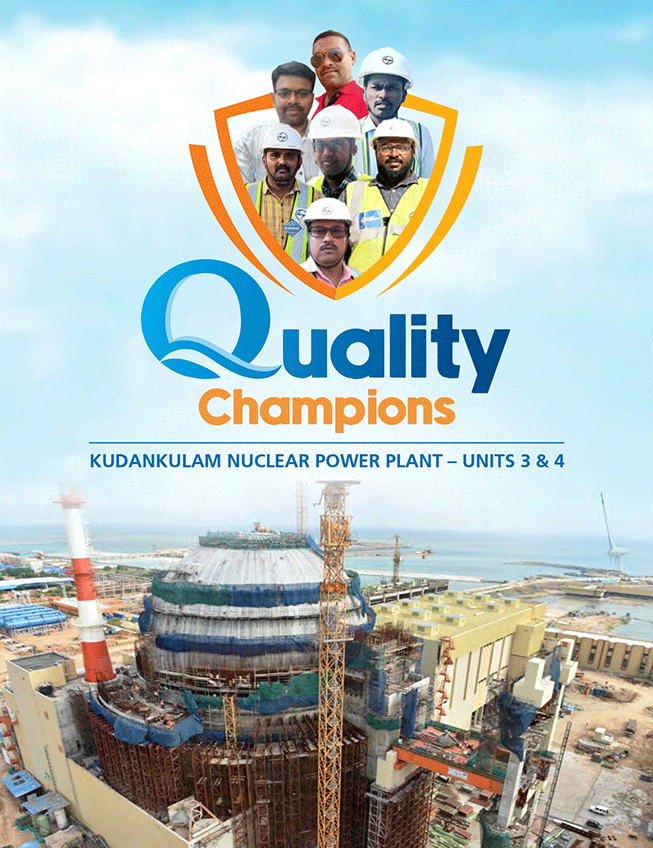

NEVER GIVE UP!

Lakshmanan Petchimuthu

Construction Manager (Mech), HCI IC

One of the things that Lakshmanan Petchimuthu has learnt from his association with L&T and L&T-ites is never to give up however big and complex the challenges may look. That josh is what has driven him right from his first assignment with L&T in 2008 at the KKNPP Units 1 & 2 Project as Senior Engineer. That was followed by a 5-year stint at the Vizag Vessel Project-III as Assistant Construction Manager and since January 2018, he has been at the KKNPP Units 3 & 4 MPCW. Not surprisingly, some his most memorable moments have been at projects that he has been a part of. “I will always remember the erection of the ventilation stack erection at my present project and load testing the Strand Jack members at the Vizag Vessel Project,” he shares with a gleam in his eyes.

To the query as to what he is doing at the site that has helped the project win L&T Construction’s Quality Award 2023, Lakshmanan responds, “Our success is thanks to sequence planning, team selection, motivating both the engineers and the workforce, and perfect coordination and teamwork between all the various departments like EHS, Quality, Planning, P&M, CMPC, IR & Admin and others.” Digitalization is helping their cause too for the design analysis of the critical structures are being conducted by the CMPC team on Auto-Cad and the Workmen Management App is another boon.

Referring to some of the challenges he has faced at site, Lakshmanan mentions the cone to cone and cylindrical shell horizontal alignment of the ventilation stack parts and the vertical alignment of the 67-meter-high ventilation stack without using a crane.

Lakshmanan is appreciative of his Project Manager & In-charge, who he says, are always initiating many new activities, and innovative things, some of which are first of their kind. “They are extremely supportive and never give up on the target,” he says with a punched fist. “All my team members from fabrication, quality, safety, civil, planning, P&M, CMPC and IR & Admin, etc have all helped a lot to achieve this Quality award,” he says, extolling the merits of collaborative working.

Hailing from Tenkasi, Tamil Nadu, Lakshmanan’s better half is Sasikala, a homemaker, and their lovely family is complete with their son, L. Petchimuthu Krishna. Taking long drives with his family and watching movies are what he finds relaxing. What impresses Lakshmanan about L&T are its EHS and quality systems and commitment from the management.

MANAGING WITHIN TOLERANCES

Sandip Das

Construction Manager (Mech), HCI IC

Shuttling between KKNPP Units 1 & 2 (2×1000 MW), his first project, and KAPP Units 3 & 4 (2×700 MW), and then back to KKNPP Units 3 & 4 (2×1000 MW), a lot of what Sandip Das does is managing within tolerances. “In the Ventilation Stack, the permissible Ovality tolerance of cone (Ø 6m) and cylindrical portion (Ø 3m) was within ±5mm and for the base plate (65 Thk plate) OD-6.44m / ID-5.56 m made in 8 segments in a single piece (100% UT joints) with the allowed flatness tolerance within 5 mm.” He pauses, and continues with a smile, “We completed all within the tolerance.”

In the case of the Dome & Crown, the Dome was fabricated with three-dimensional rolling and bending with differed radius with an allowed tolerance of within ±10mm while in the Polar Crane Assembly, the allowed flatness tolerance at the shoe location of the bracket was within 0.5 mm and the bracket elevation tolerance was within 1 mm. “Again, we assembled them all within the tolerance,” he assures.

Sandip is proud of what he and his team at the Quality Award-winning KKNPP has achieved. “The modularly fabricated ventilation stack, weighing 120 MT and spanning 66.5 m was erected in a single assembly within the specified tolerance. The 320 MT dome & crown (Radius-22000mm in hemisphere) was erected too in a single assembly within the specified tolerance.” Additionally, he mentions the fabrication and 12 assemblies of the supporting brackets of the polar crane with IC liner panel, cumulatively weighing 384 MT.

The ABAQUS software used for the ventilation stack and the ANSYS software used for the IC Dome digitally compute the stress and deformation during lifting. “We finalize the lifting schemes on the basis of this analysis,” he says.

Sandip flags off Project Manager, K. Suresh, and K. Vinayagamoorthy (Mech-Head) for special praise. “Their moral and technical support every step of the way in the fabrication and assembly activities was great,” he enthuses. “Our Team members Mr. K. Vignesh, Mr. Kolati Vinod Kumar, Mr. Bharathiraja, and Mr. Hansie Cronie have put their sincere efforts in all activities to complete the work within the schedule and stringent tolerances with zero incidents to achieve customer satisfaction.”

A native of Purba Medinipur, West Bengal, Sandip’s better half is Moumita Jana Das, a homemaker, and they are blessed with a daughter, Mrittika and a son, Shrihan. Away from the bustle of site life, Sandip finds peace playing football and listening to music. Getting selected by L&T at his campus interview is his life’s best moment.

“Clients actively choose L&T for project execution due to our outstanding Quality and Safety standards which is why I am proud to be a part of the L&T family,” says Mahesh Kumar G. He leaves no doubt that he is enjoying his association with the Company, adding that being selected at L&T through the campus placement route was his life’s most fulfilling moment.

His first assignment was at the KKNPP (Kudankulam Nuclear Power Project) Units 1 & 2, assigned to erect the reactor core equipment. Subsequently, at the KAPP (Kakrapar Nuclear Power Project) Units 3 & 4, he was engaged with civil execution, involving critical mechanical works. “As part of a collaborative team, we successfully executed several pioneering fabrication and erection activities, representing a significant learning opportunity that I am proud to have been a part of,” he states with a huge sense of achievement.

Presently, Mahesh is at the Quality Award-winning KKNPP (Kudankulam Nuclear Power Project) Units 3 & 4 and shares some insights of his activities. “We assembled two UJG transport portal beams, each weighing 120 MT at ground level, and then lifted and erected them as single units that resulted in better productivity, eliminated safety risk to work at height and achieved better quality of welding.” The team faced a challenge while assembling the UJG portal beam when the free end got distorted causing a misalignment with the embedded foundation bolts. “Because of this, erecting the UJG portal beam assembly as a single unit became unfeasible and so we proposed to enlarge the holes, which was approved by the RF designer,” he smiles at their innovative solution. On the digital front, the team uses 3D Modelling of the reactor to ascertain clashes between the rebar, embedded parts, and other critical components, eliminating rework.

Mahesh is from Keelakalangal, Tirunelveli, Tamil Nadu, is married to Vanitha M, a homemaker, and they have two children, Gowshik M and Nitin M. He loves reading books and watching matches to unwind.

He brings with him several years of rich experience across sectors and geographies. “Earlier, I was engaged in a nuclear project, ITER-France, as Quality Manager,” shares Sivanesan Rajasekaran, “where I ensured adherence to industry standards, project specifications and effectively coordinated with outsourced vendors. I have also been involved with projects involving cross-country pipelines and thermal power plants in India, as well as ventures in the oil and gas sector in Singapore, Malaysia, and the Philippines.” He therefore brings a global perspective to Quality at his present assignment, the Kudankulam Nuclear Power Plant Project that has won L&T Construction’s Quality Award 2023.

“One of our key initiatives has been to implement a comprehensive quality management system that includes regular training programs for the team, stringent quality checks at every stage, and the effort to foster a culture of continuous improvement,” he says. “Additionally, we have introduced a real-time monitoring system to identify and address potential quality issues promptly.”

Like EHS, the Quality process requires the buy-in of all stakeholders to be effective. Apart from engineers and the workers, he points out that it is critical to maintain consistent quality with the suppliers too. “It is challenging to ensure that suppliers adhere to the same quality standards,” he grimaces before adding, “but we are addressing it by establishing effective communication and collaborating with them.”

Sivanesan acknowledges that the digital solutions deployed at site have gone a long way to improve their capability to monitor and control quality. “These tools have streamlined communication, facilitated data-driven decision-making, and improved the overall efficiency of our quality control processes,” he nods vigorously.

Certainly, driving Quality is a team effort and Sivanesan is fortunate to have the company of supportive seniors who have always guided and mentored him throughout the project. “Even my team members are committed to our quality goals and their willingness to embrace new processes has significantly contributed to our success,” he says gratefully, that also reflects his pride in being associated with L&T. “L&T’s focus on pushing limits, embracing state-of-the-art technologies, and upholding the utmost standards in project execution resonates with my personal values as a Quality professional,” he says with relish.

Sivanesan hails from Kombai, in Tamil Nadu’s Theni district, is married to S. Manimala, a homemaker, and they save all their love for their daughter, S. Niranjana Kumari, whose birth is his life’s happiest moment. “I find joy in cycling and exercising,” he smiles.

Senthil Selvan is a proud and happy man for a variety of reasons. He is thrilled to be a part of an esteemed organization like L&T and contributing to nation building at his first project with the Company, the prestigious Kudankulam Nuclear Power Plant Project. Of course, the fact that his project has won L&T Construction’s Quality Award 2023, is yet another reason for him to celebrate.

To drive Quality at site, Senthil’s responsibilities include implementing a robust Quality Management System, benchmarking & sharing best practices, and organizing continuous training programmes for the working crew to improve productivity. “I strive to ensure and maintain high quality standards and effectively convey the technical requirements to the operational team, ensuring that they clearly understand what I have shared with them.” A fan of digitalization, Senthil informs that their digital document management systems are helping to organize and store all project-related documents and quality assurance records. “We are now able to easily access relevant information and documentation, promoting transparency and accountability,” he says smiling broadly.

Acknowledging the pivotal role of his seniors and team members to make his life at L&T more meaningful and fulfilling, he says gratefully that their guidance has given him valuable insights to navigate past challenges and make informed decisions. “I love the collaborative environment fostered by my team resulting in knowledge sharing and pursuing a common goal. Their mentorship and encouragement have not only accelerated my learning process but also significantly contributed to the success of our collective endeavours.”

On his personal side, Senthil hails from Virudhunagar, Tamil Nadu, and is happily married to Jegathis, who is an Assistant in the State Government’s Educational Department. About his hobbies, he says, “I find capturing moments and scenes through my camera lens very creative and rewarding. I also like to travel, explore new places and experience different cultures.” 20th August 2023, his wedding day has been his life’s happiest day. “It marks the beginning of a new chapter, filled with love, commitment, and shared experiences with my partner. It has a special place in my heart as I cherish the memories created on that joyous occasion, surrounded by family and friends celebrating,” he shares, reliving the memories of that joyous day.

Esakkiappan B has a very clear and no-nonsense approach to work. “I believe in avoiding shortcuts at all costs. Doing a job right will always get it done,” he says forcefully, quoting Albert Einstein that, “Anyone who has never made a mistake has never tried anything new.” He has pursued this sound thinking ever since he joined L&T in 2017 as an Assistant Manager (Civil) at the Kodankulam Nuclear Power Plant Project (NPCIL). “Presently I’m working as Construction Manager and In-charge of the Reactor Building,” he says.

The Kodankulam Nuclear Power Plant was designed by the Russians and one of the major issues for the project team is to understand the unique Russian drawings. “In line with the radiation zones, there are mandatory quality requirements that are varying as the graded approach of the ITNS items,” he remarks. “In the Reactor Building, for example, all the pours are critical and sequential / interfaces with special requirements. The technical requirements of nuclear projects are challenging to understanding for we need to execute within stringent requirements,” he says with a serious expression.

Sharing about how digitalization is making life easier and more efficient for people like Essakkiappan to drive Quality, he shares, “The Containment Slab (@ +31.7M EL) has terrific rebar congestion and it is next to impossible to visualize the rebar interfaces with Modules / Ducts, critical FIM embedded parts and adjacent slabs rebar, but 3D printing and BIM detailing have helped me a lot for I am able to easily decompose the activity and prepare schedules for the same.”

He is extremely appreciative of L&T for opportunities to learn from one’s mistakes and providing a platform for all to demonstrate their talent. “My most memorable moment at work is the successful casting of the Containment Slab @ +5.4M EL in the Reactor Building, Unit#4,” he says with his eyes shining.

Hailing from Tamil Nadu, Essakkiappan’s better half is Chithra, a homemaker, and their family is complete with their two lovely daughters, Thaniksha and Aditi. “I love learning from social media and listening to music during my free time,” he signs off with a smile.

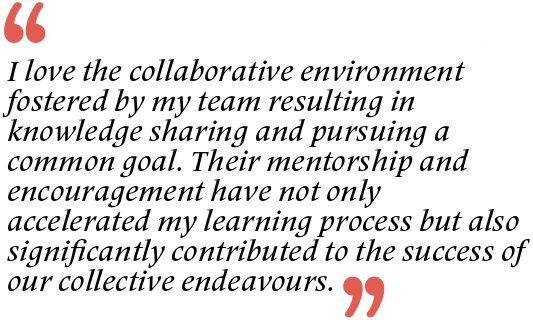

“A unique initiative that has helped our team to achieve top quality at KKNPP and also win L&T Construction’s Quality Award 2023, is working towards a single objective,” says a focused Vallimuthu S. “Everyone in my team is aware of our objective and we always focus on it during the regular team meetings, the site level toolbox talks and as we continuously monitor the progress of our project.” KKNPP is his second project after an earlier stint at the project to construct an Additional Spent Fuel Storage Facility in Tarapur.

Turning his attention to his present assignment, Vallimuthu agrees that it is not enough to only drive Quality with the L&T staff; it is equally important to get the workers aligned to it as well. “We need to take our quality objective down to the workers for them to follow it,” he stresses.

Working with L&T is a matter of great pride for Vallimuthu for he is participating in nation building which is why one of his life’s most memorable moments is work related. “It was when I received an appreciation from our customer for completing a critical concrete pour on the TG deck of the Turbine Building #4 for its quality.”

He is very happy with the support and cooperation he enjoys at L&T that are obviously helping him to grow into a more rounded construction professional. “My seniors have helped me a lot by sharing their experience in nuclear construction while my team members have been equally helpful by being open, making me introspect to improve myself,” he says honestly.

On his personal front, Vallimuthu hails from Srivilliputtur, Tamil Nadu, and the love of his life is Thenmozhi, a homemaker. He enjoys playing badminton, watching sports and movies when he is free from driving Quality at his project site.