Globally, the construction industry is considered amongst the most hazardous, owing to various factors including the dynamic nature of activities, inherent risks involved, simultaneous work at multiple locations, frequent changes in work environment, high turnover of manpower, casual nature of employment, exposure to open weather conditions, and many more. As a significant contributor to the country’s GDP, the construction industry is India’s second-largest employer after agriculture and, therefore, has a huge onus to evolve strategies & methods to keep its people safe. To achieve a satisfactory level in maintaining a safe work environment and work practices requires a sustainable and multipronged approach, to address the many challenges and pursue continuous improvement.

![]()

By merging cutting-edge technology with traditional construction methodologies, Artificial Intelligence (AI) is revolutionizing safety management – reducing risks, streamlining operations, and paving the way for a more proactive approach to workplace safety.

Krishna Nirmalya Sen

Head – EHS, Minerals & Metals IC

![]()

Artificial Intelligence leading the charge

Of late, technological developments are rewriting the rules of the game with efficient solutions in the realm of EHS for the construction industry to proactively manage complex, diverse, and dynamic workplaces. By merging cutting-edge technology with traditional construction methodologies, Artificial Intelligence (AI) is revolutionizing safety management – reducing risks, streamlining operations, and paving the way for a more proactive approach to workplace safety.

Smarter surveillance & real-time hazard detection

A most immediate application of AI in construction EHS is in enhancing site surveillance and hazard detection. Historically, safety inspections have relied almost exclusively on time-consuming manual checks, which are susceptible to oversight too. AI-driven monitoring systems, utilizing smart cameras, drones, and on-site IoT sensors, now provide continuous surveillance, identifying hazards in real time and triggering instant alerts. Smart cameras configured with AI predictive analysis, installed at M&M IC’s AMNS Hazira project site, KBL Fabrication Yard, and Kansbahal Works, trigger instant SMS & email alerts with photos for the concerned safety officers, site engineers, & in-charges to respond swiftly, significantly reducing onsite hazards.

Predictive analytics for proactive safety

Beyond identifying current risks, AI excels in forecasting potential safety issues. Leveraging predictive analytics, AI systems can analyse vast datasets – ranging from weather patterns and historical incident logs to machinery usage and worker behaviour – to forecast when and where accidents are most likely to occur.

For instance, AI can detect correlations between equipment wear-and-tear and mechanical failures or identify dangerous weather conditions in advance that could compromise worker safety. By analysing biometric and behavioural data, AI solutions can highlight workers at higher risk due to fatigue, inexperience, or underlying health conditions, insights that empower site managers to implement targeted interventions and make data-informed decisions to prevent incidents before they happen.

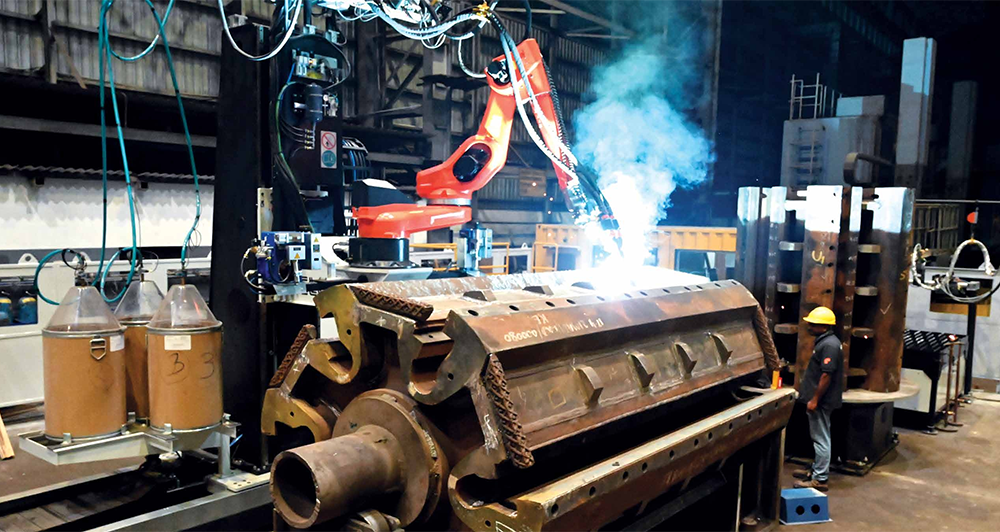

Automating high-risk tasks with robotics

AI-powered robotics are taking over dangerous and/or high-risk operations like heavy lifting, handling toxic materials, or working in confined or unstable environments, thereby reducing risk to workers. These autonomous machines are equipped with advanced sensors and adaptive learning capabilities that allow them to safely and efficiently navigate hazardous environments.

A robotic welding machine installed at M&M’s Kansbahal Works has reduced human exposure to critical tasks. It is not only minimizing injuries but enhancing productivity too and helping frontline managers to operate in critical/ challenging conditions.

Robotics in action

Immersive AR- & VR-based training

Safety training in construction is evolving from static classroom sessions to immersive AI-enhanced experiences with AI-powered Virtual Reality (VR) and Augmented Reality (AR), allowing workers to engage in realistic simulations of emergency situations and hazardous conditions. These interactive environments improve hazard recognition and decision-making skills without putting workers at actual risk.

M&M IC has developed 12 interactivebased VR safety training modules covering the movement of cranes, selection of correct lifting tools & tackles, control of suspended load, manual lifting, shifting, loading & unloading of structural materials, maintenance work for batching plants, and pick & carry crane travel with load.

These modules have additional features, extending to third-party viewing where one’s virtual experience can be seen by other participants on screens to learn about safe practices. Many of M&M’s clients have appreciated the usage of this training mechanism with advanced technologies for workers at site.

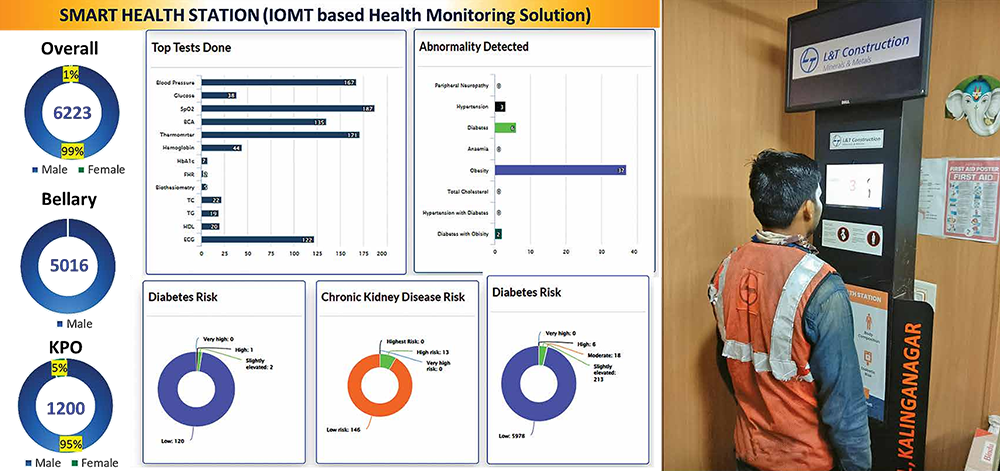

Smart Health Stations – IoMT-based health monitoring solution

IoMT-based Smart Health Stations have been set up at AMNS Hazira, JVML Ballari, Tata Steel Kalinganagar, and BALCO Korba sites. This advanced technology supports employees to identify their health score card by tracking their vital health parameters and scheduling periodical consultations with the relevant specialists through AI chatbots.

This IoMT-based Smart Health Station provides smart health monitoring, telehealth, and digital therapeutics through health analytics (assessments of diabetes risk, chronic kidney risk, etc.) and clinical interferences. It tests 60+ health parameters of the user including haemoglobin levels, blood glucose, ECG, oxygen, lipids, and more in just 15 minutes.

Some of the salient benefits of Smart Health Stations include more insights; instant reports through WhatsApp, email, and SMS; a single platform for 30+ IoMT devices (blood pressure, blood sugar, haemoglobin, spirometer, ECG, etc.); real-time data through IoMT devices; and dashboard with health analytics, automated reports, & AI-enabled reporting. The added benefits are that the management is forewarned about the health of the workforce and improved employee morale.

Exoskeletons in material handling

Exoskeletons – wearable devices designed to support, augment, or enhance the wearer’s physical abilities by providing external structural support – have been implemented at Kansbahal Works, especially for material handling and overhead working. While these reduce the chances of Musculoskeletal Disorder (MSD) and fatigue, exoskeletons enhance ergonomic posture and productivity as well.

Sustained compliance & reporting

Compliance with safety regulations is a critical, yet often burdensome, aspect of construction management. AI simplifies it by automating documentation, tracking safety metrics, and flagging areas of non-compliance. With automated record-keeping and reporting, safety personnel can focus more on strategic safety initiatives rather than administrative tasks. With up-to-date, accurate documentation and actionable insights, AI is powering us to stay ahead of regulatory requirements while reinforcing a culture of continuous improvement.

The integration of AI into OHS practices is not merely a technological upgrade; it represents a paradigm shift in how safety is managed in the construction industry, helping to create safer, smarter, and more resilient work environments. As adoption accelerates, AI is set to become an indispensable ally in the pursuit of zero-harm construction sites. Since AI has immense capabilities to support and enhance efficacy of traditional activities, it is imperative to embrace it to improve our effectiveness and efficiency. Embracing AI not only enhances safety but will also drive productivity, ensuring that the industry remains resilient and sustainable in the face of growing challenges.