J. Shanmugam always experiences an electrifying feeling every time a line is charged. “In fact, it is not only a project milestone, in some cases, people’s lives are also transformed, and the joy of building corridors of power is the greatest satisfaction for me.”

Presently, at his 400 kV Kamudhi-Ottapidram-Udangudi Transmission Line project, he has lots of feel-good factors. “We stood with our workmen during the toughest phase and apart from work, each of us had a role to ensure their wellbeing. The initiative to make the workmen feel that they were in safe hands was at times bigger and more critical than the project itself involving a lot of administrative work, roping in external stake holders, the client and the local administrators who supported us in all our schemes.”

Implementing the digital planning tool – Bhodhi, at the right time was fortuitous for the team, he exclai“It gave us a much-needed insight about variances across zones, listing out the activities to target for acceleration with the add-on cost factors. We could predict productivity, timelines, and resourcing right up front. With a clear-cut vision, we knew where to accelerate and where to be careful as operations resumed,” reveals Shanmugam.

Before getting to ground level, Shanmugam was doing what he is good at, communicating with the various stake holders. “Initially we approached the client and briefed them on our SOPs and work methodologies, following which we connected with the district magistrate for work approvals and finally conducted meetings with our workmen and subcontractors on the safety measures implemented to commence works.” Shanmugam and his team had their hands full. “A large part of this communication was specific to the pandemic situation, something that none of us had experienced before and has been an invaluable learning for many of the younger members of the team on how to build external networking.”

On ground, timely improvisations were immensely successful. “Tower cranes used for erection at some critical sections helped us complete the works faster with minimum manpower. In some stretches, we engaged local labour for the first time that gave us excellent results.”

As Shanmugam closes in on another tower milestone, his thoughts race back to his wife, Anitha, based in Chennai. “Connecting with her at the end of a hard day’s work is my way of relaxing and of course, it is always an electrifying feeling,” he sums up on a joyful note.

A PENCHANT FOR CHASING MILESTONES

Surendra Cherkady

Assistant Construction Manager, Civil, PT&D

Ever since operations resumed, Surendra Cherkady has been successfully chasing milestones at his 400 kV Kamudhi- Ottapidram-Udangudi Transmission Line project. “At the time of unlocking, I was at my 7th project with around 95 percent of the works completed and within a month, the client punch points were worked out following which the line was charged. On July 18th, I was transferred to my present assignment with a whole lot of activities to be lined up as the span runs across three districts in Tamil Nadu.”

Tower erection works were his immediate priority. “With concentrated efforts, we managed to source around 6 gangs and commenced erection works across terrains that were the most challenging. As we got going, an additional 13 gangs were mobilized which enabled us to raise 92 towers in quick time involving around 1775 t of steel handling. This was followed by adding another 67 towers and before we knew it, 77 percent of tower erection works were completed in the KOTL section.”

Mapping each task with the respective gangs required minute detailing but the digital planning tool – Bhodhi helped to plan precisely. It also gave us insights to bridge the gaps while listing out the activities to target for acceleration.

Reflecting on the process, Surendra lists out some strenuous efforts that ensured safety and progress. “Overall, there are some 400 tower locations, and the plan was to safely address the logistics and work out an execution scheme in line with the SOPs. For instance, only 3 workmen could travel per vehicle. It meant that we had to make many trips to access remote work locations that called for a micro plan taking into consideration the time taken for travel and the planning of work schedules. Mapping each task with the respective gangs required minute detailing but the digital planning tool – Bhodhi helped to plan precisely. It also gave us insights to bridge the gaps while listing out the activities to target for acceleration.”

At work, Surendra adopted the 5S methodology to ensure quality and safety standards. “The 3Ws of wearing masks, washing hands, and watching the distance was our mantra for success,” he shares. “Sometimes working in remote locations is an advantage as we have less interface with the outside environment, we cook our own food in makeshift camps but in this situation, it has out worked out very well for us.”

Relaxation is always connecting with family, says Surendra, “My wife, Deepika, a homemaker and daughter, Spoorthi, based in my hometown, Udupi, keep enquiring about what is the new thing I have achieved at site and that is something which keeps me going for milestones.

MINDFULLY STEERING THE COURSE

S.S. Naresh

Senior Engineer, Electrical, PT&D IC

For S.S. Naresh, at the 400 kV Kamudhi-Ottapidram-Udangudi Transmission Line project, the rigors of resuming operations seem like a distant past now with many of the project milestones accomplished. “We planned, replanned and realigned according to the emerging external challenges for a range of tasks. For me, there was action on my personal side with my marriage getting fixed during this period. But then, mindfully, I planned and executed my marriage to perfection during this challenging phase making it a memorable occasion.”

Into his fifth project in L&T, Naresh is aware of the priorities in a long span transmission line project, “We have to earmark the sensitive zones along the alignment and plan execution as even a minor gap can affect the whole project. When operations resumed, we had a lot of ground to cover with the alignment spread across 139 Km covering 3 districts in Tamil Nadu involving the construction of two transmission lines with more than 400 tower locations. Our immediate task was to prioritise the work zones considering the variations in terrain and the logistic restrictions.”

Working with a government client has its advantages at times, smiles Naresh, “As we prepared to take up the works, our client helped us with special permissions and stepped in whenever we needed to interact with the local administrators. This cleared a lot of issues at the field level and provided us a platform to accomplish the milestones.” Two things were abundantly clear to the entire project team as Naresh shares. “To complete the L2 schedules involving tower erection and raise the invoice as per the plan to maintain a positive cashflow but we exceeded the scheduled targets.” The benefits were passed on to the subcontractors too he adds. “With their bills cleared without any delay, they were able to address labour issues and scale up productivity across work fronts.”

Thanks to our range of digital initiatives, life is becoming easier for professionals like me with more time to focus on the critical sections, to monitor while realtime updates are comprehensively covered and automated ensuring safety and quality across work locations.

Naresh points out that the way PT&D executes long span projects has changed radically over the past 2-3 years. “Thanks to our range of digital initiatives, life is becoming easier for professionals like me with more time to focus on the critical sections, to monitor while real-time updates are comprehensively covered and automated ensuring safety and quality across work locations.”

Hailing from Thanjavur in Tamil Nadu, Naresh has motivated his wife, Sangeetha, to complete her higher studies which she is pursuing earnestly. “Planning is always key for me both at work and life and as a morning person, however busy my schedule, I spend some time for my self-development which gives me the direction to steer forward with confidence.”

Sai Mourya is delighted with the opportunities he has enjoyed at L&T, an organization he joined as a GET. “I have played many roles including Management Information Systems, Project Controls, Tendering, Planning and Execution that have helped me see the big picture without losing attention to detail. I bet no other organization can provide such opportunities to employees to showcase their capabilities and explore themselves more and more,” he adds proudly.

He is currently working as approved Planning Manager for a project titled ‘Replacement of old & obsolete stations at the MAA Refinery (LE200347)’ for the Kuwait National Petroleum Company (KNPC). In his last assignment, as planning engineer, he had to supply and construct 22 132/11 kV stations. Here too, Sai has 22 substations to focus on. “Our only strategy was robust planning at the beginning of the project and sticking to it. We communicated our plan to our employees, our subcontractors and to their lower tiers as well right down to the foremen level at site.”

When work resumed, Sai was stuck at Mahboula (in Kuwait) which was still under lockdown and thus had to monitor progress, analyse status, and forecast completion remotely. “My other challenge, as planning engineer, was to arrange resources like manpower and material on time. Supply chain was entirely disrupted and several of our manpower had fled to their native countries, so it was very difficult to convince the subcontractors to deploy their full work force on our project alone.” Staying connected with the client was tough too to measure follow ups, submit invoices and for the certification process.

“The civil and electrical teams started to work in shifts to ensure limited manpower at site.” Daily progress was circulated to all the key members and intermediate milestone charts (station wise) were displayed on the notice board to boost positive competition among site engineers. “Even though the initiatives were general, the scale of implementation was very high which makes ours a unique achievement,” Sai remarks proudly, acknowledging the immense support from Country Head, Bharathi Kumar for all initiatives taken by the site team which motivated Sai and his team to contribute more to the project’s success.

Sai has happy news on his personal front as he has just been engaged and his wedding to Raaga Sruthi has been fixed for May 23rd. “Sruthi is working as a Software Engineer at Capgemini in Bengaluru,” he shares with a smile. “My hobby is to play badminton but after my transfer to Kuwait, I never get time to follow it,” he says, a little sadly. Sai hails from Kadapa in Andhra Pradesh and happily recalls his GET orientation training programme at LDA, Lonavala.

Praloy Roy

Manager (Accounts), PT&D IC

Ever since joining L&T in early 2010, Praloy Roy has been very busy having served at 10 PT&D sites for varying lengths of time as Manager Accounts & Administration before landing at the three PAHW projects in Kuwait. Nothing he had experienced in his 11-year-plus tenure with L&T could have prepared him for life with the pandemic. “We were supposed to keep the civil and electrical works going at all the 22 substations that had totally stopped during the lockdown but as soon as the unlock happened we were faced with a whole load of challenges,” he says. Reduced subcontractor labour force was the team’s primary issue for, as he remarks, “smooth progress at site is required to achieve the desired milestones.”

One of the team’s interesting ploys to tackle the situation was not to have any uniform timings for the civil activities. “This was as per the Client’s instructions,” mentions Praloy, “so sometimes, it was in the early morning hours, sometimes in the evenings or sometimes even at night at various substations on the same day. Our strategy was to go around with a vehicle to visualise the works and facilitate the arrangement for food and water for the workmen and staff for them to perform and push progress.”

Praloy and his team had weekly review meetings with their PM and Country Heads at site to monitor weekly progress and milestones to be achieved. “All our shortcomings were discussed along with how to overcome them, plan for the following week’s progress and line up any balance works that had to be covered,” he explains. “Our client was initially very reluctant to visit the site, but we convinced them of our safety protocols and finally they did come to monitor progress and sign the JMCs.” Praloy sounds pleased. All vendor discussions were in virtual mode. “We visited and inspected subcontractor camps to ensure that they were strictly following all the SOPs and even reported them for rectifications and improvements,” he infor

Other changes that Praloy initiated were to sterilize all physical documents, if any, before handing them over, otherwise all were scanned and sent for authentication and approvals. “All payments to vendors were through bank transfers, all interactions in the digital mode including training,” he shares.

“I love the sense of independence you experience at L&T,” he shares proudly, “the freedom to be innovative, create new things and take decisions to achieve your goal.”

IT HAS BEEN ONE HUGE TEST

Rajasekaran Sundaram

Assistant Manager, Electrical, PT&D IC

The pandemic has been a huge test for all and especially for Rajasekaran Sundaram, currently working as Testing and Commissioning (T&C) Co-ordinator for PAHW Project involving 22 Substations and the KOC Project covering another 3 Substations in Kuwait. Since April, although he was ready to go full steam, he had issues of “reduced working hours due to the curfew, less number of engineers coming for inspections from the Client due to the Kuwaiti Government regulations and the lack of L&T’s testing engineers as issue of visas had been closed,” he shares.

Realizing that he had to keep pushing on, Rajasekaran and his team quickly prioritized the T&C activities system wise into LVAC / DC Systems, 11kV Systems, 132kV Systems and Transformers. “Based on this priority list, we completed the installation & cable termination activities and the T&C activities in parallel,” he informs, adding that the same strategy has been followed in all the 22 substations.

Without changing the LOI of the sub-contractor, we increased the team size to get more manhours always keeping within a comfort zone that enabled us to complete the energization in a day thus making our company proud.

“At one of our KOC substations, we had a deadline to energize the station during this pandemic which was a big challenge due to the prevailing conditions,” Rajasekaran points out. “So, without changing the LOI of the sub-contractor, we increased the team size to get more manhours always keeping within a comfort zone that enabled us to complete the energization in a day thus making our company proud,” his shares excitedly. Another challenge was to ensure the ready availability of material, and to have them checked and certified. “If we found any item missing, we immediately alerted the vendor to supply the same without delay,” he says.

Rajasekaran attributes his success to a clear structure for the projects and staying focused to achieve progress. “My Project Manager helped me by clearing all the issues in my path from both the vendor’s and the client’s sides for me to progress ahead of schedule. My team members helped too in every way, putting in extra efforts,” he acknowledges.

Hailing from the village of Rasipuram in Tamil Nadu’s Namakkal district, Rajasekaran is married to Anupriya, a homemaker and they have two children, son, S R Deepak and daughter, S.R Nithya Shree. He reads in his spare time. “At one of my earlier projects,” he recalls with pleasure, “we completed a 132 kV GIS FAC works (shutdown) ahead of schedule that gave me a lot of satisfaction. Definitely, another special moment is marrying my life partner.”

“At L&T, we have unlimited growth opportunities,” he says proudly. “I have been given the opportunity to coordinate T&C activities of two projects thanks to which I have learnt many new things and handled different teams.”

Anandamoy Mandal

Construction Manager, PT&D IC

At a time when everyone is trying to balance several things in difficult times caused by the pandemic, it is great if help comes from an unexpected quarter. Anandamoy Mandal, at his Matang 275/132/33kV Substation project in Malaysia, has found his client, Sarawak Energy, extremely supportive and cooperative that has made his life and those of his team members a whole lot easier.

We have completed the erection of the gantry, beams, fly bus, lightning protection and 360 equipment structure erected at switchyard. We applied the same strategy for the electrical control building panels and completed their erection. Now, our client has the confidence that we can complete the project as per the Original Contract Date.

“Our client follows a practice that all civil foundation and ground works must first be completed inside the switchyard before moving for the electrical works like erection of structures, busbar equipment, and the like,” he explains. Considering the situation, they convinced the client to permit them to move as and when a front was available. “With this strategy, we have completed the erection of the gantry, beams, fly bus, lightning protection and 360 equipment structure erected at switchyard. We applied the same strategy for the electrical control building panels and completed their erection. Now, our client has the confidence that we can complete the project as per the Original Contract Date,” he smiles confidently. Another area where client support has been most welcome is their acceptance to conduct remote FATs, their agreement to virtual online meetings and even remotely supervising and approving the Auto Transformer that has been a huge boon for the project.

Another group that Anandamoy and his team have been trying to convince is the workmen. “After the lockdown in March, they have been afraid to come to the site,” he says heavily. “It has been difficult to convince them to maintain social distancing and follow government approved SOPs, site progress has been slow because of that.”

However, the team could not afford to lose time or steam. “After the unlock, the civil piling works were delayed as civil foundations are not ready for the electrical works,” he points out. “Therefore, we increased the number of pilling rigs to complete the pilling to make the foundations ready quicker. We have since assembled and sub-assembled all 540 equipment structures and 45 gantry and associated beams to reduce time for erection.”

Anandamoy hails from Jamshedpur in Jharkhand, is married to Nandita, a homemaker, and they are blessed with two daughters, Saina and Lisa. His favourite pastimes are listening to music and taking morning walks and some of his best memories are of train journeys he has taken, watching the world go by sitting at the window.

Ajay Dhiman

Senior Engineer (ELEC), PT&D IC

Perhaps because he hails from Krurkshetra, Haryana, Ajay Dhiman and his team have been on a war footing to complete their milestones at Malaysia’s Matang 275/132/33 kV Substation project despite the several challenges caused by the pandemic. “We started to think of our strategy right from the initial stages of the lockdown as we foresaw its adverse effect and prepared a micro level plan for all activities with the only aim to complete the project on time as per our original contract,” he explains their approach to face a situation that he describes was tough and shocking. “It was like a war and we did not want to leave it for a single day,” he exudes vigour. “Even our productive working time increased from 8 to 12 hours.”

Their immediate milestones after resumption were clear. “Readiness of the control building was our top priority for the panel erection,” he points out, “as also were the readiness of small equipment foundation to install the small steel structure and of the cable trenches.” Workforce was a major issue as most skilled workmen are from outside Malaysia who could not be sourced due to the travel restrictions. To manage the scarcity of foreign workmen, they engaged the local subcontractor for the erection activities. Resource management for the electrical works and availability of fronts were also issues. “As our project was in progress, the restriction of travel for FAT for equipment was a huge setback so we requested our client for remote FAT inspections and they agreed,” he smiles.

“At Matang, I am a planning engineer cum project schedule cum digital officer,” shares Ajay, “so it was my responsibility to run the Primavera P6 programme to monitor progress and Align to monitor daily progress in real time.” Drones captured work completed for management reviews while CCTV cameras were installed at major locations at site to check on material and COVID-19 follow- ups.

Ajay is extremely happy for their client’s support in terms of invoicing, payments, and appreciation. “They now trust us fully,” he declares, adding that the vendors did their bit too by delivering material in time such as Transformers and EHV cables.

Although still single, Ajay has had a long relationship with L&T since 2009 beginning with the 220 kV GIS Substation project in Ridge Valley, News Delhi, the inauguration, and commissioning of which is one his life’s most cherished moments. Ajay’s involvement across several projects has showed him that, “L&T empowers you to take decisions for the good progress of a project and encourages you to give off your best,” he observes proudly.

“I like to write poems and learn local languages,” he smiles, signing off on a personal note.

DOING THE BEST IN A TOUGH SITUATION

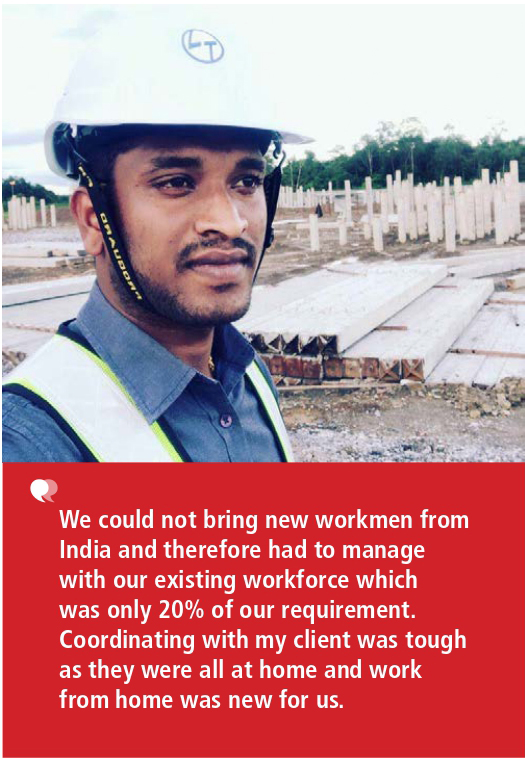

Ranjith Kumar R

Executive (Accounts), PT&D IC

At his Matang 275/132/33 kV Substation project, Sarawak in Malaysia, as Project Accountant & Admin In-charge, Ranjith Kumar’s responsibilities involve coordinating with all the Sarawak project PEs for invoicing, collections, follow ups, handling all Sarawak staff and workmen Visa, CIDB, License and other statutory requirements and administrating the Area Office. Once the pandemic broke, Ranjith’s areas saw the most disruption. “We could not bring new workmen from India and therefore had to manage with our existing workforce which was only 20% of our requirement,” he says. “Coordinating with my client was tough as they were all at home and work from home was new for us.” It was a struggle to get material at sites and the project team was under pressure to control the overheads that were shooting up due to the pandemic expenses with zero progress invoicing at site.

Despite all these challenges, Ranjith is glad that he and his team overcome all of them. Labour and material were mobilized in time by developing local staff in various departments. “We crossed our collection target of year 20-21,” he says triumphantly and a personal victory for him was, as he says, “all the statutory requirements like Visa, CIDB, BG, Insurance, Licenses were procured in time thanks to our well-established relationships.”

The team realized that it was equally important to keep the workforce motivated and well provided for. “To improve their productivity, we planned for the basic requirements of consumables, tools and safety items well ahead of time,” informs Ranjith. “We conducted weekly review meetings to plan for every project requirement.” Digitalization has helped the team enormously too during these times. “All vehicles are tracked with the GPS fitted to them,” he ticks off. “We have implemented solar lights, solar CCTVs to save on power consumption, drone photographs track progress and Bluetooth is used for effective communication at heights.” All their material requirements, statutory, admin and store related are entered in excel, weekly discussed, and frequently physically verified.

“There are several of memorable moments,” he smiles, “but in L&T, the commissioning of our Samalaju project was a really memorable moment. I was even appreciated for my contribution,” he signs off happily.

WINNING THE RACE WITH AN INCREDIBLE TEAM

Mohammad Parwez Alam

Construction Manager (Civil), PT&D

In his very first project with L&T, Mohammed Parwez Alam has defied odds, faced challenges head on and worked out multiple strategies to achieve a range of milestones at the 400/220/232/33kV Substation Mawana, Botswana

It was like landing into a no man’s zone, recalls Parwez. “There were hardly support establishments and it dawned on me that this was going to a long and arduous job. Added to that, we had the pandemic situation emerging, making things even more difficult.” Thankfully, Parwez had some excellent team members for company. “We had a mix of experience and youth, giving us the edge that helped me settle down quickly. One of our constant threats was from wild elephants, a totally new experience for me and a great learning on how to resolve such issues.” After much brainstorming, the team decided to go for the IP65 make floodlights as a deterrent system. “It worked very well,” he says, “and convinced the local administrators how sensitively we handle issues.”

For mobilisation, the team had to depend on unskilled local labour who were only familiar with the basic tasks like soil excavation and bush clearing. “Initially we faced a lot of challenges while doing shuttering and foundation works but our continuous training initiatives helped to bridge the gap with 246 workmen oriented through skill-based training,” he inforFor Parwez, training workmen has been a very fulfilling experience. “I have conducted more than 13 training programmes on different construction activities and the results are there for all to see as we have consistently improved the productivity in line with our quality and safety standards.” This has elicited very positive feedback from the client who are impressed that the team both deployed the local workforce and improved their skillsets.

My responsibility was the critical works and monitoring daily progress plus a range of other tasks. I planned, motivated my team members, and distributed responsibilities according to an individual’s expertise across work fronts that worked well as we were able to achieve the various milestones.

On ground, Parwez was busy with some timely improvements in work strategies. “We listed out the various milestones and, based on the criticality, lined up the resources. Our plan was to keep the major tasks going as ultimately the interfaces needed to be synergized with the energization of the substation.” Parwez has enjoyed the power of teamwork that has helped to steer the course. “My responsibility was the critical works and monitoring daily progress plus a range of other tasks. I planned, motivated my team members, and distributed responsibilities according to an individual’s expertise across work fronts that worked well as we were able to achieve the various milestones.”

A recent visit to Bihar, his hometown, has given Parwez, muchneeded assurance. “It was a short trip, but I got to spend some memorable moments with my wife Nahid and my three sons, Aman, Adnan and Arhaan,” he recalls joyfully.

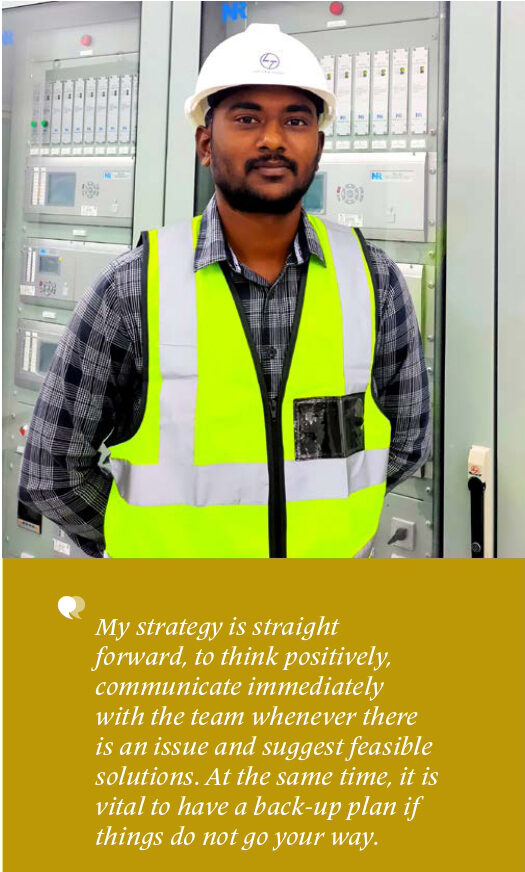

BANKING ON INHERENT STRENGTHS

V. Sundhara Raja Perumal

Senior Engineer, Electrical, PT&D

Escalating an issue is the last resort, according to V. Sundhara Raja Perumal for he believes that it is the responsibility of the concerned person to suggest a probable solution rather than wait for instructions from his/her superiors. “My strategy is straight forward, to think positively, communicate immediately with the team whenever there is an issue and suggest feasible solutions. At the same time, it is vital to have a back-up plan if things do not go your way,” he advocates.

At the Mawana 400/220/132/33/11kV substation project, Sundhara and team have set a benchmark. “With the OEM teams unavailable for testing and commissioning the circuit breakers, disconnectors, and transformers, it was clear that we would have to make do with the available resources to take up the critical works. We formed workmen teams based on their skill sets, deployed skilled workmen under one of our technical managers to do the disconnector and circuit breaker jobs while the rest took up the transformer works.” Having done the critical work, Sundhara worked out a schedule to bridge the two-month work lag, by preparing a tight schedule with two shifts at site during the testing phase. “As we were about to energize the substation, the client came up with a last-minute change to modify the complete auto change over scheme along with DC in LVAC board,” he shares.

All Sundhara required was a final thrust to energize the substation. “Guided by the Project Manager, we lined up the activities with a specific team taking charge of the works from 8 pm onwards. We worked all through the night and completed the task by 4 am as per the client’s requirements. A job of this kind that would normally have taken a minimum of 16 to 20 hours was accomplished in just 8 hours.” Obviously, the client was delighted and as Sundhara exclaims, “They acknowledged our stupendous efforts and cleared the commissioning of the substation on the same day.”

Though it has been close to 9 years since Sundhara joined L&T, he still recalls the day he received his call letter. “It was one of my most memorable days and for my parents as well as I got the call from HQ after a long wait of 3 months. L&T was my dream company, and the journey so far has been enriching as I have evolved from a DET to a professional all thanks to the guidance of my seniors at work.”

SEIZING THE MOMENT IS THE KEY

Toufik Karim

Construction Manager, Civil, PT&D

For Toufik Karim, completing the 220/33 kV GIS project, Ranchi, is one more powerful milestone achieved in his list of substation projects. “I’m fortunate to have been part of some prestigious projects over the last few years including the 1200 kV Bina and the 765 kV substation projects. Certainly, building India’s tallest super substation was the most challenging of all the assignments, more so considering the pandemic situation and the fact that we delivered the project ahead of schedule, makes this a special achievement for all of us at the project.”

For me, just being a part of such a big organization and being valued for contributions, opinions and suggestions is what makes me proud.

Toufik attributes their success in large measure to the wonderful organization he is a part of. “It’s not easy for someone to identify a single aspect about L&T which makes him/her proud. For me, just being a part of such a big organization and being valued for contributions, opinions and suggestions is what makes me proud.” At Ranchi, Toufik and team had the onus of closing in on some major civil tasks. “Concreting the GIS building raft was completed in a single pour involving 707 cum which is by far the biggest pour in PT&D,” he highlights. “It required detailed pre-planning including round the clock quality checks at the batching plants, production and execution monitoring across the day and night shifts that spanned 3 days.”

Every time we raise the bar, there is collective surge in our progress, reveals Toufik. “Ultimately, to ride over challenges, we must seize the moment. Our disadvantage of working in confined spaces suddenly became a plus as we were able to take up tasks even during the restrictions with the client’s support and set the platform to accelerate when operations resumed.” Converting adversities into opportunities also gave them the edge. “Initiatives like deploying a tower crane for civil works is not something commonly seen at PT&D projects. Innovations in basement wall casting, staging scheme and slab works gave us the much-needed thrust to close in on the milestones and timely handover the project,” says Toufik with a triumphant grin.

Acknowledging that his scope of work at site demands a lot of time, Toufik, balances between his hobbies of reading books, writing blogs, and connecting with his family that includes his wife, Subreen Nahar, a home maker, and daughter, Aleena, who are with him at the site location.

Gopal Jee

Planning Engineer, PT&D

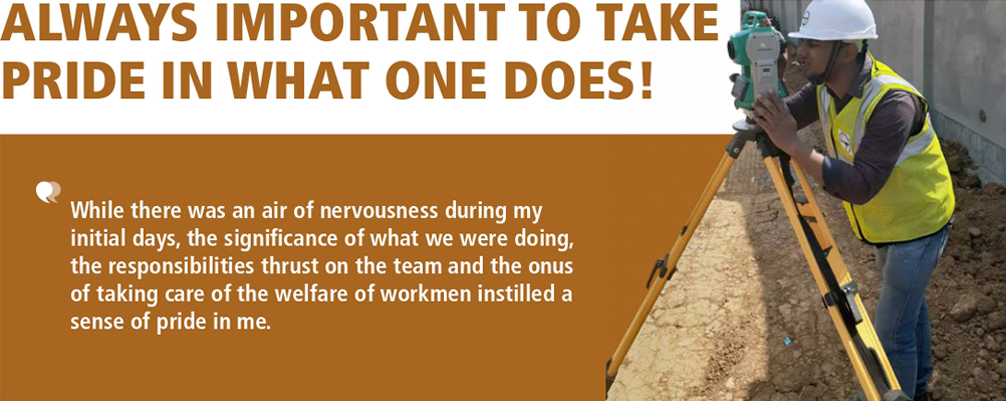

It is Gopal Jee’s first project with L&T but his transition from a GET to a planning engineer at the 220/33 kV GIS in Ranchi has been quick and eventful. “There was very little time to settle down due to the pandemic situation and before I knew I was part of many on-ground initiatives at site. While there was an air of nervousness during my initial days, the significance of what we were doing, the responsibilities thrust on the team and the onus of taking care of the welfare of workmen instilled a sense of pride in me.”

Undoubtedly, it has been a challenging start to his career. “The learnings are immense,” he says, “and of course, the one thing I love most about this organization is that every suggestion is heard irrespective of one’s position which gives courage for people like me to speak out and confidently carry out the several welfare measures at site, implement SOPs and network with external stakeholders for approvals.”

Having already developed a very good relationship with his client, Gopal handles most of the interfacing. “I have ensured that all the client’s guidelines are strictly followed, have motivated our workmen and gained their confidence which has improved productivity. I have also formulated a micro monitoring plan to push progress across fronts.”

There was a lot of catching up to do for Gopal and team when operations resumed. “Working in shifts with more night shifts was an excellent alternative during this time,” he remarks, “that was adapted to the maximum extent to achieve our target within the timeline.” Gopal attributes his success to the support from this seniors and colleagues at site. “They supported and empowered me to make strategic decisions which brought in a sense of ownership in all the tasks that I undertook.” Like all youngsters, Gopal has a leaning towards digital applications and makes good use of the in-house apps, “Most of our audits, inspections and interfaces are through digital tools and the real-time updates are shared through the N-Pulse App. Our client has also acknowledged our efforts,” adds a pleased Gopal.

Apart from work, Gopal pursues many interesting hobbies. “I like all forms of music; compose couplets and poems and I do a bit of origami crafting for which I hold a Guinness record for engaging maximum people in origami architecture.” There is a lot to look forward for this young man from Patna who has made a mark at his first assignment.

The feat of delivering India’s tallest substation has not yet sunk in for M. Manikandan, at the 220/33 kV GIS project, Ranchi. “We have achieved the impossible by delivering a six storied super substation ahead of schedule during the most challenging times. Personally, this is a big achievement for me. The civil portion in most PT&D projects is limited but here we had to complete the critical slab shuttering works for the 32 m high substation.”

Thankfully for Manikandan, not all doors were shut when the restrictions were imposed. “Working in a confined space is always a challenge but, in this situation, it worked to our advantage as the zone was secured with almost no external interference and all we had to do was to line up some of the feasible tasks with the client’s permission.” This, in a way, kept up the momentum for Manikandan and, “helped to plan for the bigger tasks ahead when operations resumed fully.”

His foremost challenge was to plan the staging works for the huge GIS hall, the key for raising the superstructure in quick time. “We deployed 3 separate gangs with 10 workmen, oriented them to the tasks and monitored their activities to meet our quality and safety standards.” To execute the slab works in the superstructure, Manikandan banked on L&T’s in-house formwork system. “We deployed a mix of both flex and heavy-duty tower systems which enabled the site team to work on multiple slabs that hastened completion.” Manikandan is delighted to have been part of perhaps the largest concrete pour for a substation in the history of PT&D. “We achieved a single pour of 707 cum with the entire activity planned to perfection over 3 days involving two concrete pumps, 12 transit mixers, 70 workmen and of course, the entire site team.”

Executing milestones is what thrills Manikandan. “Every time we face a challenge there is a solution and at projects, the experience gained is an invaluable learning that prepares one better for the next mission. My rich experience in industrial electrification, rural electrification, smart infrastructure and an overseas assignment at the historic Kensington stadium in Barbados is helping me enormously to handle such fast-track jobs.”

Manikandan always finds time to read the ‘Bhagavad Gita’ sharing effusively that “it is a book of life that directs me to make the right choices.” He credits his wife, Priyadarshani, for taking care of his two daughters, Aradhana and Ashvandhana in his hometown Nagapattinnam in Tamil Nadu.

STRIVING FOR QUALITY IN ALL THAT HE DOES

R Raghavendra

Assistant Construction Manager (Civil),

PT&D IC

R Raghavendra’s career journey resembles a Bharat darshan having started in 2007 at a project in Haryana, followed by a couple in Uttar Pradesh, then a couple in Punjab, then in Madhya Pradesh, back to UP and finally to Maharashtra after which he left Indian shores. Presently, at the 500/230kV Surat Thani Substation (GIS) project in Thailand, he is striving to bring quality into all that he does though, as he agrees, the going has been tough because of the pandemic.

Progress is dependent on a healthy and productive workforce and Raghavendra’s initial focus was to mobilize migrant workmen. “Though there were restrictions of workmen coming from Myanmar, Laos, and Cambodia and on interprovince travel, we completed the paper works for all of them and shared with the Department of Disease Control and the provincial health office to mobilize labour,” he inforAlthough there were weekly inspections by the Thailand government disease control officers, provincial health control officers, employee welfare officers, people from the immigration bureau office and local police officers, the team was able to address all their concerns, provide all the relevant documents for project work to progress smoothly.

After bringing them on board, Raghavendra and his team identified the skilled and more efficient workmen, divided them into different groups, allocated them different works to achieve targets in a defined time frame. “We allocated our resources based on the quantity and priority of the works and prepared micro schedule planning to work across various fronts,” he points out. They regularly compared daily work progress to the project base schedule, analysed daily productivity with respect to the project’s asking versus strike rates, identified site issues and did their best to resolve them. “We also followed up daily with our vendors and suppliers to ensure that material was delivered in time,” he adds.

Raghavendra is happy with their effort. “We generated 25% of invoicing despite all the restrictions and the team managed to certify 26 mn worth of variations that were approved by the client,” acknowledging at the same time the support of his senior management to achieve their targets.

Hailing from Bengaluru in Karnataka, Raghavendra’s life partner is Archana, a homemaker. Predictably, one of his hobbies is to explore new places. “I also like playing snooker and bike riding,” adding that one of his most memorable moments was an experience at the Pangong Lake in Ladakh.

“I am always striving to meet quality standards by using modern construction techniques and developing my skill without compromising on safety, and L&T has always given the freedom to explore, learn and innovate,” he rounds off positively.

“L&T HAS OPENED A NEW WORLD FOR ME!”

Patcharee Kumkrua

Senior Engineer (Civil), PT&D IC

At his first project with L&T at the 500/230 kV Surat Thani 2 GIS Substation in Thailand, Patcharee Kumkrua is in awe of the company he is a part of. “L&T has opened a new world for me,” he says, “and I have learned things here that I never would have. I am working happily with good, supportive colleagues. I love this organization and will always give my best to achieve the best results. I was born to a small family in the Bueng Kan province in the north-eastern part of Thailand and all my parents could afford was to give me a good education,” he recalls, nostalgically.

Patcharee has learnt well because he is playing a key role at his site as the project team tries to overcome the challenges posed by the pandemic. “Our biggest problem was that we have a large number of people working together so it was difficult to stay safe and keep others around you safe,” he points out. “For progress, we ranked and planned our priorities for each task, regularly followed up with our various stakeholders and then executed the work. We ensured that for every task, we planned together, followed up closely to monitor progress and solved problems together by doing root cause analysis,” he says saluting the merit of teamwork. On the digital front, he mentions the use of drone photography to track project progress.

Every problem that cropped up, whether due to design or work-related, was immediately addressed and resolved as the team was focused on getting the job done in time.

Like Patcharee’s colleagues across the world, he and his team also had to make their workmen aware of COVID-19 and the various precautions they had to follow both at the workplace and in public areas. “We kept them informed of all the official announcements by the Thailand government too to avoid mistakes and thereby avoid unwanted delays at site due to any situation,” he shares.

Still single, Patachree’s parents are Tassapon Kumkrua and Amr Kumkrua and he has two sisters, one elder and one younger. “I love to read, listen to music and eat delicious food in my pastime,” he laughs. His graduation day has been his most special day, “because that was the day when my parents smiled the most,” he shares with feeling.

Young Anil Tomar, from L&T’s GET Batch of 2015, is building a track record for himself by winning the organization’s awards for Timely Completion. “I won it for my first overseas project, the 132/33 kV Saada substation project (GIS) and won it again for the 400/132 kV substation (GIS) project, both in Oman,” he shares, visibly proud of his achievement. At his present assignment, the 500/230 kV Surat Thani 2 substation (GIS) project in Thailand, Anil is responsible to install and test two major electrical equipment: 20 bays of the 500 kV GIS and 12 bays of the 230 kV GIS along with associated electrical equipment and MEP Works.

The pandemic threw Anil’s life out of gear, leaving him with a major headache as to how to install the electrical equipment without an OEM supervisor as all international flights from and to Thailand were grounded. “During my brainstorming, I got the idea to kickstart the 500kV -20 Bays GIS installation with remote supervision from South Korea with the help of digital tools,” he shares excitedly. His idea worked and the team successfully completed the installation. To address another challenge, he says, “I planned the import of high voltage test kits from South Korea in advance, considering the long national holidays in Thailand and received delivery for the first time in our Thailand operations.”

About his style of working, Anil says, “I always adopt new, normal ideas to do tasks as per the local environment. Every project is different, and we have accelerated various works by taking the appropriate steps in the correct direction as required for each task.” Even in this digital world, Anil keeps a personal diary to make personal notes. “I keep track of my deliverables and follow up till the task is completed or even develop mitigating steps in advance for low, high or medium risks.” But that does not mean that Anil is averse to digital tools for he mentions many being used at his site. “Apart from remote supervision, we use construction time lapse cameras, drone supervision, virtual meetings. Without digital technology, it would never have been possible to kickstart the 500kV GIS -20 Bay installation without OEM Supervisors from Hyundai South Korea,” he reiterates.

Still single, Anil hails from Aligarh in Uttar Pradesh and has several interesting hobbies that include travelling, exploring new places, movies, good food and doing the gym. He mentions his four years of hostel life at NIT, Bhopal, and a visit to Georgia’s Tbilisi City as his life’s memorable moments.

What he finds special about L&T is that “any employee can perform, deliver and reach up to CEO level even from a GET which is unique as compared to other MNCs in India and around the world,” he signs off.

FOCUSED TO KEEP HER COLLEAGUES SAFE

Thanyalak Thongkhong

Officer -EHS, PT&D IC

At her two sites, the 500/230 kV Surat Thani 2 substation (GIS) and the 230 kV Thung Song substation improvement project that Thanyalak Thongkhong oversees as Safety Officer, she is focused to keep her colleagues safe. “I have a clear work goal and keep a performance scorecard,” she says, “that clearly defines what we have to do, what the supervisor has to do, what are the expectations both in terms of results and quality of work. I strictly plan our operations and follow that plan, setting priorities of a job based on its urgency. I set my goals for any event, identify the risks that could prevent the goal from being achieved, assess its likelihood, impact, and severity of the upcoming event and make plans to deal with the risks and those that might arise in future.” Her approach is very precise and methodical.

Thanyalak keeps herself informed of all the relevant job-related information by meeting supervisors and those involved in the work process. “This helps me to work quickly, accurately and deliver on time,” she smiles, adding that it also helps to remove bottlenecks and push progress.

A typical day’s work for Thanyalak involves ensuring that all the people in her project sites are safe and following all the COVID-19 safety protocols. “I have the additional responsibility to visit the Ministry of Labour office to check for new rules for construction sites to inform, implement, and follow which is very important during this nCOVID-19 situation,” she points out.

Safety is a shared response and Thanyalak is aware that her success depends on building a strong team. “Teamwork must have a competent leader,” she says, “so that there is mutual acceptance and respect for each other to create a good atmosphere to work together.”

Her first assignment with L&T has been a new, at times, unnerving experience for her. “I am Thai, I speak Thai and very little English, but I am very fortunate that L&T is allowing me to share new experiences such as culture, living, food and my fear of using the English language,” she laughs nervously. “But my team members have been very helpful both in matters of work and cultural exchange,” she adds gratefully

I am proud of L&T for having given a foreigner like me with only three years of work experience the opportunity to participate in this project, to learn and work on new technologies and consider Safety the Number One priority.

Born in Thailand’s Phatthalung province, Thanyalak is from a small place “full of rice fields, farmers, nature and only one shopping mall,” she describes. “My father is a farmer too. My husband is Orachun Csewhakan and my daughter’s name is Thanchanok Csewhakan,” she shares, adding that her pastime is watching TV after work.

“I am proud of L&T for having given a foreigner like me with only three years of work experience the opportunity to participate in this project, to learn and work on new technologies and consider Safety the Number One priority,” she shares in awe.

REINFORCING BONDS OF TRUST

T. Karthicraja

Construction Manage, Electrical, PT&D

When working in foreign lands, success to a large extent depends on the strength of the team and PT&D’s Africa BU has successfully pooled together a strong core team resulting in several youngsters like T. Karthicraja confidently shouldering larger responsibilities at site. “I was part of the team that executed significant projects in upper East Africa like the 220 kV D/C Uganda-Kenya (Bujagali-Tororo) Interconnection Transmission Line, the 220 kV D/C Uganda-Rwanda (Mbarara-Mirama) Interconnection Transmission Line and the 500 kV HVDC Ethiopia-Kenya Interconnection Transmission Line. My present assignment, the 220 kV S/C Mororgoro-Dar es Salaam for the SGR Transmission line is another marathon project with many challenges that got further complicated with the pandemic situation,” he shares.

Of the total span of 161 km, Karthicraja, is in-charge of an 80 km stretch. “Right from the start, we faced issues like severe climatic conditions and torrential rains that completely submerged the work zones. Fortunately, every time there was a bottleneck, support came from the client that helped us work out alternative strategies.” One of the team’s primary concerns was to complete the foundations across the critical areas. “We encountered flooding near the banks of the Ruvu river and therefore convinced the client to go for a raft foundation scheme that securely mitigated the risks,” he flags off a minor triumph.

By deploying heavy duty cranes instead of the conventional scaffolding arrangement, Karthicraja effectively speeded up the works. “It facilitated seamless execution of the stringing works over the live power lines, reducing manpower and ensuring total safety.”

Our biggest victory was to make the workmen feel safe with our welfare measures and SOP implementations. Today, the client advocates our secure approach and have endorsed the online FAT programs which has ensured timely delivery of the inspected material at site and fast tracking of the project.

He is particularly pleased with the way the team has handled the COVID-19 crisis that has won them accolades from the client too. “Our biggest victory was to make the workmen feel safe with our welfare measures and SOP implementations. With our management’s support, we quickly arranged for PPE kits, sanitizers, face shields at various work locations to our front-line workers which boosted their morale. Today, the client advocates our secure approach and have endorsed the online FAT programs which has ensured timely delivery of the inspected material at site and fast tracking of the project.”

Having been in Africa for a while, Karthicraja has taken a liking for Tanzania. “The people are friendly, the climate good, but when working in the interior regions, connectivity is very poor,” he says a trifle sadly. “At the end of a hard day’s work, I try to return to the main area to connect and spend some quality time with my wife, Soundarya and daughters, Jai Nisha and Kaviya Sri who are based in Karaikudi, Tamil Nadu. However, when the network is down, there is always a game of cards with my colleagues,” he smiles, with a nonchalant shrug.

RAISING THE BAR ACROSS FRONTIERS

Eshan Mahesh Jain

Assistant Construction Manager, Civil, PT&D

Having worked at projects of scale across the Middle East and presently Africa, Eshan Mahesh Jain can claim to know a thing or two about handling international projects. He has worked at the 220 kV S/C SGR Dar es Salaam to Morogoro OHTL in Tanzania, 220 kV D/C Toshka-Wadi Halfa transmission line in Egypt, 220 kV D/C North Hurghada-El Qusair transmission line in Egypt, 115 kV D/C Turbah-TEG -Rania and 115 kV D/C Shedgum-Uthmaniyah in KSA. “Long span transmission line projects are always a challenge especially in Africa,” he remarks, “as alignments run across country borders and along vast stretches of arid lands and forests.”

Eshan began with ROW & bush clearances, and later when fronts were established, he took up foundation, erection, and stringing works though the challenges he faced were of a different nature. “We have a decent number of local workmen, but they panicked because of the pandemic,” he states, shaking his head. “It was tough to address the needs of workmen of various nationalities, but we successfully worked out a range of initiatives in line with our ESH measures, convincing them in the process that it was safer inside the camps than outside.”

We have achieved around 23% of progress between March and July 2020 and with some relaxations in the restrictions during the latter part of the year, we have successfully accelerated our pace of work banking largely on our digital applications.

Handling the 120+ km span of the project was no joke but as Eshan assures, they had a plan. “We handled each work zone as an independent site with specific teams deployed to orient workmen on the do’s and don’ts along with implementation of SOPs in line with the local laws.” The good work done by PT&D in Africa is reaping rewards, he mentions. “The client has supported our initiatives, coming forward on many occasions to help us address external issues like roping in the local administrators to facilitate the implementation of specific work protocols and safety measures.”

Thanks to their hard work, Eshan and team have made excellent progress. “We have achieved around 23% of progress between March and July 2020 and with some relaxations in the restrictions during the latter part of the year, we have successfully accelerated our pace of work banking largely on our digital applications.”

ON A POWERFUL MISSION

Karthikeyan Vellaisamy

Senior Engineer, Electrical, PT&D

Over the last 5 years, PT&D’S Africa BU has made commendable progress, executing several significant power transmission and distribution projects. A large part of this success is thanks to the efforts of resilient professionals like Karthikeyan Vellaisamy, who is presently involved in the construction of the 220 kV Transmission Line from Kinyerezi to Morogoro for SGR Phase-1. “This is my fourth assignment in Africa following the 330 kV transmission line from Mumbwa substation to the Kalumbina mines, the 400 kV transmission line from the Olkaria substation to the Lessos substation and the 400 kV Singida to Babati transmission line,” he shares.

The Standard Gauge Railway project in Tanzania is a landmark project. “It is a first-of-its-kind dedicated transmission line project which will provide uninterrupted power supply to the high-speed Standard Gauge Railway line,” high-lights Karthikeyan. “Our challenge was the span along with the scope involving the construction of a 220 kV single circuit transmission line on lattice towers, along with a single conductor and 48 fiber OPGW earth wire across 161 km.” When the pandemic broke, Karthikeyan and team were spread out across different fronts, “To address the situation, we divided the alignment into smaller zones with designated teams addressing specific tasks. The going was tough with restrictions and workmen wanting to go home.”

With their various welfare measures and SOP implementations, the team won the confidence of the workmen and convinced them that they were safer in the camps than outside. “This was a huge boost to our efforts,” points out Karthikeyan enthusiastically. “By creating ‘bubble groups’ for different groups of workmen based on their tasks and skillsets, we were able to monitor and restrict their movement between sites and camps while arranging the necessary work protocols.”

We relied on our in-house digital apps for tasks such as surveying, quality inspections and project monitoring which facilitated the 15 foundation, 18 erection and two stringing teams to look at the milestones from a common perspective. From March to July 2020, we made around 23% of progress and have upped the ante thereafter

Wherever possible, Karthikeyan took the help of digital interventions with the client endorsing their initiatives, “We relied on our in-house digital apps for tasks such as surveying, quality inspections and project monitoring which facilitated the 15 foundation, 18 erection and two stringing teams to look at the milestones from a common perspective. We identified lag areas and jointly addressed the criticalities to achieve the overall milestones. From March to July 2020, we made around 23% of progress and have upped the ante thereafter.”

“I love my job and its pressures,” he nods, “but there are sacrifices to make and I think my wife, Saleena, a homemaker, is doing her best, taking care of my toddler son, Tharun, back home at Thirunindravur, near Chennai,” he concludes.

WISELY ON THE MOVE

Sunil Narayan Moolya

Senior Engineer, Civil, PT&D

At his 220/110 kV Thrissivaperur Transmission Line project project, Sunil Narayan Moolya is very much on home ground having previously executed some high voltage transmission line projects across Karnataka and Kerala. “I’m good at sourcing and coordinating with workmen gangs and in transmission line projects we are always dealing with gangs for various specialized tasks like tower erection, stringing and so on. Certainly, it is important to put the right team at the right place.”

Like more of his ilk, Sunil and team also faced some unexpected challenges due to the pandemic. “Suddenly, we had to demobilize some of our best gangs due to regulations while we were right in the middle of some core works.” The month of May was a most testing phase, he recalls, “having to complete maximum number of foundations to reduce the lag with limited resources. We stuck to the fundamentals, put our best men in challenging tasks especially when executing the narrow base towers, planned meticulously, and roped in some local labour. With our excellent networking, we achieved the impossible by completing 18 foundations.”

Normally, Sunil would have gone by the crew list prepared at the start of the project but in this scenario, he chose to work with five foundation gangs and another erection gang. “At the end of the day, it was important to derive maximum productivity with our limited resources. We worked out a matrix wherein tasks like erection and stringing were taken up at parallel ends to fast track project milestones.” Their modus operandi worked well for as Sunil proudly shares, “Overall we have completed 59 foundations, 51 tower erections and 1.75 km of stringing in a State that had the maximum work permit protocols and regulations.”

At the end of the day, it was important to derive maximum productivity with our limited resources. We worked out a matrix wherein tasks like erection and stringing were taken up at parallel ends to fast track project milestones.

Referring to his career highlights, Sunil points out that the 800 kV transmission line job in Assam was one of his toughest jobs and the Kudgi transmission line in Karnataka as one of L&T’s benchmark projects. “Every time, we bridge distances and bring power to remote areas it gives us a high. The quest to light up villages and homes drives me forward,” he says earnestly.

A cup of coffee or a dosa at an Udupi joint always brings back memories of home, he reminisces fondly. “As I stretch myself at projects, my wife Ranjini takes care of my daughter, Pavani hoping that I get a timely break for a short reunion.”

A memorable opening day at L&T as a DET has since transformed into a remarkable phase for Krishna Gurjar at his first project, the 220/110 kV Thrissivaperur Transmission Line. “We have achieved so much in such a short time overcoming many challenges and for a fresher like me this has been a dream debut,” he enthuses.

He and his team had a unique task to dismantle 71 existing towers, destring conductors and earth wire to make way to raise new towers. “It was like doing two jobs and the overall progress depended on how fast we could prepare the ground,” he observes. “Initially I was part of the on-ground teams facilitating and monitoring work fronts. Then, as I settled down, my responsibilities shifted more towards welfare measures due to the emerging pandemic situation.” All along, he rode on the support of his seniors and he is ever grateful to them for making his debut even more remarkable.

Ensuring the safety and welfare of the workmen was perhaps most fulfilling for him. “Suddenly, I saw myself more than just a DET but as a safety ambassador,” he shares. “In fact, all of us at site were Safety Champions, striving to create and secure a safe zone. No, it was not easy by any stretch of imagination especially the early days of the pandemic,” Krishna’s expression reveals the strain, “but our concerted efforts paid off.” Not only did they win over the workmen, but the local administrators started to consider their project as a role model. “During those days, I learnt many life’s lessons and the importance of networking in project management.”

Suddenly, I saw myself more than just a DET but as a safety ambassador. In fact, all of us at site were Safety Champions, striving to create and secure a safe zone.

For approaches, they adopted a mixed way of doing things. “Of course, as part of the execution team, I had a broader picture of how the various milestones were approached. The project team dismantled the old towers and stringed using HTLS-ACCC drake conductors. A range of digital applications such as QIR, EHS Shield, WISA also helped us made good ground with the result we completed 59 foundations, 51 tower erections and 1.75 km of stringing.”

Not surprisingly, when Krishna connects with his parents back home in Bhopal, there is a lot to share and celebrate and with so much happening in his first project, Krishna looks ahead to a bright future at L&T.

WORKING PURPOSEFULLY TOWARDS SET OBJECTIVES

Tushar Lashkari

Senior Engineer, Electrical, PT&D

With most of their foundations running across paddy fields and the dark clouds of the monsoon looming, Tushar Lashkari and team at the 220/110 kV Thrissivaperur Transmission Line project had a task to complete their activities quickly with the added hindrances due to the pandemic-induced restrictions. “Thanks to our concerted efforts and welfare measures, we managed to retain a fair number of the foundation gangs and with a clear strategy successfully completed our critical activities,” he shares with a satisfied smile.

Though the overall length of the alignment was never an issue for the team, its uniqueness was, involving the upgradation of the existing 66 kV line and the construction of a new transmission line. “We began by clearly listing out our priorities,” shares a methodical Tushar. “Then our plan was to first identify the soft spots that were likely to be affected by the monsoon and line up a section wise charter to complete the foundation and stringing works together. With most of these work locations in interior regions, we opted for local labour. Though a risky proposition, we supported it with proper orientation and monitoring,” and as Tushar adds, it worked to their advantage especially once the restrictions came into force.

“As a safety measure, we took the extra step of deploying a three-member team across each location to oversee the activity and ensure that the local workforce maintained our quality and safety standards.” Their strategy worked, progressing surely and steadily till they successfully completed all the critical tasks well before the rains came and thereafter took up the regular milestones.

Tushar makes special mention of the client’s support specially to facilitate work permits and clear statutory approvals. “We followed the guidelines about working in containment zones and our client even accepted some of our suggestions to streamline work safely. For sorting out local issues, we always had a helping hand as they took pride in how professionally we have managed the project.”

A home away from home is how Tushar fondly refers to L&T, “I assured my parents based in Ratlam, Madhya Pradesh, that they need not worry as the organization is taking full care of me and I’m proud to be a part of nation building.”