Anupam Kumar,

Vice President & Head (Metallurgical & Material Handling – SBG)

For a sustainable business model, construction should be planned and carried out in a socially responsible manner, augmenting tenets of health and safety at various phases including engineering, procurement and execution. As we move forward, digitalization and implementation of BIM will help project visualization, hazards identification, efficient scheduling and improvement in safety which will soon enable us to migrate from labour-intensive to equipment intensive operations to reduce exposure of workers to hazards.

A committed approach and the adoption of new technological solutions will help us to standardize processes, improve overall quality of the products and services rendered and thereby drastically reduce unsafe acts that result in Loss of Time and Cost.

IT PAYS TO PLAY SAFE WHEN LIFTING HEAVY WEIGHTS

Working out safe rigging methods for heavy lift erection

The rules of the game are never defined for heavy lift erection, as every lift is unique depending on the weight of the equipment, its placement and other on-field constraints. There is, however, a common thread to all such critical tasks, acknowledges K.N. Sen, EHS Head, Metallurgical & Material Handling SBG, “The ground work is important before taking up the mantle as it is akin to moving a mountain where even a slight error can be disastrous.” A seasoned past master, Sen has much to share on the evolution of heavy lifts at MMH and how digitalization is now giving project teams the safe edge. “Earlier, it was a lot of hard work at site involving hours of preparation to arrive at the right weight and proposition through mathematical calculations. Now, with the Rigging app, the entire process has become streamlined, and one only has to follow the system that is completely secure.”

Erection of convertor at JSW Dolvi, SMS#2

A digital approach to rigging

As trailblazers in heavy equipment erection, MMH has executed innumerable successful critical lifts but going forward the challenge will be to ensure pre-defined accountability at different levels which Sen acknowledges has been lacking at times. “Hectic schedules at site meant that nitty-gritties could often get neglected or even taken for granted. Moreover, compliance across stagewise scrutiny amongst stake holders led to execution delays, lapses and unlikely consequences. The need for a digital intervention was keenly felt,” mentions Sen for a user-friendly, coordinated and safe execution approach at site while, at the same time, reinforcing trust among clients. “One of the first things lined up to implement this process was a new position of a Rigging Engineer across sites to coordinate with stakeholders for multiple level approvals prior to the execution of tasks.”

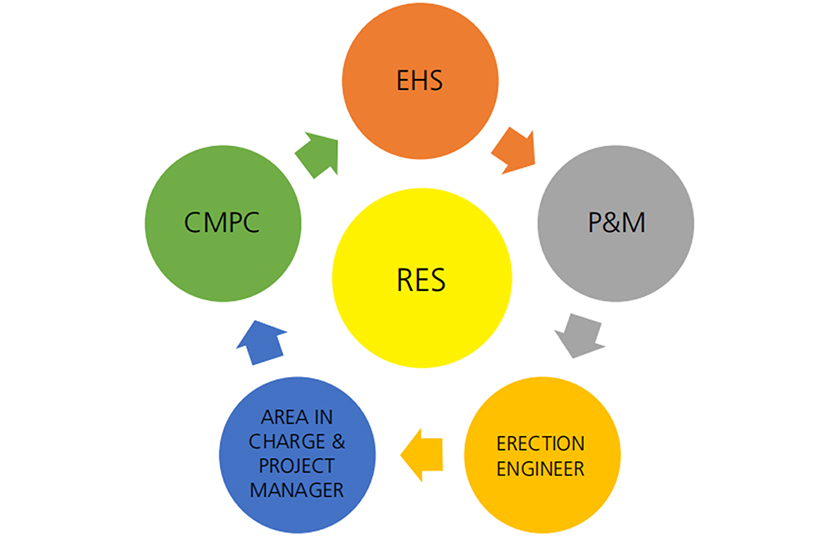

Aligning to a digitally secure approach for rigging involving multiple stakeholders

Defining the criticalities

Modern-day apps empower users to make the right choices and the Rigging app does exactly that. Developed on the underlying principle that lifts are predominately across three major categories: low, medium and critical, the platform details erection/rigging activities that are aligned at sites with predefined objectives and SOPs established by the Construction Methods Planning Centre (CMPC). For users, it’s just a swipe that connects with the essentials, acknowledges Sen. “Every technical parameter involved in rigging covering crane configurations, equipment parameters, tools and tackles, load distribution including feasibility checks are ensured through this app.” What makes this app doubly secure is the stringent approval flow mandatory for users, a feature that was developed collaborating with L&T Infotech (now LTI) factoring in the likely on field requirements at site such as crane clearance checking and loads on cranes in tandem lifting. “We have a category wise approval flow and multi-level scrutiny involving all concerned stake holders to minimize risks,” adds Sen.

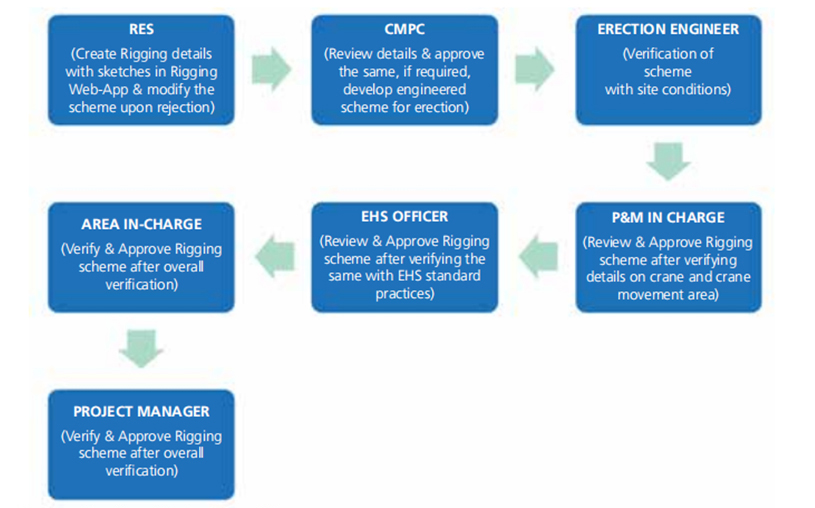

Process flow for critical category lifts

How the system secures

A typical lifting process begins after classifying the nature of lifts, informs Kausik Dutta, Head CMPC, “The

Rigging Engineer is entrusted with the responsibility to create a new rigging permit where all the inputs required for the lift, based on site conditions, are updated that are perused by the erection in-charge to verify the scheme, ratified by the EHS personnel and finally approved by the area in-charge. For larger lifts, the process runs through the respective site P&M In-charge and Project Manager.” Of course, CMPC steps in when there is a critical lift, he adds, “We have a long list of tall achievements, the most recent one being the converter erection at JSW Dolvi, the heaviest lift done in MMH, wherein we safely planned and lifted the equipment comprising trunnion ring, pin lamella, vessel guide, barrel & bottom cone weighing 415 t using a 600 t Demag CC 2800-1 crane.”

“We have a category wise approval flow and multi level scrutiny involving all concerned stake holders to minimize risks.”

– K.N. Sen

EHS Head, MMH

Satyajit Kaity, Rigging Engineer, elaborates on the process, “It was a complex task as the erection weight

handled was close to 438 t considering the weight of both the rigging and hook block. With many stake holders involved, all aspects of the lift needed to be cross-checked multiple times and each update had to be communicated precisely. Without the app, the lift would have been very difficult as we were doing the convertor module lift using a crawler crane for the first time while earlier it was done with an EOT crane or by skidding.”

“The Rigging Engineer is entrusted with the responsibility to create a new rigging permit where all the inputs required for the lift, based on site conditions, are updated and finally approved by the area in-charges.”

– Kaushik Datta

Head CMPC

EOT erection at JSW Dolvi, SMS#2 project

Another critical lift at the Dolvi site was the 300 T lower structure erection of Blast Furnace#2 which was in line with the critical path of the project. To minimize the risk of working at heights, Gagan Pal Singh, Rigging Engineer, shared the criticalities of the task with CMPC as this was the heaviest single lift of blast furnace#2 involving in-plane and out-of-plane inclinations. “After a detailed analysis backed by stability calculations, a safe way forward was conceived through a stage wise scheme that included horizontal lifting, upending and final erection.”

“Without the app, the lift would have been very difficult as we were doing the convertor module lift using a crawler crane for the first time.”

– Satyajit Kaity

Rigging Engineer, JSW Dolvi

Erection of a stacker reclaimer at the Paradip Port Terminal

At JSW Paradip Port Project, Vishal Kumar Chandel, Rigging Engineer, had the onus of seeing through a complex lift involving the tilting and erection mast weighing close to 80 T with one tyre mounted and two crawlermounted cranes. “Using the rigging app to load data on cranes for tandem lifts, the scheme was pre-planned and the lift was safely executed.”

“Using the rigging app to load data on cranes for tandem lifts, the scheme was pre-planned and the lift was safely executed.”

– Vishal Kumar Chandel

Rigging Engineer, JSW Paradip Port

Rafter erection in high rise area at JSW Dolvi, SMS#2 project

Virtual secure decisions are made at site, shares Susanta Swarnakar, Rigging Engineer at CHP TANDA, “I did not have the hassle of doing complex calculations such as boom clearance checks, tandem lift load distribution as the rigging app has it all inbuilt and just requires inputs like the number of galleries to be lifted, the span, weight and erection elevation. With CMPC’s guidance, we planned this critical lift in a brown field environment ensuring safety and optimising erection time and cost.”

“We planned this critical lift in a brown field environment ensuring safety and optimising erection time and cost.”

– Susanta Swarnakar

Rigging Engineer, CHP TANDA

A complex lift in progress

Gearing up for safer breakthroughs

There are some of very significant direct advantages derived through the rigging app. Transparency is almost 100 % with roles and responsibilities defined and drawn on a single platform accessible to all the stakeholders, credits Sen. Going forward, he assures that the huge pool of data being generated for various types of heavy lifts will augment analytics and serve as a ready-reckoner to provide inferences to ensure that every lift is a safe one at sites.