Auditing EHS at sites through the Third Eye – a post pandemic development

Although the pandemic brought travel and cross-country movement to a grinding halt, construction activities at various sites continued with the associated risks and compliance obligations remaining unchanged. The challenge before site leadership was to quickly evolve methods to continue monitoring site progress. The concerted efforts to drive digitalization across the organization stood us in good stead as people at HQ, offices and sites readily adopted and adapted to the new normal of Virtual Auditing by conducting quality audits, internal control audits, financial audits and EHS audits. From mobile devices to drones, site sensors to surveillance cameras, virtual reality and other wearables are all being used to audit EHS at sites through the Third Eye.

Resolving teething issues

A comprehensive process to verify compliance to the stipulated processes of the EHS Management System, an EHS audit needs to be carried out diligently and meticulously for it to be useful. Virtual audits, though not new for the global construction industry, were being adopted for the first time at L&T Construction and the onus on EHS managers was to comply with Occupation, Health & Safety ISO 45001, and Environmental ISO 14001 standard requirements.

However, sites did not initially take to Virtual Auditing like fish to water. There have been teething problems like issues with technology (read network), lack of involvement, building trust for the audit and finding champions to drive the process.

International Standard (ISO) 19011:2018 lays down the guidelines for auditing management systems based on which several businesses of L&T Construction like B&F, Heavy Civil Infrastructure & PT&D have released guidelines for effective virtual auditing. “We have drawn from the essence of the ISO 19011 and a few other standards to arrive at our guidelines,” explains P Nagarajan, Head – EHS, B&F IC.

We have drawn from the essence of the ISO 19011 and a few other standards to arrive at our guidelines.

P Nagarajan

Head – EHS, B&F IC

Heavy Civil, for their part, have formed an HQ Audit team to evolve a programme and structure to follow. “We first identified fully certified ISO 45001 auditors at each of our projects and having them to support audit verification has been a huge advantage for us,” remarks V Marudhukavi, Lead EHS Auditor, who is a part of the audit team.

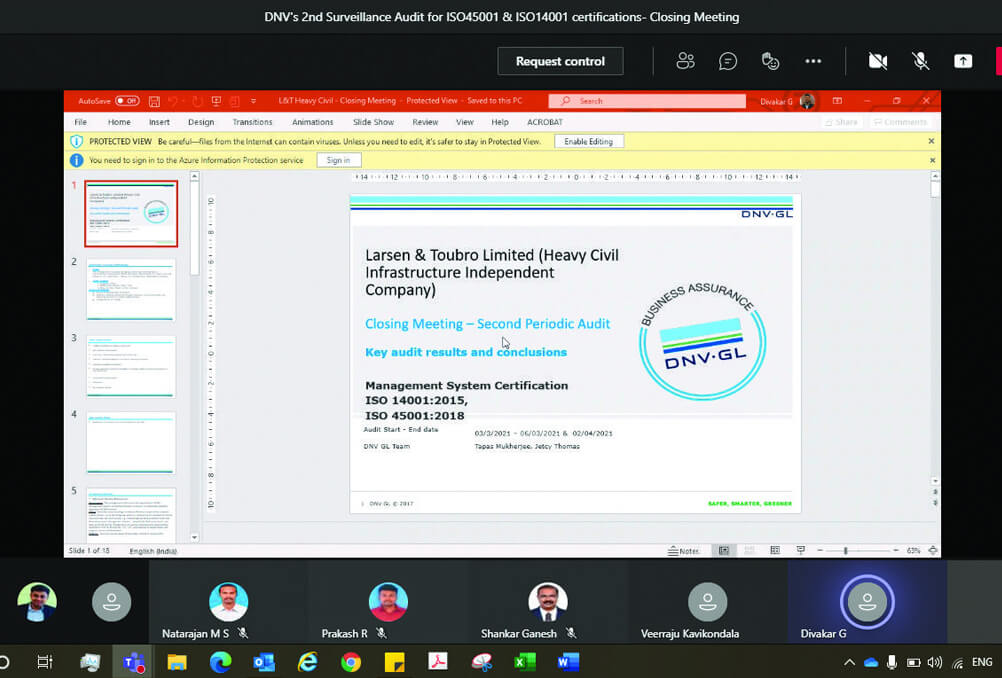

Nagarajan adds that even certification audits are being conducted remotely that are acceptable to both the certification bodies and, to some extent, the statutory bodies as well. In fact, recertification audits for half of B&F’s projects have been successfully completed remotely with recertifications issued with revised certificates that are valid till February 10, 2024.

Typically, an audit team comprising managers and SMEs (Subject Matter Experts) to audit specific, critical elements would require at least three days to travel from Chennai HQ to a project located in the eastern part of India. All this is saved – time, effort, cost and there is also a huge ‘green’ gain with less travel.

M Nachiappan

Deputy General Manager, EHS – B&F IC

Requirements for a successful virtual audit

Across L&T Construction, virtual audits are being conducted on the MS Teams platform for which a detailed checklist has been drawn up to ascertain activity and its documentation. Some reservations were aired about including QMS (Quality Management System) within the ambit of a virtual audit which were instantly quelled. “We assured our EHS managers that with the best utilization of the available technologies, we could effectively focus on Class-1 risks and the control measures taken at sites,” points out G Divakar, Head – EHS Compliance, Heavy Civil. With MS Teams, managers can submit pictures to the auditors, live stream activities like conducting site tours, with adequate connectivity.

Overall, we have conducted 155 internal audits across domestic projects/factories and 8 external audits including one at Head Office.

T.Prabhakar

Head EHS – PT&D IC (Domestic)

Virtual auditing – several pros

Virtual audits have their merits. A significant positive is that a cross section of people from across locations can participate. Usually, a lot of time is spent on planning physical audits in terms of travel and other logistics. “Typically, an audit team comprising managers and SMEs (Subject Matter Experts) to audit specific, critical elements would require at least three days to travel from Chennai HQ to a project located in the eastern part of India,” observes M Nachiappan, Deputy General Manager EHS – B&F IC. “All this is saved – time, effort, cost and there is also a huge ‘green’ gain with less travel.” All the effort to gather key people to open and close meetings is avoided, and since most of the documents are prior uploaded in the portal, tampering of data is largely reduced.

“By using the virtual platform, we have completed more than 200 audits and process reviews in a short span of three months,” adds Nagarajan, cracking a satisfied smile.

By using the virtual platform, we have completed more than 200 audits and process reviews in a short span of three months.

P Nagarajan

Head – EHS, B&F IC

At PT&D IC, several external audits have been conducted virtually. In December 2020, Bureau Veritas conducted a virtual external audit through MS teams for projects/factories/head office and successfully completed the surveillance audit for ISO certification. “Overall, we have conducted 155 internal audits across domestic projects/factories and 8 external audits including one at Head Office,” informs T Prabhakar, Head – EHS (Domestic), PT&D. “Some of the projects we have virtually audited are the 765kV Bhuj-Lakadia TL, 220kV D/C Kushma-New Butwal TL, IPDS-Jammu, RMU- North Chennai and the Mumbai Metro Line.”

More sites are accessible, more hitherto ‘hidden’ areas at remote sites have been brought within the ambit of audits that have increased both insight and control and, more importantly, helped maintain business continuity.

All EHS managers confirm that the quality and efficiency of audits have improved as audit teams with the required levels of competence are conducting these and by being virtual, it is possible to add more qualified auditors. More sites are accessible, more hitherto ‘hidden’ areas at remote sites have been brought within the ambit of audits that have increased both insight and control and, more importantly, helped maintain business continuity.

A few cons

The nature and speed of internet connectivity are major determinants for the success or failure of audits as the extent an auditor can verify site conditions is largely dependent on the technology being used. Several remote sites without the required bandwidth are still difficult to audit. At times, visuals are distorted, sometimes only audio is possible, or certain critical areas of the project are not covered by cameras. Staging an area or deliberately avoiding certain sections are possible but those can happen even with physical audits. “Some of these challenges are being overcome by agreeing in advance to the details and areas to be audited,” remarks M S Natarajan, Senior Manager, EHS – Heavy Civil. If the goal is continuous improvement, then everyone should work to make the process as efficient as possible.

If the goal is continuous improvement, then everyone should work to make the process as efficient as possible.

Tools for virtual auditing

Mobile devices: Interestingly, mobile phones are becoming a boon for EHS Managers. The now ubiquitous Safety App is entirely operated as a mobile interface. In addition, mobile apps keep EHS personnel updated about project details, work in progress, safety hazards, incident reports, investigation updates, potentially hazardous activities, the works. Both engineers and workmen now have a centralized repository of information to access readily and quickly that speeds up the entire process.

Drones have become a standard construction site practice whether to conduct economical, quick & accurate surveys, monitor progress like at several of PT&D’s transmission line projects, monitor & inspect select areas of a site that are difficult to easily access or even keep tabs on activities that are potentially dangerous.

Smart glass is an advanced technology exclusively meant for remote monitoring and virtual audits with several advantages over normal video calls. The person with a smart glass has the same view as another viewing through a laptop/system far away, thereby eliminating the slip/ trip hazard that we encounter when making video calls on the mobile. Smart Glass is replete with features like chat, send picture, take photos, annotate images, add comments, etc., during the live recording, and even review presentations. More users can be connected for the audit but there can be a restriction on the number of people who can speak. All the recordings, snaps, photos are available on cloud, instantly retrievable and most handy for auditors when writing their audit reports.

In the final analysis while virtual audits have been a huge source of learning, it is still WIP but the results are extremely encouraging. The lessons learnt during the tough days of the pandemic should be leveraged to a greater extent during the good days. Virtual auditing has come to stay. The task for EHS leadership and managers is to make it more efficient, more widespread and part of business as usual.