Mej–Indergarh Expressway Project

Where winning awards is a way of life

An animal underpass

![]()

A major reason for our excellent EHS performance is that we are all in it together; our engineers, workmen, and even our contractors and we constantly motivate our workforce to participate in hazard spotting.

Ajay Rai

Project Manager

![]()

Project Manager, Ajay Rai is proud that his Mej–Indergarh Expressway Project has won L&T Construction’s Annual Safety Award – 2023. His smile is eloquent for this award is a crowning piece to the several other awards that he and his team have won. “We have won the International Safety Award from the British Safety Council, the LIFE Award – 2023, an award from the National Safety Council for implementing best safety standards and awards from OSH India for excellence in safety training & education and innovation in safety technology,” he shares, nodding towards his team, indicating that they are the ones who have all made it happen. Almost on cue, his EHS In-charge, Shanmuga Sundaram, proudly adds that the project has already clocked 14 million safe manhours for which they have won accolades from their client, the National Highways Authority of India.

![]()

We succeeded thanks to continuous follow-up, synchronizing approvals from the Competent Authority and different stakeholders, strategic planning to complete the shifting work in 22 days, and constructing the substructure works below the HT line to ensure continuous front for the LG.

Shanmuga Sundaram

EHS In-charge

![]()

While their EHS performance has remained top notch, N Venu Babu & Rajesh Upadhyay, in-charges for Quality Assurance & Quality Control, will aver that they have not neglected Quality and proof of their effort is the Best Quality Award for implementing best quality standards and the DELTA Award for successfully shifting the 765 kV line from the alignment in record time.

The project in brief: Awarded in May 2021, and part of the Bharatmala Project, the team’s mandate is to construct a 11.63 km long 8‑lane access-controlled greenfield expressway, that will be part of the Delhi-Vadodara NH-148N, passing through the districts of Lakheri & Bundi in Rajasthan. Of the total length of the alignment, 6.8 km is a road with flexible pavement while 4.83 km has 29 structures including 4 major & 3 minor bridges, one viaduct, one vehicular overpass & five vehicular underpasses, 10 box culverts and a 15 km long & 4 m high boundary wall, replete with a 2 m high noise barrier. What’s more, one end of the project falls in the buffer zone of Ranthambhore, the Chambal Ghadiyal Tiger Reserve and the Papri Forest Areas.

Staying ahead of the curve

Traditionally, road projects are always hampered by tons of challenges that almost invariably result in delayed delivery. However, surprisingly, and creditably for Ajay and his team, this project has managed to consistently achieve its milestones ahead of time, much to the delight of Planning In-charge, Piyush Kumar Dev. “We achieved our first milestone124 days ahead of schedule, the second, 127 days ahead, the third was 31 days ahead of schedule,” he smiles triumphantly, “and we are right on schedule for our 4th milestone.”

![]()

We achieved our first milestone 124 days ahead of schedule, the second, 127 days ahead, the third was 31 days ahead of schedule and we are right on schedule for our 4th milestone.

Piyush Kumar Dev

Planning In-charge

![]()

The ’tension’ of working safely

Shifting the 2.4 km long 765 kV High Tension line to construct an animal underpass was one of the project team’s most critical activities. “Normally, such an activity would take about 78 days,” informs Swapnil Hanchate, incharge of animal underpasses, “but in our case, the approval from the Competent Authority took all of 22 days,” he says, slapping his forehead. Since the task had to be completed within the stipulated time frame, the team multi-tasked, taking up several parallel activities, all the while ensuring the safety of men, material, and equipment. “Pouring concrete below the HT line was a hazardous task,” reminds Shanmuga, “as was dismantling and re-erecting the LG due to the shifting of the HT line.

Shanmuga is both a happy and relieved man after the successful completion of the task, without incident. “We succeeded thanks to continuous followup, synchronizing approvals from the Competent Authority and different stakeholders, strategic planning to complete the shifting work in 22 days and constructing the substructure works below the HT line to ensure continuous front for LG.” He mentions that experts & consultants were also called upon to handle various issues.

Open corridor between animal overpasses

Keeping the project site safe & green

Mobile phones are always a huge distraction. A simple and effective step taken by the site team was to encourage workmen to surrender their mobiles during working hours. Another was to remove wine shops from the vicinity of the site with the help of the local administration. Apart from frequent checking, continuous patrolling, and round-the-clock inspections, the EHS team spread awareness among the workmen through TBTs, posters, and training sessions. “Most importantly, we did not hesitate to take disciplinary action, with penalties, against defaulters,” adds Shanmuga, forcefully.

“A major reason for our excellent EHS performance is that we are all in it together, our engineers, workmen and even our contractors,” remarks Ajay, “and we constantly motivate our workforce to participate in hazard spotting.” They practice onsite verifications by the Project Manager through walkdowns and feedback from workmen at the lower-level and Unsafe Acts and Unsafe Conditions are duly analyzed through the SHEILD app.

Front view of an animal overpass

“From the word go, we were very conscious our commitment to sustainability,” recalls Souptik Sarkar, Planning In-charge, “and a positive step to introduce eco-friendly Green Pellets instead of HSD or LDO for bitumen heating to minimize the carbon emission, apart from planting 10,000 plants that won NHAI’s appreciation.” A nursery is maintained at site, where a food composer manages food waste.

![]()

From the word go, we were very conscious our commitment to sustainability and a positive step to introduce eco-friendly Green Pellets instead of HSD or LDO for bitumen heating to minimize the carbon emission, apart from planting 10,000 plants that won NHAI’s appreciation.

Souptik Sarkar

Planning In-charge

![]()

With zero LTIs, zero fatalities since inception, a mere 4 reported near misses and a Safety Audit Score of 91%, Ajay and team are living Mission Zero Harm and committed to completing and handing over their project, that has been extended at the recommendation of the Authority Engineer, with their spotless EHS record intact.

“WORKING IN AN OCEAN OF

INNOVATIONS AND INSPIRATION”

He describes L&T as “an ocean of innovations and inspiration where, as a Safety Champion, I feel Zero Harm.” Swapnil Shrikant Hanchate’s description of his association with L&T is certainly unique, a journey that began at the Mumbai–Vadodara Expressway Project, a challenging assignment involving the construction of an eight-lane expressway spanning 23.74 km. Currently at the Safety Award–winning Mej–Indergarh Expressway Project, his primary challenges have been to retain manpower and maintain safety standards in a remote location.

“I have handled 700 manpower who worked daily at the Animal Underpass (AUP) structure in a close stretch of 250 m,” he explains. “Our launching activity was going on parallelly in an adjacent span along with shifting and placing of box segments weighing 100 MT. The whole structure was completed in time with no loss time injury,” he says with a sense of having got the job done. “Despite the challenging environment, we succeeded thanks to our careful planning and unwavering adherence to safety protocols,” he says, beaming with pride.

Swapnil attributes much of his success to the invaluable guidance and mentorship of his seniors including Project Director, Jeeva David, and Project Manager, Ajay Rai. “Their advice and unwavering support have constantly inspired and motivated all of us at site.” He acknowledges the role played by his subordinates and department colleagues in everyday execution, ensuring that the workers walk the talk when it comes to safety.

In his team’s quest to enhance safety awareness and maintain a secure workplace, Swapnil spearheaded the implementation of various digital initiatives at the site level such as RTR, UA/UC, and Near Miss reporting systems that have been crucial to the project’s EHS success.

Beyond the call of duty, Swapnil’s passion for music is a source of solace and connection. Whether unwinding with his favourite tunes or bonding with loved ones over shared melodies, music enriches his life, he adds with childlike enthusiasm. Hailing from Pune, Maharashtra, Swapnil finds strength in the continued support of his family. His wife, Sonali, a homemaker, and their daughters, Shreeya and Sarvadnya, are the pillars of his life, inspiring him to strive for success in both his personal and professional endeavours.

ON THE HIGH ROAD TO GROWTH

Varun Kumar N R

Senior Manager (Mech) – P&M, TI IC (RBF)

After joining L&T in 2008, Varun Kumar N R has been associated with 5 road projects over the past 15 years starting with the Varodara–Bharuch Road Project followed by the Rajkot–Jamnagar–Vadinar Road Project, Samhkyali–Gandhidham Road Project, and the Hospet Chitradurga Road Project. Presently, he is at the Safety Award– winning Mej–Indergarh Expressway Project handling P&M.

Varun is excited about some of their new initiatives. “A green pellet burner we have implemented has reduced 192 MT in carbon emissions and saved Rs. 56 lakhs for the project, while with our bucket elevator and silo system to handle the hydrated lime in SMA production, we have controlled 2% wastage against the conventional method and eliminated the environmental hazards associated with the task.” Other innovations include the mini-gantry set-up for the cellulose fibre handling system for SMA production and a digital measuring and monitoring system for bitumen and other bulk materials that gives the team real-time data and eliminates the safety hazards of conventional measurements.

- A green pellet burner we have implemented has reduced 192 MT in carbon emissions and saved Rs. 56 lakhs for the project, while with our bucket elevator and silo system to handle the hydrated lime in SMA production, we have controlled 2% wastage against the conventional method and eliminated the environmental hazards associated with the task.

Change must be managed well, and Varun admits that the introduction of new gadgets in P&M requires a change of mindset of the operators to be successful. “We tackle this through daily TBTs, regular training sessions, and frequent awareness programmes on various past incidents as to how these gadgets can eliminate incidents and risks,” he shares. Orienting the new workmen to the construction industry and aligning them to the organization’s EHS mission is key to the safe completion of the project.

Varun is full of praise for Project Manager Ajay Rai’s enthusiasm to implement their ideas that benefit the organization. “Once we pitched our new ideas, the required resources were immediately sanctioned, which enabled us to implement in a targeted timeline,” Varun notes. “He constantly motivates us, making us to push the boundaries to think beyond the conventional and come up with innovative solutions.” He appreciates the faith, experience, confidence, and collaboration of the team members to drive the project. They were once hit by a flood, since the site was in a valley, but the way they stood together and faced the crisis has given Varun huge confidence.

A native of Srinivaspur in Karnataka’s Kolar district, Varun is married to Kavya J S, a homemaker, and they are blessed with a son, Yuvin Reddy N V. Not surprisingly, he spends his free time updating himself about new gadgets and technologies.

CONTRIBUTING TO SAFETY EXCELLENCE

B. Murugan

Manager (Civil), TI IC (RBF)

In 2020 at CSTI, I conducted training for new

FLS team members, leading a full-day session

on Precast Basics, marking my debut as an L&T

faculty member – an unforgettable experience

for me, personally

A steadfast L&T‑ite since November 2012, B. Murugan has worked at various projects starting with the Kolkata Metro Development Authority (KMDA), where he oversaw girder casting operations for multiple locations, learning under the mentorship of Mr. Subhendu Ghosh. Subsequently, he managed highway road widening for the BBT Flyover Project and then transitioned to projects like Amaravati and MVRP, where he handled I‑girder casting operations. “Each project posed unique challenges,” Murugan reflects seriously, “that we handled along with our leadership to successfully complete them.”

Currently, at the MIEP project, Murugan and team have showcased their commitment to safety through various measures leading to the project winning the L&T Construction Safety Award – 2023. Murugan emphasizes the importance of the IESL method, ensuring comprehensive hazard assessment and diligent implementation of safety protocols at every level.

Murugan attributes his success to the support of his seniors, notably Mr. Ajay Rai and Mr. S K Giri, whose guidance has been instrumental in achieving EHS goals. Working alongside a supportive team leader, Murugan collaborates with his team to meet targets, ensuring thorough training for new workers and promoting a culture of safety awareness. He remarks, “This award is due to the efforts of each individual, who got the right things done following the right method at the right moment.”

“Maintaining proper housekeeping is crucial in achieving our safety objectives,” he notes, mentioning the daily RTR and SHEILD Apps that support them by identifying hazards to be avoided and recommending additions to enhance workplace safety.

Outside of work, Murugan cherishes time with his family, hailing from Rajapalayam, near Virudhunagar, Tamil Nadu. His wife, Peula Gracy, runs a tuition centre, while his 10-year-old daughter Meenakshi adds joy to their lives. Murugan indulges in hobbies like listening to stories and jokes, finding moments of relaxation during free time. He recalls, “In 2020 at CSTI, I conducted training for new FLS team members, leading a full-day session on Precast Basics, marking my debut as an L&T faculty member – an unforgettable experience for me, personally.”

On his long stint with L&T, Murugan takes pride in the organization’s commitment to safety and systems. He concludes, “The emphasis on women’s safety and the culture of independent decision-making is a huge plus, and I am happy to be a part of L&T’s success story.”

DILIGENTLY FOLLOWING THE BASICS TO SUCCEED

Kommoju Ayyappaswami

Assistant Manager (Mech), TI IC (RBF)

- Daily PEP talks, raising RTRs before commencing work, maintaining the 5S golden rules, and ensuring simple things everyday such as housekeeping and keeping equipment in prime order like crusher plants, are some of our key steps that have contributed to our success.

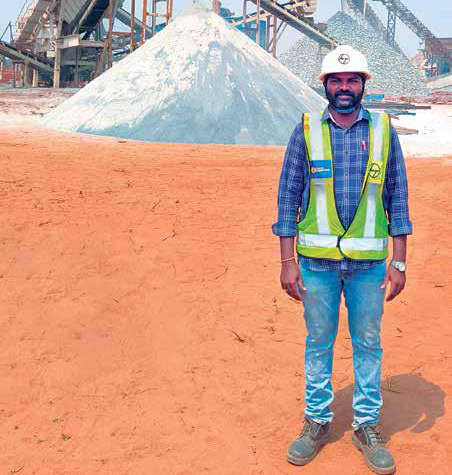

Often, following the basics is the secret to success and people like Kommoju Ayyappaswami have realized with experience that to achieve Mission Zero Harm, it is important to stick to the basis of EHS, as a team. That they have been doing that, and well at the Mej–Indergarh Expressway Project, is reflected in the project winning L&T Construction’s Safety Award 2023.

“Daily PEP talks, raising RTRs before commencing work, maintaining the 5S golden rules, and ensuring simple things everyday such as housekeeping and keeping equipment in prime order like crusher plants, are some of our key steps that have contributed to our success,” shares Kommoju. Although not an EHS professional, he understands and appreciates how vital it is for everyone at site to be safety conscious and as someone contributing to the EHS at the project, he faces unique challenges, particularly in ensuring the safe establishment, commissioning, operation, and demobilization of crusher plants without any incidents or near misses.

Digitalization is aiding him and his team to improve their efficiency and thereby improve their safety performance. “With the SHEILD App, we ensure that daily work permits and work intimations are seamlessly managed,” he explains.

Expressing gratitude for the support of his seniors and team members, Kommoju acknowledges their continuous motivation throughout his journey with the project. “My seniors have been incredibly supportive,” he confirms.

At MIEP, Kommoju, at his second assignment having joined L&T at the WDFC Railway Project, is a proud L&T‑ite, impressed with the Company’s commitment to quality and safety across projects.

Away from the construction site, Kommoju is a complete family man. Hailing from Jalluru, Andhra Pradesh, he is married to Anusha, a homemaker, and they have one son, Bhargava Aryananthan. Kommoju likes watching movies and playing cricket. He fondly recalls the joy of seeing his baby boy for the first time and the priceless moments spent playing with him as memorable.

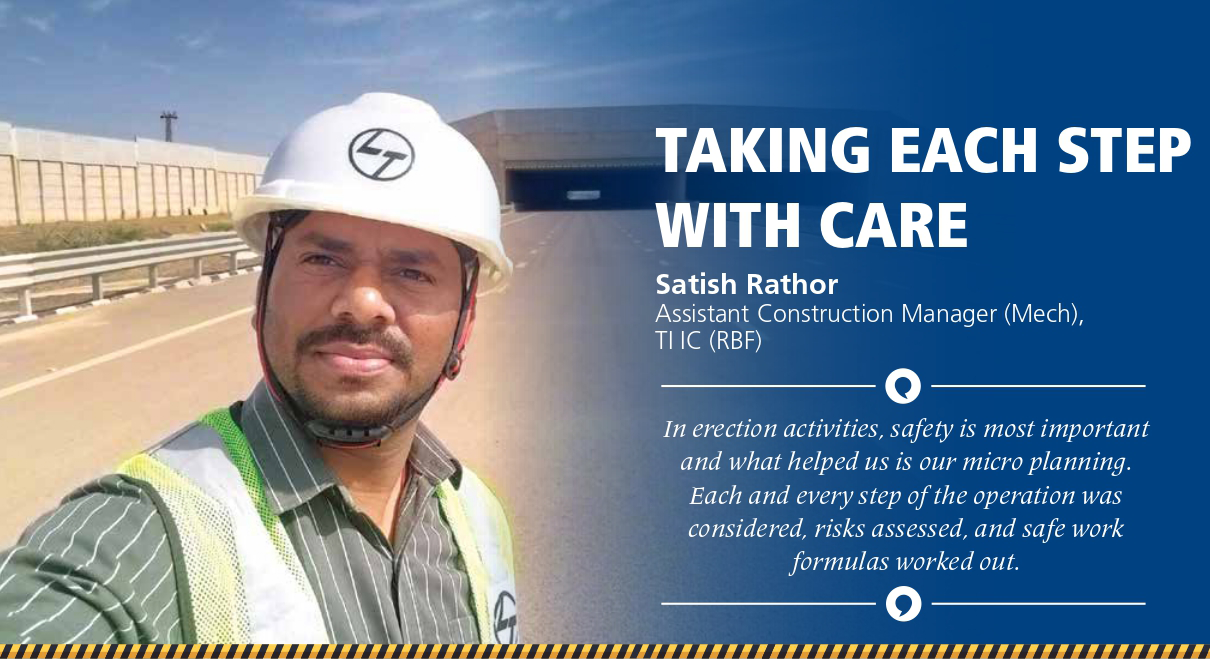

The Safety Award–winning Mej–Indergarh Expressway Project (MIEP-11) was predominantly a structure project involving animal overpasses, underpasses and prestressed girders, remarks Satish Rathor. “In erection activities, safety is most important and what helped us is our micro planning,” he reveals. “Each and every step of the operation was considered, risks assessed, and safe work formulas worked out.” The digital SHIELD app played a crucial role to ensure safety in their day-to-day operations like RTR, UA/UC and permits. “Our workers visualize safe operations and procedures through the VR training module,” he informs, adding that the team adopted drone surveys for making the traffic diversions and identify the various hazards.

With the site located in a very remote place adjacent to the Ranthambhore Tiger Reserve, Papdi Forest and Chambal Gharial Sanctuary, the team had wild animals roaming around. “We had to keep our people safe and also ensure that their natural habitat was not violated,” points out Satish. Retaining workers was another tough issue largely due to the severe climate, but the team addressed it by providing good labour welfare. Another unique problem that the team faced was honeybees frequently forming honeycombs in their equipment like girders and cranes.

“Our Project Manager, Mr. Ajay Rai Sir, deserves all the credit for his invaluable suggestions, guidance, and unwavering support, which has played a pivotal role in our success,” enthuses Satish. “Additionally, guidance from the Senior Management, including SR Sir, RKB Sir, CSL Sir, AC Sir, and SKM Sir, during several STECO meetings, team gatherings, and site visits, boosted our morale and helped us overcome obstacles, ensuring timely and incident-free completion of our targets.” He acknowledges the efforts and guidance of his immediate senior Mr. MR Nagendran Sir and Mr. Shital Kumar Das.

Satish is already at his 7th project with L&T and loves the freedom he has been given to take up challenging tasks. “Over my 3 years at this project, I have taken up different roles, like outsourcing fabrication works inspection of other projects namely the ROB Inspection at Delhi, MPEP & Mauritius metro station canopy fabrication inspection at Ahmedabad.”

A native of Kota, Rajasthan, Satish’s better half is Kiran, a homemaker, and their son is Yashvardhan. He spends his free time watching movies, listening to music, and visiting temples to worship. Shifting and lifting 45 girders in a day, LG erection and launching 5 spans of 90 segments in a month, which is now a benchmark for segmental launching, are some of his memorable moments.