Lifting safety to greater heights

435 KTPA BALCO Expansion Project

“Strong lifts start with safe plans – every load, every time,” states Sanjay Saha, Project Head at M&M IC’s BALCO Project in Korba, whose team is executing critical activities within a live process plant – a sensitive brownfield environment. “Working in such zones brings elevated risks, as we are continuously interfacing with existing operational facilities and live systems. Every task demands precise planning, thorough risk assessment, and seamless coordination with the operations team to ensure both safety and process integrity.”

EHS Head Bikash Parida reveals that movement of heavy vehicles and equipment within constrained areas is one of their major challenges. “Proper route management, strict supervision, and compliance with site protocols are crucial when executing under these complex conditions, and we have shown exceptional control,” he notes with a proud smile.

“Being a critical activity for us, every lift begins with a detailed rigging & lifting plan, which is reviewed and certified by a competent rigging supervisor and a third-party lifting expert from Crane Brainz,” explains Sanjay, “and we deploy only certified riggers, operators, and rigging foremen – all trained and approved by Crane Brainz.” In addition, a rigging Safety Task Assessment (STA) is conducted with the crew to reinforce critical checks and hazard awareness.

“For all lifting tasks, especially critical lifts, we mandate the use of certified lifting and rigging equipment, an approved erection scheme, and real-time supervision by qualified personnel,” chips in Bikash. “Our structured and disciplined approach enables us to maintain full control over lifting operations, ensuring they are carried out with precision, accountability, and the highest standard of safety.”

![]()

Every task demands precise planning, thorough risk assessment, and seamless coordination with the operations team to ensure both safety and process integrity.

Sanjay Saha

Project Head

![]()

Pre-emptive measures to remain alert in a brownfield site

The project is situated in a fully operational brownfield facility with frequent heavy vehicle movement along service roads. Solar-powered blinking barricade systems installed around active erection zones have improved visibility and safety, especially in lowlight conditions. A proximity sensor system installed around the working radius of the crane triggers a siren if any unauthorized personnel enters the restricted zone, alerting both the person and the crane operator.

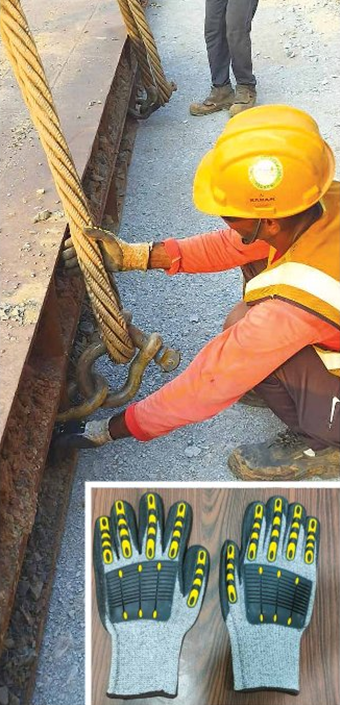

To minimize the risk of hand injuries during heavy lifting and material handling, Bikash and team have introduced specialized impact-resistant hand gloves for the rigging teams that are designed to absorb shocks and protect against pinch points, crush hazards, and sudden impacts.

Roadside barricade with solar blinker

“Each rigger is issued a specialized yellow identification jacket to be easily recognizable on site,” adds Bikash. “These targeted, proactive safety measures have ensured safer and more confident handling of materials on site, reinforcing our commitment to protecting those performing highrisk lifting operations.” Walkie-talkies used by the crane operators, riggers, and supervisors ensure immediate and effective communication.

![]()

Our structured and disciplined approach enables us to maintain full control over lifting operations, ensuring they are carried out with precision, accountability, and the highest standard of safety.

Bikash Parida

EHS Head

![]()

Working near a high magnetic field

In the Potline‑3 area of the project site, work activity is complicated by the presence of high electrical currents that generate intense magnetic fields that can and sometimes do interfere with equipment functionality, thereby compromising safety. “We understood these tricky conditions right from the start and have taken adequate proactive measures to mitigate risks,” shares Bikash with a serious look.

All lifting activities are closely supervised by a Senior Foreman and Site Engineer; only qualified lifting experts are authorized to perform such tasks, and every lift is executed in accordance with a detailed and approved lifting scheme. “We utilize double-rated cranes to improve safety and stability,” he adds, “and walkie-talkies have proven effective, ensuring quick decision-making in highrisk zones like Potline‑3.”

Mitigation measures inside the brownfield area

A safe site all around

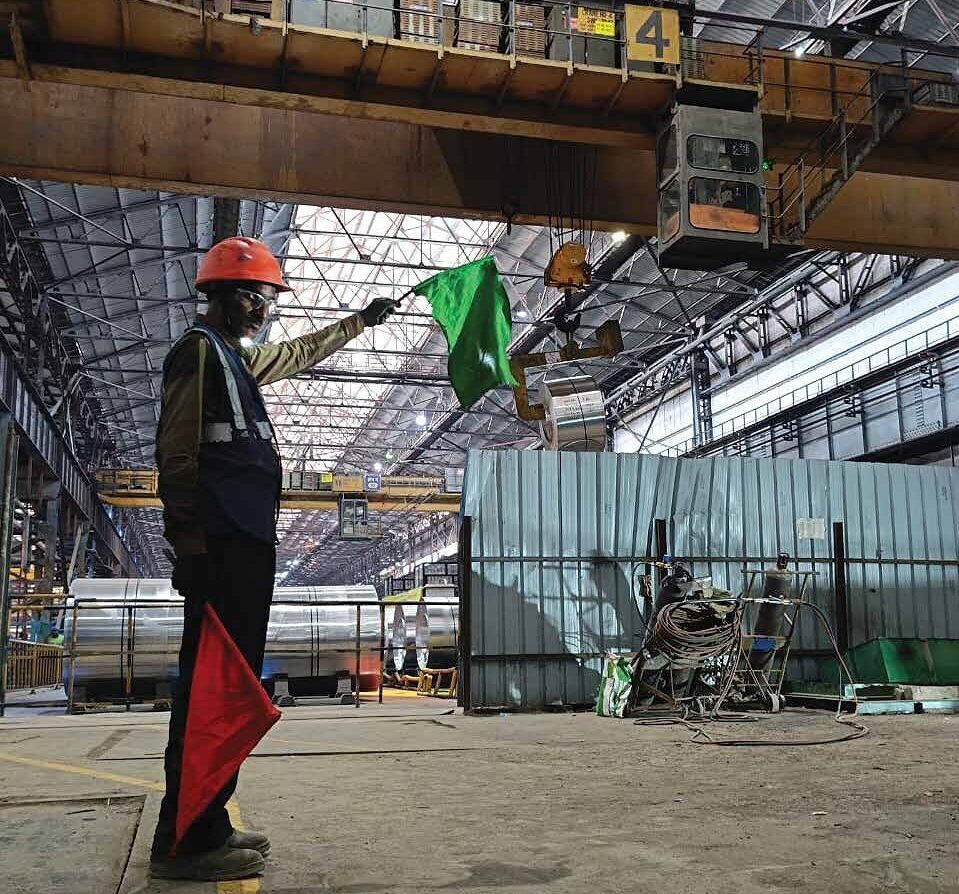

To mitigate the other typical challenges of working in a brownfield environment, the site team has incorporated measures such as dedicated walkways; a dedicated signalman for Electric Overhead Traveling (EOT) crane movement who is equipped with a flag, baton light for night visibility, and a whistle to alert & guide both crane operators & ground personnel; daily toolbox talks (TBTs) to reinforce safe practices; pictorial STA formats to ensure better understanding of job-specific risks; a robust internal permit-to-work system; and refresher training sessions & regular on-site safety interactions and counselling.

The team receives an Appreciation Certificate from the client for achieving 20 million safe manhours

Riggers use impact-resistant hand gloves for protection

EHS initiatives like Suraksha Sankalp (monthly mass TBTs), My Hand, My Life (a safety campaign on the well-being of hands), Suraksha Ratha (a traveling ‘chariot’ to raise safety awareness), and such have driven the EHS culture at site.

While ensuring the safety and wellbeing of all at the BALCO site, Sanjay and team have not forgotten the ‘E’ in EHS, either. They have planted 5,800 saplings in FY 2023–24 & 7,152 saplings in FY 2024–25, maintaining a survival rate of 96%. To minimize dust from movement of construction equipment, the team performs regular water sprinkling and deploys road-cleaning vehicles across the site, helping maintain air quality.

“We have installed solar-powered lights throughout the site and labour colony, and a water flow meter monitors & manages water consumption efficiently,” informs Bikash. “Moreover, we have completely eliminated plastic caution tape, replacing it with a durable chain barricading system, supporting sustainable and ecofriendly construction practices.”

The site achieved 20 million safe manhours in April 2025, another proud achievement that Sanjay and team hold close to their hearts, after winning the L&T Construction Quality Award 2024. “It’s a remarkable accomplishment that reflects our shared commitment to safety, discipline, and operational excellence,” remarks Sanjay to sum up. “From field workers & supervisors to engineers & EHS officers – every team member’s disciplined approach and unwavering focus on safety are the pillars of our success.”