Driving quality across a formidable landscape

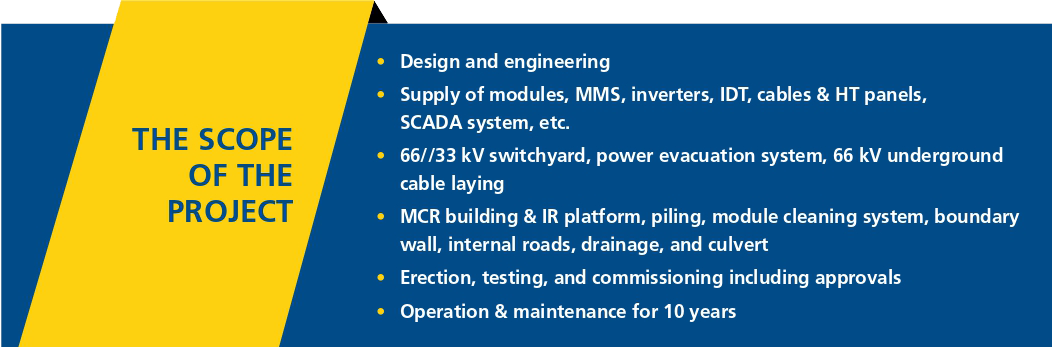

In the village of Babarzar, in Gujarat’s Jamnagar district, what was once an abandoned and rugged wasteland will now be a thriving green corridor. PT&D IC’s Renewables BU has constructed the 210 MWac / 315 MWp DC groundmounted, fixed-tilted solar power plant for the Gujarat State Electricity Company Ltd (GSECL), and Project Manager,

V R Thanumalayan, and team are a happy lot, for in the process of building the highest-capacity solar plant in the state, they have bagged L&T Construction’s Quality Award – 2023.

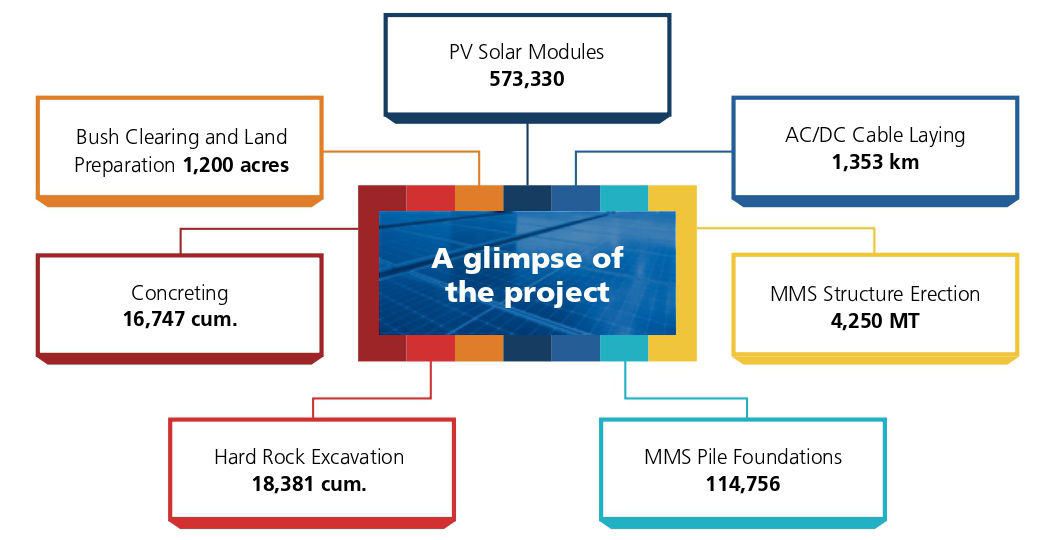

The abandoned wasteland with rocky soil strata has an elevation difference of 30 m between its highest and lowest points. Preparing a comprehensive plan for monitoring and controlling was crucial, as we had a whole host of activities occurring across the entire 1,200-acre area comprising 18 blocks, each with varying capacities.

V R Thanumalayan

Project Manager

“It is immensely satisfying to have served a larger cause of providing clean, renewable energy to the industrial hub of Jamnagar and the agricultural belt of the Saurashtra region, delivered with the quality that L&T is known for,” Thanumalayan declares, patting the trophy presented to the team by T Madhava Das, Whole-Time Director & Senior Executive Vice President (Utilities).

Surmounting the challenges of an undulated terrain

“The abandoned wasteland with rocky soil strata has an elevation difference of 30 m between its highest and lowest points,” explains Thanumalyan. “Preparing a comprehensive plan for monitoring and controlling was crucial, as we had a whole host of activities occurring across the entire 1,200-acre area comprising 18 blocks, each with varying capacities. The highly undulated terrain is spread across both sides of a state highway and takes about 45 minutes to traverse from one end to the other.”

Thanks to effective project management, Thanumalayan and team have successfully executed with this 45-minute tolerance without any incidents, with a dedicated emergency vehicle placed at the centre of the site for immediate assistance.

The hurdles to cross were not only confined to the nature of the land. Being an EPC project awarded on a lumpsum turnkey basis, the project faced a unique financial challenge right from the tendering stage. “It was originally envisioned with a negative cash flow,” informs Shantanu Dey, Project Accountant. “But we strategically organized a billing breakup (BBU), which was approved by GSECL, that guaranteed a positive cash flow throughout the project.” Leveraging this BBU, Shantanu and team effectively overcame the challenging payment terms stipulated in the contract and were able to make timely payments to subcontractors. “A critical task for any project!” he adds with a relieved laugh.

A culture of continuous improvement

Thanumalayan believes in individual accountability, a virtue that is reflected in all the team members, who take personal ownership of their tasks. “At Babarzar, we foster a sense of responsibility to achieve quality outcomes. Right from the beginning, we introduced clear processes and guidelines to streamline operations, reduce errors, and ensure a more efficient workflow.”

Debarghya Bose, Quality In-charge, has been a busy man ensuring that the project earned the Quality Award. “Regular quality audits along with well-structured feedback mechanisms have helped us maintain a no-nonsense quality culture,” he relates seriously, before mentioning that the team has a cohort of young, energetic minds, including 8 GETs. “We imparted targeted training to upskill the team to help develop future intellect. It is important that we keep up the verve!” he adds with a flourish. The QIR, N-pulse, and CQI apps have all been instrumental in achieving a high level of quality.

Debarghya Bose

Quality In-charge

Regular quality audits along with wellstructured feedback mechanisms have helped us maintain a nononsense quality culture. We imparted targeted training to upskill the team and help develop future intellect. It is important that we keep up the verve!

Based on QIR analytics, the BU runs quarterly quality campaigns where every quarter a theme is decided, such as concrete curing or earthing. As a part of this campaign, daily morning peptalks and training programmes are conducted. During his daily site visits, Thanumalayan conducts a quiz and rewards one worker who displays his knowledge on the theme. “This has made sure that all our workmen, subcontractor supervisors, and the rest of the site team are aware of good practices. This initiative has been extremely effective in driving quality work at site!” Debarghya relates

with a smile.

Debarghya mentions the pivotal role played by Mayank Hajela, Segment QA/QC Manager, in fostering a quality culture. “His guidance has been invaluable in identifying key aspects that require focus to uphold excellence, ensuring that quality becomes ingrained in the very fabric of our operations. We promote and celebrate the achievements of our staff to create a positive and inspiring work environment, with a commitment to quality at every level.”

Onwards past the rocky road

With the project about 85% complete, it is safe to say that Thanumalayan and team have crossed the most difficult of their hurdles. “We have completed the civil & module mounting structure work till date and have started the erection for 550 Wp; installing 573,330 modules within the stipulated time is a herculean task,” he notes as he signs off. “We are now giving it our all to make sure that we hand over a quality output to the customer.” Here’s wishing the Babarzar Project team all the best in commissioning the plant by March 2024!