S Kanappan,

Head & Chief Executive (L&T Geostructure)

Business growth needs speed. Speed drives people to perform. Safety is a culture and value enhances performance. Attitude and discipline are required to observe, learn and practise. These are the most important behaviours for safe working. In today’s digitalised world,people across the globe are connected 24×7. To be ‘live’ and active we must be online, otherwise we become offline! Mobile phones have revolutionised our life, but its abuse and misuse can cause us great harm. Let us show restraint by using phones only in safe locations at the required time, giving it our undivided attention. Multi-tasking while on the phone can cause serious damage and harm and should be avoided. Safety and environment protection do not stop with the workmen. It is applicable from the top to bottom of the organization.Safety being top-driven, it is every senior’s responsibility and duty to give utmost importance to safe working.

BEING PREPARED TO MEET THE FLOW

Evolving strategies to mitigate the threat of water

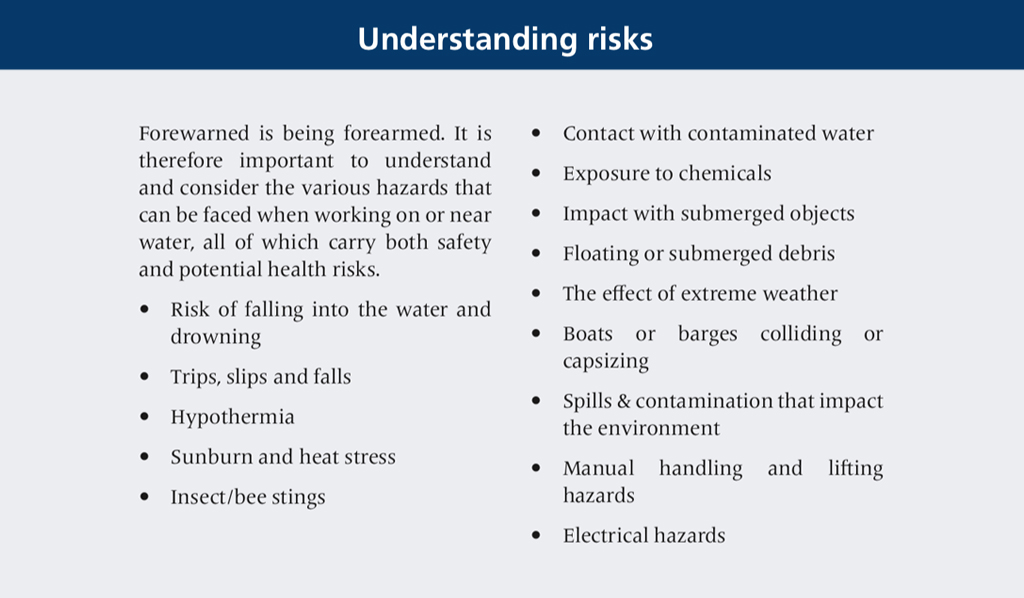

Water has a mind and a force of its own that EHS managers and project teams must be wary of when constructing infrastructure on or close to water. Hazards vary from drowning, boats or barges capsizing or colliding, machinery sliding into the water on slippery surfaces, spillages, erosion of soil and sandbanks to fire and health. “During the monsoons, all these hazards become doubly dangerous,” informs K P Ravinath (KPRn), Head – EHS, L&T GeoStructure. “In fact, at times the threats posed by different types of water bodies are varied. The challenges posed by the sea when we are building a diaphragm wall are so very different from those thrown up by a river when constructing a bridge while the challenges of the backwaters are even more unpredictable, so we need to be prepared for any and every exigency.”

Bridging the sea at the Mumbai Trans-Harbour Link project

While Project Manager, Samir Sarkar and team are being constantly challenged by the “deep, perennial and extremely turbulent river Ganges” during their offshore construction of an inland waterways terminal at Sahibganj, the Heavy Civil Infra team at the Patna Bridge project find themselves pretty much in the same boat constantly wary of the temperamental Ganges springing unpleasant surprises. The might of the River Godawari was always the focus of Project Manager, M.V.Ramakrishna Raju and team at the Medigadda Barrage as they built a huge 1.6 km long barrage across it, while the team working on the Mumbai Trans Harbour Link (MTHL) project need to keep adjusting to the tidal shifts of the Sewri backwaters.

“Of course, working on or near water carries important and serious risks, which should be properly considered and controlled through an efficient process of risk assessment,” adds KPRn “While the risks can be varied, the prevention of drowning must always be our key priority.” The legal requirements concentrate on the need to perform ‘suitable and sufficient’ risk assessments, which can only be achieved if the risk assessment process is effectively planned and managed.

“While the risks can be varied, the prevention of drowning must always be our key priority.”

– K P Ravinath

Head – EHS, L&T GeoStructure.

Nature of work & threats

Operations near or over water can be of various kinds: pile driving, breakwater or jetty construction, working platforms close to the water, watercraft operations, vessel or barge transfers including their mooring and unmooring and diving works. Only recently, there were reports of a boat carrying some government officials to the site earmarked for the Shivaji Statue capsizing and claiming a life. There are several other potential hazards to workmen close to the water: flash floods, natural calamities like storms, cyclones & earthquakes, toppling of a vessel or barge due to loading imbalance, people falling to lower levels or getting knocked over by moving objects or equipment, extreme weather conditions or even oil spills into water bodies. There is also the risk of Weil’s disease if workmen are exposed to contaminated water.

“The shifting of the 330 MT gantry loaded with a 150 MT piling rig BG 36 and 80 MT crawler crane after each row of piling and turning the entire set-up 90 degrees, was a hugely risky operation.”

– Shashanka Pakreh

Gantry piling In-charge, Sahibganj

Gearing up for a safe venture

A peculiar challenge for the Sahibganj team constructing an offshore jetty was using the gantry pilling method with a 600 MT gantry to do DCIS piling. “The shifting of the 330 MT gantry loaded with a 150 MT piling rig BG 36 and 80 MT crawler crane after each row of piling and turning the entire set-up 90 degrees, was a hugely risky operation,” shares gantry piling In-charge, Shashanka Pakreh but along with Project Manager Samir Sarkar, the whole exercise was flawlessly executed. “Every aspect was meticulously checked, followed and the enormous task was completed without incident to everyone’s satisfaction,” sums up KPRn.

“The effectiveness of a safety plan depends on it being regularly reviewed, the situation continuously reassessed and the plan reviewed as an”

– Sanjay Mishra

EHS In-charge, MTHL Project

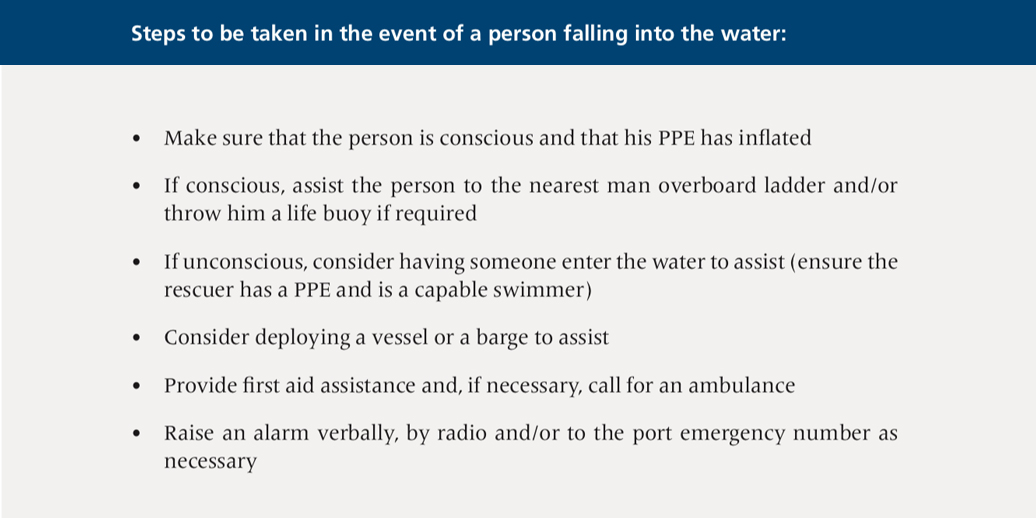

“You can never be too careful when working around water, so it is essentialthat workmen are well protected at all times,” warns Sanjay Mishra, EHS In-charge, MTHL. “When working over water without fall protection if a workman falls from a height of say even 10 feet, in all probability, he’ll be knocked unconscious but without a life jacket or buoyant work vest, he could drown!” A very important consideration when constructing bridges especially when the bridge being constructed is between two other fully functioning bridges as was the case with Goa’s Mandovi Bridge. “It threw up several seen and unseen risks,” shares Assistant Engineering Manager, D Naveen Babu. “In fact, for the foundation we encountered rock boulders left behind from the construction of the other two bridges that were loose and couldn’t support our piling operations. We had to chisel and ground them to reach solid rock.”

Large crowds congregating at funeral points close to the project site is one of EHS In-Charge at the Patna Bridge site, Paras Nath Singh Abhaya’s unique headaches. “Many a time, the local villagers forcefully use our boats without using life jackets which is extremely dangerous for all of us,” he laments.

Multi-model terminal at Sahibganj, Jharkhand

Safe placing of an equipment

Floating barge intake at Sahibganj, Jharkhand

To ensure smooth sailing

A sound safety plan is a good starting point that should essentially establish work plans, method statements, safe working procedures and emergency preparedness replete with contingency plans, rescue/evacuation arrangements and drills. Sanjay Mishra, EHS In-charge at the MTHL project chips in that “the effectiveness of a safety plan depends on it being regularly reviewed, the situation continuously reassessed and the plan reviewed as and when necessary.”

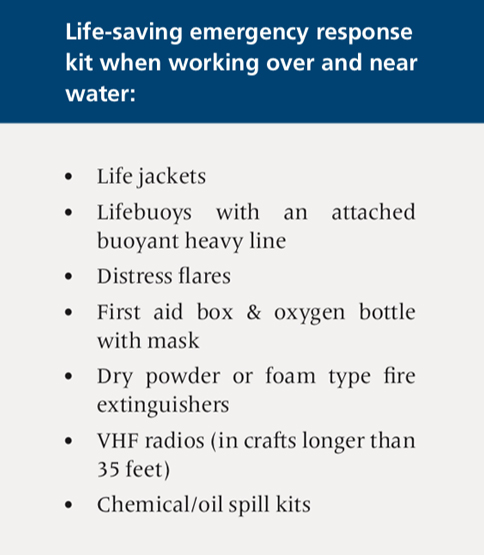

The significant movement of men and machinery in vessels and barges as work proceeds in top gear at the MTHL project, sternly tests Sanjay’s protection plan every day. “All the vessels and barges we use are carefully maintained, always inspected before use by certified and operated only by trained and competent personnel with records kept,” elaborates Sanjay. “Although designed for loading people and material, we ensure that these barges and vessels are never overloaded and by segregating them with signage and physical barriers, they are out of bounds for unauthorized people and members of the public.” In addition, these are fitted with handrails, appropriate warning, running lights and lifesaving equipment such as personal buoyancy aids.

“In fact, for the foundation we encountered rock boulders left behind from the construction of the other two bridges that were loose and couldn’t support our piling operations. We had to chisel and ground them to reach solid rock.”

– D Naveen Babu

Assistant Engineering Manager

Workmen being trained to remain safe in water

Keeping safe on or near water

Life jackets, or, in some cases, immersion suits, are an imperative for all people working over or near water; in heavy swells it is advisable to have safety lines and a harness too. Adequate training in the use and maintenance of lifesaving and rescue equipment is vital like for example, the operation of a lifebuoy comes with its own set of rules and regulations. It should have enough lifeline of not less than 30 m, located at intervals of not less than 50 m around where the work is being carried out and should not be tightly tied to posts. The life jacket or buoyancy aid should be fitted with a whistle, a self-activating light, be regularly and thoroughly inspected and checked by a competent person.

Stable platforms to work from: Guard rails and toe-boards along the edges of access ramps, covered openings and strong, stable work platforms with safe access and egress will prevent people from falling into the water. For the LNG pipeline project of L&T GeoStructure, work at height was unavoidable therefore to monitor erection and fitness of scaffolds, weekly inspections were carried out by the scaffold foremen, green tags pasted, and workmen were given demonstrations and trained to work safely.

All floating work platforms are normally fitted with cranes or lifting devices as per the requirements of IC Lifting Operations procedures and standards and the crane operators and riggers who carry out these lifting operations from floating work platforms are specifically trained and experienced in such operations. Constant communications are a must during lifting operations ideally via the radio; hand signals are generally avoided. There are prescribed number of lifebuoys that are to be available on a craft depending on its length.

“All our electrical components and accessories (distribution boards, switches, fuses, circuit breakers, cabling, sockets and splitters) are ISI-approved.”

– Paras Nath Singh Abhaya

EHS In-Charge, Patna Bridge

Someone to watch your back: It is imperative to work with a partner, always in sight of each other. The operation zone should be clearly demarcated, properly fenced off with a signaller positioned if the operator’s view is obstructed.

Combating Weil’s disease: PPE should be provided to protect workmen against hazards like exposure to chemicals or contaminated water. “Operators need to cover broken skin and wash their hands thoroughly after coming into contact with water in ratcontaminated areas,” advises KPR. Early symptoms of Weil’s disease are non-specific and can be misdiagnosed at the stage when treatment is most effective. Those who work in ratinfested areas should consult their doctor if symptoms such as feverish headaches and general aches and pains like influenza occur. Insect repellent should be worn along with long-sleeved work wear.

Closely inspecting finishing processes

Electrical hazards: All electrical installations and equipment should be constructed, installed, operated, protected and maintained to prevent the risk of danger from electric shock or burns after duly considering foreseeable weather conditions and the environment in which they are being used. Special attention should be paid to “earthing” if the supply is from portable generators. “All our electrical components and accessories (distribution boards, switches, fuses, circuit breakers, cabling, sockets and splitters) are ISI- approved,” adds Paras Nath. Cables, accessories are periodically checked for insulation resistance and fitness for use while electrical panels are inspected on a monthly basis and the green card system followed.

Constructing the Ennore offshore facility

Rescue and emergency arrangements involve evacuation, escape and rescue. Evacuation involves leaving an installation or site systematically without entering the water with rescue boats or service/tugboats. Escape is resorted to when the evacuation has failed while ‘recovery & rescue’ is taking people at site to a safe place.

The IOCLPL LNG terminal project in Chennai had to face the wrath and 205-km winds accompanying cyclone Vardah in December 2016. While there was extensive damage to the flotillas and workstations and operations had to be suspended, the oil spill as a result of two ships colliding inside the Kamarajar Port gave the team several sleepless nights.

Just like all other construction activities, working on or around water is fraught with risk which if identified, assessed and planned for can ensure safe project progress.