D K SEN

Whole Time Director & Senior Executive Vice President, Head – Infrastructure

Road infrastructure development is a key requisite for growth and the Government of India is focused on

rapidly expanding the country’s huge 143,000 kms of National Highway network. Statistics reveal that

highway construction peaked at 10,800 km during 2018-19, an all-time high, reflecting a 30% growth and

is expected to remain at similar levels in this fiscal too. The Government is now planning to expand the National

Highway network to over 200,000 kms. In fact, the Bharatmala Pariyojana aims to build 66,100 km of economic

corridors, border roads, coastal roads and expressways, to provide 4-lane connectivity to 550 districts, increase

vehicular speed by 20-25% and reduce the logistics costs by 5-6%.

However, there are multiple challenges facing this program. There are headwinds in the form of funding issues,

cost escalations, unfavourable payment schedules, delays in land acquisition, utility shifting, tree cutting, mining

clearances among several others. The recent trend to award projects on PPP and HAM is unsuitable for us,

shrinking our addressable market even further.

Against this scenario, we at RREC, have trained our focus inward to improve our systems and processes to increase

productivity, reduce costs, cut out non-critical processes and thereby drive operational efficiency. The following

major OPEX initiatives were taken after deep diving into various activities and implemented at ground level:

Preconstruction Cell: For extensive interaction between the client and other departments to expedite land

acquisition and relocation of utilities obstructing highway projects.

Road Finishing Activity Cell: In every project, finishing activities are a bottleneck during project completion and this cell is to execute finishing activity in a focused manner.

Engineering Project Control: Quantity reconciliation before submitting designs and drawings to the consultant.

Digital Monitoring: Monitoring of productivity and dispenses of diesel through digital data.

P&M Profit Centre: Designed to accelerate P&M driven performance through digitalization, collaboration and advanced analytics; the P&M Profit Centre in RREC has contributed to benchmark productivity, asset deployment and energy efficiency in P&M Operations.

B2B Subcontracting: Major activities have started awarding to Sub contractors on a B2B basis to minimize risk.

Smart Execution: Invoiced based execution approach to monitor and improve cashflow.

Finishing & Demobilisation of Project: Co-ordinating with various internal departments to expedite and complete finishing works, including interaction with Consultants and Clients.

Listing of Region Specific Sub-Contractors: Discussion and enlistment of vendors in every region for common items such as survey, soil investigation, RE Wall, excavation, etc.

With strong leadership and efforts at sharper OPEX, planning and execution have started to bear fruit. These are initial steps, but we are convinced that we are moving in the right direction.

ON THE HIGH ROAD TO GREATER EFFICIENCY

Initiatives to enhance productivity in RREC

The transportation sector is arguably the backbone of the economy reflected in the announced outlay of INR 1,70,000 Crores for the sector in the Union Budget 2020. This special attention from the central government would pre-suppose a sector in high gear but the reality is slightly different as contractors face strong headwinds and uncertainties to succeed. Against a challenging backdrop, D K Sen, Whole Time Director & Senior Executive Vice President, Head – Infrastructure, L&T puts up a brave front: “While external factors are not within our control, I am driving my team to introspect and deep dive into our own systems and processes to evolve methods and kick start initiatives that can significantly improve our operational efficiencies. I am delighted that they have heeded my call and the RREC (Roads, Runways & Elevated Corridors) business have some encouraging results to show.”

“We initiated internal technical audits to benchmark effectiveness, efficiency of operational processes and procedures with a complete review of the documentation, interactions with design, procurement, P&M, construction practices, planning and other critical functions.”

G Shettar

Head – Quality, RREC

Benchmarking for competitiveness

To remain competitive in the face of odds has been the dictate for the business as the ‘headwinds’ that DKS referred to are manifested in surreal forms. “With increased focus on projects in the HAM or PPP mode, our addressable market is shrinking,” reminds DKS and hence the onus to improve internal efficiencies is even greater.

To drive operational efficiency, the RREC team has adopted a lean, integrated and design intent verified construction conforming to specified quality. “We initiated internal technical audits to benchmark effectiveness, efficiency of operational processes and procedures with a complete review of the documentation, interactions with design, procurement, P&M, construction practices, planning and other critical functions,” shares G Shettar, Head – Quality, RREC. “To further strengthen quality checks at site, a dedicated Quality Assurance cross functional team has been deployed at a handful of pilot sites like Bangalore International Airport, Dholera Smart City, Delhi International Airport, Mumbai Nagpur Expressway & Mumbai Vadodara Expressway with encouraging results.”

Infrastructure works for Dholera Smart City

A robust system to finalize quarry sources has been developed and maintained as quantity of aggregates plays a vital role in the success of any project. Based on a thorough study of past performances, select suppliers of critical bulk materials like cement, fly ash, admixtures and agencies for critical work like RE wall construction, girder erections, road furniture works have been identified for better control.

A technical bulletin on critical activities, analysis of common and oft-repeated quality lapses, technical training programs featuring external industry experts specially on rigid pavement construction, best construction practices, Dos & Don’ts and learning from mistakes have significantly improved product quality and work efficiency.

An exclusive training programme titled ‘Quality – The path to the excellence’, focused on behavioural and attitudinal aspects was developed for senior employees. “Behaviour is a key determinant to achieve project quality,” shares Shettar. “Just to quote an example: Honeycomb in concrete can be dealt with in two ways either by accepting it or by avoiding it but always remaining alert to it. In the former case, there are bound to be product quality lapses either due to ignorance or insufficient effort to solve issues. The training is to create this mindset of being always on the solution side.”

Line drain work

A P&M Profit Centre to drive excellence

Designed to accelerate performance, the P&M Profit Centre strives to streamline core processes, achieve optimal resource allocation, adopt a profit-oriented approach and inculcate greater accountability. “Value creation aims to optimize hiring charges by blending owned and hired equipment guided by productivity benchmarking, maximizing energy efficiency and responsive use of digital tools,” shares S P Rajan, Head – Plant & Machinery, RREC. “We have accepted an ambitious cost reduction target and aim to achieve it with a multi-dimensional approach to improve internal efficiency through collaborations, digitalization, advanced analytics, etc.”

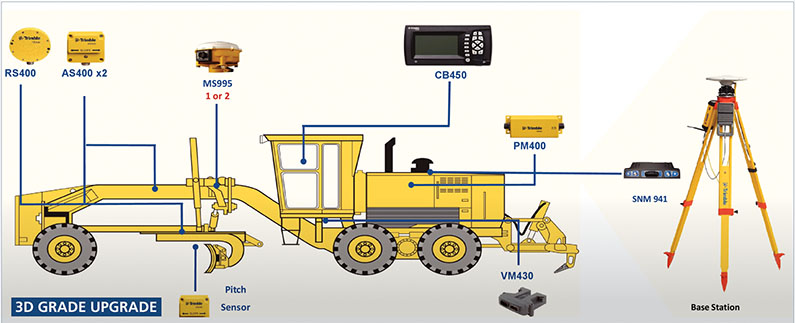

‘Asset Insights’ are mapping equipment across the Bangalore International Airport (BIAL) project to improve turnaround time and quicken movement of men and machinery. Machine automation in motor graders and excavators has helped BIAL achieve speed and accuracy, deploying lesser manpower while in house development of the mulching machine has obviated procurement time and cost. The Karodi Aurangabad Expressway project has consistently clocked more than 900 cu.m. per transit mixer per month despite operating in a rough terrain. Helwak Karad Road Project, Dholera Smart City, Delhi International Airport, Mumbai Vadodara Expressway projects meet their power requirement of plants and camps through a combination of Grid & Solar power, PNG.

“Value creation aims to optimize hiring charges by blending owned and hired equipment guided by productivity benchmarking, maximizing energy efficiency and responsive use of digital tools. Speed and time dictate modernday construction and P&M is integrating solutions with a clear target to achieve operational excellence.”

S P Rajan

Head – Plant & Machinery, RREC

A critical review of the business trained focus on the significance of balancing owned and leased equipment, equipment life-cycle management, skill upgradation and productive fleet management in tandem with project needs. “An integrated perspective on construction quality and P&M efficiency improvement is leading to improved construction productivity and business competitiveness in a market filled with new entrants,” adds S P Rajan.

Apart from cultivating business acumen in the team, the model has introduced a cultural shift too that is helping RREC optimize solutions, increase team engagement, reduce costs like never before and create key differentiators through value creation. “Speed and time dictate modern-day construction,” says S P Rajan, “and P&M is integrating solutions with a clear target to achieve operational excellence.”

Precast girders installed for fast tracking the construction of an elevated corridor

Reducing costs and rate contracts: imperatives for success

For DKS and team, the thrust to improve the bottom line is a continuous process, “for which we have planned strategic interventions, formed task forces and mandated SCM to re-negotiate all major existing contracts to reduce costs,” shares DKS. Against an annual targeted spend base of INR 618 Crores, the initial internal target for re-negotiation was INR 30 Crores by Q3 of FY 20 but after presenting the plan to the management, the matter was referred to E&Y and target was revised to INR 100 Crores.

“Tough targets require tough strategies and equally tough actions to achieve them,” smiles Sumit Bardhan Head – SCM, TI IC, who leads the initiative, “and therefore we carefully evolved our strategy looking at major spend areas like earthwork, transportation, aggregate procurement and production that were already on stream. We targeted subcontracts that were above INR 10 Crores. In some subcontracts PBG, Retention Deposit and LD had a major impact on cost, partial relaxation aligned with risk profile of our business eased their cashflow so that they could pass one-time discount to us.”

“Reorganising hiring contracts regionally and creating competition through reverse auction along with shifting to item rate contract for major equipment opened new avenues of cost along with shifting reduction. We involved PM & PDs too in the process, however foreign subcontracts were kept out of the ambit of this plan,” he adds.

The team scrutinized work and purchase orders for all projects. Works orders included aggregate and concrete transportation, geo-composites, earthwork, quarrying & crushing works, pre-stressing and equipment hiring. Purchase orders included admixture, fly ash, GGBS, river & filling sand, GSB and aggregate procurement. “It was strenuous but with E&Y we aggressively followed our strategies and are confident to lock INR 51 Crores by March 2020 which will be a significant achievement,” remarks Sumit, “but it is an on-going process so we cannot afford to rest on our laurels.”

“Tough targets require tough strategies and equally tough actions to achieve them and therefore we carefully evolved our strategy looking at major spend areas like earthwork, transportation, aggregate procurement and production that were already on stream.”

Sumit Bardhan

Head – SCM, TI IC

Close out of any project is a specialized activity that depends to a large extent on finishing items and the SCM set itself the task of enhancing the efficiency of project closeouts. “We therefore identified 16 finishing items that were required across all RREC projects but observed that the processes of RFQ, negotiations, approvals and agency selection were repeated over and over again,” shares Sumit. “To avoid this and reduce the time taken to finalize with agencies and / or suppliers, we decided to enter into rate contracts with shortlisted business partners that helped us lock rates for the project duration.” The items considered were MBCB, admixtures, PVC membranes, road markings, geo-composites, canopies, curing compounds, bus shelters, polysulfides, PGR, prefab structures, traffic signage, TMS, toll booths and such like. The results have been more than encouraging for the business with orders placed in advance at projects like Mumbai Nagpur Expressway, Mumbai Vadodara Expressway, Karodi Aurangabad Expressway, Veer Wadpale Bhogaon Khurd Road, Helwak Patan Karad Road, Dwarka Expressway and the Delhi International Airport.

Infrastructure works for Bidkin Smart City

OPEX planning for better planning and execution

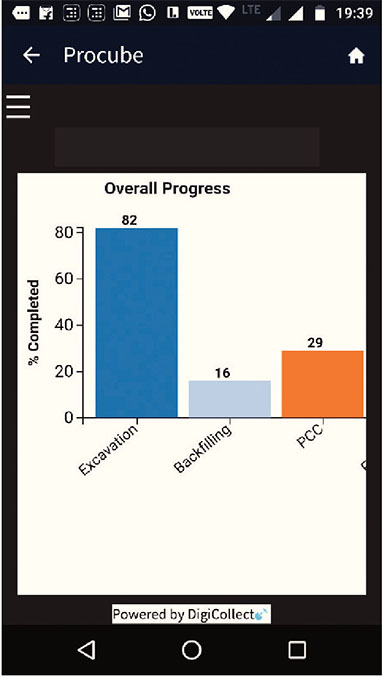

A pilot project is being implemented to achieve a superior rate of invoicing, keep costs under control and judiciously deploy fixed / variable resources by combining land map (obstruction management), engineering deliverables (engineering drawing management) and other related factors. “We identified 3 key areas – invoicing, planning and working capital,” reveals Manish Agarwal – Head Project Control RREC. Under ‘Invoicing’, the basis for analysis were one-on-one interactions, initial analysis of select projects, observations during visits and cross-functional discussions both at site and HQ. For planning, the criteria considered included oneon-one interactions, appreciation of execution processes and aligning P&M deployment, analysis of Schedule-H, prioritization of work and readiness of processes. First cut projections of Mumbai Nagpur Expressway formed the basis to analyse working capital.

The improvement opportunities for Manish Agarwal, and team are multifold. Under invoicing, there is greater focus on pre-construction activities like quarrying & crushing, burrow pits and land acquisition planning and to identify, prepare and prioritize invoice-able work unit packages. Work front availability is easier with better planning and stretch-wise planning considering LA mapping, economic stretches and prioritization of construction work. Rigour in village or stretch-specific execution and alignment of sub-cons with Schedule – H i.e. setting village specific targets have been achieved in the realm of working capital as seen in various expressway projects like Karodi Aurangabad, Dwarka, Mumbai-Vadodara and Mumbai Nagpur expressways.

A pilot project is being implemented to achieve a superior rate of invoicing, keep costs under control and judiciously deploy fixed / variable resources by combining land map (obstruction management), engineering deliverables (engineering drawing management) and other related factors.

Manish explains the 5 high-level initiatives RREC has adopted to put this elaborate plan into action. Integrated project planning involves stretch prioritization, synergized P&M mobilization, execution planning (including last level) and daily management. Pre-construction activities entail land acquisitions and utilities status mapping before NTP, speed up timelines for quarrying, crushing, pit set-ups while the aspects under Sub-contract management are sub-contract management in line with Schedule – H, prioritization and cash management. He is confident that these initiatives will fetch huge benefits because, “there is better clarity and consistency of last level activities across all administrative levels, greater predictability about progression of physical work, financial impact and associated challenges.” There are gains of reduced costs due to improved operational discipline, improved assessment and mitigation of project risks and projects are geared up for quicker and more successful closures. At the end of the day, these initiatives maximise utilization of the critical period between LOI and NTP, speed up decision making across levels, improve P&M utilization and low productivity levels of the workforce and reduce mismatch between resource and front readiness.

These initiatives maximise utilization of the critical period between LOI and NTP, speed up decision making across levels, improve P&M utilization and low productivity levels of the workforce and reduce mismatch between resource and front readiness.

On the high road to adopting cutting-edge technologies

“Several of our equipment are now equipped with sensors that help achieve enhanced levels of efficiency,” says Utkarsh Desai, Digital Officer, TI IC, “In fact, currently we are using 3D Grade Control Systems for motor graders and expanding the technology to excavators and pavers.” BIM is being implemented at Delhi International Airport, Bangalore International Airport, Mumbai Nagpur Expressway,

BIDKIN & Dholera Smart City Projects; Concrete Infilled Geocell System for lined drains at the Unnao-Lucknow Road project and Reclaimed Asphalt Layer introduced in road construction at the Kankatora Jharsugoda Road Project for the first time in India which is fast becoming a norm with other contractors.

Some of the digital initiatives include:

TORQ Tying Operations with Revenue & Quality integrates lab and on-field quality management, progress strip charts (from PROCUBE), creating and managing RFIs and link them to invoicing.

EMTRACK provides real time visibility of project progress, facilitates smooth return or transfer of material between projects/stores and helps reconcile material issued to various subcontractors and those being consumed against activities.

Extracting greater value from motor graders: Drawings are fed into the onboard computer that enables accurate GPS-aided positioning and automatic control of blades for accurate cut and fill.

“Several of our equipment are now equipped with sensors that help achieve enhanced levels of efficiency. In fact, currently we are using 3D Grade Control Systems for motor graders and expanding the technology to excavators and pavers.”

Utkarsh Desai

Digital Officer, TI IC

RtR Safety App: Has been a boon to the RREC team that aids performance enhancements, triggers daily alerts to project, Cluster and SBG users, has ushered in all-new scoring parameters, allows for offline filling up of checklists and is replete with an updated mobile and web dashboard for the new scoring parameters.

“Although the macroeconomic sentiment for Infrastructure remains sluggish with poor awarding and ambiguity of sources of funds, the underlying potential is huge. We have realigned the way we do business by improving the way we Plan, Design & Build to bring in significant improvement in our operations.”

R K Bansal

Head – Roads & Runways

“Although the macroeconomic sentiment for Infrastructure remains sluggish with poor awarding and ambiguity of sources of funds, the underlying potential is huge,” opines R K Bansal (RKB), Head – Roads & Runways, “with the government planning major programmes like Bharatmala, Smart Cities and improved airport connectivity. We have realigned the way we do business by improving the way we Plan, Design & Build to bring in significant improvement in our operations. Today, we take up only large jobs above a certain threshold value making sure there is scale and we use our resources optimally in fewer projects to improve our top and bottom lines. We get our designs ready within 6 months from the date of NTP, we are already targeting for early completion of new projects and our dedicated preconstruction team works on all the utility shifting and hindrances to ensure that we sail through during the execution phase. We have a host of operational excellence initiatives to improve quarrying, machine & manpower productivity and diesel consumption.”

In summation, RKB says, “we have taken a conscious effort to close all our old legacy projects by putting taskforces to quickly wind up jobs that are at finishing stage in all respects which will help the business to free valuable resources and utilize them in larger projects.”