Sutanu Ganguly joined L&T on April 1st, 1991, and 31 years later, he is at his 15th project with the Company as Project Manager and Civil In-Charge for the Blast Furnace-5 project at JVML Ballary. He, however, exhibits the energy and drive of a newcomer as he enthusiastically shares the various accolades he and his team have received from the client. “They commended us for clocking 7.22 safe million man hours for the period April 2021 to June 2022 without LTI and zero harm, they appreciated us for the timely completion of the concrete milestone of 1.5 lakh cum within 10 months (August 21 to May 22) and they gave us an excellent Customer Satisfaction Report for the period July 21 to June 22.” His expression is clearly of one who has gone the extra mile to deliver and will continue to do so with his full heart and soul.

Located in a remote area of Karnataka, Sutanu’s primary concern was to first mobilize and then retain workmen at site since labour was not available in the vicinity of the site. “Our constant endeavour therefore was timely mobilization and remobilisation of workmen with strong network to mitigate the challenges,” he remarks, “and, at the same time, develop proper facilities for the workmen to increase retention.”

Having addressed the issues of manpower and resources, Sutanu’s next target was to push progress and keep their enviable record with the client intact. “We adopted several new systems at site like LTMS, plastic formwork (NOVA) and Koehppa modular formwork with 3D drawing arrangement,” he enumerates. “Of course, digitalization is helping us to improve our efficiencies and make significant progress,” he nods, mentioning the various digital solutions adopted at site including WRENCH for drawing, CHATBOT for daily progress reporting, nPULSE for daily RFI of all activities, SOSC, Indents and others.

“We make the things that make India proud, that also imprints ‘Make in India across the Globe’,” shares this proud L&T-ite. “We are successful as an organization because we have a supportive work culture, empowerment in decision making and a systematic way of working. These certainly are our standout features,” he emphasizes, referring to his experience spread across 14 other M&M projects for a variety of clients before his present one.

Hailing from Bishnupur, Bankura in West Bengal, Sutanu is married to Deepa, a homemaker and they are blessed with two children, daughter, Sutapa, and son, Sudeep. Although Sutanu smiles that his hobbies are listening to music and reading books, his real passion is obviously his work at projects that he worships.

ONE WORD DESCRIBES L&T: EMPOWERMENT

Niladri Paul

Deputy General Manager (Civil), M&M SBG

“If there is one word that I can use to describe my journey with L&T thus far, it is ‘empowerment’,” states Niladri Paul. “Even when I was the junior most member in the project team, I used to be empowered by my seniors in every aspect to achieve the team goals. Nothing has changed since the day I joined L&T as a DET in August 1997, for even now my seniors always support me by appreciating my decisions and ideas to provide all the necessary approvals and procure resources to complete my assignments on time. In fact, all our achievements are the outcome of excellent teamwork where all my team members equally participate and give their best efforts,” he says with the gravity of a seasoned campaigner which Niladri is, for as Civil In-charge at the Steel Melting Shop (SMS-4) project for JVML at Bellary, he is already working at his 16th project with the Company.

When queried about delighting the customer, Niladri is quick to share the several certificates of appreciation they have received from their customer JVML for their sterling work. “We were awarded a Certificate of Appreciation recognizing the significant milestone of cumulatively crossing 1,50,000 cum of concreting from August 2021 to May 2022 and a Certificate of Recognition for achieving 7.22 million safe man hours from April 2021 to June 2022, both for the BF-5 and SMS-4 projects. What’s more, we also received an ‘Excellent’ Customer Satisfaction Report for the overall assessment for the period January 2022 to June 2022,” he shares, visibly proud of his and his team’s achievements.

Of course, Niladri has several challenges to face and overcome at site and workmen mobilization and their retention have been particularly painful thorns in their flesh. “Most of the workmen are from the eastern and northern parts of the country as skilled workers are not available locally, so mobilization of workers in bulk numbers is a big challenge,” he shares with a serious expression. They mobilize workmen through sub-agencies. “We continuously encourage and motivate them to augment the workmen strength, regularly discuss about their current progress status and new scope of work going forward.”

Customer connect is crucial for project progress. “Our resource utilization is hugely dependent on our customer for the ready availability of drawings and work fronts for which we regularly communicate with them.”

Niladri is a native of Kolkata, West Bengal, married to Dalia, a homemaker, and they are blessed with a son, Saptarshi. When free, he makes time to watch action movies.

Memorable moments? “My last day at a site!”

“NEVER GIVE UP AND ALWAYS THINK DIFFERENTLY TO ACHIEVE SOMETHING DIFFERENT.”

Jiten Dutta

Senior Construction Manager (MECH), M&M SBG

“Never give up and always think differently to achieve something different,” seems to be Jiten Dutta’s life motto. A lover of football, he has been merrily dribbling his way through several projects with M&M SBG ever since he joined L&T in July 2004 and presently, is at his 10th project at the Steel Melting Augmentation, Phase-II project for Tata Steel at Kalinga Nagar, as Senior Construction Manager.

“Construction being a labour-oriented activity, and with the market open for workmen, it is extremely challenging to retain workmen, especially the skilled ones,” he remarks seriously. “So, ensuring timely payment to the sub-contractors has helped me a lot to extract work from them, and frequent skill training sessions have made my shoulder stronger to execute critical jobs.” In terms of achieving greater efficiencies at work, Jiten shares, “I have always emphasized for modular erection to save time and cost, have breached longterm plans into short term ones and have always tried for milestone dates to increase our success rate.”

Jiten has tasted success by adopting digital solutions. “Since construction sites are often spread over wide areas, the SLIM system has helped us a lot to trace materials while the online permit system has saved lot of time for engineers to concentrate on other aspects of the job,” he says with a half-smile. “WRENCH is another platform that has made our lives easier in terms of accessing drawings and documents.”

Having spent almost two decades with the Company it is not surprising that his best moment professionally has been with L&T. “It was at the commissioning of the 17 km long conveyor belt at Sheelabazar for Lafarge which is also Asia’s longest cross-country single belt conveyor,” he recalls proudly. About his L&T experience, Jiten says, “Continuous guidance and swift decisions from my Project Manager have helped me move forward smoothly. My seniors have been very cooperative and understanding, always giving me a free hand to achieve my goals in the stipulated time, cost efficiently and safely.”

On his home front, Jiten hails from Bhatur in West Bengal’s West Midnapore district that he describes as “a small village on the West Bengal-Jharkhand border.” He is married to Rashmi, a homemaker, and they are blessed with two children: daughter, Niharika who is 12, who’s birth is his most precious personal moment, and son, Prankit who is 7. “Though life is hectic, I still sometimes make time to dribble a ball in the morning,” he laughs.

“CHALLENGES BRING OUT THE BEST IN ME”

Ranganathan M

Senior Manager (Accounts & Admin), M&M SBG

He is a bit of an all-rounder having had the opportunity to work at various projects taking care of fund management, accounts payable, and MIS reports. After joining L&T as a GCT in 2001, M. Ranganathan flags off the Hiriyur–Ballari Road project for giving him valuable exposure. “It helped me to understand the importance of maintaining cordial relationships with external customers,” he remarks, which has reinforced his belief that good professional rapport with clients drives projects to excellence. “We are the face of the company at projects, and we need to take utmost care especially during the initial set up of the project,” he adds wisely.

At the Blast Furnace 5 & Steel Melt Shop 4 projects for JVML, Ballari, Ranganathan leads the Accounts & Admin department. He insists that challenges bring out the best in him. “Especially during the initial stages, setting up workmen camps, office infrastructure, staff accommodation and finalizing the overhead related rate finalization are critical tasks.” He admits that retaining the workforce is one of the biggest challenges faced at projects. “At the JVML site, we have established an environment-friendly workmen camp with all amenities and transport arrangements. We frequently identify performing workmen and reward them on a monthly basis, which encourages others to perform well.”

Ranganathan pays attention to the client’s needs and works to exceed their expectations. He relates one such incident at the start of the JVML project: “Handling a huge workforce at their gate was the client’s biggest challenge, as the project is being executed inside an operating factory. Jumping into action, we assured them that we could manage workmen entry into the premises, ensuring entry of authorized personnel only. They provided a dedicated gate for L&T that helped us get the workmen to site in time.”

Over his two-decade-plus career at L&T, Ranganathan has seen the evolution of digital solutions according to project needs. “Digitalization has enabled us to monitor projects with ease,” he comments with a satisfied look. “We can track project financials on a daily basis and take appropriate steps to improve profitability.”

When asked about the pride of being an L&T-ite, Ranganathan replies earnestly, “L&T gives equal opportunity to all. The one who owns their responsibility can perform extraordinarily.” He is grateful to Project Director, R. Umasathiyan for being a guiding force to the project. “Immediate decision making and adapting to changes are primary for success. The enormous support provided by our SBG empowers me to take timely decisions and resolve situations.”

A native of Chennai, Ranganathan is a bachelor. He enjoys reading books, gardening, and traveling.

“L&T HAS BEEN HAND-HOLDING ME IN MY CAREER.”

Srinivas Pabolu

Senior Construction Manager (MECH), M&M SBG

Srinivas Pabolu, Planning Manager at the JVML Ballari Projects (BF5 & SMS4) which is a part of the 18 million tonne expansion plan of the JSW-Vijayanagar works, mentions the commissioning of the Bokaro Caster project as one of the highpoints of his career. “I will always remember and cherish that occasion in my heart for it was achieved after years of hard work and struggle,” he says emotionally. “L&T has been handholding me in my professional career since I joined in June 2008 through various learning and development programmes like BIS & MEP. I reckon no other organization will do so much to invest in their people to be in sync with the latest technology trends and be prepared to take up higher positions in the corporate journey.” He leaves us in no doubt that he really loves the company he keeps.

At his present assignment, Srinivas’s primary motive is to delight his customer by completing the works as quickly as possible for which among several other initiatives, the team has formulated formats for cost monitoring on each head and agency wise & activity wise productivity monitoring. “Getting the data in real time helps us to take quick decisions,” he points out, “and is helping us to monitor productivity and resource utilization which in-turn helps us to take corrective actions whenever required. Initiatives like maximizing modularization and implementation of various mechanized solutions like automatic SAW Welding, Automatic FCAW for the first time have also added to our operational excellence efforts.”

That their efforts are being appreciated is reflected by the accolades they have won from the client and internally. “We achieved the milestone of pouring 1.5 lakh cum of concrete in 10 months (August 2021 – May 2022) and received an Excellent Customer Satisfaction Report for the July 2021 to June 2022 period,” Srinivas flags off proudly. In the same vein, he adds that their site has clocked 7.22 safe million-man hours for the period April 2021 to June 2022 and was recognized as the most ‘Digitally Enabled Site’ in 2021.

Srinivas is at his 4th project with L&T and attributes much of his success to his seniors. “They have always encouraged and supported me with their valuable inputs and by sharing their experiences. My team members have always supported me. We work together for a common goal which is beneficial both for the project and for the organization,” he says with conviction.

On his personal front, Srinivas hails from Parchur in the Bapatla district of Andhra Pradesh and his better half is Saveri, a homemaker. “I like playing chess and watching movies,” he says with a smile, “but travelling to different places along with family and spending time with my loved ones is what I love.”

AWARDS ARE THE TRUE

REFLECTION OF HIS SUCCESS

Biswajit Dey

Senior Manager (EHS), M&M SBG

For Biswajit Dey, presently Project EHS Head for the Steel Melt Expansion Project for Tata Steel Ltd., Kalinganagar, his EHS awards are a measure of his success. RoSPA Golds for the Bakreswar Thermal Power Plant project in 2009, the Dhamra Port project in 2010, and the Haldia Refinery project in 2019 are in addition to the Golden Safety Awards he has won from the National Safety Council of India for the Bakreswar Thermal Power Plant and the Dhamra Port projects in 2007 & 2011 respectively. “I am a firm believer of innovative practices yet give due respect to existing standard practices, a habit that has earned me the ‘Best Safety Professional & Implementer’ Award from Tata Steel in July 2022,” he says proudly, citing it as an example of client delight.

A construction veteran, having joined L&T on April 1st, 2006, and into his 11th project, Biswajit has witnessed a perceptible shift towards digitalization in EHS management, right from signing permits to logging observations and safety training. Online permit systems, the Safety App, the Shield App, WISA, RAPL platform for training are some digital solutions adopted at site. “Working inside operational plants calls for proactive measures and real time monitoring is essential for brownfield projects,” he says, his experience speaking. “I have adopted several digital initiatives like CCTV monitoring, frequent SOSC observations and online permit system to mitigate risks.”

Like all good EHS professionals, Biswajit realizes that an EHS system is only as strong as its weakest link – the workman. “I am very particular about the behavioural aspects of workmen towards safety. I have revealed a comprehensive package like conducting theme-based monthly safety programs, on job training modules, motivational programs and the like to drive EHS awareness and adoption by workmen.” He is also aware that EHS is not a one-man’s job and readily acknowledges the support and cooperation from all around. “All my seniors are very supportive of my initiatives and are happier than me when I am appreciated either by the client or our management,” he smiles delightedly.

Hailing from Berhampore, West Bengal, one is hardly surprised that Biswajit’s passions are listening to music and playing soccer. He is married to Mithu, whom he describes as “a homemaker and a big support for me in all my endeavours.” They are blessed with two children: daughter, Rajlakshmi and son, Aharsi. A personal high for Biswajit was being a Guard of Honour to the Prime Minister of India at the Annual NCC Republic Day Camp, New Delhi while professionally, it was receiving an appreciation letter on EHS from Mr. K. V. Rangaswami (L&T Board of Director & President – Projects) for Best Safety Performance at project site as per an Audit Report 2006 -2007 at Chennai.

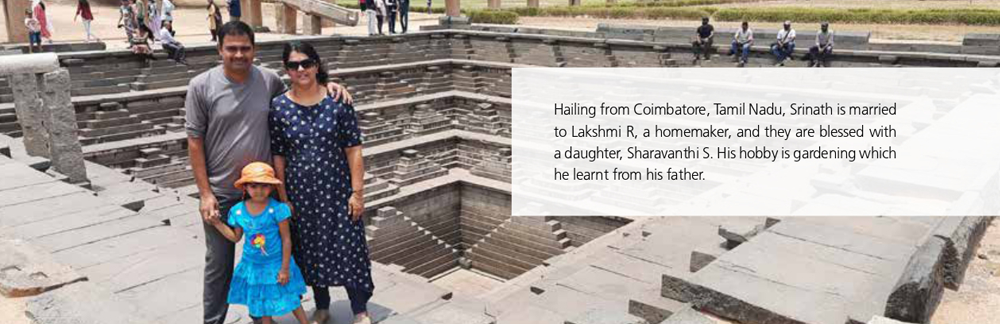

“L&T empowers and equips young engineers to make world class projects and landmarks,” declares C Srinath, adding that it is a matter of great personal pride to share and explain about these projects to family and friends. As Scheduling and Customer Relationship Manager at the JVML Ballari BF5 and SMS projects, he has another opportunity at nation-building, building from scratch to set a global benchmark by completing the job in record time. “We are on a non-stop drive to ensure progress every day and even if we encounter multiple critical paths on the way, we cannot afford to slacken in the major areas if we are to deliver as committed,” he says with a strong sense of purpose.

“We are executing high volume jobs,” he says, reeling off some numbers: 3.5 lakh cum concreting, 1.3 lakh MT of structural supply and erection, 45000 MT of equipment installation and 14 Lakh piping along with electrical and instrumentation jobs. “We have built this project from scratch including the labour camp, site facilities and fabrication yard,” he points out, adding that they are in constant need of more stakeholders like fabricators, suppliers and sub-contractors. “Even though the second pandemic wave and the spike in steel prices affected engineering and supply progress, the team has been putting in their best efforts to complete the project as per the client’s stipulation,” he says tightly.

“Our client has been very appreciative of our rate of progress,” he says with deep satisfaction and perhaps one of the reasons for their speedy progress has been the adoption of several digital solutions like WRENCH EDMS for documentation, EPC Proman for fabrication and continuous monitoring of project with primavera updates. “These have helped in in-depth project monitoring starting from engineering, supply of fabricated structures and project installation including civil works. We alert our individual stakeholders too about deviations so that actions can be taken swiftly,” he shares. “In fact, the JVML project team, including the Project Director and Project Managers are very supportive of our new initiatives like daily progress updates with Chatbot, etc.”

Srinath attributes his success to the experience he has gained at L&T that he joined in July 2009, and the opportunity to work on several flagship projects including Bhushan Steel SMS2 as Site Engineer, Bhushan Steel BF2 as Planning Engineer, MIS & Operations Excellence Co-ordinator – Kolkata Cluster, Project Co-ordinator – erstwhile Ferrous Business unit, Planning Manager – Rourkela Hot Strip Mill project, Senior Manager, Scheduling and Monitoring – presently at JVML Ballari.

At his 1.5 MTPA Expansion of Coke Oven Complex (Phase II) project for Tata Steel at Kalinga Nagar, Odisha, Subhasish Sarkar’s attention is focused on how to control costs to maintain project profitability. “In the present unavoidable volatile global market, it is critical to control the cost of raw steel, consumables and other high value items within our targeted budget,” he says with due seriousness, “for which we need to keep feeding the sequential fabricated structures to meet unit wise completion targets.” He adds that it is equally important to control overheads and P&M costs especially in view of the initial delays to release deliverables like work fronts and free issue items from the customer. “Yet,” he nods, “project progress and success lie in meeting customer expectations to match project delivery schedule.”

Having understood the lay of the land and the challenges involved, Subhasish and his team went about their mitigatory measures that included quick mobilization of workmen & P&M to commence execution and meticulous micro planning & review with the execution team to ensure timely proactive action. “We continuously coordinate with all our key stakeholders like the customer, vendors and sub-contractors to ensure steady progress.”

“We have completed and handed over the structural erection works within the stipulated time to the customer,” he shares confidently. “Our client is delighted and has appreciated us for timely completion of the job which was in the critical path of the entire Coke Oven project.” Good work is often rewarded and Subhasish is delighted that L&T has won another project from Tata Steel to execute a critical structure (TOPR – 3B battery) after another agency had failed.

Considering the huge volume and complexity of bricks involved (17.5 lakh bricks of 783 different types), the team decided to digitalize material management for seamless execution and are using QR codes on the various types of bricks & mortar and for record & reconciliation, and EPC Proman for entry and issue of materials. “These initiatives ensure smooth progress of refractory works to achieve progress as planned,” says a determined Subhasish, who acknowledges the teamwork at site. “We work as a team; my seniors always guide me, and my Project Manager always supports me to handle any tough or pressure situations in my own way that pushes my performance even higher which hit a high when I received a ‘PRAISE’ award early in my career,” he shares proudly.

Hailing from Balurghat, South Dinajpur district in West Bengal, Subhasish is married to Pubali, a homemaker, and they are blessed with a daughter, Soumili, who’s birth has been his life’s most cherished moment. “I love watching movies, listening to music and spending quality time with my family and friends,” he says happily.

Having started his association with L&T on January 1st , 2014, Pradeep Dash has a good run and is onto his 5th assignment at the 1.5 MTPA Coke Oven Ph-II Project at Tata Steel in Kalinga Nagar. His previous stints were at the 7.0MTPA SAIL Bhilai Steel Plant Expansion Project (BF-8 & SP-II), the 3.0MTPA Steel Plant at Tata Steel Kalinga Nagar PH-I Project, the 3.0MTPA New Hot Strip Mill, Sail Rourkela Steel Plant and the 0.5MTPA Utkal Alumina Refinery Project, Rayagada. “What impresses me about L&T is the passion for work, the guidance from the seniors always encouraging me to do my best to achieve the goal and the freedom to handle any challenging situation that always drives me to move forward,” he shares with a positive air about him. “Apart from that, I love the culture and the systems at L&T,” he adds.

Life is never easy for a construction professional, and Pradeep lists his issues at site very matter-of-factly. “The first is to feed the structural materials in line with our erection targets according to the availability of work fronts at site, then to arrange matching steels to complete the fabrication of priority items, to increase suppliers’ production to meet the project sales targets and resolve dimensional discrepancies in drawing, that threaten to hamper the progress of fabrication and erection.”

Pradeep is ready with his mitigation measures too. “We do micro level follow-up, day to day planning, monitoring and tracking of erectable materials, follow up with steel manufactures like SAIL, JINDAL, RINL, Tata and other traders, monitor daily progress and coordinate with the concerned teams to resolve the issues faced by the vendor during the course of fabrication and, most importantly, coordinate with the client’s and our design teams to resolve technical issues faced during execution on priority to expedite progress.” He mentions the WRENCH & EPC Proman digital platforms that help the team to monitor supply vs erection progress and material identification during the course of project execution.

His focus on project progress is unwavering and is perhaps the single, most critical contributor to his success. Proper monitoring, tracking of supply materials to support the site to expedite erection to meet the project schedule and requirements is, according to him, key to winning the client’s confidence and trust. “Equally important is coordination with the client as well as with other stakeholders to resolve the issues at site,” he reminds.

Hailing from Bhadrak, Odisha, Pradeep is married to Jyotsna Rani Patri, a homemaker, and they are blessed with a son, Rudra Narayan, who’s birth is his life’s most precious moment. When free, he watches TV or takes long drives.

EVOLVING AS A PROFESSIONAL.

THANKS TO L&T!

Shubhranshu Mohapatra

Assistant Construction Manager (ELECT), M&M SBG

A GET of batch 2017, Shubhranshu Mohapatra’s rapid growth as a construction professional has been thanks to his opportunity to work on a series of complex projects starting with the construction of a basic oxygen furnace at the Bokaro Steel Plant for SAIL. “Being an EPC Project, I was exposed to various facets of Project Life Cycle and Management,” he recalls. “Initially, in the planning department, I looked after work order management and subcontractor billing and thereafter assigned for E&I Site execution with end-to-end responsibility of Primary & Secondary Dedusting System along with Gas Recovery System works including both erection and commissioning. I was awarded an NMR for saving time and cost by modifying the control & instrumentation cable schedule,” he adds proudly.

Next, at the Single Strand Slab Caster project again at the Bokaro Steel Plant for SAIL, Shubhranshu successfully increased overall site productivity by restructuring worker gangs and at the JSW, Dolvi Coke Dry Quenching – 1, 2 & 3 project, he was involved to close the site, settle all pending invoices & additional claims pertaining to the E&I Works. “Presently, at the SMS-II Expansion Project for Tata Steel at Kalinganagar, I have end-to-end responsibility of MIS, scheduling works and implement Primavera 6 to track project deliverables,” he shares.

Challenges are part and parcel of projects and Shubhranshu has his fair share that he mitigates by preparing permanent shifting arrangements and planning activities well beforehand to reduce the lag time due to the space constraints of executing a brownfield project, extract details from the basic engineering drawings, and prepare JMRs and invoices ahead of time to mitigate payment delays. He well realizes that client is king. “We maintain a close relationship with our client, keeping them in the loop of our day-to-day activities that has helped a lot to achieve our goals,” he mentions. “We hold meetings with them to understand their basic needs and implement them to their satisfaction,” that has resulted in JSW, Dolvi awarding additional jobs to L&T even when executing the COB & CDQ project and throwing a celebratory party for its successful commissioning despite several challenges due to the pandemic. “They even recognized ours as the ‘Safest site to Work’ across all the working sites in India,” he says, his eyes alight.

“I have always received constant support and mentorship from my seniors who have empowered and guided me,” he says gratefully. “I always value my team members, treat them like family for it is only due to their constant support and motivation that I have accomplished so much.”

Still single, Shubhranshu shares about his family. “We are blessed with a nuclear family with my parents and 2 elder sisters, currently settled in Rourkela, Odisha.” He likes to write articles, read manga, play table tennis and badminton.

Young DET, Kriti Jaiswal, is a girl on a mission. “Personally, I feel that we should break the stereotypes around a female engineer and counter all the odds this generation holds that the construction industry is not for women,” she states with steely determination. But beneath this exterior, Kriti is still a youngster with stars in her eyes about joining the company of her dreams. “For me, joining L&T is a childhood dream come true. I can still feel the goosebumps wearing the L&T logo for the very first time and I distinctly remember the look of pride and happiness on the faces of my family. And then, the day when I met our CEO & MD, SNS, at our project site and his few words of encouragement to me personally left me awestruck. Those memories are still fresh in my mind.”

Hailing from Mirzapur, Uttar Pradesh, Kriti completed her H.S.E. at the Guru Nanak Girls Inter College and a Diploma in Mechanical Engineering from the IERT (Institute of Engineering & Rural Technology), Prayagraj before joining L&T. “I reported at the JVML Ballari project site on October 31st, 2021, along with two female DET colleagues, with plenty of curiosity, doubts and fears in my mind,” she recalls her baptism, which was indeed one of fire. “The project site, as expected, showed its rough and tough nature at the start that forced my two colleagues to quit but what kept me going and driving me forward was the constant guidance and support from my seniors, who are some of the best minds in the industry.”

Having survived the tough initial phase, Kriti started to settle down and through her first-year training programme, she understood a lot about project management, costing and people management. “My responsibilities at site include making timely payment to vendors, keeping workmen morale high to retain them as well as improving our productivity.” She is all praise for the collaborative and dynamic work culture and hands-on guidance that is empowering her to develop her technical and cognitive skills. “These are all helping give wings to my ambitions.”

Kriti’s family comprises her father, Sunil, an advocate, mother, Anita, a teacher, and younger brother, Dipesh, who is doing his graduation in arts. During her free time, she loves to read.