Using BIM to manage fall risks

Working near leading edges

Appreciating that the highest risk in their business is associated with working at heights, the B&F IC leadership has turned to BIM to manage fall risks, in a significant move to use technology for safety. “This is the result of effective risk profiling, identifying the risks of working near building edges, shafts and openings,” points of P Nagarajan, Head – EHS, RCF SBG, B&F IC. “We have been continuously evolving our engineered fall protection systems, benchmarking them against global best practices, designed to cover the entire life cycle of fall protection, from installation to maintenance, including protocols for safely removing temporary systems during enabling works.”

We have been continuously evolving our engineered fall protection systems, benchmarking them against global best practices, designed to cover the entire life cycle of fall protection, from installation to maintenance.

P Nagarajan

Head – EHS, RCF SBG, B&F IC

Their efforts should be viewed in the large context of L&T’s lead role to set national safety standards. Earlier this year, in March 2024, the Bureau of Indian Standards (BIS) published the new Indian Standard, IS 4912: 2024, titled ‘Temporary Protection of Floor and Wall Openings, Open-side Floors, Staircases, and Guardrail Systems – Safety Requirements.’ As the convenor of the working group,

M. Nachiappan, Senior DGM, B&F IC, had played a pivotal role in developing this standard that sets the benchmark for temporary fall protection systems across the country.

BIM for Safety: A new frontier

With BIM, the EHS team can manage the entire life cycle of fall protection systems digitally, improving both accuracy & efficiency.

BIM can …

- Identify fall protection requirements

- Aid in planning & tendering

- Help with procurement & coordinate installation

- Enable prior visualization for the execution & EHS teams

- Aid planning site installation

- Periodically monitor via the fall protection tracker

- Take corrective actions in the event of non-compliance

- Provide VR training for supervisors & workers

Currently, fully implemented in five B&F projects, we plan to

cover 12 more sites over the next 3 months.

M Nachiappan

Senior DGM B&F IC

Working near floor openings

Eight key protection systems identified for digital implementation

- Modular Floor Protection

- Floor Protection Handrails

- Staircase Handrails

- Floor Opening Grills

- Gates for Shaft Openings

- Safety Nets inside Shafts

- Safety Catch Nets

- Safety Screens

The new order with BIM

“L&T’s Digital Engineering team has converted each of these systems from standard 2D drawings to parametric 3D BIM components, which are stored in L&T Construction’s BIMbased ‘Parimaan Portal’,” informs Bangalore Sreevatsan Mukund, Head – Building Information Modeling, L&T Construction. “With Revit’s Dynamo scripts, we have automated the safety modeling process. Now, with just a click, safety components such as edge protection, floor cutouts, and safety screens can be applied, enabling quick quantification and BOQ estimation.”

With Revit’s Dynamo scripts, we have automated the safety modeling process. Now, with just a click, safety components such as edge protection, floor cutouts, and safety screens can be applied, enabling quick quantification and BOQ estimation.

Bangalore Sreevatsan Mukund

Head – Building Information Modeling

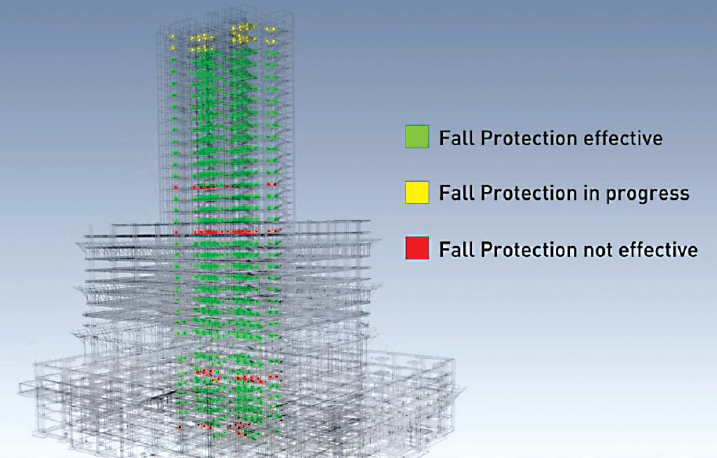

This digital safety model is then exported to the ‘Integrated BIM Platform’, enabling field engineers, safety personnel, and BIM coordinators to track and monitor the real-time status of fall protection systems. The web-based platform can be accessed via mobile devices, allowing on-site teams to verify the effectiveness of safety measures. Identified deviations, if any, are captured through photographs, updated in the system, and corrective actions promptly initiated.

Modular floor edge barricades & catch net

“This innovation empowers project managers and section heads to monitor compliance and address any gaps swiftly,” notes Mohammad Moizuddin, Head – EHS, HPA SBG, B&F IC. “Additionally, BIM for Safety will help create tailored training modules for workers, educating them on the types of fall protection systems in use and safety protocols,” he elaborates.

This innovation empowers project managers and section heads to monitor compliance and address any gaps swiftly. Additionally, BIM for Safety will help create tailored training modules for workers, educating them on the types of fall protection systems in use and safety protocols.

Mohammad Moizuddin

Head – EHS, HPA SBG, B&F IC

Impact and future plans

Nagarajan and team are confident that BIM will revolutionize the way fall protection is managed, enabling realtime monitoring, improving compliance, and raising awareness among both supervisors and workers. “Currently, fully implemented in five B&F projects, we plan to cover 12 more sites over the next 3 months,” informs Nachiappan. Eventually, all projects with BIM models will be covered in this initiative.

Fall Protection Tracker – Dashboard for review by leaders

BIM for fall protection systems has already been implemented at:

- Technology Centre 4 Project, Chennai

- Phoenix P25 Triton, Hyderabad

- IKEA GMP PACKAGE 2 Project, Gurugram

- Equinix MB3 Data Center Development Project, Mumbai

- ITC Limited Green Centre Ph-IIBuilding-3, Bengaluru

A matter of pride for the B&F EHS team is that this initiative was roundly appreciated at the recent ‘BSC Five-Star Safety Audit’, where it received a perfect score in the benchmarking category in four of its projects.

“By embracing technology, we are not just addressing today’s challenges but setting the foundation for a safer, more efficient future in construction safety management,” sums up Nagarajan. “Together, we are taking strides towards a safer workplace and ensure that we continue to lead the industry in fall protection standards.”