RAIlWAYS SBG

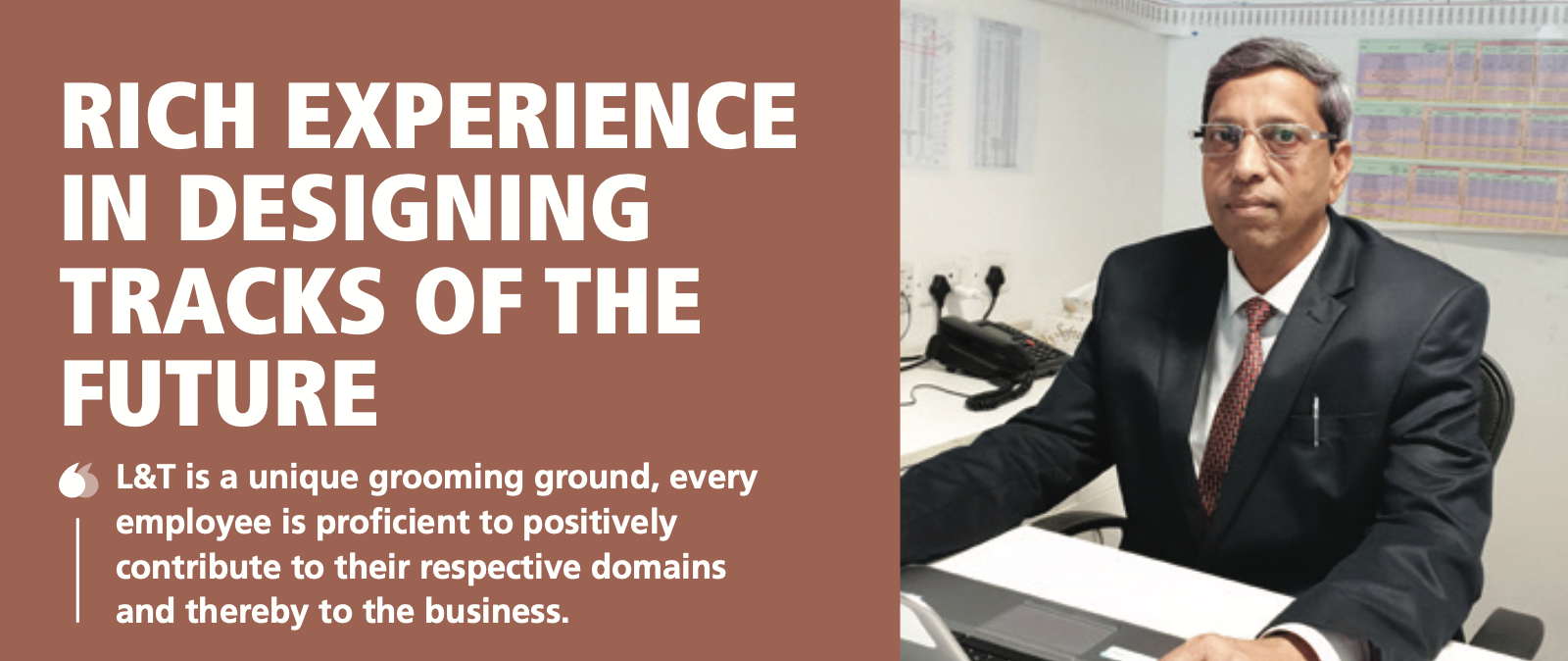

Shyam Baboo Saraswat,

Head – Design & Operations, Civil & Track Projects, Railways SBG

Having joined L&T in 2013 for the design of tracks and associated works at EDRC, Shyam Saraswat, an ex-Railway IRSE Officer, is in effect playing the second innings of his career having spent his first 30 working years in various capacities with the Indian Railways. In fact, he shares, “One of my most memorable moments was to receive the MR (Ministry of Railways) Award – the highest honorary award for maintaining the best track in the whole of the Indian Railways!” Certainly, his rich experience is helping push the design and operation of the entire set projects presently being executed by the Railways SBG.

“We were entering new territories with this project,” says Saraswat. “The design for many of the track components was new (no RDSO/Indian Standards available) as the 25 T axle load was not in use in the Indian Railways with the result approvals for the new designs was both a challenge and time consuming.

Being the first railway track heavy haul project to be executed, we neither had enough skilled staff nor a decent vendor pool as several new track components had to be sourced. It was almost like setting up of a new organization to handle this vast and linear project,” he sums up. “We schemed out the complete process of track laying, broke it down to individual processes and then each team was specially trained, and demonstrations given for them to meet our overall objective.” After he pause, he adds, “all the hurdles we encountered were thus streamlined.”

Saraswat shares about some of the other initiatives he and his team have taken to improve operational efficiency. “The decision to opt for the NTC over pre laid turnouts was a big one for it was being attempted for the first time in the history of the Indian Railways but we were confident because we took the decision only after extensive trials conducted at site. We avoided the excessive use of BRM by devising a scheme of unloading through Hoppers and to increase track speed capacity we did first tamping using bed ballast that quickens post track linking activities.”

“L&T is a unique grooming ground,” he says with awe. “Every employee is proficient to positively contribute to their respective domains and thereby to the business. We have, however, found it difficult to train employees in the emerging railway domain which is an area we need to look into seriously to control attrition.”

A native of the city of the Taj Mahal, Saraswat’s better half, Veena, is a homemaker looking after their three children, daughter, Shelja and sons, Abhishek and Vivek. When he is not designing tracks, Saraswat reads and walks.

– Kailash Chand Yadav,

Head – Track Construction, CTP 1 & 2, Railways SBG

He is an expert Railway man. An Ex-IRSE 2001 batch officer, Kailash Yadav has spent 27 years with the Indian Railways executing several projects prior to which he was involved in constructing Asia’s biggest ever canal project – the Indira Gandhi Canal Project. Presently, he oversees track construction of a linear project that stretches 650 route km and covers three states – Haryana, Rajasthan and Gujarat. “My project that is now almost over is divided into two major parts, CTP – 1 & 2, with control depots for track construction at Bhagega and Marwar with full establishment of P&M, sleeper plants, gantries etc. and with the backend support of a comprehensive track design team at Faridabad.”

Challenges in a project of this magnitude and complexity is a given and Kailash agrees that he has had more than his fair share of them. “Of course, there was a huge safety issue as we were working close to ‘live’ and busy railway lines. We had to overcome many technical challenges as we had introduced and implemented several technologies and machineries in track construction and then there was the whole complicated approval process,” he shakes his head. “We had to procure approvals for fittings, track components, designs, drawings of rail/sleepers, FB weld plants from RDSO; IR;DFC; RITES, and routing all the technical correspondence through the contracts team to the client was another uphill battle.” Temperature variations and weather conditions had a significant bearing on track construction for which the team used a continuous rail temperature recording device, installed at all depots, to monitor rail temperature data.

“Distributing our staff in groups of about 50-100 across various linear locations and with effective administration and safety units, we were able to maintain up to 1000-1500 track work labour daily at site,” shares Kailash who feels that the arrangement to fuel the huge P&M rail bound vehicles from two central petrol pumps one at each depot proved extremely beneficial.“With Incharges for every big activity directly reporting to the Head – Track Works and monitoring the project through ‘Tilos’ significantly boosted progress with better role clarity and effective project management,” Kailash adds with satisfaction.

Indigenizing the NTCs to suit Indian conditions, introducing Amberg trollies for track geometry surveys, monitoring hopper turn rounds for efficient ballasting, introducing ‘Y’ connections to change the direction or orientation of the NTC were some more efficiency boosting steps taken at site.

“Safely piloting the first ever goods train up to Kishangarh Balawas after travelling 306 km on the newly constructed Western DFC track traversing the states of Rajasthan & Haryana was a wonderful experience,” shares Kailash, who hails from Rajasthan. His wife, Kamlesh is, as he says, “making my house a home,” and they have two children, daughter, Ankita and son, Apurv.

Rajnish Kumar,

Head – Project Planning & Monitoring (Sr. DGM), Railway SBG

Rajnish Kumar’s wife, Smita, teaches fine arts to children. She also seems to have taught Rajnish the fine art of planning and closely monitoring the progress of the mega DFC project plus that of the Dhaka Metro, Konkan Railway and various other CORE electrification projects. “I joined L&T in 2018 and this is my first assignment,” shares Rajnish. “A section of about 300 km in the DFC western corridor has already been completed by us along with the electrification works, which has attracted the appreciation from DFCCIL & other concerned authorities.” His satisfaction is evident. A civil engineer from IIT-Kharagpur, Rajnish joined SAIL as management trainee in 1994 before jumping on board the Indian Railways as part of the IRSE Batch of 1995 till he shifted tracks to join L&T.

“Almost all the Railway SBG projects have centralised planning under TILOS, a linear project management software,” informs Rajnish. “TILOS enables us to present the whole project in a single view of time and distance through which all the stakeholders can have a better view of “when and where” of the project. Identification of bottlenecks has become easier which has led to better control and adoption of corrective actions to avert potential crisis. We are also driving to increase the productivity of track machines vis-a-vis benchmarks set among all the concerned teams through planning, regular monitoring and effective control. Again, TILOS is being used extensively for this purpose.” Rajnish mentions their integrated asset planning for different track machines for the whole of Railway SBG that, as he elaborates, “strikes a balance between timely completion of projects and minimizing capex.”

Apart from setting up a centralized Planning & Monitoring Cell at Faridabad for holistic planning of projects, Rajnish talks about their focus on making their assets sweat more, providing timely inputs for buying or hiring new machines for future projects to avoid unnecessary capex and planning for the deployment of machines within and across various projects.

Rajnish and Smita, who is also a homemaker and freelance artist, are blessed with a daughter, Suhani. “I like a game of tennis when I can find the time and am a voracious reader of diverse fields, fiction to mythology, management to finance.” He fondly remembers taking his grandmother on a pilgrimage of Haridwar, Mathura and Vrindavan and her look of happiness when she took a holy dip.

Brij Mohan Sharma,

Project Director, Mumbai Metro Line 3, TI IC

Leading a complex project with a load of unique challenges, it is no surprise that Project Director, Brij Mohan Sharma believes that a problem shared is half solved. “I involve both our client and the consultant in problem solving since it is easier to thrash out solutions when everyone is on the same platform,” he shares sagely. “By getting the client on our side also helps us to convince them to release our payments promptly after the work is completed,” he quips. With a track record of having been involved in the Mumbai Monorail project as Head – Electrical Systems and the Lucknow Metro project as Chief Project Manager, Brij Mohan is handling three mini projects within the large Mumbai Metro Line 3 project. “I am involved with one power supply project (11 B) and two track projects (10A & 10B).”

Apart from collaborative problem solving, which, as he describes, is all about creating a common goal and alignment amongst the various stakeholders, Brij Mohan believes in empowering his colleagues and sub-ordinates to get the best out of them. “Firstly, I have developed a belief in all my teams to successfully complete the project. Then, I have imbibed in every execution engineer financial awareness and our provisions of ACE for that activity to make them aware that an early or delayed finish can fetch us gains or losses respectively for the project. I make them understand that every action of theirs has a direct bearing on the financials of the project. I created guardians of GETs to manage groups of workmen that has given us wonderful results. At the same time, multi-skilling is also helping us reduce our resources,” he states, understandably proud of his people management skills. “Apart from efficient utilization of resources, it is important to keep a close eye on safety and quality and to get things right the first time,” he reminds.

WhatsApp, he says, keeps everyone abreast of developments and helps to address problems at the right stage while digital solutions like Procube, TILOS and mtrack are giving the team a decisive edge.

“I would like to give more authority to Project Managers in terms of financial power,” he opines, looking ahead, “and introduce physical training at regular intervals to improve the physical health of employees in addition to mental health for presently there is more stress on improving soft and technical skills.”

He would love a game of basketball if he found the time for it, laughs Brij Mohan. His better half, Madhu, is a homemaker and his two sons, Praveen and Adarsh, make up his lovely family. “My most memorable moment,” he recalls with feeling, “was the successful trial of the Lucknow Metro within very stringent timelines on 01 Dec 2016 which has been my toughest project so far.”

Venigalla Venkata Ramana,

Project Manager, TI IC

There are times when Venigalla Ramana is confused whether rules have been framed for work or vice versa which is a confusion that he would like to clear but for the time being, his days are full as Project Manager handling the mega ballastless track works for Ahmedabad Metro. In his second project, after having been Project Manager at the Rewari – Mahneru Railway doubling project, Venigalla must deliver 80 tkm of BLT track with 45 ballastless turnouts and 20 tkm of ballasted track with 79 ballasted turnouts.

“Laying the ballastless track and plinth with provision for vertical fixing of the third rail bracket is the biggest challenge,” he explains, “that needs high precision execution within the stipulated time to cast the track plinths. In fact, at one point, the asking rate of daily progress was almost beyond our limit: our working rate was 1.5 tkm per month while the asking rate was 2.6 tkm to achieve the target set by the PMO to open the metro for commercial services.”

Venigalla and team moved into high gear to meet the asking rate by increasing workmen strength by 20%, thanks to which average casting of track plinths improved from 60 to 100 tkm and adopting a special shuttering arrangement with dowel provision further pushed up speed and precision of construction. “With these measures, we were able to meet our targets and it was my most memorable moment when the EW corridor was completed in December 2018 and commissioned in March 2019 to meet the PM’s schedule.”

Identifying the right man for the right job and delegating required powers for people to perform are, what he believes, work best at L&T Construction. “The shuttering mechanism was designed and adopted for precise casting of track plinths as per the requirement of the third rail fixing arrangements and we were able to implement it after I won the confidence of my BU Head on my assurance that it would succeed,” he smiles victoriously. “I cannot think of anything special we have done to achieve our goal other than being keenly vigilant and planning and improving our resources dynamically.” He mentions that engineers keep uploading progress photographs on WhatsApp to monitor daily progress and “we ensure that failures, if any, are attended to immediately to avoid any loss of time to achieve our daily targets,” he adds.

“I believe in self-growth,” he declares, “and make time of at least two hours every day to improve my knowledge and keep abreast of new developments.” A native of Donepudi, in the Guntur district of Andhra Pradesh, Venigalla’s better half, Satyasree, is a homemaker and they are blessed with two children: daughter, Dhana Lakshmi and son, Eswar.

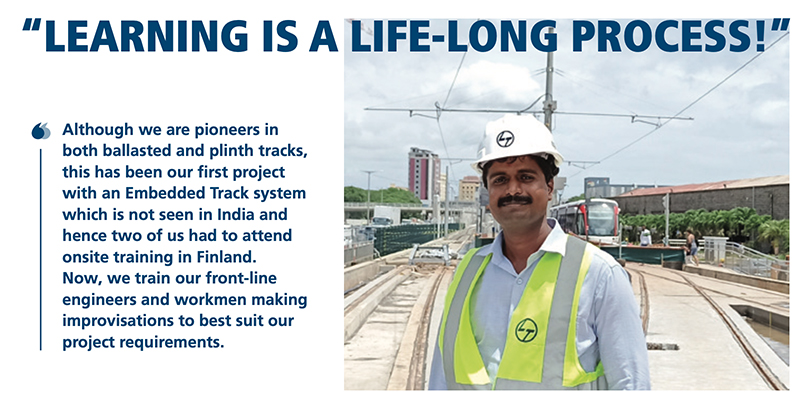

– S Balamurugan,

Lead – Track Works, Mauritius Metro, Railways SBG

For S Balamurugan, the Mauritius Metro Express project has certainly been a steep learning curve. “This is our first overseas composite project where we are dealing with five different types of LRT tracks – Ballasted, Embedded, Plinth, Column and Slab Track – so envisaging the technical requirements from an EPC perspective was a challenge,” he shares. “Although we are pioneers in both ballasted and plinth tracks, this has been our first project with an Embedded Track system which is not seen in India and hence two of us had to attend onsite training in Finland. Now, we train our front-line engineers and workmen making improvisations to best suit our project requirements.” A key determinant of success at this project is precise planning as most things have to be imported including skilled labour and components and “since the dates of commissioning were fixed, we have to crash our deadlines and have multiple teams to work on several work fronts,” says Balamurugan.

He enumerates four ways the team has adopted to drive operational efficiency. “By pre-fabricating steel beams separately and placing them bound with distribution rods only when the site is ready has reduced the time for rebar works by 40% that has in turn resulted in better turnaround for the ballastless track works and better utilization of workmen as a gang. This initiative was highly appreciated by management and recommended for the DELTA award. The As-builts levels of the deck slab are taken at intervals of 500 mm and the BBS for plinth/ slab track are prepared for each plinth (typically of 4.3m in length) with a unique plinth identification number has eliminated rebar wastage completely.” An innovative use of scrap to convert old scaffolding staircase footboards into shutters to precast cable troughs with minor modifications has won them another recommendation for the DELTA Award. They have also reduced fuel consumption for the flash butt welding works. “We deployed a separate portable 3kVA PG to supply power to the grinding works eliminating the use of large in-built DGs that resulted in savings of 3900 Litres of HSD (High Speed Diesel) and further savings of approximately 4000 Litres of HSD is expected in the Phase-II project cycle. We won the DELTA Award (2019) for this initiative,” he smiles.

Archit Agarwal,

Lead – Traction and PS, Railway SBG

For most people, Mauritius conjures up images of sylvan beaches, golden sunshine and deep blue seas but for Archit Agarwal and the project team constructing the Light Rail Transit (LRT) system there, Mauritius is about meeting a tough timeline in an alien land where hard work and perseverance matter the most. “Planning is critical as being in an isolated place, everything from skilled labour, P&M, material, consumables have long lead times. We are doing DC traction system for the first time, so I had to learn, teach and get work done adopting the best practices, and being one of the fastest executed LRT projects across the globe, the pressures are huge.”

Archit’s baptism, after joining L&T as a GET in 2010, was at the Cast Wheel Plant project in Chhapra during which he was elevated to Team Lead. Next, was a 5-year stint at DMRC, starting as Planning Manager, later as Chief Project Manager post which he is now leading the Traction & Power Systems at Mauritius. “I manage three different systems – 750V DC Traction Sub-stations, Overhead Catenary System and Non-Traction Power Systems (Lifts, Escalators, EOT Cranes, External Lighting and Cable Containment),” explains Archit, “and a crucial aspect to improve operational efficiency is proper planning of the construction activities. The best way to avoid delays and cost overruns is to devote enough time at the initial stage of the project to figure out the right skill set of people, processes, equipment, machinery, and materials that are required before starting work and then break them down to micro levels to take decisions but continue to improvise constantly.”

“As we are doing a fully integrated railway project for the first time, DC systems, NTPS are new to us. There was also shortage of experienced manpower within RBG. Hence, we organized various onsite training not only for engineers but for supervisors and workmen as well. Training is critical,” he stresses.

Detailed planning, careful sequencing and carrying out linear activities parallelly have reduced cycle time and improved productivity, he points out, “and I have spent a fair amount of quality time with EDRC and SCM to work out best possible results. Of course, digital solutions are helping us hugely like Procube, Tilos and mtrack.” Apart from these, balanced engagement of departmental and sub-contractor teams based on expertise requirement, activity duration, site access have helped improve efficiency.

His better half, Sharmistha Goel, is a dentist by profession but presently on a break to look after their new-born daughter, Akshara. “Holding my daughter in my arms for the first time is a feeling that just cannot be expressed in words,” shares an emotional Archit.

“Stress levels are increasing, and it would help to make the work environment less stressful for it is a happy workforce that is more productive,” he says meaningfully.