IKEA GMP Project

A team that ‘thinks’ Mission Zero Harm

“Ever since we were awarded this project in November 2022, our standards of delivery have been cast in stone,” declares Project Director, Anup Chulliyil, setting a high benchmark for his team. 2023 turned out to be a year of awards for them, starting with the Global Safety Award in the Platinum category, followed by the B&F IC PAF SBG Annual EHS Trophy Award and then the big one: L&T Construction’s Safety Award – 2023.

![]()

Ever since we were awarded this project in November 2022, our standards of delivery have been cast in stone.

Anup Chulliyil

Project Director

![]()

“From the word go, we have been implementing a robust safety culture, backed by continuous monitoring, reviews, and strict adherence to auditing protocols from various stakeholders including third parties,” reaffirms Deputy Project Director, Sanjay Goel.

![]()

From the word go, we have been implementing a robust safety culture, backed by continuous monitoring, reviews, and strict adherence to auditing protocols from various stakeholders including third parties.

Sanjay Goel

Deputy Project Director

![]()

About the project: IKEA, a European multinational group that designs and sells ready-to-assemble furniture and kitchen appliances, is one of the world’s largest furniture retailers. Having established themselves in various major Metros, L&T has been mandated to build their first-of-its-kind Mix Use Development in Gurugram that will feature 5 levels of retail, four levels of parking, and 7 floors for office space, all of which sits over a total built-up area of

28 lakh sq. ft.

A matter that EHS In-charge, Vijaya Kumar Peethambaram, is immensely pleased with is the culture of near-miss reporting that is encouraged at site: since inception the project has recorded 72 near misses – 72 incidents detected and averted in time. “At a recent Inter IC Audit, our project was rated ‘Excellent’ in terms of EHS implementation and practices and scored more than 97%,” he shares proudly. “Of course, clocking 3.5 safe million manhours is obviously a matter of great pride for us and we are continuously striving to achieve even more.” With a Safety Audit score of 91%, it is clear that EHS is high on the site team’s list of priorities.

![]()

At a recent Inter IC Audit, our project was rated ‘Excellent’ in terms of EHS implementation and practices and scored more than 97%. Of course, clocking 3.5 safe million manhours is obviously a matter of great pride for us and we are continuously striving to achieve even more.

Vijaya Kumar Peethambaram

EHS In-charge

![]()

Thinking EHS

EHS Head – North, Dr Sanjai Kumar Srivastva, attributes the team’s EHS performance to their collaborative approach towards eliminating risk. “By involving as many people from the project as possible, they have successfully evolved an inherently safer thinking that has helped the project immensely, especially during the developmental stage to put together a sound method statement, identify hazards, assess risks, and select the right, most convenient, and safest method of work.” The question posed to everyone at site is: Can I eliminate risk by adopting the right tools and processes?

![]()

By involving as many people from the project as possible, they have successfully evolved an inherently safer thinking that has helped the project immensely, especially during the developmental stage to put together a sound method statement, identify hazards, assess risks, and select the right, most convenient, and safest method of work.

Dr Sanjai Kumar Srivastva

EHS Head — North

![]()

Know risk; no risk

While sky is the limit to suggest controls, there is widespread understanding that the basic ground rules should be simple, easy to adopt, and not impede progress. “We have eliminated several hazards and, in some cases, smartly substituted them with less hazardous equipment and tools, while in others, we have put in place well-designed engineering controls to achieve the best results,” points out Vijaya, who is eager to share their various EHS practices that have clearly delivered.

Biometric authorization has been installed at operator cabins & near the pan mixer access of the batching plant, and a floor calling system has been installed in the passenger hoist. Grievances are recorded by a QR-based mechanism, as also floor cutout/openings, which are monitored through a tracker system. “We have also introduced a certification programme in tower crane rescue for the P&M team and frontline supervisors,” adds Vijaya.

Some of their other EHS initiatives include:

-

- Cloud-based turnstiles for the entry & exit of workmen

- Dedicated & properly navigated pedestrian access across the site with UPS-backed emergency lighting, illuminated reflective signages, and more

- Use of safe & efficient prefab structures for scaffolds instead of the conventional methods

- Substituting diesel air compressors with electrically operated ones

- Deploying E smart concrete pumps instead of the conventional pumps

- Using battery-operated vacuum sweeping machines and vacuumfitted power tools for interior works

Thinking & staying ‘green’

Aware of the Company’s ESG commitments, Anup and his team have kept sustainability as a primary theme reflected in some of their ‘green’ practices like using a renewable source of energy to light up the workmen habitat, using at site a sewage treatment plant, an RO plant, an Organic Waste Convertor, and a green concrete recycling plant at the batching plant, which has saved over 720 MT in CO2 emissions. The AQI at site is monitored 24×7 to ensure that the team breathes easy and thereby perform better.

Happy, content workmen are more productive

The team has taken the effort to provide their workmen with a state-of-theart habitat with every room equipped with a fire alarm, smoke detectors, locker facilities, bunker beds, and separate mobile charging ports. While the on-site canteen can accommodate about 600 workers at a time, there are volleyball courts and facilities for indoor games. “We ensure that there are not more than 8 workmen in a room,” informs Vijaya, “and we have a team that monitors hygiene, sanitation, and the overall habitat round the clock.”

The site has a well-equipped ambulance, Health Centre, emergency control rooms, and safety parks. “Some of our interactive measures like a Wall of Fame to celebrate, inspire, motivate, educate, and promote values and the safety mirror plays a vital role in promoting safety and well-being,” sums up a happy Anup.

“SHARED COMMITMENT IS KEY”

Venkataramaraju P

Manager (EHS), B&F IC

“Safety is a collective responsibility, woven into the fabric of our organization,” says Venkataramaraju, Manager (EHS) at the IKEA GMP Project, emphatically. With nearly two decades of experience, he advocates a collaborative approach to safety, having led safety initiatives at key projects like Seawoods Overpass, Seawoods Grand Central, IKEA Mumbai, and IIT Bhilai, showcasing his dedication and expertise.

Reflecting on his journey and the recent accolade of his project winning the L&T Construction Safety Award 2023, Venkataramaraju emphasizes the importance of individual contribution to create and sustain a secure and thriving workplace. He attributes the success of the IKEA GMP Project, including its milestone achievement of 4 million safe man-hours without LTI, to the “collective effort of every team member.”

Venkataramaraju’ s leadership shines through his involvement in day-to-day activities, EHS walkdowns, and committee meetings involving the project leadership team. “Shared commitment is the key,” he says, “and leveraging digital predictive analysis tools are helping to effectively navigate safety challenges.” Coming to practicing safety at site, technology provides valuable insights into the current skillsets of workers and their training needs.

- Shared commitment is the key and leveraging digital predictive analysis tools are helping to effectively navigate safety challenges.

His present project involves the challenge of dealing with multiple nominated subcontractors that he tackles with finesse. Crediting the management for giving top priority to safety, he says, “We are one big family at L&T; our seniors walk the way with us, and our continuous effort is to maintain our safety standards.”

A proud L&T‑ite, Venkataramaraju values the freedom and encouragement to implement new initiatives, adapting to the evolving EHS landscape. He acknowledges the support and guidance of Project Director, Mr. Anup Chulliyil; Deputy Project Director, Mr. Sanjay Goel; Head – EHS (North), Dr. Sanjai Kumar Srivastava; and Head – EHS, PAF SBG, Mr. Mohd. Moizuddin, emphasizing L&T’s teamwork and familial bond.

In addition to his professional pursuits day in and day out, Venkataramaraju cherishes time spent with his family. Hailing from Bellari, Karnataka, he is married to Aparna Potturi, with their son Nischith Varma Potturi completing their family. Despite his busy schedule, he finds some time to play badminton and explore new places around the project location.

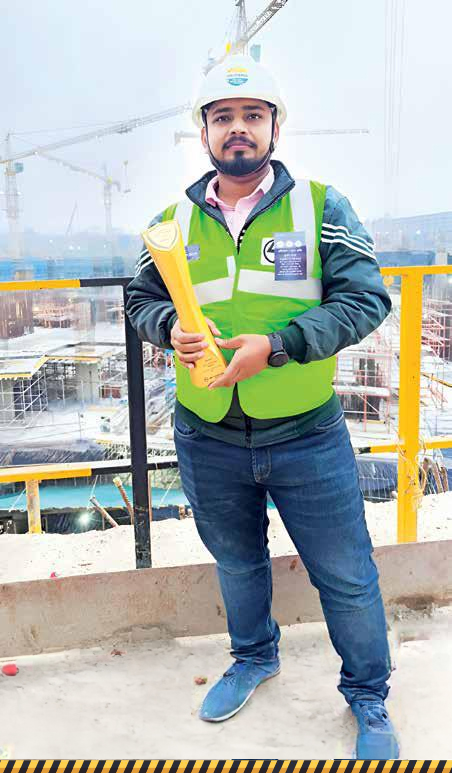

LEARNING THE ROPES, SAFELY

Ashutosh Singh

Senior. Engineer (EHS), B&F IC

Ashutosh Singh is representative of the collective responsibility for safety that permeates every aspect of working at L&T. “What’s great about L&T are that every employee and worker understand their role and are truly committed to safety,” he avers, referring to the safety DNA of his team members.

At the IKEA GMP project in Gurugram, young Ashutosh is on his second assignment and although the junior-most member in the EHS team, he brings a fresh perspective, having played a key role in the project team’s safety achievements including clocking 4 million safe manhours without LTI, the Global Safety Award in the Platinum category, and L&T Construction’s Safety Award 2023. “These awards are not personal victories, but a testament to the dedication and hard work of every individual involved, to ensure that things are done right, at the right time, in the right way,” he mentions.

Attributing his success to the support and encouragement of his superiors and the site management, he elaborates, “The project leadership team placed their trust on us which has personally shaped my career journey too. We actively advocate strict adherence to EHSMS and SOPs every single day.” Recognizing the transformative impact of technology to enhance safety standards within the construction industry, he shares, “The implementation of WISA is a game-changer in L&T that provides a comprehensive databank of workers’ skills and trades, enabling tailored training and efficient job assignments.”

These awards are not personal victories,

but a testament to the dedication and hard

work of every individual involved, to ensure

that things are done right, at the right time,

in the right way.

He expresses gratitude to his Project Director, Anup Chulliyil; Deputy Project Director, Sanjay Goel; Head – EHS (North), Dr. Sanjai Kumar Srivastava; Site EHS Head, Vijaya Kumar P; and EHS Manager, Venkataramaraju P, for their trust and unstinted support.

A native of Etawah, Uttar Pradesh, Ashutosh enjoys traveling, exploring new places, and watching movies in his free time, reflecting a balanced approach to work and life.