S. RAJAVEL

Senior, Vice President & Head, Water, Smart World & Communication

At WET, we have a two-pronged approach to operational efficiency with the initial focus to maximise project delivery and the other being seamless O&M management, pivotal for most water infrastructure projects. Over the years, we have consolidated and enhanced these two approaches with resounding success.

Today, our OPEX initiatives are giving us a head start in all projects. Survey is no longer a time-consuming activity as a range of digital and geospatial tools help to firm up alignments even as the scale of our jobs is becoming larger and more complex. With sustainable water management becoming the need of the hour, it’s imperative that we prep up execution with the right kind of technology through smart engineering initiatives like micro tunnelling and Dusk to Dawn (D2D) construction that are now our signatures of excellence across the industry.

Taking a cue from BIM, we have established a dedicated BIM hub, ‘PratiBIMb’, equipped with advanced clash analysis software for virtual construction that has significantly improved productivity with better cost control and precision. Digital tools like e-Pragati and PEARL are redefining the way we review projects to keep projects on track with a 360-degree forward vision. With a computerized maintenance management system, we now have the advantage of predictive maintenance with in-depth information to streamline and automate processes that are benefiting the industry at large.

In all our excellence initiatives, people have been our prime movers and our larger vision is to nurture an innovative culture with employees as process owners in our quest towards outgrowing our potential.

SCALING NEW LEVELS OF EFFICIENCY

Charting OPEX processes across WET IC

K. ASOK KUMAR

Executive Vice President & Head Water & Effluent Treatment

Water & Effluent Treatment (WET) IC has been in the thick of the action, engineering a slew of world-class infrastructure projects for water and wastewater treatment across India and in select overseas geographies. The good work has enabled us to record a CAGR of more than 25% in the last 5 years, and most remarkable about this achievement is that our success has been largely attributable to our continuous focus on and commitment towards OPEX initiatives.

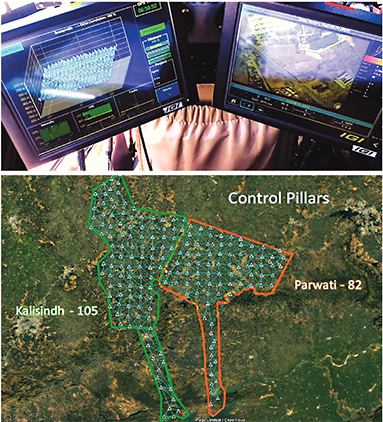

Helicopter-mounted Light Detection and Ranging (LiDAR) survey at Parwati and Kalisindh micro lift irrigation project

In today’s water starved world, the future hinges on sustainability. In fact, all that glitters is not only gold but every drop of water. Though countries like Singapore are far advanced in the realm of water sustainability, India has been making rapid strides by building new-age water infrastructure and implementing sustainable technologies to meet the government’s promise to deliver piped water to all rural homes by 2024.

Giving wings to survey

As the scale of projects become larger, the need to add value to project execution has assumed greater importance with innovative execution methods to accomplish both initial and long-term milestones “To a large extent, we have succeeded in eliminating elaborate manual processes that had extremely long lead times,” shares G.Balasubramanian, Head Corporate Center, “and likewise enhance productivity and monitor progress, all thanks to several inhouse developed digital applications. With much of our work happening below ground, it is always a challenge to make headway as there are no records available of the existing underground utilities.

Geospatial technologies have literally given us an x-ray vision to see what lies beneath the surface before we start work as was done in the case of the integrated sewer and water distribution system in Pali, Rajasthan, where GNSSbased surveys helped us immensely.””

Design customization of the bioreactor at the Coronation Pillar Project

After the success at Pali, geospatial technologies have been generously deployed across WET projects, to fast track execution. More innovation has driven digital surveys even further at the Parwati and Kalisindh Micro Lift Irrigation Schemes where an area of more than 4,500 sq. km was surveyed within two months against the normal time of 8 months using helicopter-mounted Light Detection and Ranging (LiDAR) technology. The precise levels of the survey provide scope for digital terrain and surface modelling, design of various structures and pipeline routes, finalisation of locations of important structures, right of way and the number of trees to cut to clear forests. Close to 8000 t of steel scope was avoided by optimizing the route.

“To a large extent, we have succeeded in eliminating elaborate manual processes that had extremely long lead times.”

G. Balasubramanian

Head Corporate Center, WET IC

BIM resolves project clashes

The entry of Building Information Modelling (BIM) has made life easier for engineers with prompt clash detection, analysis and resolution. With BIM, the geometric interference of elements can be immediately identified and resolved at the mere click of a button. A dedicated BIM hub, ‘PratiBIMb’, is equipped with advanced clash analyses software for virtual construction that improves productivity with better cost control, quantifies accurately, dynamically uploads construction documents and enables WEB-ex training. “We have resolved over 15000 clashes, reduced 4000 manhours and made substantial savings in cost,” says Arun Venkatesh, Head BIM, WET IC.

A standout feature of BIM is its capability to change project scenarios as was the case at the Coronation Pillar site. “We addressed a last-minute client requirement to scale up the size of the bioreactor after most of the surrounding infrastructure was completed by proposing feasible options in a couple of days that would have normally taken two months to develop,” adds Arun.

“We have resolved over 15000 clashes, reduced 4000 manhours and made substantial savings in cost.”

Arun Venkatesh

Head BIM, WET IC

Design automation

The construction of storage tanks and elevated reservoirs though largely repetitive yet important calls for a lot of detailing. An OPEX initiative has automated the design for such work through visual basis/google earth and autolisp applications along with parametric modelling through BIM based on multiple parameters that have improved efficiency and saved costs by a whopping 33% and 30% respectively, the latter thanks to GA drawing preparation instead of manual drafting.

It pays more to work at night

A novel scheme developed by the Wastewater BU, the ‘Dusk to Dawn’ concept is a first-of-its-kind in the construction industry according to which a specific portion of the alignment is earmarked for sewer network construction after the evening peak hours to be completed by dawn. V Dakshinamurthy, In-charge Operations Support, shares how he and his team started with a 100 m stretch at Jhunjhunu in Rajasthan. “It is a unique service as various digital and process improvement techniques are amalgamated including a remotely operated time lapse camera for real time monitoring and laser level monitoring with a Geo-tag enabled GIS App.” He recounts how they took up a busy section of the road on 3rd October 2019 to try out the initiative for the first time. “We started the initiative at 8 pm and despite challenges, like a sudden rain that lashed for over 90 minutes and undocumented buried utilities in our way, we still completed the task on time i.e., by 8 am, the next day, thanks to our preparedness.”

“We opted for micro-tunnelling technology, deploying three types of micro tunnelling machines depending on the size of the pipes and terrain.”

K. Hariharan

Cluster Head, WET IC

Having tasted success, the initiative then took flight and has been implemented across 10 wastewater projects and “and with every succeeding project, our insights have got deeper,” adds Dakshinamurthy. “Eventually, we should be able to stretch pipelines up to 200 m.” The plaudits from customers and the public have been overwhelming proving without doubt the runaway success of dusk-to-dawn construction.

Tunnelling made more efficient

A landmark project is being executed by the Wastewater BU at Cuttack that will be certainly the largest sewer network construction in India and therefore, unsurprisingly, extremely challenging. A feasibility study of the predominately high-water table revealed that conventional trenching was possible only in certain portions. “After deep analysis, we opted for micro-tunnelling technology,” informs K. Hariharan, Cluster Head, “deploying three types of micro tunnelling machines depending on the size of the pipes and terrain. For smaller dia pipes, a compact pit launcher was installed in a manhole or a launch cradle to link the works.” For slightly larger pipes, a pilot tube machine was deployed, the pipes precisely aligned with a monitor installed inside the shaft with a theodolite. For larger cross overs, the Akkerman slurry type machine was pressed into service. “Thanks to micro tunnelling, we have successfully fast-tracked execution, project management has been quicker and easier, and efficiencies have improved immeasurably.” Hariharan is a mighty pleased man.

A winch and trolley system devised by the project team at Alirajpur MLIS to shift and lay MS pipes across hills has fast-tracked execution and ensured safety. The combined casting of conical frames and integrating the SFRC frame portion within the precast segment across 110 villages saved close to 17,000 man-days for the Bommanhalli Wastewater project team, again speeding up execution and maintaining safety standards. Allu Screener is a new age machine for backfilling that is being extensively deployed especially by the Surya WSS project team, who are enjoying the benefits of completing backfilling of large trenches in double quick time.

GIS progress monitoring

A GIS progress monitoring system, implemented to lay pipes and keep track of the pipeline network, picks up visual images of the alignment with differentiated colour coding that keeps the client abreast of progress. Gaps are highlighted and ROU availability linked with the activities.

Thirsting for success

The entire IC was keen to succeed at the Jebel Ali STP project, the IC’s largest international project and hence it merited a tailor-made OPEX plan that combined a slew of initiatives such as the 5S method for productivity, last planer system for critical works, makeready meetings, bar coding systems and a computerized maintenance management system. “We zoned the entire project into 7 control areas by breaking down the construction activities to align each activity with individual targets that were monitored daily through the Time Quality Report (TQR),” shares Project Director, Syed Abdul Noor. To construct complex structures like the anaerobic digesters, an automatic climbing scaffolding system with three hanging platforms for the different layers of work was deployed. While the topmost platform catered to the reinforcement work, the middle focussed on continuous concreting and the bottom bench on finishing. “This way, we achieved phase wise finishing by putting close to 150 workmen per shift and completing the entire activity in just about 5 days with utmost safety.” Process innovation was required for the 3-level tertiary filter beds too. “It was extremely risky at the lower levels because of the confined space,” Noor points out, “so we used a thermocol block as a dead bed for the base slab to align the sequence of works as per the schedule.”

e-Pragati keeps projects on track

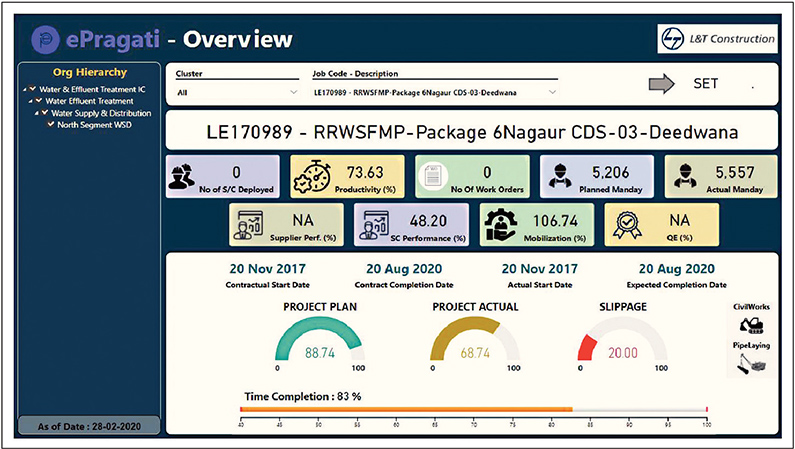

As the quantum of their jobs leapt, the onus to plan, schedule, control and track projects increased and the answer was an in-house developed, web-based, project management platform – ‘ePragati’ – for efficient project progress monitoring. It typically follows a quantity-based scheduling to facilitate effective planning of works for extensive linear jobs spread across huge areas of 3000 sq. m, at an average.

The project engineer must feed in daily progress in terms of quantity of work executed and manpower employed. e-Pragati juxtaposes the actual progress vis-à-vis plan to highlight variance (viz. lead or lag) based on which, it triggers an alert in case of lag to the appropriate hierarchy in the management to initiate necessary action to bring projects back on track.

With progress and manpower consumption data recorded on a daily basis, the leads generated are helpful to perform big data analytics to ascertain productivity norms for major execution activities; projects can also be monitored on a regular basis to tap the unlockable potential for productivity improvement.

e-Pragati captures a project at its lowest level thus enabling monitoring of project progress with respect to its financials, as each level of work is mapped with its corresponding unit cost. It is integrated with several modules of the Enterprise Resource Portal to measure works, generate subcontractor bills and calculate the budget on completion.

“We have enhanced productivity with less manpower, possess the knowhow of predictive maintenance for quick breakdown resolutions while effectively scheduling tasks for 100% achievement of contractual parameters.”

Rajmohan

Head O&M

Using a PEARL of wisdom

Productivity Excellence, Analysis & Realization League (PEARL) is a gamification platform with weighted average scores (60% to productivity and 40% to baseline improvement) assigned to each project site. The present productivity data (weighted by mandays) is compared with its historic productivity data and any improvement in productivity fetches points for baseline improvement. Piloted across 7 projects, the initiative created substantial cost savings from workforce productivity enhancement within 13 weeks that prompted PEARL to be rolled out across projects under different leader boards where each league houses projects based on similar scope of work. On the safety front, Apps such as ‘SWADESH’ and ‘ViewEHS’ have brought in unprecedented transparency in overall site EHS assessment,” shares K.S. Sudeesh Kumar, Head, EHS. “We have already submitted 6,23,656 forms, 1,47, 892 SECs involving 3478 users and considerably brought down the severity frequency.”

Computerized Maintenance Management System

WET IC constructs defining water infrastructure and are now being increasingly called to operate and maintain structures that led to the setting up of the O&M Department in FY 17 to provide scientific management of the various water and wastewater assets. However, achieving contractual parameters in terms of quality, quantity and safety was a challenge due to the absence of an integrated maintenance management system. To effectively bridge strategic management and operational layers, an in-house Computerized Maintenance Management System (CMMS) was developed that translates goals into operational metrics while automating the hitherto fragmented maintenance information for better information processing and actionable insights. More than 35 projects are presently being monitored through CMMS giving WET IC a sustainable competitive edge.

Rajmohan, Head O&M explains its advantages, “Our earlier practice for pump over hauling was based on elapsed time but condition monitoring has helped us analyse the critical parameters and pump performance thereby postponing the overhaul has resulted in substantial cost savings. Elsewhere, a timely alert on the higher vibration of a motor avoided a costly breakdown. Today, we have enhanced productivity with less manpower, possess the knowhow of predictive maintenance for quick breakdown resolutions while effectively scheduling tasks for 100% achievement of contractual parameters.”

People are our excellence movers

“All our processes and improvements are driven by our people,” asserts SRV, “and with more than 5000+ plus employees engaged across various phases of OPEX, the idea is to nurture an open and innovative culture across levels that is already reaping us rich rewards and is sure to stand us in excellent stead as we explore new horizons and take up challenging projects.”