Keeping safe when constructing a steel plant

JVML Projects, Ballari

When tasked to construct and commission a steel plant involving action in highrisk zones like steel structures, heavy machinery, and elevated workspaces, the challenge to keep men, material, & machinery safe is critical. It becomes even more demanding when the project team must manage a large 5,000-strong diversified and rotating workforce. “To address the various operational, logistical, and human resource challenges, we adopted a stringent EHS management system, and having clocked 37.5 million safe manhours till date, we can safely assume that our efforts are yielding fruit,” smiles Project Manager, C Srinath of M&M IC’s JVML Projects at Ballari involving the Blast Furnace (BF) #5 and Steel Melt Shop

(SMS) #4 packages.

Identifying ‘hot’ risk spots

An important first step in the project team’s EHS efforts was to identify spots that were most high-risk, and as EHS In-charge, R Umashankara, shares with a shake of his head, there were many. “We have identified work at height, transporting risks, and material handling with equipment as the top hazards during the planning stage itself and conducted detailed risk assessments with control measures to address them, continuously monitoring them to ensure compliance,” he informs, proudly adding that a couple of unique risk mitigation measures appreciated by the auditor are competency assurance for safety critical roles among the workers and standardized training for them in the form of pictures & videos in regional languages.

In addition, the team’s robust safety monitoring procedures include regular site inspections to identify potential hazards, near-miss reporting, and incident investigations. Mandatory multilingual safety inductions for all new workers, regular toolbox talks, mock drills, visual safety campaigns to ensure awareness about emergencies, fire & evacuation drills, safety training, and strict enforcement of safety protocols complete their methods to maintain safety.

![]()

To ensure that our practices are not just compliant but exemplary, we benchmark our safety management systems against national and international standards, including those from the OSHA and ISO 45001.

C Srinath

Project Manager

![]()

While strict protocols, anchored systems, and competent supervision govern working above 1.8 m, working in confined spaces involves pre-entry assessments, continuous monitoring, and rescue readiness; to minimize electrical hazards, the team has lockouttagout (LOTO) systems & LOTO boxes for multiple gang involvement, certified equipment, and trained electricians.

Even though scheduling, progress tracking, and resource planning are Planning Engineer, Rauvula Nandakishore’s primary responsibilities, he is still actively engaged in addressing site safety concerns by implementing methodical planning interventions. “Our weekly & biweekly look-ahead plans highlighting high-risk tasks help to identify and mitigate risks in advance, our dynamic scheduling and rescheduling avoids dangerous overlaps, and by working closely with the execution and procurement teams, I guarantee timely delivery of safetycritical resources like PPEs, fire-fighting equipment, barricading materials, and more,” he highlights.

Handling material without incidents

As the project involves massive volumes of material handling, including heavy erections of structural steel, equipment installations, and manual handling of civil and structural materials, the team implements robust systems and safe work practices to ensure zero harm in all material handling operations. “Manual and mechanical handling of structures, equipment, bulky, heavy, irregularly shaped components, and the like require perfect coordination between the multiple teams working together in a dynamic environment,” points out Planning Manager, Karri Uday Bhaskar. “Our comprehensive safety strategy includes planning, risk assessment, training, use of the right equipment, supervision, communication, and continuous improvement.”

![]()

We have identified work at height, transporting risks, and material handling with equipment as the top hazards during the planning stage itself and conducted detailed risk assessments with control measures to address them, continuously monitoring them to ensure compliance.

R Umashankara

EHS In-charge

![]()

Safety induction and job-specific training is mandatory for all personnel prior to commencing work, and Uday mentions a comprehensive scheme for heavy lifts detailing crane capacity, utilization percentage, sling selection, and location specifics. Rigging charts for all material handling activities have been developed and authorized by the relevant departments, and a monthly colour-coding system for lifting tools and tackles meet regulatory requirements.

All material handling operations, affirms Umashankara, are carried out under the strict supervision of the rigging foreman and supervisor. Outsourced and fabricated materials from the yard are visually pre-inspected against a standardized checklist, which are then approved by the foreman, site engineer, supervisor, and EHS engineer. “Recognizing the increased risks during night operations, we ensure more supervision and adequate lighting in addition to the standard precautions,” he adds.

![]()

Our weekly & biweekly look-ahead plans highlighting high-risk tasks help to identify and mitigate risks in advance, our dynamic scheduling and rescheduling avoids dangerous overlaps, and by working closely with the execution and procurement teams, I guarantee timely delivery of safety-critical resources.

Rauvula Nandakishore

Planning Engineer

![]()

At the Steel Melt Shop project, Construction Manager Suvith Shetty agrees that working in a high-risk environment with heavy equipment, hot work, and elevated structures demands constant vigilance and proactive safety management. “I carry out surprise inspections and routine site visits to identify dangerous behaviours to immediately fix them, and our daily toolbox talks are to draw attention to hazards associated with continuing jobs, like working at heights, lifting, or confined space operations,” he says.

Preventing fall from height through an advanced personnel fall arrest system

Sustaining a strong EHS culture

Every EHS professional knows that continuous training is key to create and sustain a strong EHS culture at site, ensuring that the weakest link in the chain, the worker, is ingrained with the merits of safe working. Training programmes include those on HIRA, SOPs, behaviour-based safety, defensive driving, electrical safety, and working at height, in confined spaces, & near gas lines. “One critical aspect of training for us, particularly, is to work safely in a functioning plant,” notes Umashankara. “Our short videos of 3–4 minutes on the top 5 mandatory safe behaviours for an activity emphasize behaviours and controls, reduce ambiguity, and strictly deal with non-compliance. Most importantly, we have empowered the Supervisor and the workforce to stop work in case of high-risk behaviour.” A safety team leader nominated from among the crew is trained and empowered to act against any deviation and/or unsafe behaviour. Daily mass meetings at various locations of the job site further drive EHS awareness.

Keeping safe at hot spots

The big challenge before Swagath H, Safety In-charge at the SMS#4 project, was to safely execute extremely complex and high-risk tasks such as roof sheeting operations at heights exceeding 70 m with a diverse workforce. “Our concentration has been to align them onto a unified safety platform by focusing on behavioural transformation through targeted, continuous training interventions and intelligent use of digital technology,” he apprises.

![]()

Our comprehensive safety strategy includes planning, risk assessment, training, use of the right equipment, supervision, communication, and continuous improvement.

Karri Uday Bhaskar

Planning Manager

![]()

Srinath refers to the monthly and quarterly incentives based on worker performance & attendance, celebrated at a monthly prize distribution function attended by the workforce, supervisors, engineers, and senior managers, which have significantly improved morale.

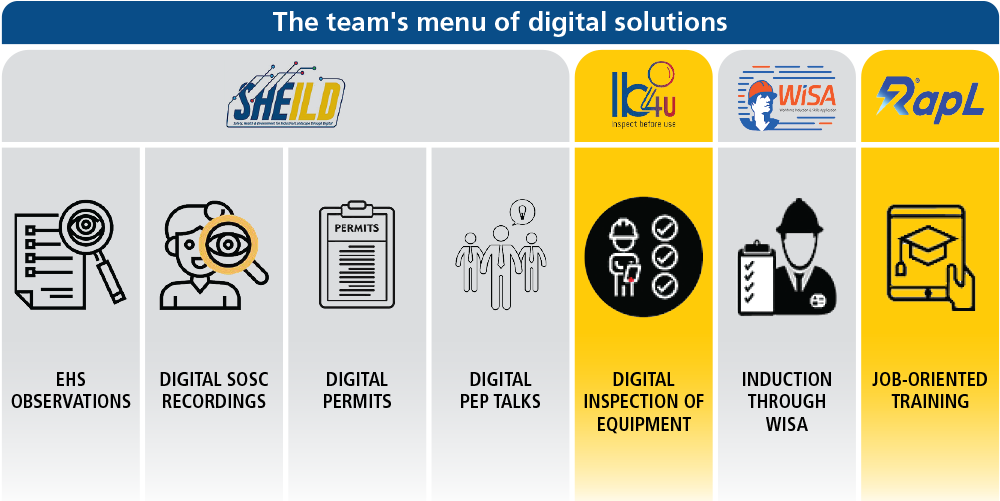

He is happy that digitalization is aiding their EHS efforts. The SHEILD app is widely used for Permit to Work for various activities, assigning safety tasks, recording Safety Observation & Safety Contact (SOSC), making EHS observations, evaluating subcontractor performance, reporting near misses, and monitoring 360° active learning of the entire workforce, apart from WISA & IB4U.

![]()

I carry out surprise inspections and routine site visits to identify dangerous behaviours to immediately fix them, and our daily toolbox talks are to draw attention to hazards associated with continuing jobs, like working at heights, lifting, or confined space operations.

Suvith Shetty

Construction Manager

![]()

Building a ‘Parivar’

A safe working environment is essential for a healthy workforce. Regular safety drills and awareness programmes ensure their preparedness against any potential risks at the construction site. Maintaining clean & hygienic work environments is a top priority, with regular cleaning schedules and robust healthcare facilities set up close to the site. “We employ qualified medical professionals, including doctors and first aiders, to ensure the health of our people, apart from conducting health checkup camps and other activities in collaboration with local hospitals and health providers,” elaborates Umashankara.

Having clocked 37.5 million safe manhours till date, we can safely assume that our efforts are yielding fruit. – C Srinath

The worker colony is considered a ‘Parivar’ that not only provides shelter but also offers several amenities to promote well-being with comfortable living quarters, clean water, nutritious meals, and access to recreational activities. “We provide meals to the workforce at a minimal cost, and by creating a ‘Parivar’ for them away from home, we reduce their stress that often comes from long hours,” observes Srinath. The opportunity to socialize, relax, and engage in fitness activities have improved their overall mental health.

Towards building trust and fostering a culture of respect, support, & mutual care, the team conducts feedback sessions, one-on-one meetings, and surveys to listen, understand, and respond.

![]()

Our concentration has been to align the workforce onto a unified safety platform by focusing on behavioural transformation through targeted, continuous training interventions and intelligent use of digital technology.

Swagath H

Safety In-charge

![]()

Not just the best. Better than the best!

“To ensure that our practices are not just compliant but exemplary, we benchmark our safety management systems against national and international standards, including those from the OSHA and ISO 45001,” says Srinath, his determination shining through. “We are constantly identifying areas of improvement, innovating on the ground, and continuously evolving, which includes learning from incidents, root cause analyses, and lesson-sharing sessions that promote a culture of transparency and improvement. Safety is everyone’s responsibility, and our goal is clear: zero harm, every day.”