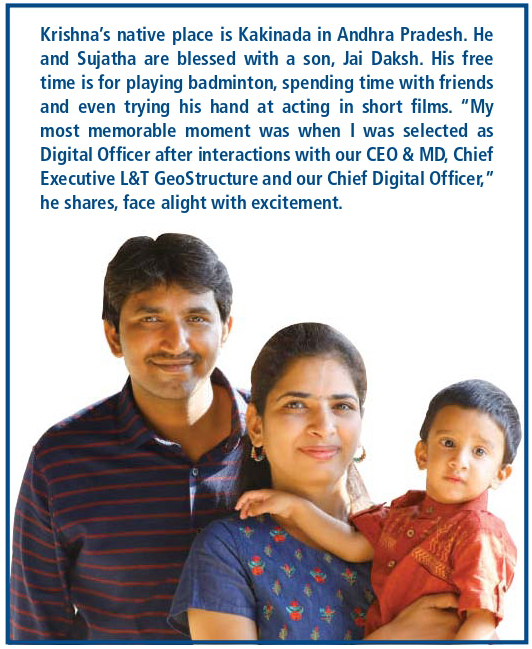

Krishna Karteek Velidi

Planning In-charge, L&T GeoStructure

He is a GET from the 2008 batch. He is a BIS scholar. His wife, Sujatha Danthuluri, works as an Engineering Manager with L&T Hydrocarbon and he is heading a unique initiative for elevated & embedded structures for L&T GeoStructure so it will not be wrong to state that L&T runs in Krishna Karteek’s family. Presently, he has been delegated to the 2 X 660 MW Ennore SEZ Super Thermal Power Project as Planning In-charge to lend a helping hand to the Project Manager and team to fight against the pandemic and get things rolling at site.

“On 24th March we had 501 workmen at site; on 28th May we had only 8!” Krishna sizes up his problem. “Secondly, even when the lockdown was relaxed, site operations could not resume as the personnel were all staying 15 km away and could not travel so we appealed to the client (BHEL) for 15,000 sqm of space within the site to build a new labour colony. With concerted team effort, we received their approval in July and work has commenced,” Krishna informs.

His next target was to remobilize workmen. “I got contacts from various ICs, seniors, our HR team and through the subcontractor mobilization app, we initially mobilized about 150 workmen in July. It was tough,” he says grimly, “as many of the sub-contractors were scared to return plus there were the individual lockdowns imposed by the respective state governments.” He stares for a moment. “That initial phase was most stressful. Things have improved since as we mobilized 300 in August and 350 in September touching 800 in all.”

Cost saving is a recurring theme at all sites and Krishna has lent his efforts to cut overheads by reducing piling equipment based on front end utilization “Further, we reduced our departmental staff to 48 from an original strength of 90 and with this lean setup we invoiced INR 8 crores instead of INR 3 Crores for consecutive months.” His face reveals both relief and triumph as he reels off the progress numbers: Piling: 360 numbers; Concrete: 17,990 cum; Reinforcement: 1635 MT; Structural Steel Fabrication: 2029 MT.

Krishna flags off the subcontractor mobilization app as a boon. “By entering details of the project, location, nature & duration of work, we receive responses from various subcontractors in less than 6 hours that has helped a lot in workmen mobilization.”

‘OUR FAMILY, OUR SAFETY’

Rajesh Pundlik Barskar

Manager (Accounts), L&T GeoStructure

‘Our family, our safety’ was a tagline introduced by the Government to spread the message of keeping oneself and one’s family safe from the threat of COVID-19. Rajesh Barskar at L&T GeoStructure’s Seawater Intake Project at Uppur, which is also his first with L&T, found the tagline most appropriate to drive the message of safety to his workmen and employees at site. “We have never seen a virus like this before and we have been telling our people that it is only by being careful and taking all the right precautions that you, your loved ones and colleagues can stay safe,” he explains.

Rajesh’s challenges at site are like that faced by most other sites across the country: the shortage of labour as many left as soon as the lockdown was announced or unable to return because of lack of transportation; non-availability of skilled workmen; and thirdly, workmen employed at site slowly losing hope and panicking due to the overwhelmingly negative news in the media. “They were disturbed,” observes Rajesh, “and therefore our first step was to improve their mental health. We asked them to ignore all the fake news and think positively. Only then could they work productively at site.”

In his capacity as Manager – Accounts, it has been Rajesh’s responsibility to arrange for all essential commodities for the workmen and staff, arrange for a Doctor and the healthcare team to be available round-the-clock. “In fact, the ready availability of medical care is one reason why we have been able to control the spread of the virus at our site restricting it to just 6 positive cases at the beginning amongst a workforce of 450,” he points out. “Thereafter, we have had no positive cases,” he smiles, “even after we have resumed operations to full steam.”

Rajesh is extremely appreciative of the leadership of his Project Manager for setting an example, staying with his team, coordinating with the client, and giving them all the support and guidance. “My team members and colleagues have stood with me shoulder-to-shoulder that has helped us cope with the situation. I am also thankful to our management for their moral support and assistance that helped maintain our enthusiasm during these tough times.”

Rajesh hails from the city that never sleeps, Mumbai, is married to Minal, a homemaker and they are blessed with a daughter, Riddhi. During his free time, he loves to explore new places and nods that he does find time to pursue it.

Rajesh is most impressed that L&T is playing a lead role in fulling the Prime Minister’s dream of an

Atmanirbhar Bharat!

ENJOYING THE FRUITS OF TEAMWORK

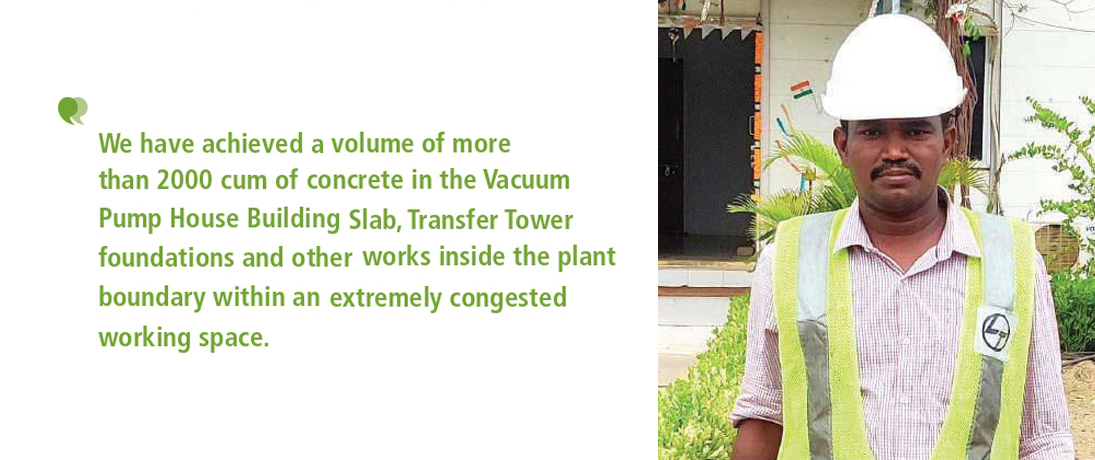

Muthumariappan S

Construction Manager (Civil), L&T GeoStructure

When faced with a crisis, it is critical for people to come together to fight a common enemy and Muthumariappan S (or, MMS, as he would like to be called) is enjoying the feeling of oneness and teamwork as he, his leadership and team at the 2 X 660 MW Ennore SEZ Super Thermal Power Project in North Chennai, combat COVID-19 together. “I have been constantly supported by my Project Manager, Mr. Sanjeevi Perumal and the planning team to achieve our set targets,” shares MMS. “In fact, Mr. Perumal is very experienced, a great motivator and has proven to be a great support for the entire project team as well.” MMS adds that the support from the P&M and Quality teams have been note-worthy too.

At site, MMS’s issues have been labour and client (BHEL) related. “First, we had the labour exodus so to keep things ticking over, we started to engage with local labour but managing them has been really a task,” he says, “though we did manage to bring in some local workmen by visiting them in the nearby villages and assigning them to an existing subcontractor. My other issue has been that the client’s visits to site have reduced to three days per week which is putting a lot of pressure on us to obtain all the necessary clearances and approvals in time.” MMS and team have, however, been able to address this issue with proper weekly planning that are in sync with their monthly plans. “We have also been trying to convince the client to agree to digital mode of clearances through video conferencing and the like,” he adds.

The good thing is that their efforts have borne fruit as MMS explains. “We have achieved a volume of more than 2000 cum of concrete in the Vacuum Pump House Building Slab, Transfer Tower foundations and other works inside the plant boundary within an extremely congested working space.”

BHEL is MMS’s second project after a stint with B&F IC at the Chennai International Airport project. His native place is Tenkasi in Tamil Nadu, is married to Aruna, a homemaker, and they are blessed with two children: son, Juswanth and daughter, Sakshitha, whose birth has been her father’s most wonderful moment. MMS loves to read books in his free time, adding quickly that he gets very little free time these days.

MANDATED TO COVER LOST GROUND

Maramreddy Srinivasa Reddy

Assistant Manager (Civil), L&T GeoStructure

“After working for 1.5 years as Project Coordinator in operations at the Chennai Head Office till end June of 2020, the Management has identified and transferred me to my present site – the 2 X 660 MW Ennore SEZ Super Thermal Power Project in North Chennai, to remobilise workmen and cover lost ground due to COVID-19,” states young Maramreddy Srinivasa Reddy. Though the mandate is tough and challenging, MSR, as he is better known at work, is adapting himself well and his earnest effort is showing positive results. “By effectively planning the work for the available workmen along with the remobilised workmen with clear target completion dates, we have completed some major works viz. VPH building slab, Transfer Tower pile cap (800cum), 360 numbers of piling and pile cap works of more than 5000 Cum at the External Coal Handling System in the marine stretch,” shares MSR, with a certain degree of pride.

On landing at the site, one of MSR’s first assignments was to convince the client (BHEL) and principal employer M/s. TANGEDCO to allocate land for a new labour colony within the site premises. “Work could not immediately start at site after unlock as the personnel staying 15 km away could not commute due to the travel ban,” he explains. “We have finally received the client’s permission and have commenced construction of the new labour colony for 600 workmen in about a month and a half with proper planning and utilising material from the old labour colony to control additional costs, to be further extended to accommodate 1000 workmen.” He believes this will convince the subcontractors to mobilize more who have been reluctant to mobilize workmen due to the widespread fear of the virus.

MSR attributes his success to the support and guidance from Project Manager- Mr. Sanjeevi Perumal, Head Operations — Mr. T. Srinivasan, Segment Head – Mr. R. Ganesh and Project Coordinator ‑Mr. G. Boobathy Vishwanath and of course his whole team and all departments. “I have experienced the true meaning of teamwork during these difficult times,” he admits.

By ensuring work fronts and drawings, the team has achieved uninterrupted progress and MSR is particularly happy that they have mobilized 700+ workmen since the unlock. “We have effectively utilised our resources like the boom placer, deployed additional carpenters from a nearby site for the Transfer Tower Pile Cap (800 Cum) and Building slab (300 Cum) to meet our targets as per the planned schedule.”

Hailing from Kanigiri in Andhra Pradesh, MSR loves to watch movies and hang out with friends, perhaps because he is still single. “It is amazing the kind of respect we receive from client for the quality of work we deliver which makes me feel high of being in L&T,” he signs off proudly.

SUCCESSFULLY FOLLOWING THE PRINCIPLES OF 3M

Jagadeesh Soundararajan

Assistant Manager (Civil), L&T GeoStructure

After joining L&T as a GET in 2011, Jagadeesh Soundararajan has grown in the organization with more responsibilities to prove his worth. Presently as Precast Yard and Shore Civil Work In-Charge at the 2x800 MW supercritical coal based thermal power plant at Uppur, Tamil Nadu, he is part of the exercise to achieve progress in the face of the pandemic. “I resorted to the basic principles of 3M focussing on Man, Machinery and Material,” he says. “With our first target being to mobilize workmen, we initially decided to try out with local labour but neither were they productive nor were they able to align to our safety and quality norms or match our schedules so we had to look elsewhere.”

“We motivated the subcontractors to deploy workmen, interacted closely with those who had remained with us, setting them small goals to achieve some quick wins to boost their morale and make them reach for bigger goals with additional effort,” shares Jagadeesh. As part of their action plan, the team identified activities planned for the following 3 months, mapped resource requirements, slightly tweaked the sequencing for more productivity and encouraged the extensive use of machinery. “We ensured timely availability of resources and material to the workmen to avoid any delays.”

Trust is the bedrock on which relationships are built and Jagadeesh acknowledges the need for trust between company and client. “We like our clients to challenge us, ask questions, request for our inputs. At the same time, we should be free to express ourselves when we think that clients are missing out on opportunities,” he observes. “The process of building trust usually starts off discussing little things before moving on to larger opportunities.”

Productivity was closely monitored at site and workmen who were not meeting the set targets were earmarked for special training. Jagadeesh praises his Project Manager who stood with the team at site, leading from the front. “Tweaking sequencing in a prepared plan is not conventional but with our seniors’ support, we brainstormed, made fresh plans that were approved to set the ball rolling,” he says with gusto.

Jagadeesh comes from the village of Jagir Ammapalayam, in Tamil Nadu’s Salem district and is married to J Vinitha, a MSC, B.ED (Maths) who was teaching but is presently a mother and a homemaker, though with plans to return to work in a couple of years. Obviously, the apple of Jagadeesh’s eye is his 2‑year-old son, J.V. Krishnavendhan, playing with whom is his favourite pastime, when not listening to soft music or cooking.

Having worked at 4 other projects before his present assignment at Uppur, Jagadeesh is both proud and respectful of L&T for the tremendous impact the company has on people.

FOCUSED ON CLEARING

THE BACKLOG

Dudekula Haji Babavalli

Assistant Manager (Civil), L&T GeoStructure

For most projects, the lockdown not only robbed them of a clean two months of progress but the unlock came only a couple of months before the monsoon increasing pressure on teams like Dudekula Babavalli’s project team at the Runj Composite Gravity Dam project to complete critical works before the rains hit. “Our overall plan was to gear up and push progress to cover the target backlog to complete the project in the stipulated time,” he shares, looking serious. “Secondly, with the monsoon only two months away, we had to achieve our first milestone of filling the cut-off trench that is 300 m long, 30 m wide and 23 m below ground level.” Having described his challenge, Dudekula smiles, “We successfully filled the trench to 12 m thus saving our excavated foundation from flash floods from the adjoining water bodies.”

As directed by the client, the cut-off trench was to be filled only after complete dewatering to keep the trench founding level dry. “With the new SOPs in place, instead of manual labour for dewatering, we used pumps with less personnel to reduce the chance of any spread of infections,” he says. At the same time, the new SOPs were causing problems for their subcontractors to mobilize manpower. “We swiftly swung into action,” says Dudekula energetically, “by engaging with the locals who were experienced in similar functions and thereby reduced the time and effort for remobilization.”

Dudekula, though at his first project with L&T, yet brings with him rich experience of having worked on a host of other projects before joining L&T involving the construction of canals, pumphouses, reservoirs, pipelines, dams and canals and so he is certainly on familiar ground at the Runj project. “My seniors and team members have been very supportive and positive about the actions to be taken to improve our progress,” he says sincerely, “by providing 100% attention and assistance to achieve our interim target of filling the cut-off trench prior to the onset of the monsoon.”

While reading and listening to music are his favourite pastimes, Dudekula would love to spend more time with his family that includes, his wife, Ammu, daughter, Harshiya and son, Haron, like they did on a trip to Goa that he recalls with pleasure.

Before signing off, he says, “The initiatives taken by the Management to implement various welfare and safety measures during this pandemic, has increased my pride of being a part of this wonderful organization!”

A BAPTISM BY FIRE

Nishant Katoch

Assistant Manager (Civil), L&T GeoStructure

The 1x660 MW Panki TPS extension project for BHEL is Nishant Katoch’s first project with L&T GeoStructure and it has been truly a baptism by fire with the pandemic-induced disruptions. “To ensure that we were ready to roll as soon as the lockdown was lifted, we required sufficient workmen at site which is why retaining our workforce was our main challenge,” says Nishant, echoing what most of his colleagues across the organization have been saying. “To address this issue, we created a safe work environment, free from COVID infections and convinced the workforce that it was indeed safe for them to work.

If several of the L&T GeoStructure projects were quickly off the blocks as soon as the restrictions were relaxed, it was primarily because of their forward planning and as Nishant explains, his team too did not waste the inactive period of the lockdown. “We had e‑meetings with our Project Manager and teams to discuss our plan of action,” he shares. “We put together some microplans, setting our targets about starting work with the available manpower. Even our subcontractor mobilization plans from the green zone were in place with the result we could start work at site the very next day after the Unlock and started the first concreting within another 5 days.” Nishant looks suitably happy about their team’s achievement.

Of course, it was not easy but then nothing is, smiles Nishant. “Our client asked us to follow the protocol of the local DM in Kanpur by which only workmen from the green zone were allowed to work at site,” he points out. “We followed this protocol religiously by cross-checking every workman’s location before he was allowed into our site. We also followed all the other protocols of checking everyone’s temperature in the morning and evening, using masks, and maintaining social distancing as much as possible.” Quarantine facilities ensured that the new workmen did not mingle with the workforce already at site and timing of lunch breaks was staggered to avoid crowding.

On his personal front, Nishant’s native place is Kangara in Himachal Pradesh. His life partner is Jyoti, a homemaker and they are blessed with a daughter, Tanisha. Not surprisingly, Nishant’s most memorable moment is when Tanisha was born. He follows cricket during his free time.

“Many of the most prestigious and unique projects in India have been constructed by L&T across sectors that is helping our nation grow at a rapid pace and being a part of this organization helps me to contribute towards nation building,” signs off Nishant, quite in awe of the company he keeps.

FOCUSED ON DELIVERY

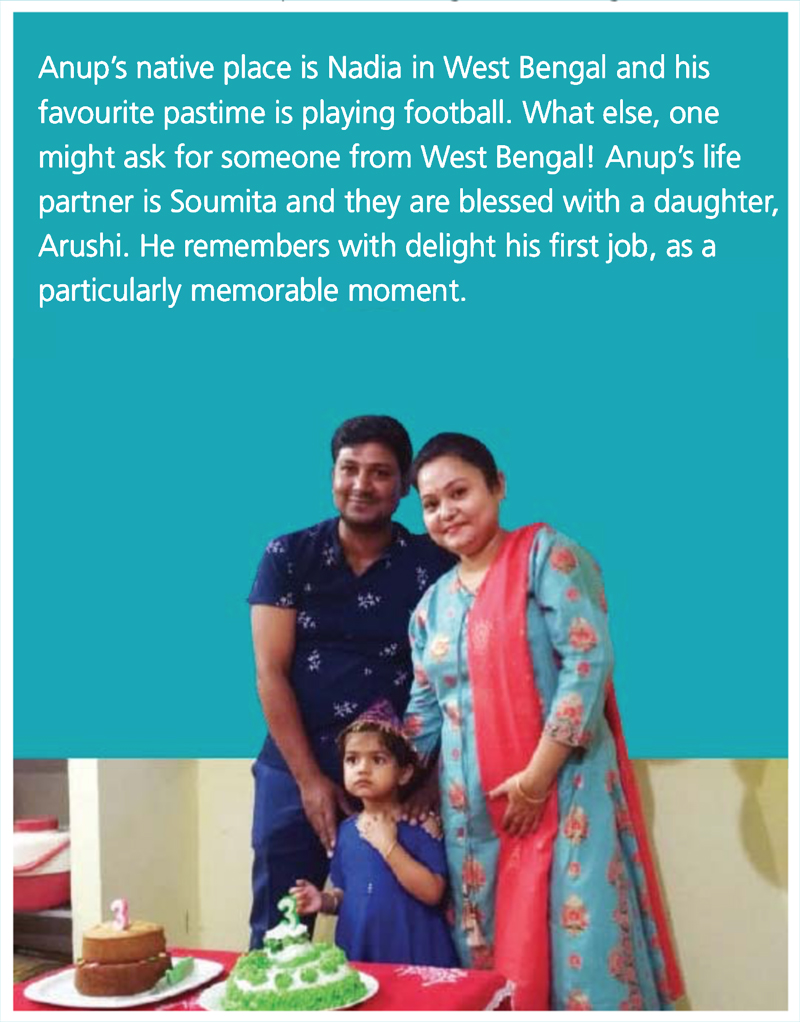

Anup Kumar Biswas

Senior Engineer (Dam execution), L&T GeoStructure

With an expertise in the construction of dams, Anup Kumar Biswas is certainly at the right place involved in the design and construction of the Runj Dam in Panna, Madhya Pradesh, which is also his first project with L&T. “I came to L&T with the experience of having worked on a 54 MW hydro power project in Sikkim and another 720 MW hydro power project in Bhutan,” he shares. “At Runj, my focus has been on how to gear up and push progress after the lockdown,” revealing a single-minded focus on delivery.

To resume operations, skilled labour was required and since most of their workforce had deserted the site before the lockdown, workmen mobilization was high on the team’s list of priorities. “During this situation, our subcontractors were facing challenges regarding mobilizing manpower, so we stepped in and took swift action to identify and engage with locals who were equally experienced in similar operations. Our prompt actions helped to reduce the time taken for mobilization.” Anup looks suitably impressed with his team’s and his efforts in a crisis.

Once they received the permissions to resume operations and they had mobilized adequate number of skilled workmen, Anup and his team got to work. “Our client directed us to pour concrete after cleaning the surface with air jets and make the formwork ready as per the new SOP,” he says. “We started pour with 720 cum concrete and have maintained our rate till date to meet all our future targets. We are strictly following all the COVID-19 guidelines and SOPs which is why the incidence of infections at our site is relatively less,” he adds.

“Even during the lockdown, we worked together as a team,” Anup points out, “and even after we have resumed operations, we are continuing in the same vein. All my seniors and team members have been very supportive and clear about the actions to be taken to improve our progress. They have always been giving 100% attention and every assistance to achieve our interim target of the dam,” shares Anup, extremely thankful to his leadership and team for their cooperation during these testing times.

He is proud of being a part of L&T for the way the company has implemented various welfare and safety measures during the time of the pandemic.

“I AM WHAT I AM TODAY BECAUSE

OF L&T!”

G Vasanth

Assistant Officer (Industrial Relations),

L&T GeoStructure

His life’s most memorable moment till date has been when he was selected to work at L&T through a campus interview. G Vasanth also happened to be the only one from his college to earn this distinction that was acknowledged even by his director, the retired Assistant Labour Commissioner of Tamil Nadu. Since he joined L&T on 10th July 2012, there has been no looking back as he has moved from project to project, from strength to strength. “What I am today is because of L&T,” he says proudly. “I am inspired by our systems and many other aspects. Doing the right things at the right time at the right place is most important and decision-making is what I have learnt at L&T that is helping me in my personal life too!”

Vasanth is presently managing workmen and employee relations at the BHEL Ennore project which is also his 13th project in his relatively short tenure of 8 years with the organization. “Whichever project I have been assigned to, I have been posted alone to handle the IR and admin part,” he shares. “I have had to handle local people and unions but handling them is very different and it is something that I have learnt the hard way though it certainly has been an interesting part of my career,” he agrees.

After Chennai’s second lockdown, it fell on Vasanth’s shoulders to procure passes for the transit of workmen and essentials. “First, I had to read more than 200 Circulars from the Central and State Governments to resume operations at site,” he begins. “Then, I had to deal with the District Collector or the District Magistrate as he is known here, the local authorities and the local police to ensure smooth operation. Convincing the government body was a big challenge,” he adds with a grimace. Mobilization of workforce was the other big issue. “I had to work with travel agencies, vendors, travel supervisors, drivers, the Thasildhar, RTO, the local government bodies and even the Deputy Director of BOCW to ensure that the workmen reached our site safely, in the process convincing all of them that we were strictly following all the SOPs at site to keep us all safe.”

Having recently married Pushpavalli, a B Tech in Biotechnology, on November 1st 2019, Vasanth smiles that presently she is doing great things as a homemaker. He likes cricket and swimming and games like chess and carom but when he does not find time for these hobbies, he entertains himself by watching movies and reading novels: Mel Robbins’ ‘5 Second Rule’ and Tony Robbins’ ‘Awaken the Giant Within’ are two he specially mentions.

RELISHING NEW BEGINNINGS

Praveen Kumar Palanisamy (or PKP, as he is better known as) is at a stage in life when he is relishing several new beginnings. On his personal front, he is beginning a new life with his newly married wife, Sathya, while on the professional side, he is working on his first project – the 2 X 660 MW Ennore SEZ Super Thermal Power Project at Ash dyke of North Chennai TPS, Chennai, handling piling, pile cap, civil, structural and architectural works for the coal handling and ash handling plants for BHEL.

Like everyone else’s across the globe, PKP’s life too has undergone major change with the onset of COVID-19. “Non availability of workmen has been our major concern and therefore our effort has been to optimally utilize the available workforce,” shares a determined PKP. “Progress at site has been slow on two counts: working with the new social distancing norms and following the SOPs have slowed things and secondly, our client is only available on alternate days because of government regulations which is hindering the inspection and clearance process.”

PKP and the project team have quickly understood the constraints and have started working on new plans of action as he explains. “Keeping in mind our monthly schedule, we have been micro planning our day-to-day work activities and resource requirements after consulting with the Planning team to achieve and meet our milestones.” To push progress, the team has been convincing subcontractors to work both shifts while urging the client for timely approvals. “We have succeeded to a fair extent in our effort,” smiles a pleased PKP, “for we have achieved a volume of more than 5000 cum for the marine pile cap structures under these critical conditions.” PKP realizes that it has been excellent teamwork in a time of crisis. “We have been constantly supported by our Project Manager, Mr. Sanjeevi Perumal and the planning team to achieve the set targets,” shares PKP genuinely, adding that he would like to appreciate the efforts of his P&M and Quality teams as well for their continuous support.

For PKP, being campus recruited by L&T was a dream come true and agrees that he is living his dream for L&T offers, “continuous learning, the freedom to improvise on works and the opportunity to perform and achieve key milestones with continuous support from the Project team.”

PKP, who hails from Coimbatore in Tamil Nadu, loves to spend time with his family and Sathiya, who is a homemaker, when not playing cricket that is his favourite pastime.