Speed has become the operative word as businesses and projects strive to play catch up. For Roopesh Dandapat, Precast Yard In-charge at the MTHL Package-3 project in Mumbai, the situation is no different. “Of the 3Ms, I handle two of them – Material & Manpower,” he explains. “Material had been ordered but due to rectifications, the blister panels used for segment casting were delayed and the factory was also closed due to COVID-19. Even if the panels had arrived, we would have struggled as we had zero manpower in the Precast Yard.” The fear of Mumbai being a hot COVID zone was deterring workmen despite which some were arranged for shorter periods of time and production re- started. “Our strategy was focused to reduce cycle time of our various activities as we had to make up for lost time,” reminds Roopesh.

He and his team drove progress by following a few basic rules of functioning. “My team members and I discussed about the scheduling of works to create a progress outline to track the different work fronts, we established goals and every team member was clear of the milestones to be achieved. We agreed upon clear deadlines and regularly monitored progress.” His SOPs were brief, easy-to understand and he used documents to show action to achieve targets. “Quality control was critical, and we ensured quality output and uniform performance for the segment castings,” he adds.

To work in L&T was my dream, I am proud to wear the L&T logo and I feel that I am in my No. 1 workplace.

Although at his first project with L&T, Roopesh is glad that his seniors gave him a free hand to accomplish his goals in the stipulated time; he is also grateful for his team’s support in his success. “With the help of Arvind Nerurkar Sir, Satya Prakash Sir, and my P&M team, we introduced a push pull mechanism by using gears added to the existing inner trolley formworks of PCY segments for the moulds to easily move that significantly reduced the cycle time. This earlier was a time-consuming, manual process,” he says, flagging off a major triumph.

Apart from using the Safety App, Roopesh says that the silver lining has been the increasing internet penetration and automation. “We are able to take decisions quickly, eliminate communication gaps which directly helps in improved workflows, lower costs, better resource management and faster turnaround times.”

Roopesh hails from Baripada, Odisha and is married to Sanjukta, a homemaker, “who,” as he says, “cares and looks after me and my adorable children,” who are Ishita and Akshita. “I love playing cricket, listening to music and going on long drives,” he smiles adding that his working stint abroad was memorable as was the feeling when he laid his child on his lap for the first time.

“To work in L&T was my dream, I am proud to wear the L&T logo and I feel that I am in my No. 1 workplace,” he declares.

KEEP THINKING TO COME UP WITH NEW IDEAS

Santhosh Kumar S R

Senior Engineering Manager (Civil), Heavy Civil IC

L&T gives you the opportunity to take decisions and course correct in case of mistakes. It teaches you to be responsible for your decisions and helps self-improvement by providing excellent training. I have learnt mainly by facing challenges.

One aspect about L&T that Santhosh Kumar holds very dear is that it is a great place to learn. “In fact, I have learned something new every time,” he states, referring to his 4-project long association with the organization. When faced with the onus of pushing progress at his present assignment at the Mumbai Trans Harbour Link project, he ticks off three things that they adopted as a team: “Change the methodology from what was tried previously, think of alternate methods to meet targets and try unique methods that have not been done in the past.”

It is good that Santhosh and his team have adopted this open-minded approach as they were facing some major challenges at site. “We had to re-look at our erection & dismantling methodology for superstructures,” he shares. “We were forced to redesign the foundations due to a change in the strata after excavation, we had to contend with frequent design changes proposed by the client and design approvals of ROB although,” he adds, “major approvals had already been taken prior to design from external stakeholders like NHAI, the Railways and CIDCO.”

Speaking about innovative approaches, Santhosh describes a noteworthy one from MTHL. “We observed that the portal rebars were being tied in situ on an erected platform that was both time-consuming and risky. Instead, we proposed a cage fabricated on the ground so that the staging and shuttering works could be carried out parallelly. The cage was finally lifted by a crane and placed on the erected staging. We were able to complete this activity in 1-2 hours so that we successfully cast the portal ahead of schedule,” his smile is indicative of their success. Another innovation was to reduce the time taken to dismantle the underslung system from a minimum of 20 days to 10 days, with reduced manpower.

Santhosh mentions kick-off, weekly progress & design meetings to keep the ball rolling; method statements and checklists are prepared for each activity and circulated. “All the activities use checklists to guarantee that steps are followed in order and we ensure that all activities are carried out as per SOPs checked by periodic/detailed inspection,” he shares.

Santhosh loves trekking, cricket and exploring new places with his wife, Chaitra G, a homemaker, and his children, Gagan SS and Vismaya, his daughter whose birth is one of his life’s most memorable moments. He is a native of Davangere in Karnataka.

“L&T gives you the opportunity to take decisions and course correct in case of mistakes,” he reiterates. “It teaches you to be responsible for your decisions and helps self-improvement by providing excellent training. I have learnt mainly by facing challenges,” he rounds off.

“I admire the professionalism at L&T and our ability, as an organization, to rise to any occasion, especially if there is a crisis or a challenging situation facing our country,” shares Sachin Pansare, who at the Rapid Rail Transit System project P3, L1 at Ghaziabad is at his third project with L&T after stints as Construction Manager at the Hyderabad Metro and Chennai Metro rail projects. “Post the unlock, our main issue was mobilization of resources, mainly skilled manpower,” remarks Sachin. “and we have actually developed a ‘new normal’ culture among our workmen at site due to the pandemic.”

Sachin and his team made good use of the lockdown by pre-planning many of their activities to be ready to mobilize and achieve immediate project milestones as soon as operations resumed. “Our pre-planning involved preparing resource mobilization schedules, design approvals, material finalization that helped greatly in accelerating progress,” says a determined Sachin. “We monitored progress, planned versus achieved, both physically and virtually with software tools,” he says. “Overall, as a team we strictly adhered to the guidelines issued by the government and our senior management and carried out works in line with the SOPs that helped us achieve our targets.”

Our pre-planning involved preparing resource mobilization schedules, design approvals, material finalization that helped greatly in accelerating progress. We monitored progress, planned versus achieved, both physically and virtually with software tools.

For the workmen, the team conducted pre-deployment checks before reaching the site including general medical tests at their hometowns. “This way, they could start work immediately without endangering others already at work,” Sachin says. Regular briefings and pep talks kept the workmen engaged and in the right frame of mind to work at site.

Digital solutions helped Sachin and his team improve efficiencies at site. “Apart from conducting all our meetings virtually, digital tools helped us monitor our progress to ensure that work proceeded smoothly and safely. Most importantly, online billing helped us to process our bills and receive payments without compromising on the safety of the staff and workmen.” Sachin is quick to acknowledge the support of his seniors and the contribution of his team members during this tough phase. “It has been a test and triumph of teamwork,” he gives a thumbs up.

Sachin is from Hyderabad and is married to Rashmi, a homemaker, and the couple are blessed with a daughter, Samriddhi, whose birth is one of his most memorable moments. The other is his wedding day. “I like playing cricket and listening to music but rarely find the time for them,” he says with a slightly sad smile.

He can be considered a bit of a ‘bridge specialist,’ for after joining L&T on September 15th, 2014, Akhilesh Singh started to work on the 3rd Narmada Bridge project as Deputy Construction Manager after which in October 2017, he was transferred to work on the 3rd Mandovi Bridge project. From July 2019, he has been involved in constructing India’s longest sea bridge, the Mumbai Trans Harbour Link.

His pandemic related challenges were the non-availability of workmen, junior engineers, supporting staff, the consultant and how to safely transport his people. “As soon as the lockdown was announced, which lasted from March 21st to April 20th, I immediately called my immediate superior and our Project Manager to discuss the way forward with our client and the administration,” recalls Akhilesh. The timely action of the team resulted in the project receiving special work and vehicle passes to commence work.

“Like true L&T-ites, we converted a crisis into opportunity and doubled our daily activity targets with limited manpower and resources and succeeded with the help of our seniors, subcontractor, consultant, and project team,” he shares, recognizing the rewards of teamwork. “In fact,” he adds, “I targeted for bigger work fronts in terms of both quantity and invoicing due to our limited resources and set daily, weekly and monthly targets that were diligently reviewed every 3 days with our staff and subcontractor.”

Like true L&T-ites, we converted a crisis into opportunity and doubled our daily activity targets with limited manpower and resources and succeeded with the help of our seniors, subcontractor, consultant, and project team.

At the same time, the team strictly followed all the health advisories and guidelines issued by the government and the management to stay safe in the face of COVID-19. Akhilesh specially marks out the effort of the EHS and admin teams in this regard.

“In my experience, L&T differs from other companies on three aspects,” he opines in conclusion. “Here, our priority is safety and Vision Zero Harm, then excellent quality and finally productivity which is not the case elsewhere and that is why we are known as builders of nations!”

Akhilesh’s native place is Azamgarh in Uttar Pradesh. He is married to Supriya, who is presently a homemaker taking care of him, his son, Advik and their home, but is planning to take up the job of a schoolteacher shortly. “I have several hobbies,” he laughs, “playing chess, singing, and studying statistics related to our country and world infrastructure. Normally, I follow them over weekends.” He has several lovely memories to share: an award he received from his previous company, his marriage, becoming a father, joining L&T and, of course, winning an award from the Governor of Goa for his contribution towards constructing the 3rd Mandovi Bridge.

TUNNELLING INTO UNKNOWN TERRITORY

Sunil Kumar Khatri

Construction Manager (Civil), Heavy Civil IC

Tunnel Construction Manager at the challenging Rishikesh Karnaprayag Rail Line Tunnel project, Package-2, Sunil Khatri is on home ground for he hails from Roorkee in the Haridwar district of Uttarakhand. However, he finds himself facing multiple new challenges as he strives to push progress despite the pandemic. Lack of workmen was his primary issue, and is thankful to the project management and admin teams for stepping in to mobilize some workmen from within the state to restart works with limited resources. “Here, we are using the NATM method which is a new technology for most of the subcontractor workmen,” he points out, “that requires close monitoring of individual activity. With continuous site base training for the workmen, we started with tunnel excavation of 40 m a month and gradually pushed it up to 60 m within 3 months against the targeted progress of 55 m for the escape tunnel in B3 class rock.”

The team had commenced excavation from the Byasi Escape Tunnel 45 days before the scheduled start date by concentrating resources in one location and opening multiple parallel working benches. “We planned our activities in such a way that we could shift our equipment from one location to another after every shift so that non equipment related activities could parallelly happen at both locations.” Sunil adds that the activities were so sequenced that not more than 3 to 4 workmen were together at any given time. The sequencing was also being constantly improvised based on the available resources to ensure smooth progress. “Further, since the market was uncertain and volatile, we sourced and ordered resources from multiple vendors to maintain a continuous flow of material.”

Progress for the day was compared with that of the previous day for daily improvements and with continuous training and monitoring, we successful brought things to normalcy within three months.

Cycle time for every activity was monitored daily for improvements. “Progress for the day was compared with that of the previous day for daily improvements,” Sunil remarks, “and with continuous training and monitoring, we successful brought things to normalcy within three months.” Monthly targets were fixed based on the overall schedule in consultation with the seniors and team members. “The Wi Fi network we installed inside the tunnel has hugely improved the communication system,” Sunil enthuses, “that helps us to monitor what is going on inside the tunnel better and manage our resources inside.”

Sunil, at his third project with L&T after stints at the Parbati and Punatsangchu hydroelectric projects, is married to Jaya, a homemaker and they are blessed with a son, Aryan. “I love to watch cricket and listen to Hindi movie songs,” and flags off his completion of B Tech in civil engineering from Patiala’s Thapar University as one of his most cherished moments.

“I am proud to be an employee of L&T which is both a leading construction company in India and a most professionally managed company,” he says in conclusion.

M Jaya Prakash

Deputy Project Manager RRTS-P3, L1, Heavy Civil IC

“What I admire most about this esteemed organization is the ‘Never give up’ attitude that really motivates me to perform even better,” shares M Jaya Prakash, obviously proud of the company he keeps, an attitude that has gone a long way to sustain the organization to overcome the challenges posed by the pandemic. Presently, at the Rapid Rail Transit System – Package 3 Lot 1 in the Delhi NCR region after a stint as Station In-charge at the Chennai Metro handling the underground construction for three stations, Jaya Prakash has had his fair share of issues during and after the lockdown.

“Reaching the site to ascertain the actual situation was in itself a major task,” he says with a shake of his head. “Getting workmen to secure the open site and do important works during lockdown was next to impossible. Managing them, controlling their agitation, and then transporting them back to their hometowns after the unlock were tough tasks. At the same time, we had to push progress for which we concentrated only on immediate milestones rather than spreading the workforce across locations.” The team clearly identified groups of workmen and engineers for each task and asked to do only the allotted work. No shuffling was allowed, and each group was regularly monitored for COVID symptoms.

“Our client formulated a fool proof protocol to be followed by us to start the work at site after lockdown that we positively accepted and demonstrated our L&T capability of following all the required protocols,” Jaya Prakash points out. “In fact, our protocols were even tougher.” Progress of works was digitally monitored, all discussions with engineers and workmen at site were on MS Teams and Google Meet and all the required permits were digitally raised and approved by all departments before the start of an activity.

Tough times test teamwork and Jaya Prakash is happy that his team has held its own in a tough situation. “Our Seniors and team members have been very cooperative and understanding,” he says earnestly. “They are always ready to discuss the difficulties faced at site locations related to the COVID protocols and provide valuable inputs to speed up the work without breaking the protocols.”

Hailing from Dharmapuri in Tamil Nadu, Jaya Prakash is married to Poorani, a homemaker, “who has the extra responsibility of looking after my family and my mother since I cannot devote time due to my site pressures,” he says sadly. They are blessed with two sons, Gautham and Ragunathan. While listening to some good music and reading relaxes him, Jaya Prakash recalls an unplanned trip that he took with his family. “It was thrilling not knowing where our next stop was,” he laughs, his face bright with fond memories.

The outbreak of the pandemic put enormous additional pressure on the project admin and IR teams to engineer ways and means to keep their people safe and their projects sites and offices functioning. Ajai Pratap Singh found himself in a similar situation at the Rishikesh-Karnaprayag Rail Project. “Our project fronts are at five locations spread over 20 km and I had to arrange for workmen accommodation at all these fronts to avoid or at least reduce their travel from one place to another,” he shares his responsibilities.

It was most difficult to procure the statutory permissions from the government authorities especially during the lockdown as either their offices were closed due to positive cases or the officials were working remotely. “It was only after close and continuous follow up and liaising that we could get all the required permissions for the batching plant, crusher, use of explosives, borewell, electricity, draw water from the Ganges, aggregate storage permits, short term permits (mining) on time,” Ajai says.

At a point when positive cases started to spike, the team conducted COVID testing for all the staff and workmen with those positive, removed to quarantine centers. “We did about 800 tests in two days,” Ajai inforTo meet the project demand for manpower, Ajai and his team arranged for several workmen from within the state while those coming from other States were accommodated separately for 7 days before engaging them for works. All other safety protocols of daily sanitization of the work area, wearing masks, daily temperature monitoring for all and restricted entry at site for unauthorized personnel were all strictly followed.

We continuously motivated the workmen and built up their confidence by demonstrating our arrangements for them. We worked as a team which is the only reason why we succeeded.

“We continuously motivated the workmen and built up their confidence by demonstrating our arrangements for them,” mentions Ajai. “We spread awareness during our daily interactions with them, persuading them to follow the guidelines to prevent the virus.” Ajai is very happy with the support of his seniors and team members for this tough task. “We worked as a team,” he says, holding both hands together, “which is the only reason why we succeeded.”

“I am proud to be an employee of India’s No. 1 construction company that is so professionally managed,” he says, “and I enjoy the freedom of work that is unique to L&T.”

On his personal front, Ajai is married to Sweta, a homemaker, and they are blessed with two children, daughter, Ashmita and son, Vaibhav. He loves to play cricket and listen to old music, but time is a constraint. “What I did for my parents with my first salary is what I hold very dear to my heart,” he shares with feeling.

Rahul Sriwastava proudly states that he was the first man at the Delhi-Meerut RRTS P3L2 project site. Post the unlock, his hands have been full retaining labour, mobilizing fresh workmen, counselling vendors & staff and managing the uncertainties caused by the pandemic. “Focusing on specific tasks with the limited resources available and by planning ahead, we have achieved several milestones like the first working pile, the first pile cap, the first pier casting, all of them well ahead of schedule. Each of these milestones have been small victories for us,” he says with fervour.

At site, he has been mobilizing multiple vendors, fixing responsibilities for front line supervisors for each sub-stretch and micro planning to accelerate progress as and when new fronts opened. “The site management has been supportive by promptly allocating resources,” he remarks. “I must thank all the Service Departments too for their timely arrangement of resources, subcontractors, RMC whenever required and the Fabrication team who arranged shutters and moulds. Ours has been the victory of good, solid teamwork,” says Rahul, pumping a fist.

“Before commencing work on each day, we inform the engineers and FLSs their targets for the day that are reviewed at the end of each day. Daily progress reports are generated for better planning to identify any drop in targets and take immediate corrective action, if required.” Rahul’s approach is sure and methodical. At the same time, he and his team motivate the workmen through awareness programmes and have introduced motivational awards to drive productivity. “One topic at our morning briefings is precautionary measures to be taken to stay safe from COVID-19,” he adds.

Rahul’s native place is Dehri On Sone. He is married to Shivani, who is an Assistant Professor, and they are blessed with a son, Prakarsh, who is certainly the light of their lives. “My most memorable moment was when he took my hand for the first time,” shares a loving father. “My favourite pastimes are listening to music and driving.”

He is presently at his 5th project with L&T since 2012, after previous stints at the DMRC CC 06, DMRC CC 77, Lucknow Metro LKCC 01, and the Lucknow Metro LKCC 07 projects. Presently, at the Delhi-Meerut project, Rahul has independent charge to handle the 6.2 km stretch including building the station with about 330 workmen under him. “At L&T, we are treated like family. We are all friends at work and outside of work, our Bosses treat us as equals. I particularly like the freedom to take decisions to perform better,” he concludes positively.

GOING ALL OUT TO ACHIEVE THE TARGET

Pranav Kumar Tyagi

Assistant Construction Manager (Mech.), Heavy Civil IC

As Fabrication and Steel Bridge In-charge at the P3L2 Rapid Rail Metro project in Meerut, Pranav Tyagi is already at his 4th project with L&T after joining in 2013 and stints at the Hyderabad Metro project as Site Fabrication Manager, at two Lucknow Metro projects – LKCC01 as Fabrication In-charge and LKCC07 again as Fabrication and Steel Bridge In-charge where he completed, as he proudly states, 8,900 MT of fabrication. “Here, my team consists of two site engineers, four contractors and a labour strength of 150,” he infor

Post the unlock in April 2020, Pranav’s main challenges were labour, resource and equipment mobilization, material procurement and transportation and sensitising the workmen about the dangers of COVID-19. “My other challenge was to accelerate the progress of the project with full force and ensure the availability of equipment during these pandemic times,” he stresses, adding that his problems were even bigger as the external vendors were not sticking to their delivery commitments.

“To achieve my immediate milestones, I worked out the activities myself doing a backward analysis to ascertain where a particular activity started and what was the end result, I wanted,” shares Pranav of his approach. “I depended on proper scheduling and planning of work, hourly monitoring of progress with the help of DPR and also through personal follow up, better resource management and from time to time, I took time out to motivate the labour and my subordinates to perform better.”

To achieve my immediate milestones, I worked out the activities myself doing a backward analysis to ascertain where a particular activity started and what was the end result, I wanted.

Pranav is happy for his client’s support and encouragement for their effort while the vendors were urged to raise the bar with motivational awards. The team went all out to ensure that all the health advisories and safety protocols were followed by the workmen as they realized that progress was only possible with a healthy workforce. “I am thankful to my seniors for taking the time to guide and motivate me to improve my quality and provide me with sufficient opportunities to achieve my target,” he says gratefully. “I have also taken the initiative to implement the E-tap App to track material,” he adds, “that has already proven extremely helpful to track LG material, trestles, etc.”

From Muzaffarnagar in Uttar Pradesh, Pranav’s life partner is Vishi and they are blessed with a daughter, Aavya, whose first step is one of the most memorable moments of his life. Pranav spends his free time reading books and watching movies. Most of the time otherwise he is driving progress at his site.

“L&T IS SYSTEM-RUN, NOT INDIVIDUAL DEPENDENT.”

Rahul Dev Yadav

Assistant Construction Manager, Heavy Civil IC

One aspect about L&T that appeals to Rahul Dev Yadav is that it is system run and not individual dependent. “We all abide by the system and follow it,” he declares, in admiration of the company he is a part of. He has more reason to be happy of his association as he was recognized as the Best Performer for the Month within three months of joining his present assignment, the RRTS project Lot2 that involves constructing an elevated viaduct of approximately 16 km and five stations from Modinagar North to Shatabdi Nagar in Meerut.

We mainly focused on reinforcement tying activity in every structure well in advance whether it was pile cap, pier or pier cap, so that the shutters could be rotated timely for maximum output through repeated use, get more manpower productivity and utilize machinery more efficiently.

The foremost challenge for the project team was the mobilisation of manpower. When work restarted at the project, their initial focus was to complete the substructure and superstructure for 2.5 km within six months to hand over the site for the launching team to erect LG-1 and LG-2 at the same location. “This, we achieved successfully,” shares a happy Rahul. “We mainly focused on reinforcement tying activity in every structure well in advance whether it was pile cap, pier or pier cap, so that the shutters could be rotated timely for maximum output through repeated use, get more manpower productivity and utilize machinery more efficiently.” Rahul adds that every activity was minutely monitored for its cycle time and duration with a catch-up programme for any slippage.

While the team worked with drive and purpose, Rahul acknowledges the vital role played by the client and vendors to help them achieve their milestones. “Our Client suggested us to form workmen groups and allocate them to work separately without mixing them either at the workplace or in their colony,” he remarks. “We had regular awareness sessions, toolbox talks, proper sanitisation at both workplace and work site and strictly followed all the guidelines and SOPs issued by the Government authorities and our senior management.”

Rahul is thankful to his seniors for their help to achieve their targets marking out especially Project Manager, S.S. Gangwar sir, for his guidance and support. “Our team members equally contributed and put in their best efforts to achieve our goals on time by maintaining all the safety and quality aspects,” he says.

His present project is not Rahul’s first with L&T having been previously involved with the CC-06 DMRC project of 14 km and eight stations, at Faridabad, and the Lucknow Metro LKCC-01 projects. Rahul hails from Barwan village in Bihar’s Chhapra district, his parents are D P Yadav and Rekha Yadav, he is married to Surbhi, a homemaker, and they are blessed with two children, 3-year-old Dhanvita and 6-month-old, Lohit. “I like to watch movies and I plan to spend quality time with my family members that I truly enjoy,” he shares with a satisfied smile.

Sujeet Kumar Pandey

Assistant Manager (Civil), Heavy Civil IC

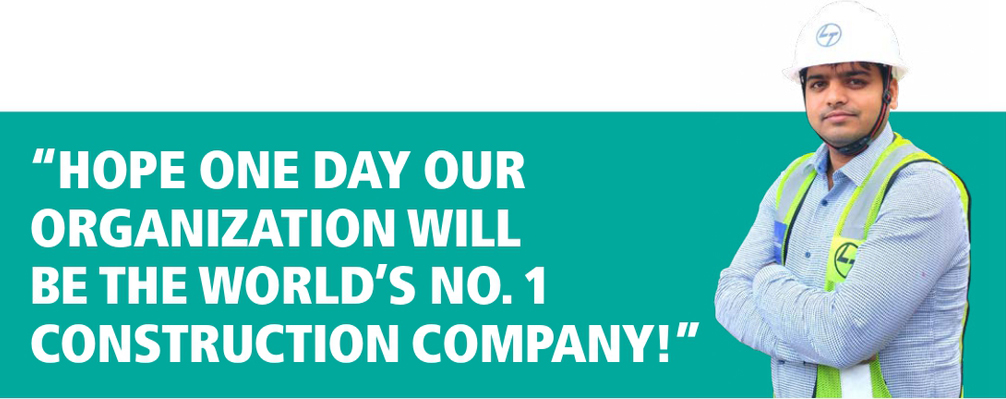

“I am proud to be an employee of India’s No 1 Construction Company,” declares Sujeet Kumar Pandey, “for working for Larsen & Toubro makes you feel that you are serving the country. We are playing a major role in infrastructure development, information technology, smart cities, space technology and Defence equipment for our country and I hope that one day our organisation will be the world’s No 1 Construction Company.”

Presently busy at the Rishikesh-Karnaprayag Railway Project, Package-2, Sujeet’s issues when restrictions were lifted were to mobilize manpower and other resources. “As soon as we completed the infrastructure work, we started tunnel excavation with limited resources due to the pandemic,” he says. “Tunnel excavation requires regular and close monitoring which we, as a team, did by paying special attention to individual activities to improve cycle time and, at the same time, train workmen in the NATM or New Austrian Tunneling Method which requires precision works. In fact, we monitored progress on an hourly basis for various activities at each work front to optimize the use of men and machine to improve cycle time,” he points out.

It was important to keep workmen motivated for which the team organized daily pep talks and all were trained to strictly follow the COVID-19 guidelines issued by the Central Government while a COVID-19 prevention plan was made in consultation with the Client. “At one point, when COVID cases started to rise in the project area, the Project Management decided to test all the workmen and staff,” informs Sujeet, “and those who tested positive were immediately shifted to COVID cells because of which we have been able to control further rise in cases.”

Sujeet mentions the installation of an IP-based Tunnel Communication System for better communication and data transfer within the tunnel that saves time and reduces gaps in communication. He acknowledges the support of the Project Management team during these difficult times to achieve targets and the support of other departments like Geology, P&M, Survey & Safety to achieve their milestones.

Working for Larsen & Toubro makes you feel that you are serving the country. We are playing a major role in infrastructure development, information technology, smart cities, space technology and Defence equipment for our country and I hope that one day our organisation will be the world’s No 1 Construction Company

Already on his 5th project with L&T after stints at the Parbati Hydro Electric, Punatsangchu Hydro Electric (Bhutan), Ratle Hydro Electric and Singoli Bhatwari Hydro Electric projects, Sujeet hails from the holy city of Ayodhya in Uttar Pradesh and is married to Pratibha, who has completed her M.A. & B. Ed., “but enjoys taking care of me and the family,” he shares with a delighted smile. “She always inspires me to work for excellence,” he adds. They are blessed with a son, Atharva. “He is very cute, and I enjoy every moment with him,” says a proud and loving father.

PROGRESS IS DEPENDENT ON A HEALTHY WORKFORCE

Javed Mohammad Akil Shaikh

Manager (Accounts), Heavy Civil IC

Even as project sites and their respective leadership, threw all their might to restart operations and chase progress, there were also people like Javed Mohammad, who took on the responsibility of keeping the workforce safe and healthy without which progress would only remain on paper. “Even though we were in a red-hot zone in Mumbai, our primary responsibility was to retain our labour at our various labour camps,” says Javed, “and to achieve that we went all out.” Workmen were provided with groceries, vegetables, and fruits, hand wash, sanitizers, masks, and hand gloves, they were restricted from going out of the labour camp and site area, provided with conveyance vehicles and the site area and labour camp were sanitized every alternate day. “We even arranged for a medical health team to attend to them 24/7 with a first aid person and a doctor at site,” adds Javed.

At the Mumbai Trans Harbour Link project as Project Accountant & Admin Head, Javed is already at his 4th project with L&T after earlier stints at the Pimpalgaon-Nashik-Gonde Project, his first, as second line in account and admin after which he flew to the Riyadh Metro Project as Admin In-charge. “After my overseas assignment, I returned to India when I was transferred to the Mandovi River Bridge in Goa as Project Accounts second line, in addition to being the admin In-charge. Now, I am here at MTHL,” he smiles, “where after the unlock, I am managing the movement of the workmen and site progress after taking the required permissions from the government and controlling workmen strength.”

Javed confirms that work has been proceeding at full throttle taking all the necessary precautions. “We did have a spike of infections but with proper follow up and ensuring that guidelines were followed, we have reduced the number of COVID-19 cases at site,” he says, mopping his brow. Javed acknowledges the support of both the seniors at site and all the staff thanks to which, “we have completed the work within the stipulated period with zero accident! Insha-Allah!” he exclaims with relief.

“I like to play cricket, watch classics, listen to ghazals and solve puzzles,” he laughs but shakes his head that he hardly finds time to pursue his hobbies. He nostalgically recalls a holy Haj to Mecca Madina of 35 days.

“I am proud to be working for one of the largest infrastructure companies having a global footprint,” he says in awe of L&T.