Building Sustainable Water Infrastructure

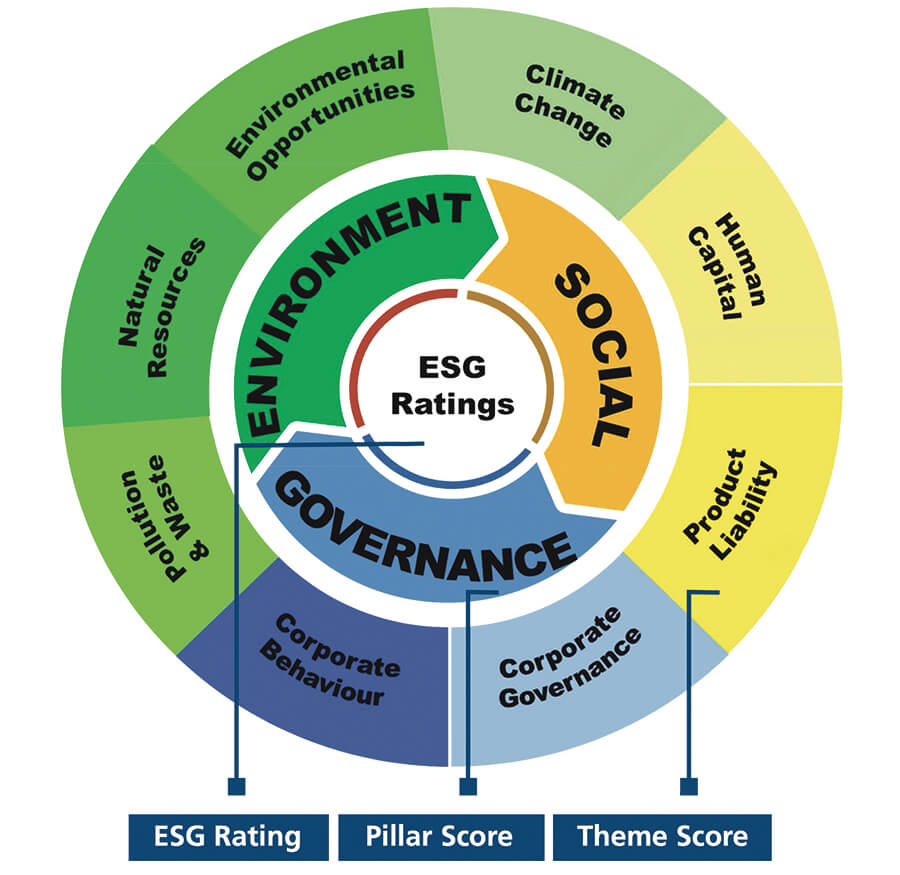

ESG (Environmental, Social Responsibility and Governance) is the new buzz term with investors and financial institutions keenly watching how companies integrate sustainability into their operations. A set of standards within the ESG framework determine a company’s ESG score based on its commitment to implementing green initiatives across a project’s life cycle involving economic, financial, social, environmental (including climate resilience), and institutional sustainability. These ESG criteria can be used to evaluate any environmental risks a company might face and how it manages them.

Creating sustainable infrastructure is an inclusive process across all our operations. Internalising sustainability and governance into decision making, we give clients the green edge by demonstrating our steadfast commitment to the environment and society at large. This cleantech approach is one of the key factors for the recent upgradation of L&T’s ESG score.

Our Water & Effluent Treatment (WET) business has been a key contributor to this process by transforming the lives of millions by building sustainable water infrastructure. We share with you a few snippets from WET IC’s green portfolio that has helped enhance the sustainability quotient across their projects.

Ambient air quality test

Breathe easy

Even though WET IC has not been engaging large fleet of diesel operated heavy Plant & Machinery (P&M), the business still stringently monitors ambient air quality at all construction sites, for power generators and other P&M deployed. In line with the statutory requirements of air management, WET IC has implemented an Ambient Air Monitoring System as a part of its EHS objective across project sites to assess air quality for pollutants that monitors the presence of sulphur dioxide (SO2), carbon monoxide (CO), nitrogen dioxide (NO2), ozone (O3), and total suspended particles (TSP) in the air.

Power generator installed on fabricated stack to ensure soil protection

Sons of the soil

While aligning to the emission norms during the operation of power generators, WET IC has gone a step ahead to take extra care for the soil on which the equipment is installed with specially fabricated stacks for different capacity power generators as per the standard norms across sites. Further, dip trays, customized trolleys and extension of exhaust pipes ensure that the spillages are safely collected.

Stack monitoring

RO Plant installed at site

Making every drop count

Under normal conditions, discharge water finds very little use as it contains high level of total dissolved solids rendering it unsuitable for drinking. WET IC, however, effectively reuses discharged water from the RO filters at its projects. A couple of cases in point are the 20 MLD CETP Dholera project that uses nearly 900 litres of discharge water for bathroom flushing and washing and the Koppal WSP, where more than 2500 litres is reused for various tasks. The reuse strategy is evolved on the basis of the amount of water discharged for various construction activities.

Rainwater harvesting pits

Our ‘Ulta Chaata’ initiative has become very popular as a simple method of catching rainwater. It is set up on the rooftops of offices, workmen habitats, storerooms to collect and store rainwater through an umbrella blown into an inverted conical shape to recharge ground water.

K S Sudheesh Kumar

Head – EHS, WET IC

“Our ‘Ulta Chaata’ initiative has become very popular as a simple method of catching rainwater,” informs K S Sudheesh Kumar, Head – EHS, WET IC. “It is set up on the rooftops of offices, workmen habitats, storerooms to collect and store rainwater through an umbrella blown into an inverted conical shape to recharge ground water.”

Another small but effective step implemented at sites is the reuse of dewatered water through temporary storage pits for dust suppression during construction activities.

Dewatering

Storage water

Re-use of water for dust suppression

The Miyawaki method creates a self-sustaining forest ten times faster than a conventional tree planning scheme. At our Bidkin and Erode projects, we have planted more than 60000 saplings using this method with 100% survivability.

Miyawaki method used for tree plantation

Enhancing green cover

Overall, L&T planted 1.4 million + trees during 2020 with WET IC spearheading the initiative adopting some unique techniques. “The Miyawaki method creates a self-sustaining forest ten times faster than a conventional tree planning scheme,” points out Sudheesh. “At our Bidkin and Erode projects, we have planted more than 60000 saplings using this method with 100% survivability. In fact, we are also acting on special requests from the client to either replant or replace aged trees after the construction activities.”

Ensuring waste minimisation

Certain wastages that can be reused effectively in line with the EHS and ISO standards are standardized at sites and as a part of this initiative, over 12009 MT of recyclable waste was handed over to approved vendors as a part of a ‘GO GREEN’ campaign during the safety month celebrations. The success of this campaign has been a significant triumph in the IC’s mission to minimise waste projects, and in the process, ensure good housekeeping and overall safety.

Achieving energy efficiency

Solar panels installed at workmen habitats at some WET projects are proving to be decisive both in terms of cost savings and achieving energy efficiency. With most of the projects based at remote locations, such initiatives have now been extended to power remote onsite training vans for workmen orientation. When it comes to conservation of conventional energy, project sites are migrating to energy efficiency appliances and LED lights.

Solar panels at workmen habitat

Go green campaign

On a green mission

For WET IC, ensuring water security and continuous supply to end-users have always been matters of topmost priority and through its green measures at project sites, it is redefining the process of building sustainable water infrastructure.