SEE NO HAZARDS! HEAR NO HAZARDS!

A closer look at essential protection for the eyes and ears

According to NASA, a spacesuit is more than just the clothes astronauts wear. It is, for all practical purposes, a small spacecraft protecting the astronaut from a variety of hazards. In the construction industry, although there is nothing akin to a space suit, it is imperative in a risky environment to protect every part of a workman’s body from harm or injury.

A few years ago, an enterprising team at one of the Chennai Metro project sites led by Project Director, S V Rao, conducted an interesting exercise as part of the Hand Injury Prevention Day. For half a shift at all station locations, everyone was asked to work with one hand tied behind their backs! “It was difficult for me to attend a meeting with the CMRL MD with one of my hands tied,” recalls Rao but the message was clear to everyone who participated in that exercise just how important every part of the body is for us to lead normal lives. Helmets protect the head which has been dealt with in detail elsewhere in this issue, so this article looks at protecting the eyes and ears.

See the threat!

The wonderful career of South African wicket-keeper-batsman, Mark Boucher ended abruptly when a flying bail hit him in the eye during a match. Multiple operations later, he couldn’t regain his complete eyesight or resume playing! In fact, it is after Boucher’s injury that wicketkeepers have started to don helmets when standing up to the stumps. Although Boucher’s was a freak incident, the sad fact is that thousands of workmen across construction sites sustain eye injuries every year.

At a construction site, the eyes can be assailed by a variety of hazards, mechanical, thermal, chemical, electrical and even radiation.

V Ramanathan

EHS – Head, PT&D IC

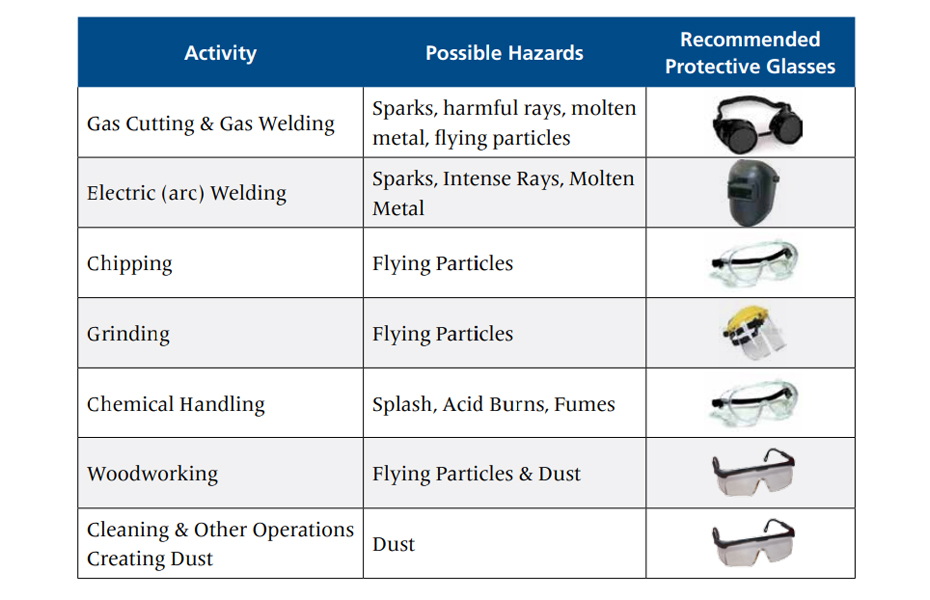

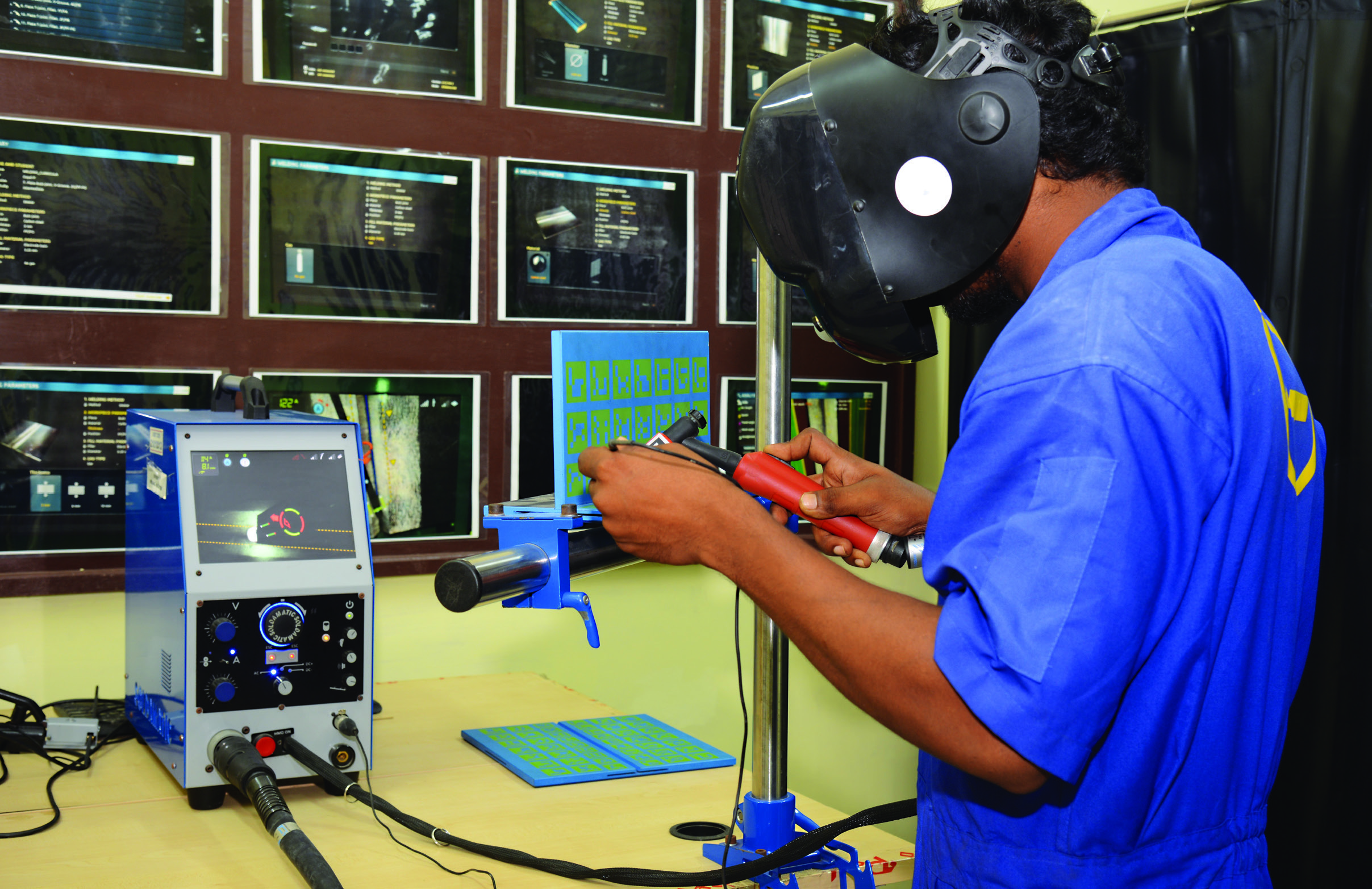

Use eyewear: The eyes are perhaps the most delicate sensory organ positioned perfectly in the head, naturally protected by eyelids and eyelashes. “This natural protection is inadequate at a construction site,” warns V Ramanathan, EHS – Head, PT&D IC, “where the eyes can be assailed by a variety of hazards, mechanical, thermal, chemical, electrical and even radiation.” Safety glasses, face shields, welding goggles and shields are some of the protective eyewear that are recommended specially during activities like welding work, gas-cutting, chipping, grinding, carpentry, chemical handling operations that can create a wide array of hazards like sparks, harmful & intense rays, flying particles & debris, concrete particles, nails, screws, molten metal, splashes, burns and dust. OSHA standards require that employees and workmen should be provided with effective eye protection, adequate to combat these multiple hazards.

It’s a case of horses for courses, for one type of safety glasses will not protect you from all types of hazards.

M Kamarajan

EHS – Advisor, B&F IC

Use the right kind of eyewear: “It’s a case of horses for courses,” remarks M Kamarajan, EHS – Advisor, B&F IC, “for one type of safety glasses will not protect you from all types of hazards. For example, glasses to be worn during welding work are not the same that you wear when working on top of a bridge or a high-rise tower buffeted by strong, dusty winds.” The onus on EHS managers is therefore to ensure that workmen are wearing the appropriate eyewear for their activity they are involved in.

Wear it right! Having chosen the right kind of eyewear, it needs to be worn right fitting snugly and comfortably on the face with gaps to allow for air circulation and sturdy straps to keep them in place. “Often PPE does not include safety glasses which is asking for trouble,” says Ramanathan, “for imagine if one of my men when stringing on top of a transmission tower is suddenly blinded by some wind-borne foreign particle entering his eye?”

Maintain it to see right! It is equally important to maintain eyewear and keep it free from scratches, dirt, for that can blur the vision and reduce its effectiveness. Bent or broken eyewear should be immediately replaced.

Treat eye injuries immediately! “The danger with eye injuries is that they are not always immediately obvious,” cautions K P Ravinath (KPRn), Head EHS – L&T GeoStructure. “Early detection and treatment are crucial because delay in medical attention can result in longlasting damage.” Pain in the eye, cuts on the eyelid, enlargement of the pupil, blood spots, difficulty in moving the eye, presence of any foreign particle should immediately be referred to a doctor, preferably an ophthalmologist. Avoid self-medication, rubbing, applying ointments or administering selfprescribed eye-drops.

Reduce, move or block that din!

At the best of times, a construction site is a noisy place! The 3 best ways to reduce the din: 1) Reduce it by using the quietest equipment available; 2) Move it by locating noisy equipment as far away as possible from workmen and 3) Block it by erecting temporary barriers to block the noise from reaching workmen. “Or, managing it by the I SAID ways,”adds KPRn, “that involves Isolation, Silencing, Absorption, Insulation and Damping.”

I SAID is at play at the Mumbai Trans Harbour Link project where EHS – In charge, Sanjay Mishra and his team have a serious, contractual obligation to reduce noise. “The mudflats of Sewri in Mumbai are the habitat of some rare species of birds including flamingos and we had to plan our construction without disrupting their lives,” he smiles, mentioning the several measures that they have taken at site to dampen sound and reduce light so that their feathery neighbours are undisturbed. The ICC Towers team in the heart of Mumbai had another ticklish issue about noise creation as Project Manager Ranjeet Kumar shares. “Initially, all noise creating work had to stop by 9 pm which was later relaxed to 10 pm but the bigger problem was that the client, Bombay Dyeing’s MD stays in a penthouse in the adjoining tower and we used to receive his sms messages at times if we made too much noise at night!”

Apart from causing a disturbance to the neighbouring populace, high decibel noise at sites can be injurious to employees and workmen too. “Consistent loud noise on the eardrums is a silent killer,” says MK, quickly adding with a chuckle, “pun totally unintended!” The problem is that workmen are rarely aware that their hearing is getting progressively impaired. A simple thumb rule to check if one is being ‘noise-polluted’ is to try and converse with a fellow workman standing 2 m away. The need to raise one’s voice is a warning sign. OSHA recommends that workplace noise levels be kept at 85 decibels over an 8-hour shift; anything over the 100-mark level is dangerous. EHS managers need to conduct regular checks to ensure that noise levels are maintained within permissible levels and initiate immediate corrective measures if they are not.

Constant noise pollution can lead to acute and chronic disorders including acoustic trauma or gradual noiseinduced hearing loss that can make it difficult for one to hear normal conversations, trouble in speaking or hearing on the mobile, difficulty to catch all the words, being confused by similar sounding words, a constant ringing, buzzing or humming in the ears, depression and loss of sleep. “It can reduce productivity,” warns KPRn, “and can cause accidents at the workplace if one is unable to hear warning sounds.” Noise can affect other parts of the body as well as a recent study reveals that workmen constantly exposed to noise show greater likelihood of suffering from heart disease that those who are not. Hearing can be lost also due to a sudden, powerful loud sound like an explosion.

Effective noise management is ensured by the I SAID ways, that involves Isolation, Silencing, Absorption, Insulation and Damping.

K P Ravinath

Head EHS – L&T GeoStructure

Safe earwear: Foam earplugs or earmuffs are the best way out, made of sound-attenuating material and soft ear cushions that fit around the ear, with hard outer caps. Again, like in eyewear, one type cannot combat all noise hazards. EHS managers should help workmen choose the right kind of earwear depending on their activity and help them wear the protective gear right. The choice of earwear is also dictated by the communication needs, convenience, comfort, hygiene and the individual’s hearing ability. Avoid earwear that are worn, dirty or broken. Music-player headphones are not protective earwear by any stretch of imagination! If routinely exposed to hazardous levels of noise, then it is important to have one’s hearing checked for any loss of hearing.

Like eyewear, earwear needs to be maintained too; frequently checked, cleaned regularly to avoid infections and replaced whenever required. If damaged or dirty, it would be a sound idea to replace them.

Planning: One way to reduce noise pollution is to plan, eliminate noisy activities to the extent possible with different, quieter equipment perhaps, equip workmen with the right kind of earwear to combat unavoidable high noise levels and limit hours of exposure.

At the end of the day, we have only one set of eyes and ears! Let’s guard them as well as we all can!