GET … SET … GEO!

How L&T GeoStructure stayed prepared to resume operations as soon as the lockdown relaxed!

On 20th April, with the first relaxation of the lockdown strictures by the government for certain ‘green’ areas, one of the first projects to take off the blocks and resume operations was L&T GeoStructure’s JSW project team involved in the construction of a coal handling terminal at Paradip under the leadership of Project Manager, Tulasi Das Govvada. “We were able to start as soon as we received the required permissions because we had pre-planned for it and were thus prepared,” states S Kanappan (SK), Head and Chief Executive – L&T GesStructure, not overtly surprised by the alacrity of his project team. “This pandemic was new for all of us and we did not know how things would pan out, so we tried to manage all those factors that were within our control and try and be ahead of the virus. As a team, we have succeeded to a large extent!” His smile is eloquent of his sense of achievement.

“We achieved the 1st base raft of 330 cum of concrete up to 16 m below ground level, in a single day.”

Tulasi Das Govvada

Project Manager, JSW Project

330 Cum of concrete up to 16 m below ground level poured in one day at JSW Paradip site

Hit the board running …

Not only did the JSW project resume operations but literally hit the board running! “We achieved the 1st base raft of 330 cum of concrete up to 16 m below ground level, in a single day,” says a charged Tulasi Das. “The excavation works (47500 cum total scope) are being carried out using the huge strut system of 1050 MT, more than 60 deep well dewatering systems are being operated round the clock and we are achieving all this implementing all the Government guidelines and SOPs to ensure the safety of all,” he assures.

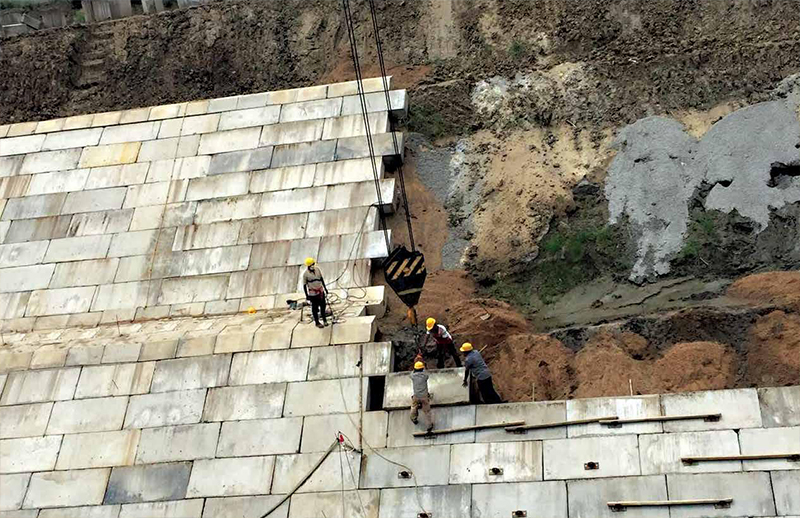

Close on the heels of the JSW team, the project site at Farakka constructing the Navigational Lock facility for IWAI led by Project Manager, Rajaneesh Kumar Rai, re-commenced operations too in high gear, well aware of the approaching monsoons that normally break in June. “We executed the excavation for block placing, earthwork for the cofferdam, block erection, guide wall joint work and concreting work for the critical counterfort wall with a pour of 7 m length, second lift for 36 Cum, in just 3 days.” The speed with which Rajaneesh shares the work done is reflective of the scorching pace they have set. Soon, Project Manager, Sarasindu Datta’s project team at Panna, MP who are designing and constructing a Composite Gravity Dam, jumped onto the bandwagon by pouring 720 Cum concrete, rock breaking of foundation in spillway completing 400 Cum / day (1600 Cum) and completing 3000 Cum of filling for the earthwork embankment works.

“Workmen make or break projects, but in this scenario with a complete lockdown and very little activity possible at site, it was even more critical to look after our workmen, keep them engaged and in a sufficiently positive frame of mind to be willing to resume work when the lockdown was relaxed.”

Bino Mathew Jose

Head – Human Resources, L&T GeoStructure

Keeping the workmen engaged was the key

“Workmen make or break projects,” remarks Bino Mathew Jose, Head – Human Resources, L&T GeoStructure, “but in this scenario with a complete lockdown and very little activity possible at site, it was even more critical to look after our workmen, keep them engaged and in a sufficiently positive frame of mind to be willing to resume work when the lockdown was relaxed.” All their workmen-centric efforts and initiatives were therefore focused on these deliverables. “My day, during the lockdown days, started early with a series of video calls and meetings to take daily updates from all our sites and report to the management,” shares Bino. “At the same time, if there were any issues, we had to immediately evolve remedial measures and get our project teams to act at once to resolve them.”

The impact of these focused initiatives is evident at site level as can be gauged from the Uppur project team who are busy constructing vital sea water intake works. Although they had completed a large amount of the construction, the lockdown brought activity to a grinding halt. Thereafter, the team of Operations Head – T Srinivasan, Project Manager – R Ravikumar, Site Accountant – Rajesh Barsakar and Site Admin – Ahilavel have been on a 360-degree vigil. “Rajesh, Ahilavel and team put in place a series of welfare and safety measures to boost the morale of the workmen,” shares Srinivasan. “The ground force team was constantly in touch with the key coordinates – EHS, IR, Operations and HR for detailed day-to-day reports of the activities and control methods. The IR and Administration teams were in touch with the local authorities, government agencies and local panchayats to ensure uninterrupted delivery of essential requirements to our site.”

“It is often said that good practices take root during times of crisis. Each department head has taken the initiative to interact daily with their teams before start of work and it has become a practice now. We maintained excellent relationships with the client that has also stood us in good stead.”

Rajaneesh Kumar Rai

Project Manager, Farakka Site

At the Farakka site, Project Manager, Rajaneesh had two issues to contend with: firstly, the physical isolation of his site lying in a remote, northern part of West Bengal some 300 km from Kolkata and the other was the disorganized nature of his labour force. Both assumed serious criticality against the backdrop of the lockdown. “The moment the lockdown was announced, getting provisions, material, medicines, PPEs, became a huge struggle,” he points out. “We also do not have full strength labour camps at site as many of the workmen are from the nearby local villages belonging to mainly two committees (trade union type) who are led by their own rules and systems. So, first convincing them to wear masks, practice social distancing and maintain hygiene were huge challenges.” He pauses and then adds, “now, even remobilizing them is a big headache for us.” Rajaneesh and his team reached out to the local administration and authorities for supplies and to the sub-contractors to control and convince the workmen.

Concreting work for Critical Counterfort wall, with a pour of 7 m length, second lift for 36 Cum at the Farakka site

Keeping the employees motivated

What do you do when one of your employees desperately wants to get married and is unable to do so because of the lockdown? In addition to his external challenges, Rajaneesh had to face some internal ones as well. “Apparently, his marriage had been fixed for April 22nd before the lockdown and he was stuck with us at the guest house. He was very keen to get back for his marriage but despite our best efforts he was not able to and finally the marriage had to be cancelled. It was a very emotional scene,” says Rajaneesh with genuine sadness. “We had another case of one of our people getting extremely worked up as his small family of wife and 12-year-old daughter were alone in a housing society at Kolkata. He was stranded at site and was paranoid as to who would look after them if they were infected by COVID-19.” Rajaneesh shakes his head, saying, “Actually we are talking about professionally successful people who are known to normally show emotional balance in their day to day life but reacting emotionally when depressed and frustrated that unfortunately has a dampening effect on other members of the team as well!”

But all was not gloom as he shares. “It is often said that good practices take root during times of crisis. Each department head has taken the initiative to interact daily with their teams before start of work and it has become a practice now. We maintained excellent relationships with the client that has also stood us in good stead,” he finally cracks a smile.

Apart from the challenges of availability of food, provisions, safety of personnel and site progress, Tulasi Das at the JSW site had one more consideration regarding the critical structure in the project – the Track Hopper that entails excavation of up to 18 m below ground level using sheet pile, 1050 MT of struts system and about 60 dewatering pumps running round the clock that could not be stopped suddenly. There was also the need to safeguard a lot of high value project materials and a huge fleet of P&M at site. “We had to continue carrying out emergency works at the Track Hopper area and keep security levels high,” mentions Tulasi Das, “but difficult times often bring out the best in people. We as a team responded to the situation and found ways to overcome these challenges.”

Concrete of 720 Cum poured at Runj Dam project in Panna (Madhya Pradesh)

“Of course, for a project-based organization like ours, progress at site is of paramount importance but with increased use of digital platforms, greater connect and collaboration, we were able to move the needle across various functions like design, planning, operations, contracts, business development and general management.”

Bino Mathew Jose

Head – Human Resources, L&T GeoStructure

For Track Hopper activities, special permissions were obtained from the local authorities and work continued with minimum resources and workmen, he mentions and appreciates the special efforts of K V Vinod and K V Sunil Kumar of the track hopper team. “We also completed 330 cum of raft concreting that provided the much-needed stability for the structure,” he says. Sufficient security personnel were deployed at site with special support availed from the CISF Personnel of PPT. He then adds with a broad smile, “to ensure cash flows in these tough times, we got our RA bills of March’20 certified and even collected the payments!”

Successfully working offsite

With offices shut down, Work From Home was a paradigm shift for employees and Bino points out that the experience has been a good one. “Of course, for a project-based organization like ours, progress at site is of paramount importance but with increased use of digital platforms, greater connect and collaboration, we were able to move the needle across various functions like design, planning, operations, contracts, business development and general management.”

Lighting of Diya at EQ Paradip jobsite as instructed by our Prime Minister

S KANAPPAN

Head & Chief Executive (L&T GeoStructure)

We are an ideal organization and during these days of lockdown, our team came up with several innovative ideas to keep our business ticking. We also scored high on parameters like productivity, quality of output, use of digital tools, people availability and stakeholder management. Now, that operations have recommenced, our focus is to make up for lost time and achieve our Lakshya.