MMH SITES FIGHT COVID-19 TO EMERGE STRONGER!

The extent of disruption caused by COVID-19 can be best gauged by what transpired at MMH SBG’s 3 MPTA Hot Strip Mill for SAIL at Rourkela. At one point, the entire project team was functioning in high gear: the project had been commissioned on 31 January 2020 and with the first coil rolling out, it was all systems go to start hot commissioning to reach the contractual production milestone of 66% of plant capacity by April 2020. For Project Manager,

R. Umasathiyan and his team those were hectic but extremely satisfying days. “Even while our efforts were on in full throttle, we started to sense the first signs of trouble,” shares Umasathiyan. “Many of our technology providers from China and Europe started to postpone their visits to India due to travel restrictions in their respective countries and our own travel ban from 23rd March. Soon, all the foreign experts from countries like Japan, Spain, UK left. On the home front, several of our vendors and technology supporters started to recall their representatives. Effectively, our progress had completely stopped!” One can sense his anguish and disappointment.

To keep the ball rolling …

Umasathiyan and his site management team were faced with two issues. The first, to keep certain essential services running round the clock as the plant had been commissioned for which they required dedicated personnel. Secondly, they had to take care of the wellbeing, health, and safety of a 1,300-strong workforce at site. While a roster with clearly defined roles and responsibilities for the selected personnel took care of the first issue, a task force was formed to address the second. “I have to thank my colleagues for their wonderful and whole-hearted support without which we would not have achieved half of what we did,” shares a grateful Umasathiyan. He mentions his able lieutenants that included L A Anurag & P K Das, both from IR, Suman Mukherjee, Satish Maredla, Niladri Paul, Tulsi Das, X Francis, and N Jhothiramalingam, all from Execution, M P Suresh & K P Srinivas from F&A, Partha Dutta from ISD and Chandan and Bhupesh, both from Safety.

“I have to thank my colleagues for their wonderful and wholehearted support without which we would not have achieved half of what we did.”

R. Umasathiyan

Project Manager, RSP-HSM

MCL-Bhubaneswari Project, Talcher, Odisha

We are used to dealing with objective problems but dealing with subjective issues is far tougher. The workers were in deep mental distress, because of the sudden lockdown, worried about their families and as the lockdown extended, the situation became even more severe. It required some deft handling, an empathetic approach and constant interaction to manage the situation.

C N Padhi

Project Manager, MCL-Bhubaneswar

Something similar was experienced by Project Manager, C N Padhi at the MCL- Bhubaneshwari project site. “We were running at peak speed with critical erection and concrete works taking place when the lockdown was declared,” he shares. “There was also a large amount of material scattered around the site at various places that were vulnerable to theft. Not an easy task, but not impossible,” he remarks with determination. His other critical task was to safeguard his people which was again not easy since the site and camp is situated in an open area in the vicinity of a coal mine. “And, again, not impossible,” he laughs, mentioning the sterling efforts and sacrifices of his IR In-charge, Pradeep Kumar Swain and Accounts In-charge, Khirod Sahukar to keep things under control.

Padhi’s third challenge was perhaps the toughest of all. “We are used to dealing with objective problems but dealing with subjective issues is far tougher. The workers were in deep mental distress, because of the sudden lockdown, worried about their families and as the lockdown extended, the situation became even more severe. It required some deft handling, an empathetic approach and constant interaction to manage the situation,” he says with a sigh.

“Regular reviews with the EHS teams have helped significantly to control the situation at our sites. We evolved several innovative methods to ensure hygiene at workplaces and habitats. A robust procedure to thoroughly check and escort was introduced to ensure limited exposure apart from thorough sanitization and social distancing. Accommodation in the camps was reorganized to meet with enhanced social distancing requirements.”

K N Sen

Head – EHS

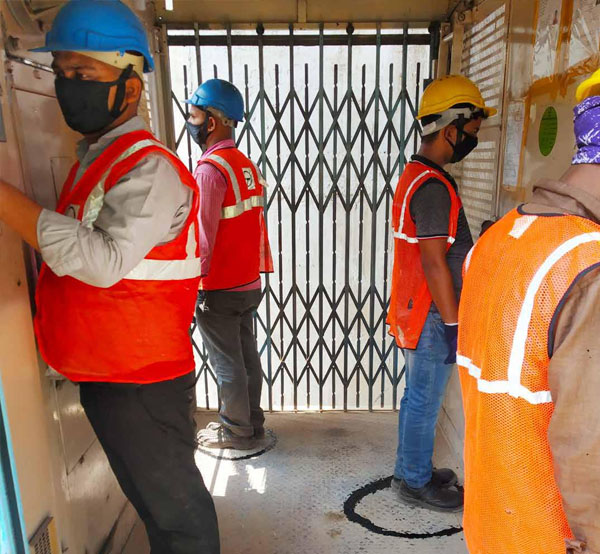

The responsibility of disseminating SOPs and putting the precautionary measures in place fell on the shoulders of Head – EHS, K N Sen. “Regular reviews with the EHS teams have helped significantly to control the situation at our sites,” he says. “We evolved several innovative methods to ensure hygiene at workplaces and habitats. A robust procedure to thoroughly check and escort was introduced to ensure limited exposure apart from thorough sanitization and social distancing. Accommodation in the camps was reorganized to meet with enhanced social distancing requirements.”

“Keeping the workmen engaged and stable was a Herculean task and it is the fantastic work of my team that we were able to manage”

Mukesh Kumar

Project Manager, CHP, Khargone

Tucked away in a remote corner of Madhya Pradesh, Project Manager, Mukesh Kumar had to contend with the remoteness of his Khargone Thermal Power Project site when dealing with the COVID-19 threat, located in a village named Selda that is about 100 km from the nearest city of Indore and 60 km from the district town of Khargone. “You can imagine our difficulties to get provisions for our 950 workmen so far away during the lockdown!” Mukesh’s first task was to arrange an uninterrupted supply chain of necessities and then to procure permissions to move during the days of curfew, that they resolved by speaking to and convincing the government and local authorities. “Keeping the workmen engaged and stable was a Herculean task,” adds Mukesh, “and it is the fantastic work of my team that we were able to manage.” A thoughtful initiative by the team was to request the local MLA, a few journalists, and some administrative bodies to visit the site off and on, to address the workmen, boost their morale and keep them informed of authentic news to prevent them from being swayed by rumours and fake news. “Our efforts have been well appreciated and even published in Dainik Bhaskar, a local newspaper,” shares Mukesh proudly.

“We adopted a proactive and systematic approach to strategically evolve initiatives to keep all of us safe. We quickly got our act together and formed Emergency Response Teams (ERTs) with specific roles, responsibilities and accountability comprising various functions to handle any eventuality”

Bhanu Pratap Singh

Project Director, JSW, Dolvi

With some 8,000 workmen and 300 employees at site to look after, one can only imagine the tremendous pressure on Project Director, Bhanu Pratap Singh and his team at the JSW Project Site, at Dolvi, in Maharashtra’s Raigad district. “We adopted a proactive and systematic approach to strategically evolve initiatives to keep all of us safe,” says Bhanu, putting up a brave front. “We quickly got our act together and formed Emergency Response Teams (ERTs) with specific roles, responsibilities and accountability comprising various functions to handle any eventuality.” The ERTs were led by Accounts & Administration Head, Debashish Ghosh & Senthilkumar Mani (Assistant ManagerIndustrial Relations).

“We needed to constantly control, inspect and monitor the workmen for health hazards. In the final analysis, creating and maintaining a clean, healthy, and safe work environment is all about checking, re-checking and ensuring that nothing is amiss at our workmen habitats”

Debashish Ghosh

Accounts & Administration Head, JSW, Dolvi

The onus on Debashish Ghosh was multiplied as the huge workforce was accommodated at four different locations – Wadkhal, Kharpalle, Churgundi & Hamarapur. “We needed to constantly control, inspect and monitor them for health hazards. In the final analysis, creating and maintaining a clean, healthy, and safe work environment is all about checking, re-checking and ensuring that nothing is amiss at our workmen habitats,” he sums up. Another interesting ploy adopted by Bhanu and team was to motivate and empower the workmen to stop others from committing unhealthy acts. “This awareness, motivation and empowerment brought about extremely positive results among the workforce,” says a very satisfied, Satish Chandra Yadav, Manager – EHS. “They have started to fearlessly raise a flag if they see any unhealthy act or situation, which is a strong indicator of workmen empowerment from an EHS perspective and, more importantly, an excellent best practice to follow in future!”

“This awareness, motivation and empowerment brought about extremely positive results among the workforce. They have started to fearlessly raise a flag if they see any unhealthy act or situation, which is a strong indicator of workmen empowerment from an EHS perspective and, more importantly, an excellent best practice to follow in future!”

Satish Chandra Yadav

Manager – EHS, JSW, Dolv

The situation was novel and the impact unprecedented, remarks Head – M&M BU, T Kumaresan, appreciating the efforts of the various teams. “We have encountered three phases during this lockdown. First, the ‘Fear Zone’ – How to adapt to the new change and face challenges? Then, the ‘Learning Zone’ – become aware of the situation and think how to act. We are now in the ‘Growth Zone’ – Look for ways to accept the new changes and adopt the new normal! Through all these three zones, we have bounced back with a bang like true L&T-ites and have successfully resumed work across sites with 70 to 80% workmen strength. Our Corona Warriors across sites have displayed the passion, devotion and commitment, to once again prove in L&T that People are the prime movers!”

“We have encountered three phases during this lockdown. First, the ‘Fear Zone’ – How to adapt to the new change and face challenges? Then, the ‘Learning Zone’ – become aware of the situation and think how to act. We are now in the ‘Growth Zone’ – Look for ways to accept the new changes and adopt the new normal! Through all these three zones, we have bounced back with a bang like true L&T-ites and have successfully resumed work across sites with 70 to 80% workmen strength. Our Corona Warriors across sites have displayed the passion, devotion and commitment, to once again prove in L&T that People are the prime movers!”

T Kumaresan

Head – M&M BU

A foreign side to the same problem

While the threat posed by the pandemic is universal, its severity and implications vary across geographies as Project Director, Hare Ram, found out at his Mansourah Massarah Gold Project (MMGP). “The topographical location of our project was a challenge.” he begins, “While Riyadh was 536 km away, the other main city of Taif was 274 km away from our site and with more than 600 employees to manage, it was a challenge to obtain basic amenities such as food, medicines, PPEs, and other materials.” To make matters worse, the cities of Riyadh and Taif were also under lockdown. Sealing a perimeter that stretched all of 38 km, was another steep task. “In fact, we had to set up a temporary check point about 5 km from site to control entry and exit for both our people and outsiders,” adds Hare Ram.

“While Riyadh was 536 km away, the other main city of Taif was 274 km away from our site and with more than 600 employees to manage, it was a challenge to obtain basic amenities such as food, medicines, PPEs, and other materials.”

Hare Ram

Project Director, Ma’aden Gold Project, KSA

One of the key weapons to fight such crises is good, clear, and regular communication and that is where the team ran into heavy weather initially as very few of the local personnel and security could understand English. This issue was subsequently resolved with the appointment of English speaking and experienced Saudi nationals as PRO and GRO. “Dealing with the local govt bodies and medical institutions especially in the initial stages was tricky,” informs A. Swarnkar, Head-MENA BU. “In fact, the nearest hospital recommended by the authorities for COVID-19 was at Taif and therefore we had to consider other options.” The site therefore had a medical team and a clinic facility comprising a Doctor, an experienced paramedic, a fully equipped ambulance with a trained driver to attend to any emergency. Another matter that needed to be addressed on a war footing was accommodation. “The initially planning did not take into consideration tackling a pandemic situation,” mentions Construction Director, Praveen Hajare. “Re-thinking, re-planning and re-organizing the accommodation facility was a big challenge.”

“The nearest hospital recommended by the authorities for COVID-19 was at Taif (more than 200 kms away) and therefore we had to consider other options.”

A. Swarnkar

Head- MENA BU

“Although the threat was huge, we decided to approach it as just another hurdle to overcome,” says Hare Ram, sounding matter of fact though obviously not feeling so. “And with the right team, limited resources, forecast planning, and a positive spirit, we have taken COVID-19 in our stride,” he smiles quickly admitting that it has been thus far a triumph of teamwork. “I will be failing in my duty if I did not mention my wonderful teammates, Project Manager, Pranav Kumar Vatsa, my three colleagues from EHS – EHS Head, Bikash Parida, Ajay Kumar Poddar and Rahul Mohan, Construction Manager – Anindya Dey, A R Mohanty, who looks after IR & Admin. A special word of appreciation for our site doctor, Dr Taimoor Khan and his support staff of stewards, nurses and doctors for their yeoman service to the workmen.”

“Although the threat was huge, we decided to approach it as just another hurdle to overcome and with the right team, limited resources, forecast planning, and a positive spirit, we have taken COVID-19 in our stride”

Hare Ram

Project Director

Returning to work

With the relaxation of strictures, Umasathiyan and his team prepared to recommence operations following all the prescribed SOPs. Almost, immediately they met with a setback as seven positive cases surfaced in the vicinity of the camp. Operations were stopped and people from the containment and buffer zones had to be rescreened. “After a thorough analysis of the workmen data and ensuring that the targeted workmen were not from a containment zone, we were able to resume work from 2nd May after taking self-declarations from workmen and agencies as per guidelines and SOP,” he says with obvious relief.

R. Suresh Kumar, Operations Head – M&M BU takes pride that the SOPs and the discipline followed at KBL new fabrication yard received a certificate of appreciation from the Joint Labour Commissioner, Rourkela.

Other MMH sites including the Utkal Alumina Tikiri Project helmed by Project Manager, Prasanta Tikadar and

C N Padhi’s MCL- Bhubaneshwari project site have resumed operations followed by several others across geographies as things slowly start limping back to normal.

ANUPAM KUMAR

Vice President & Head (Metallurgical & Material Handling – SBG)

Without doubt this has been a most testing and challenging time. Several of our sites were running full throttle and to bring them to a shuddering halt was a huge setback. We have never faced such a situation before so there were no precedents to fall back on. We were learning and course correcting as we went along. I am extremely grateful to all our Corona Warriors at our various sites for their focus, dedication and passion in the face of some overwhelming odds to stay committed, hold the fort and emerge even stronger now that we have started to gradually restart operations.