “I am passionate about music and was a former member of the University Music Band as drummer and singer,” says Sukanta Saha, “and I never miss an opportunity to sing and play an instrument.” This passion is evident in his work too, right from starting his journey with L&T in 2011 and giving it full expression at the challenging Mauritius Metro project. “To start with, it was tough,” he grimaces, “being a building architect, I had to change my perspective from vertical to linear but once I got the hang of it, it was smooth sailing,” he smiles.

After the successful completion of Phase-1, the management gave Sukanta dual responsibilities of finishing execution with procurement along with architectural drawing and design. “It was a unique opportunity for me as an architect to see materialized what I had visualized,” he says with dreamy eyes. “It helped a lot to properly coordinate in advance with the structural and MEP work at site, sequentially complete the objectives and maintain a healthy relationship with the Employer and their representative to quicken execution,” he winks. With dual responsibility, it was easier to forecast and calculate resource mobilisation which is why they successfully completed the Phase-2 project before time.

The total design responsibilities of the Mahatma Gandhi Station were Sukanta’s, a responsibility that carried with it huge expectations from all the stakeholders. “Keeping the same basic structure, I incorporated a few sculptures and architectural elements related to Gandhiji to give it a heritage look.” Thereafter, sourcing these elements from India in a short period was a challenge but the team delivered.

Material and local skilled manpower mobilisation were perennial headaches for the team. “Most of the finishing materials were outsourced and imported from India, Dubai or China, more than 6000 km away,” he shakes his head. “So, we proactively ordered all the finishing material parallelly at the design stage itself to avoid any kind of delay during execution.”

Sukanta attributes their success to great teamwork, proper coordination and true leadership with teamwork based on the four pillars of Trust, Freedom, Confidence and Belief. “Our mantra was that success comes when we are confident of our work, confidence when we are free to work, freedom when our seniors believe in us and belief builds trust,” he says insightfully.

A native of Kolkata, West Bengal. Sukanta is married to Ranjana, an MBA in Finance and associated with the banking service before moving to Mauritius. They are blessed with a son, 6-year-old Samadarshi.

“There are lot of reasons to feel proud as a L&T-ite, difficult to choose one,” he smiles.

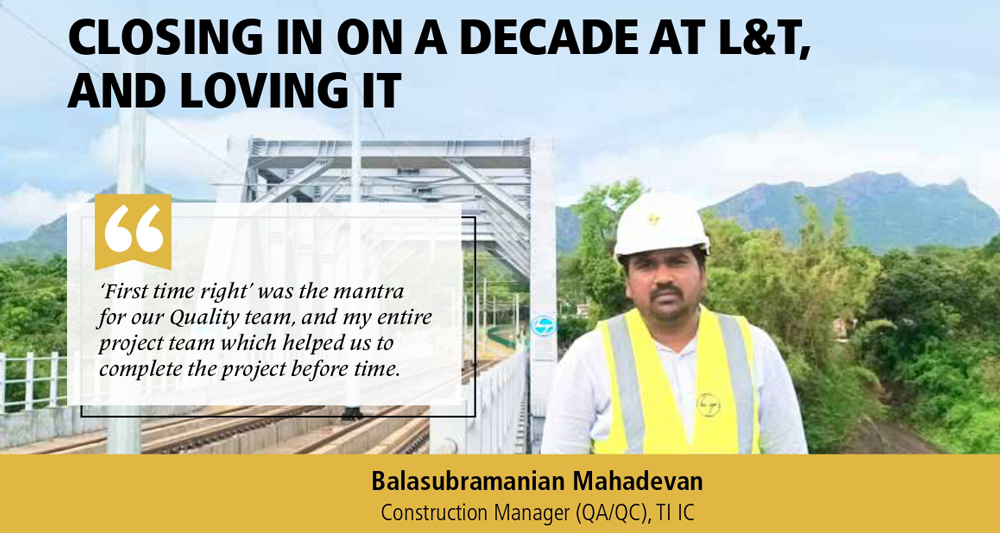

After executing various projects in India, Oman, and Saudi Arabia for other organisations, Balasubramanian Mahadevan joined L&T in 2013. “Soon, I am going to complete a decade with L&T which is already a part of my extended family. Like me, L&T also takes care of my family, giving enough opportunities to learn and grow,” he shares his pride about the company he keeps. After a 4-year stint with RREC HQ in Mumbai, he moved to the Mauritius Metro project, his first with L&T, to head the QA/QC department. “‘First time right’ was the mantra for our Quality team, and my entire project team which helped us to complete the project before time.”

Time constraints and to avoid reworks or rejections when inspecting reinforcement for structures (bridges & viaducts) from foundation to superstructure, Bala posted his team at site to constantly monitor and correct the work in line with approved drawings with the site engineers. “With nothing much available in Mauritius, most materials had to be imported which was time-consuming,” he frowns. “To avoid rejection of materials from various countries, third party inspection agencies like SGS, TUV, Bureau Veritas were deployed to inspect the process from production to dispatch and witness the test in line with approved ITP before dispatch of all the bought-out items at supplier premises.”

Setting up a state-of the-art Quality Control laboratory at site for various disciplines like soil, aggregates, concrete, cement, asphalt, etc in line with European standards that are completely different from Indian Standards was a master stroke, thinks Bala, that saved cost and time significantly. Construction of the Warren Truss bridge was his most difficult task, that was first fabricated in Gujarat. “To avoid rework after receiving the fabricated steel components at site, we deployed an independent third party agency (M/s Bureau Veritas) full-time from fabrication to dispatch of materials to Mauritius for 5 months. Further, I gave technical guidance to the fabricator to carry out all the step-by-step inspections and testing in line with the European Standards.” Even during assembly, Bala and his team worked in shifts along with the erection team to achieve their milestone.

Bala mentions Sanjeev Gupta, Subhendu Ghosh and Sanjay Upadhyay for their support and encouragement for all his initiatives. “I am so lucky to have very cooperative team members who always extended every assistance to complete our target,” he says passionately.

Hailing from Thanjavur, Tamil Nadu, Bala’s better half, Priyadharshini, was a software engineer till marriage, and they are blessed with two children, elder son, Sai Venkatesh and daughter, Harshavarthini. “Listening to music and exploring new places with my beloved family are what I love,” he smilingly concludes.

INTRODUCING THE ‘MAN OF FORMWORK’

FOR THE MAURITIUS PROJECT

Dinesh R

Manager (Civil) & Head, Formwork & Scaffolding, TI IC

A GET of the 2013 batch, R Dinesh is presently Head – Formwork for the Mauritius Metro Express project with end-to-end responsibility to manage and execute the L&T Formwork System. Having successfully completed the National Certificate Level-4 in scaffolding from the Mauritius Institute of Training and Development and Registered as a Scaffold Inspector at the Ministry of OSHD Mauritius for L&T across Mauritius, he is both qualified and experienced to be called the ‘Man of Formwork.’

“We achieved a cycle time of 3 days for one of the most critical structures of the project, the 62 m long Warren Truss Bridge Deck slab,” flags off Dinesh as a ‘big’ achievement, for which the shuttering arrangement was crucial as the deck was around 20 m above the river HFL. With no possible arrangements for staging or fabricated brackets, the team prepared a mock-up of the shuttering at the assembly location to gauge the size and quantity of material required. “This helped us to identify the difficulties and points of improvement in the designed shuttering scheme,” points out Dinesh. The meticulously planned task succeeded, reducing material wastage in primary members in the process. “We cast 10 deck slabs at the Rosehill Flyover Extension in a month’s time and casted a 12 m pier in a single pour at the GRNW 6 Bridge, both to meet our target schedules,” he shares proudly, adding that he won the DELTA Award 2019 from TI IC for ‘Best reduction in cycle time.’

Dinesh has had to contend with the non-availability of ready resources (men, material & machinery) on an island in the middle of the Indian Ocean, working with ‘live’ traffic & dense pedestrian movement, overcoming issues of land acquisition, inclement weather, and he adds, “having to learn to deliver such a complex project that involved bridges, flyovers, Warren Trusses, TSS building, depot, admin buildings, box culverts, retaining walls and drains coming from a background of commercial buildings and airport structures.”

He is delighted with the support, encouragement, and freedom to perform he has received from his seniors and the top management, marking Sanjeev Gupta (Project Director), Pankaj Lamyan (Head – Project Control), Sanjay Upadhyay (Head – Formation) and KVD Malleswar (Head – Formwork TI IC) for special mention.

From Thiruvengadam in Tamil Nadu’s Tirunelveli district, Dinesh is married to Jeneta Kalyani Sundaram, who has completed her B. Tech (ECE), ME, and worked as a HRM in the Vivekanada Group of Institutions. They are blessed with two children, Saatvik and Jhanvika. Playing cricket is his hobby and rejoices that L&T won a cricket tournament in Mauritius. His most memorable moment is his marriage and finding his ideal partner for life.

SHIFTING ROLES,

BUT SAME FOCUS AND EFFICIENCY

A DET from the 2013 batch, Joydeep Barui began his professional journey with L&T at the DMRC CE07 project in New Delhi. “In 2018, I moved to the Mauritius Metro project in the procurement department as Material Engineer,” he says, and soon realized that on that tiny island in the Indian Ocean there were very few suppliers, no manufacturing facilities and no labor oriented towards metro construction. “Everything had to be imported,” he says rolling his eyes. “To start with, we developed local vendors, created a vendor pool, maintained a fruitful relationship with them for their support to deliver on time.”

The team was dependent on imports for Railway / Metro components and their first huge roadblock was the pandemic. “No sooner were we recovering from the impact of COVID that the geo-political tensions due to Russia’s invasion of Ukraine in 2022 disrupted global trade and shipments and sent petroleum and commodity prices soaring,” he says with a long face. Meticulous planning and continuous follow-up with vendors saved the day for them. “We short-listed and procured materials, tools and consumables in bulk from foreign suppliers for cost benefits, better transportation charges and timely delivery as time was the essence for this project,” he states, purposefully.

2020 brought with it a change of role for Joydeep as Planning Engineer and the pressure to maintain an extremely stringent execution schedule. “It was important to monitor every execution method at a microscopic level and we adopted a scenario-based strategy to identify the critical driving factors for each section and tracked critical activities to conclude them,” he lays out his plan of action. For the time-consuming Pullpit Works (Cable Containment), the team adopted precast methodology to reduce execution time and that enabled them to complete the project 3 months ahead of schedule. For the critical erection of the cable trough, the length of the cables was reduced from 1.2 m to 0.6 m for easier transportation and improved productivity.

That all their effort delighted their customer is what makes Joydeep a proud L&T-ite. “We were proud when our customer acknowledged our efforts to deliver the project timely at a public event.” Successful teams do not happen by accident, they are not born but made and Joydeep is overjoyed with not only his superiors, but with the whole team for being so supportive and passionate about their responsibilities.

Joydeep is married to Arpita, who was a teacher in their native place, Hooghly, West Bengal, but now makes their home that is complete with their daughter, Krittika. “I enjoy badminton and photography and my most memorable moment was when I first held my daughter.”

EFFICIENTLY MANAGING

INTERDEPENDENCIES

Tejesh Sharma

Manager (Electrical), TI IC

A GET from the batch of 2014, Tejesh Sharma’s first assignment with L&T was at the DMRC CE-08 LOT 2 Project after which his focus has been to deliver the Mauritius Metro Project on time. “When interdependencies are at their peak, great effort is required through brainstorming to ultimately implement the plans by converting conventional working into innovative steps,” he says with the seriousness of a seasoned campaigner, but quickly substantiates his statement.

“All the cantilevers and MCCs (Multi Channel Cantilevers) were installed using scaffolding before access through track for RRV movement was made available,” he begins. “In fact, civil works along the alignment and installation of OHL accessories simultaneously, was a common sight. Our focus was primarily to prioritise the interdependent linear works such as OHL and cabling activities, which is resource intensive. We engaged teams for Traction Substation readiness and other mandatory minor works first to avoid the resource crunch at the later stages when access was available.” Substation works, however, commenced earlier than expected with some requisite equipment and parts still in transit.

Tejesh cites another example of the battery and battery bank. “The first TSS charging was completed in a record time of 3 months before commissioning with local arrangements acting as decoys to support finalization of testing requirements,” he says. “Before the local Electricity Board could extend their connection to TSS, DG arrangements with convertors provided the requisite power to accelerate testing.” Other hurdles the team had to overcome included combatting windy conditions when working at height, understanding the mentality of the workforce and form gangs with a positive attitude, working around rain gaps, and maintaining the highest safety standards.

Tejesh acknowledges the role of the seniors to readily make available the requisite resources to keep things rolling. “Once our target was decided unanimously, we instilled a feeling of responsibility in all and built an environment of trust to succeed,” he says, complimenting his juniors for their perseverance. “Ideas were formed and discussed at every level and the entire team had a basic understanding of what was at stake.” After all the hard work, when you see your effort fructifying, it is a thrilling experience which is what Tejesh and his team felt on seeing the first trial run of the Mauritius Metro on the priority stretch.

“L&T is a bag full of surprises and opportunities being a company that has the power of imagineering to pioneer and construct iconic projects,” he says with josh.

HIS FIRST PROJECT WITH L&T, AND A RESOUNDING

SUCCESS

Raviteja Polineni

Assistant Manager (S&T), Railways SBG

After working for six years on the Singapore Metro, first as an Application Engineer, and then as Project Coordinator, Raviteja Polineni joined L&T at the Mauritius Metro project and is delighted that it has been a runaway success. “My role was with the Signalling & Telecom (S&T) team, responsible to deploy S&T systems through OEMs like CAF, Hanning & Kahl, Aximum, HFCL and Consort,” he informs, adding that the various systems involved were interlockings at 9 zones and the depot, Traffic Signals Priority System (TSPS) at 43 locations, station equipment at 22 stations, Operational Control Centre (OCC) and S&T onboard equipment for 18 LRVs.

Executed in multiple phases, Ravi points out that the pace of each phase, mammoth tasks, picked up exponentially with the deployment of software and integration. “We handled 8+ subsystems with subcontractor OEMs each with diverse scopes, working in different stages of integration, supported remotely by teams working in different time zones across the globe,” Ravi shares the extent of his challenge. “The integration had almost 1000+ variables across multiple systems to be made operational within a short timeline.” Resource management stretched the team both due to the geographical location of Mauritius and the impact of the pandemic on supply chains.

Adaption was the name of the game to changing scenarios as Ravi explains. In Phase 2A due to the pandemic induced restrictions, testing and commissioning were with remote support. “At the deployment of Phase-2B, we ensured that the elements for the next phases were predefined in all the software programs to minimise cycle time. In fact, we were multi-tasking with commissioning of Phase-2B, equipment installation at Phase-2C and foundation installation (track interfaced) at Phase-3 all happening in the same time frame.”

He attributes their success to Project Director, Sanjeev Gupta’s vision, Project Manager, Chirag Singhal’s timely guidance, backend support from the RBG Faridabad office, timely decisions of the project leadership and marks the MLRT S&T team for special mention for working tirelessly to make this possible.

From Ongole, Andhra Pradesh, Ravi’s family comprises his wife, Supriya, a homemaker, and their son, one-year-old, Manvith, whose birth is one of his life’s most cherished moments. Reading books and cooking are his favourite hobbies, and family time.

He’s a proud L&T-ite as the company is “constantly exploring new technologies and methods to make projects more efficient, sustainable, cost-effective and driving innovation to make a positive impact on the world,” he sums up with a sense of awe.

A vital component that influences the timely completion of any project is the adequate and timely supply of skilled and unskilled manpower, that is even more critical for projects being executed overseas like D S Raju discovered at his Mauritius Metro Express site. “It was major challenge to mobilize workers from India and Nepal to Mauritius due to the stringent Government policies,” he says scratching his head. The long-winded process involved a workman having to undergo the prescribed medical tests in India, forwarding the original test reports to Mauritius to be filed with the Ministry of Health to issue the medical clearance certificate for employment, then preparing contract of employment, getting it approved from the migrant workmen section, applying for the work permit to the Ministry of Labour and finally the Residence Permit (RP) from the Passport and Immigration office after issuance of the work permit.

“A worker could travel to Mauritius only after obtaining the RP and the entire process used to take about 3 months,” moans Raju, “because it involved several Government departments and was not a parallel process.” The project however could ill-afford three months for mobilization. “After struggling with this cycle till March 2019, we realized that we had to reduce mobilization time to just a month to maintain the project timeline,” he says seriously, “and I fixed my own target as 15 working days from receipt of the worker’s medical test report to obtaining the residence permit.”

To achieve this, the team involved senior officials of the Ministries of Health & Labour, Passport and Immigration offices, the health and labour ministers and even the PMO. Working with colour-scanned copies of test reports, the Labour ministry agreed to fast track applications and the passport & immigration departments agreed to issue RPs in two working days. Armed with this Raju went into overdrive. “I managed to onboard 900 workers in 15–20-day cycles to meet an urgent requirement to complete Phase 1 in October 2019,” he says proudly. “Post COVID, I managed 600+ permits despite strict restrictions and another 800 workers in 3 months to complete the Phases 2B and C and Phase 3 schedules.”

Raju’s internal support has been FAA Head, S S Samal, “who has motivated me to set my own timelines and pushed me continuously to deliver as per committed dates.”

A GCT from the 2010 batch, Raju hails from Visakhapatnam, Andhra Pradesh, and is married to Priya who is presently a homemaker though a Hindi teacher prior to marriage. Gardening and trekking are what keeps Raju going. His marriage and purchasing his new home, both at the same time, are his life’s most memorable moments.

Raju is a proud L&T-ite, for he says, “L&T gives growth opportunities by encouraging employees to take independent responsibility, supports them in their journey and takes care of their welfare in a crisis.”

A MAN OF MANY PARTS

Meet Toshan Unnoop – a communications specialist, a photographer, a certified drone pilot, a musician, a breeder of ornamental fish, grows aquatic plants and even tries his hand at aqua-scaping. He came on board at the start of the Mauritius Metro project, his first with L&T, in January 2018 as part of the communications team. “I was, at that time, completing my Bachelor of Science in the field of Sustainable Product Design and Engineering,” he recalls, “and was initially employed as a photographer and designer but later had the opportunity to become a certified drone pilot.” He is delighted that with time he was able to apply his skills in content creation and marketing (graphic design, motion graphics, social media set up and management and video production).

The communications team were facilitators, and while Toshan’s work was not directly related to the actual project construction, he played a key role in facilitating the process. “Monthly drone progress images smoothened the overall progress reviews by providing a unique viewpoint showcasing the work done at a glance and revealing clear differences month after month,” he elaborates. “I also got more experience by working on the diversion maps that clearly communicated to the public about the impact of site works on the traffic and put in place a process to attenuate their inconveniences, thereby decreasing the number of complaints and preventing interruptions in the work.”

Being in the content creation sphere, Toshan’s biggest challenge was the review process. “Too many review channels sometimes slow down the finalization of artworks and videos due to differing views,” he grimaces, adding that equipment limitations also impacted how much could be achieved in a given period of time.

Toshan’s experience at the Mauritius project has been a fulfilling one with the entire L&T team ever willing to help facilitate the work of the communications team. “The technical teams at site and at office were always receptive to our requirements to ensure that correct and accurate information was conveyed to the public,” he remarks. He mentions their support to install timelapse cameras and build stands for communication materials. “Our inputs during team briefings on our communication strategies and content requirements hastened the content creation process,” he shares.

A Mauritian by birth, hailing from Quatre Bornes, Toshan is still single, living with his parents, two sisters and aunt. “I was thrilled to bits when I witnessed the first trial run of the metro from Rose Hill to Port Louis,” he says with relish, still basking in the great feedback he has received for the official film he created for the Phase 3 launch.