S. KANAPPAN

Chief Executive, L&T GeoStructure

Being a specialized business, operational efficiency for us at L&T GeoStructure has a lot to do with smart customer relationship management. First and foremost, it is imperative to have 360-degree data about our key stakeholders. For this, we draw up a list of all our current and past projects, understand our clients/customers, identify their key decision makers, analyse our own bid strategy, identify the key marine P&M owners/ hirers, specialist sub-contractors and competent partners/associates. We prepare ourselves with a database of emerging or forthcoming projects for various customers so that we can provide techno-commercial and robust conceptual designs at the drawing board itself to partner them throughout the life cycle of the project.

To improve our strike rate, we appreciate the importance of educating and enlightening our customers about our specialized offerings and the advantages of EPC solutions to create innovative designs and engineer cost-effective execution strategies by leveraging our strong in-house design and engineering team to reduce competition and increase our hit rate. Even after either a win or loss, we conduct a threadbare post bid analysis to arrive at appropriate counter strategies vis-à-vis that of our competitors.

Last, but not the least, success in our field has a lot to do with retaining our customers by constantly staying in touch with the key decision makers, proffering help to resolve operational or contractual conflicts to sustain and nurture relationships and thereby win repeat orders.

DIGGING DEEP TO MINE GREATER VALUE

Driving operational efficients at L&T GeoStructure

“To have an operationally consistent and sustainable business, it is imperative to have an inclusive strategy,” declares S Kanappan (SK), Chief Executive, L&T GeoStructure, “whereby inputs are gathered, discussions conducted, strategies evolved, decisions taken and initiatives adopted with the buy-in of everyone involved.” During the execution of a project, it pays to involve all the departments to consider innovative ideas and options, discuss and decide on them only after carrying out due diligence. “We adopt a holistic approach, studying the different components and provisions of the project as a whole, analysing both the engineering and commercial aspects before taking a final call.”

“We always seek to value-add to client proposals by following a process of consultative selling, A case in point is the Uppur Project, where the advantages of the Cathodic Protection Systems were recommended to the owner to increase the durability of marine structures that were readily accepted and are now acknowledged as best industry practices.”

S Kanappan

Chief Executive, L&T GeoStructure

Inclusive strategy translated into action

The earlier the involvement, better the cohesion and results, which is why general arrangement drawings are regularly updated and shared with the Construction Methodology and Planning Cell (CMPC) and Formwork teams at the planning and design stage itself, to take on board valid suggestions from the perspective of constructability that saves time, rework, redesign and helps procure timely approvals. For concrete structures, the choice of precast and/or cast in situ construction methodologies are decided at the design stage that improves efficiency and flexibility in material allocation and manpower planning. “We are able to speedily resolve issues at site or promptly address customer or consultant queries by deputing designers to site,” explains Amit Mishra, Head – Planning. “Issues are resolved quicker with face-to-face technical discussions and by being at the centre of action, they are able to continuously interact with onsite personnel to modify methods or even experiment to enhance efficiencies that are immediately communicated with the PMC or client to highlight the resultant change in scope vis-a-vis the tender and the accruing cost benefits.”

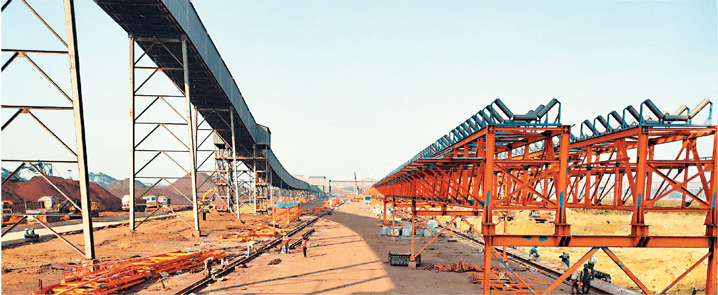

Coal terminal at Paradip, Odisha

“We always seek to value-add to client proposals by following a process of consultative selling,” shares SK, “and it is a win-win situation in which the client enjoys a more efficient process and we gain with additional scope of work.” A case in point is the Uppur Project, where the advantages of the Cathodic Protection Systems were recommended to the owner to increase the durability of marine structures that were readily accepted and are now acknowledged as best industry practices. Faced with certain execution issues for curved rectangular precast girders in the BHEL Project at Ennore, the team recommended straight, smaller, rectangular girders fixed on a chord to achieve the curve. The client accepted the recommendations and the girders were executed with only a modification to the pier cap dimensions. In the IndusInd Project too, a ‘D-Wall’ was proposed instead of sheet pile excavation that even the client recognized as a more viable, feasible and modern solution.

Multi modal terminal at Sahibganj, Jharkhand

Recognizing the key roles of CMPC & formwork teams

The role of the CMPC and formwork teams is vital from day one of a project especially in the choice of the construction methodology, its planning, testing and constant improvisation with the available material to speed up execution. “We analyse various equipment positions in the process,” shares E. Sathish Kumar, Head – CMPC, L&T GeoStructure, “prepare and share sequenced drawings with the site for easier comprehension.” Geotechnical test setups and schemes are recommended based on experience, ease of execution and site safety like 3D models for formwork and shuttering that were prepared for the BHEL and Runj Projects or the piling sequence modelling for clash detection developed for the IOLPL Project.

“The process called for high precision, because as the raker piles go below the soil stratum, the possibility of clashes is huge but as we had modelled the whole piling sequence and arrangement in BIM by calculating the exact coordinates, we were able to execute flawlessly.”

M. Kumaran

Head – Engineering

Making 3D models at home near the sea

In marine works, the most common equipment for pile driving offshore work is a jack-up barge (also known as a self-elevating platform) with 400 MT payload capacity equipped with a driving setup of two cranes and material handling barges to shift piles and precast members. A 250 MT crane is positioned over the jack-up barge to drive the raker and vertical steel piles while a 300 MT crane handles the piles and other precast elements in both the travel barges. A hydraulic pile guide system mounted on the jack-up barge guides the pile at the required angle.

The process involves a Vibro hammer pile-driving to the required penetration based on the soil condition, ensuring that the pile centre does not shift by more than D/10 (where D indicates the diameter of the pile) from the drawing coordinate and the deviation in verticality does not exceed 1.5%. On attaining the desired depth, the hydraulic impact hammer is lifted by the 250 MT crane. “The process called for high precision,” says M. Kumaran – Head – Engineering, “because as the raker piles go below the soil stratum, the possibility of clashes is huge but as we had modelled the whole piling sequence and arrangement in BIM by calculating the exact coordinates, we were able to execute flawlessly.” At the IWT Sahibganj project, gantry piling that is easy to assemble, operate, detach and reuse, was efficiently deployed. Project Manager, Samir Sarkar, shares that they were equipped with and guided by all the necessary calculations and sequence drawings for every movement of the gantry. “What’s more, we could operate the gantry smoothly and safely even in bad weather.”

Enjoying the fruits of collaborative working

In most projects, the selection of construction methodologies is based on a multi-disciplinary analysis; the more realistic and reliable the analysis, the better the choice of methodologies and excavation techniques. Six basements were planned at the IndusInd Project, a diaphragm wall with four level struts and a waler system (excavation shoring system) to demolish the existing structure. The team resorted to the Plaxis 2D software to model the soil structure interaction, using a finite element method for a 2-dimensional analysis of deformation and stability that optimized the design solution for excavation and ensured stability during construction. The Plaxis 2D software was used similarly by the Uppur Project team to successfully construct an offshore intake well.

“Our Quality Management System is in line with the requirements of ISO 9001:2015, and we believe that the capability of an organization is directly related to the capabilities of the people employed: obviously better the people, better the productivity. Therefore, training and development are the focus areas for us in QMS.”

S.N. Rajan

Head – QMS, L&T GeoStructure

Achieving operational excellence at the Sahibganj Project

The IWAI-IWT Project at Sahibganj in Jharkhand is part of the Indian Government’s Sagarmala Project to

improve waterways along the river Ganges. The project warranted the deployment of a mobile harbor crane that had to be transported from the Kolkata Port to the project site – a tall order considering that the consignment comprised 34 packages, weighing all of 244 MT. Transit of such a huge consignment 472 km by road to a remote, not-too-wellconnected site was a non-starter. Instead, the team decided to transport it on a barge via the NW 1 Inland Waterway to be unloaded directly at the IWT Sahibganj terminal. “We had a deadline to deliver the cargo before 26 February 2019,” points out Balaji Sree Ranganatharao P, Head – Logistics, “and to plan this timebound exercise we had to consider a number of aspects like custom clearance, material handling, lashing, choking, river transit, Farakka Lock Gate permission and a lot more.” They managed them all and against an estimated transit time of 21 days, the consignment was delivered right on schedule in 8 days. “The last package was unloaded bang on dot on 26 February,” exults Balaji, “and in the process we managed to save 10% in costs and 13-man days!”

Using quality to drive efficiency

“Our Quality Management System is in line with the requirements of ISO 9001:2015,” says S.N. Rajan, Head – QMS, L&T GeoStructure, “and we believe that the capability of an organization is directly related to the capabilities of the people employed: obviously better the people, better the productivity. Therefore, training and development are the focus areas for us in QMS.” Strategic planning and risk management are two other areas under QMS. Under risk management, potential risks and possible variabilities from anticipated conditions are analyzed and captured. Allowance for these risks during the pre-tender and operational stages avoids delays or cost variations. “Our Quality Assurance Plan for specific activities defines work method statements, inspection test plans and checklists,” adds Rajan. Routine, periodical checks and inspections of processes, materials and products improve the quality of construction and, at the same time, substantially reduce the chances of potential liability and rework.

For SK, better quality management results in delighted customers who open the door for future business. “While customer feedback is a valuable input for improvement, continual self-driven improvement is just as important,” he stresses.

“Our theme of 3G3 is to grow 3 times in 3 years, and to achieve this ambitious target, we must keep raising the operational efficiency bar, which we are sure to.”

S Kanappan

Chief Executive, L&T GeoStructure

EHS – an important determinant of efficiency

On K P Ravinath’s (KPRn), Head – EHS, L&T GeoStructure shoulders, rest the responsibility of ensuring that a positive safety culture prevails. “17 out of our total 18 sites performed without LTIs,” he shares with a sense of achievement. “The National Safety Council of India recognized our efforts at the IWT Sahibganj site and two of our clients – VIH Stone Column Work, Vizag and Nabinagar Super Thermal Power Plant awarded the EHSOs for their sterling performances.” Apart from employee engagement, rewards and recognition, sub-contractor management is another focus area for KPRn. “Sub-contractors are assessed and evaluated on their previous safety performance prior to engagement at our projects,” he says, “and their EHS performance is continuously assessed. We use the carrot and stick approach,” he grins, “support them when required, but reprimand when necessary, with the threat of dire consequences if they do not follow our EHS requirements.” Involvement and demonstration of EHS by the leadership goes a long way to create and sustain a positive EHS culture and one of KPRn’s mandates is to see that leadership is visibly driving EHS at sites.

“17 out of our total 18 sites performed without LTIs. The National Safety Council of India recognized our efforts at the IWT Sahibganj site and two of our clients – VIH Stone Column Work, Vizag and Nabinagar Super Thermal Power Plant awarded the EHSOs for their sterling performances.”

K P Ravinath

Head – EHS, L&T GeoStructure

The right person for the right job

For Bino Mathew Jose, Head – HR, L&T GeoStructure and team, talent acquisition is all about hiring special talent for extremely niche areas like building marine structures, construction of dams, barrages, diaphragm walls, lift irrigation projects, piling, ground improvement works, Reverse Circulation Drilling (RCD) and the like. “We achieved operational efficiency by tapping the right talent at the required time,” he points out, “with substantial savings on cost of talent acquisition. We tapped 85% of our candidates through a strong external and internal network domain.” Understanding the available skillsets is an imperative to leverage human capital and fill gaps. “Skill gap analysis and expertise mapping have helped us fill various key positions in Engineering Design,” says Bino. “In terms of operational efficiency, this has helped us leverage the available talent pool from a short- and longterm strategic perspective.”

“We achieved operational efficiency by tapping the right talent at the required time, with substantial savings on cost of talent acquisition. We tapped 85% of our candidates through a strong external and internal network domain.”

Bino Mathew Jose

Head – HR, L&T GeoStructure

Sea water intake and outfall structure at Uppur, Tamil Nadu

Planning was identified for skill development for which the HR team initiated the Planning Engineers Programme, an 8-month long exercise, to train and develop a bunch of strong planning engineers. Recognized as the Best Skill Development Programme, the initiative won the Golden Category HR Award presented by Tata Institute of Social Sciences & LeapVault CLO (Chief Learning Officers) in 2019 while L&T GeoStructure had won the Golden Category HR Award for Best On-the-job Training in 2018.

“Our theme of 3G3 is to grow 3 times in 3 years,” affirms SK, “and to achieve this ambitious target, we must keep raising the operational efficiency bar, which we are sure to,” he signs off confidently!