WDFC – EMP 16 Project

Unrelenting in their pursuit of Safety

Mechanized wiring train – first time in India

![]()

We continuously face several EHS challenges during execution like working next to a ‘live’, busy railway line, working at heights over a length of 932 TKM, and moving multiple heavy machinery, men, and material; hence Safety is our primary consideration.

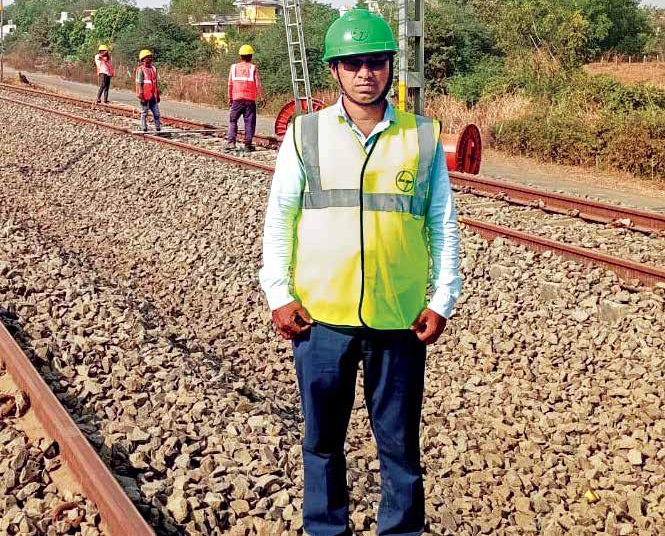

Samir Kumar Gupta

Project Director

![]()

For a project to maintain a clean safety record even after 7 years of execution in some of the sternest environments and conditions is certainly worthy of high praise. Project Director, Samir Kumar Gupta; his EHS In-charge, Sandeep Bhaurao Shirsat; and team at the WDFC – EMP 16 project of Transportation Infrastructure IC (RBG – Railways Business Group) can collectively hold their heads high. Awarded in May 2016, the project has already clocked 7.64 million safe manhours without a single LTI or fatality. Such a performance merits recognition even at the Company level, in the form of L&T Construction’s Safety Award – 2023.

![]()

We have ensured high safety standards through consistent teamwork, collaboration, early anticipation, and resolution of problems blended with the mechanized working, digital solutions, and constant learning from a pool of near miss data received from similar ongoing projects and past experiences.

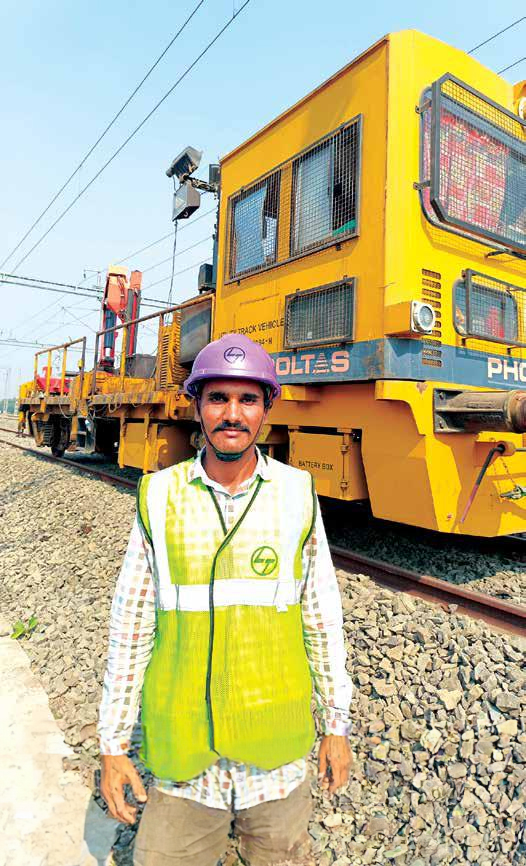

Sandeep Bhaurao Shirsat

EHS In-charge

![]()

The project scope for Samir and his army of Project Managers – Rajagopal Mahesh, B V Naik, Sathya Kumar, and E Balakrishnan – involves electrification of 2×25 kV High Rise OHE (932 TKM), including a Gas Insulated Traction Substation, 6 Air Insulated Traction Substations, 40 Switching Stations, and SCADA System between JNPT and Makarpura on an EPC basis.

Aerial view of TSS

Facing a variety of challenges, EHS and otherwise

Throwing light on some of their challenges, Samir refers to the huge task of completing 600 TKM out of 932 TKM of wiring in a single year (2023), despite the presence of multiple stakeholders at site, drawing special attention to the commissioning of the 484 TKM stretch in 2023, out of which train operations commenced on the 208 TKM stretch between Gothan–Makarpura. “There was a delay in work front handover,” he says with a shake of his head. “In fact, the last 60 TKM of track in the Gothan–Makarpura stretch was handed over by the Interfacing Contractor (M/s TATA) in June 2023, after the arrival of the monsoon.” The approach to site was a problem due to a 10 m high embankment area, especially during the rainy season with the site only accessible via a 3 m wide ramp. B V Naik adds, “The track was being laid without tamping and destressing with the CTP contractor working in parallel, because of which machineries of multiple stakeholders were moving on the same track, and obtaining sufficient traffic blocks was a huge challenge.”

“We continuously face several EHS challenges during execution like working next to a ‘live’, busy railway line, working at heights over a length of 932 TKM, and moving multiple heavy machinery, men, and material; hence Safety is our primary consideration,” declares Samir, and their focus has translated into a slew of EHS awards that Sandeep proudly shares: “We won the RoSPA Gold Medal for winning the RoSPA Gold for 5 consecutive years from 2019 to 2023, and we have also won the BSC International Safety Award for 4 years in a row from 2020 to 2023.”

Winning awards consecutively seems the norm for the project, which has been recognized with the NSC’s Prashansa Patra in 2021 and NSC’s Appreciation Certificates in 2020, 2022, & 2023.

Some of their other awards include FICCI’s Certificate of Appreciation for Excellence in Safety Systems (2023), the LIFE Award – Mainline (RBG) (2022) and the LIFE Award – Platinum category – TI IC (2023).

For seven years, the team has been executing the project adjacent to the high traffic, electrified Delhi–Mumbai Indian Railway line that daily witnesses about 180 trains speeding up and down. The team has deployed discharge rods, high-voltage induction sensors, and detectors to ward against the threat of induction and implemented the work permit system to work adjacent to the railway line during power/traffic blocks. “We have ensured high safety standards through consistent teamwork, collaboration, early anticipation, and resolution of problems blended with the mechanized working, digital solutions, and constant learning from a pool of near miss data received from similar ongoing projects and past experiences,” remarks Sandeep. The team’s relentless pursuit of maintaining a safe work environment for the workmen keeps them ahead consistently.

Electric loco trial run carried out at speed of 100 kmph

The safety of workmen working at height is one of Sandeep’s tall challenges, for which they use Vertical Carrying Platforms (VCP), RRV scissor lifts, and tower wagons for wiring, final adjustments, & checking. EMP 16 has also commissioned Indian Railway’s first 220 kV Gas Insulated Traction Substation. The risk of leakage of SF6 gas in the confined space of the 220 kV GIS building is another hazard, against which precautions have been taken as per MSDS & devising emergency measures and evacuation route plans.

The team’s work entails the movement and handling of multiple heavy electrical equipment through rural & urban area roads, which calls for efficient traffic management, coordination with village heads, and regimented safety procedures to handle movement of heavy Scott Transformers weighing up to 120 MT. Regular interfacing with all stakeholders ensures risk-free movement of the track and construction machineries of other stakeholders (NTC, Ballast Hoppers, Tamping Machines, etc.) on the common DFCC track.

The winning team

Safety measures unique to EMP 16

Planning Head, Purushottam Khadye, points out that they have adopted several safety measures that are unique to their project like the use of helmetmounted induction sensors & highvoltage induction detectors (mounted on top of discharge rods) by the frontline staff when working in proximity to the railway line. “For the first time, we have used window and rescue kits for conductor jumper cable works at heights of 12–15 m in all substations and cradle platforms made from site scrap for OHE cantilever erection work to guard the workers from ergonomic hazards while working at heights.”

On the digital front, VR & AR training modules on railway construction safety are used to effectively train workmen. Several other modern mechanized machineries at par with global standards, like wiring trains, Tescar augers, mast grabbers, VCPs, tower wagons, RRV scissor lifts, concrete conveyors, etc. have been deployed to mitigate hazards of excavation, erection of masts, booms, and working at height.

Certainly, Samir and his team have been pulling out all stops to ensure a spotless EHS track record that they are keen to keep till they hand over this critical and challenging project.

A FULLY CHARGED JOURNEY

A Vijayaraman

Manager (EHS), TI IC (RBG)

Vijayaraman strongly believes that the devil is in the details. With sharp focus and a clear eye for detail, he has won recognition for creating safe work environments. His 18 years of experience across sectors like railway, windmill, and substation projects have significantly expanded his EHS knowledge. It is commendable to note that the EMP 16 Project has maintained a clean safety record throughout its 7 years of execution. Vijay says proudly, “We have clocked 7.64 million safe manhours without a single LTI or fatality” – no surprise that WDFC EMP 16 won L&T Construction’s Safety Award – 2023!

- Our high EHS standards have won us the RoSPA Gold medal, NSCI, BSC and FICCI awards and these have been possible due to the support from my seniors and team members.

“It has been challenging to work next to a live & busy railway line and at heights over a length of 932 TKM,” observes Vijay. “While we emphasize the importance of upskilling and maintaining a good mental health at our toolbox meetings, we have developed training modules and evaluation metrics for hazards of Induction Current & Discharging procedures.”

To address the challenge of frequent change of workers at site, the team has regular and robust processes for training and retraining them. “In tough and non-navigable sections of our site where workers are vulnerable to dangerous hazards, we ensure that they are equipped with the right safety gadgets like helmet mounted induction sensors and induction detectors. Nurturing a safe work culture requires the commitment of the entire site team,” he emphasizes for good measure.

Their digital initiatives ensure better efficiency and productivity like the SHEILD App that has sharpened the team’s EHS observations and enabled quicker implementation of control measures while skilling workers with AR/VR modules has helped them understand site challenges better. Vijay breaks out into a happy smile, “Our high EHS standards have won us the RoSPA Gold medal, NSCI, BSC and FICCI awards and these have been possible due to the support from my seniors and team members, who have actively participated in all the site EHS activities, like trainings, audits, health surveillance, committee meetings, etc.”

Vijay hails from Sengottai, Tamil Nadu, and is happily married to Muthulakshmi, who is an online marketeer. He loves spending time with his sons Santosh Kumar & Sai Charan and is addicted to driving & watching movies in his free time. One of the most memorable moments in his career was when the EMP16 project achieved the ‘LIFE Award’ consecutively for 2 years. His pride of being a part of the L&T family comes from the fact that the organisation and the leadership provide him the freedom to work independently. He ends on a happy note: “I am glad to have played a role in L&T being certified a ‘Great Place to Work’ again.”

ON THE RIGHT TRACK, DRIVING EHS

Satyajit Roy

Construction Manager (Elec), TI IC (RBG)

- We spearhead various safety motivational programmes for the workers to make them realise the importance of working safely and blend them into the L&T safety culture.

The WDFC EMP-16 project is Satyajit Roy’s first project with L&T though he brings with him a rich 23 years’ experience of handling substation projects up to 765 kV. He is extremely happy that he has been part of the team that has won L&T Construction’s Safety Award 2023, a wonderful recognition of the team’s efforts to drive EHS at the project.

“One of the major challenges we face at site is the frequent change of manpower,” he says with a long face, “with the result we must keep repeating the process of inducting and training new workers for them to develop familiarity with the desired safety requirements.” Another issue they contend with is adhering to stringent delivery schedules which requires the team to work speedily but always keeping Safety uppermost in their minds.

What then has the team done differently to have such an impressive EHS track record? “We spearhead various safety motivational programmes for the workers to make them realise the importance of working safely and blend them into the L&T safety culture and inspire them to realise how, by following Safety, it benefits not just them personally, but the society, the organization and the country at large as well.” In addition, the team creates awareness among the workers about good health and creating and maintaining a healthy environment, conducts regular housekeeping drives in their working areas and complies with the legal and contractual Safety requirements by maintaining proper EHS documentation.

Satyajit is grateful to the higher management for their instant approvals and support for him to drive EHS at site. “All our team members unconditionally support safety,” he says with a wide smile, also mentioning the SHEILD App that has proved a boon for the team to fulfil their checklists and record observations.

Hailing from Asansol, West Bengal, Satyajit is married to Anjana Roy, a homemaker, and they are blessed with a son, Indrashish. “I love playing cricket and watching Indian football,” he laughs, sharing his favourite pastime. “My most memorable moment occurred in 2012 at the charging of PGCIL’s 765 kV substation at Solapur and also being a member of the ONE GRID ONE NATION team,” he signs off proudly.

“SAFETY IS A COLLECTIVE RESPONSIBILITY”

Ved Prakash Singh

Construction Manager (Elec), TI IC (RBG)

Having previously been associated with the WDFC EMP‑4 Phase‑1 and EPC‑7 Railway Project as Section In-charge, Ved Prakash Singh brings valuable railways experience to his third project at L&T, the WDFC EMP 16 Project. “My approach is to make workmen understand that safety is a collective responsibility that benefits not only themselves but everyone around too,” About his role at the Safety Award– winning project, he mentions conducting regular programmes with his team to imbibe the L&T safety culture in the workmen.

“All workmen who are engaged at the site attend an induction to drive home the importance of safety,” Ved informs. “We also impart time-to-time safety training, and day-to-day work is supervised by competent staff who ensure that all required safety equipment are available and safety standards followed.”

Ved consults his EHS team regularly to address the challenges of a changing workforce. “It is crucial that the new workmen familiarize themselves with our safety standards,” he notes astutely. “We have stringent delivery schedules, but our Safety team supports us steadily and ensures that dedicated time is given for safety awareness/initiatives.”

Ved and team are grateful to the top management for their support. “They have always provided us necessary safetyrelated approvals instantly, and we can work with certainty that we have their guidance whenever required,” he adds with a smile, also mentioning the usefulness of the SHEILD app for checklists and observations.

Hailing from Barabanki, Uttar Pradesh, Ved is married to Jyoti, a working professional. They are blessed with two children, Chintransh Singh and Bittu Singh. When he isn’t too busy with Railways projects, Ved loves to read books.

“Carrying out the loaded electric goods trial run from Rewari to Kishangarh and Makkerpura to Sanajan sections with 2×25 kV OHE and PSI is an unforgettable moment for me professionally,” Ved notes with a smile as he signs off, adding that he is proud to be a part of an organization that takes care of its employees’ family and health with adequate benefits where needed.

ENJOYING HIS

‘LEARNING’ EXPERIENCE

Shubham Pandharinath Gangurde

Senior Engineer (Elec), TI IC (RBG)

I always insist all my employees and workers

to wear proper safety equipment for the task

they have been assigned because without

appropriate safety equipment, they run the risk

of injuring either themselves or others.

Young Shubham Gangurde is still taking baby steps in the world of construction at the WDFC EMP-16 project having joined L&T as a GET. What has impressed him most about L&T is the commitment towards Safety and Quality. “L&T gives top priority to the Safety of its people and acts accordingly, which inspires and motivates me and drives me to work only with standard procedures to ensure safety,” he declares with josh. His and his team’s efforts have culminated in the project winning L&T Construction’s Safety Award 2023.

“Wearing proper PPE is an essential part of workplace safety for any industry and, more particularly, at a construction site,” he remarks. “I always insist all my employees and workers to wear proper safety equipment for the task they have been assigned because without appropriate safety equipment, they run the risk of injuring either themselves or others.” He ensures that they wear helmets, proper footwear, and other personal protective equipment. A point of grave concern for the EMP-16 team is that they work next to a live, busy railway line that calls for close monitoring. “At times in the project, we engage lots of workers to complete a task within a specific time frame; here, it becomes challenging for us to cope with the bulk of activities to be done in this small timeframe without compromising on safety and quality standards,” he notes seriously. “However, we keep maintaining the standards without fail. In many cases, workers are well experienced in their work but unaware of Safety, which is why we conduct TBTs before starting working.” Shubham mentions that at TBTs they focus on hazards, safe work practices, and how to minimize hazards during work. “Digitalization is also helping us to ensure a safe and secure work environment by promptly addressing any safety hazards and concerns that arise,” he adds.

For someone learning the ropes, Shubham is appreciative of the support from his seniors. On their collaboration, he says, “Every evening we discuss about the next day’s work and the possible challenges and problems we may have to face at site. If there are major issues arising, then we directly inform our superior to discuss the problem.” He is grateful for the regular guidance and constructive feedback he receives from all around.

Hailing from Nashik, Maharashtra, Shubham is still single and spends his free time reading technical books related to electricals, apart from learning through the various digital learning platforms provided by L&T. “Every moment in L&T is special for me; every day I learn and gain valuable experience,” he says with great satisfaction.