QUENCHING HIS THIRST FOR EXCELLENCE

Sunil Thakre

Project Manager, WET IC

After stints at a couple of Hydrocarbon projects since joining L&T in 1996, Sunil Thakre has been a part of several WET IC projects over the past decade or two. “Successfully commissioning the Bagheri Ka Naka WSS is an achievement that I will always cherish,” he remarks with a smile. Having served as the Project Manager at the Alirajpur Lift Irrigation Scheme until May 2022, he is currently stationed at the Parwati Micro Lift Irrigation Scheme – Phase III & IV.

At the Alirajpur project, Sunil and team faced a plethora of hurdles. “The work of procuring statutory permissions like environmental and forest clearances and land acquisition was distributed within our team,” reveals Sunil. “We implemented strategic and time-bound actions followed by close internal reviews to overcome the challenges with grit, courage and patience,” he says with a victorious thump. The land acquisition for the factory, storage yards, and various permanent structures was also completed within 9 months.

Coming to the terrain, all pumphouses and distribution chambers are on a hill ranging 15–80 m in height. “The Pumphouse-1 required 40 m deep excavation in weathered and rock strata,” Sunil explains. “This being in a submergence zone, we used the slip form technique and were able to complete construction within 18 months under the stewardship of Mr. Sunil Nayek and Mr. D. K. Shrivastava.”

For the rising mains of 26 km in a series of hills, valleys, and forest area of 8 km, Sunil’s team employed special methods for safe earthwork. As the ROU could not be developed across hills, on average the team had to develop new roads for every 500–800 meters.

The adage that necessity is the mother of invention proved right at the project, as they had to innovate a winch-and-trolley method for the rising main pipeline of 2,770 mm without the use of a crane. “Our method was recognized as the Best Innovative Practice in WET IC for 2019–20,” Sunil says with a triumphant smile.

It is no wonder, then, that Sunil and team have delighted the client with prompt milestones. “The superiors Mr. K. Masilamani (SBG Head) and the dedicated engineers and QA/QC teams under him researched and facilitated a new vendor to establish the spiral pipe mill factory at site,” Sunil elaborates. “The site team under the able leadership of K. Prabakaran and the guidance of the HQ and segment teams toiled day and night, overcoming various setbacks to make it a reality within 4.5 months, and the BIS license was successfully obtained.”

Hailing from Nagpur, Sunil is married to Dipali, a home maker. The birth of their son, Siddharth, is Sunil’s most precious personal moment. Sunil enjoys sports, and he regularly reads books and listens to classical music.

“MY LIFE CHANGED FOREVER

THE DAY I JOINED L&T!”

Sudamani Sankaralingam

Project Head, WET IC

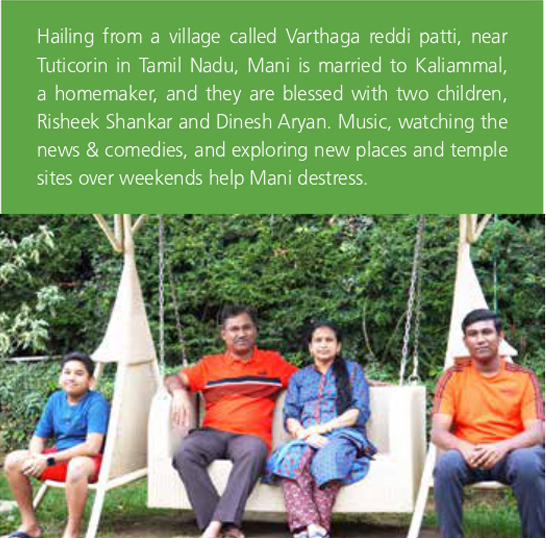

“I began my association with L&T in 1995 as Site Engineer at the Puttapurthy Sri Sathya Sai water supply project and has ever since formed and nurtured my career,” says a satisfied Sudamani Sankaralingam, also known as S S Mani. “My life changed forever the day I joined L&T, relishing the varied exposure, the rich experience through various roles I have played and responsibilities I have shouldered across several projects, growing from a site engineer to a Project Head for large water projects. My journey has been incredibly challenging too, facing numerous hardships that have taught me lots of worthwhile lessons and helping me to grow both professionally and personally.”

As Project Head of the mega lift irrigation project – Cluster IX & XII, Sundargarh, Odisha, Mani faces several challenges to conduct the initial survey, finalize the cultivable command area, solve land acquisition and Right of Way issues, and overcome disruptions due to pollical interferences. “To address these unique issues, we have deployed special teams whether it is to liaise with the local district administration to reduce political influences or with various state & district authorities to resolve land acquisition problems. To resolve RoW issues, we engaged with the government revenue authorities, conducting Gram Sabha meetings with the beneficiaries in all gram panchayats to explain the Government’s vision and the benefits from our project,” explains Mani. “We were involved right through the approval process, followed up regularly for early approvals and avoided enormous delays in the pipeline laying and transmission line works,” he says, acknowledging the crucial role played by the IR, Admin & Execution teams.

Another of Mani’s responsibility is to keep the Client happy, flagging off anticipating customer objectives and needs as the primary consideration. “We regularly communicate all day-to-day activities with them, go the extra mile and take periodic feedback from both the Client and PMCs to ensure that we are moving in the right direction and at the right speed,” points out Mani. “We maintain good relationships and build long time associations,” he avers though he acknowledges Business Segment Head, S Dakshinamurthy and Cluster Head, K Sesha Sai for their inspiring leadership, excellent support, and continued motivation to execute the project, that he proudly adds is one that has achieved an impressive margin with good negative working capital due to excellent support from all shareholders.

“L&T’s brand name makes me proud for wherever I use it, it immediately speaks of the high trust that people have in it,” he concludes on a high.

PLAYING A LONG,

FRUITFUL INNINGS AT L&T

Divesh Kumar

Deputy General Manager (Civil), WET IC

Ever since he joined L&T as a DET in 1993, Divesh Kumar has been steadily ascending the professional ladder and is Section Head for the Parvati Micro Lift Irrigation Scheme Phases 1 & 2 and now with Phases 3 & 4. “My tenure with this wonderful organization is split into two with my initial years with MMH SBG (now M&M) and, since February 2015, with WET IC,” he informs, “and both my innings thus far of some eight projects with MMH and another three with WET IC have been extremely fulfilling.” His smile is equally bright.

With his Parvati site remotely located, Divesh and his team have had to constantly face the trouble of mobilizing labour who are not interested to work at a site in the back of beyond and arranging material. “In the case of our workmen, it is important to understand their issues and resolve them like maintaining good livelihood at their colonies, setting up RO plants, arranging boosters for mobile connectivity and arranging for their smooth transportation from and to the site. Communication is the key to tackle such situations,” points out Divesh, “and we addressed them as a team, regularly interacting with the subcontractors, supervisors, and workmen and conducting frequent and regular walkthroughs.”

While it is great to have plans, it is even more critical to implement them and Divesh is happy that through regular site visits and monitoring, his seniors were able to understand his point of view and allocate the right kind of resources to address his issues. “My entire team stands next to me, and we function as a unit, which is why we have achieved the pace and progress that has been appreciated by the client,” he shares with a sense of achievement.

It is obvious that he and his team have been able to delight their client and he shares a case in point. “When I was transferred to Phases 3 & 4, that had the same Project Manager, my segment teams were regularly discussing about a critical work left at Phases 1 & 2 which was the Pumphouse 1. So, they brought me to handle it when it was on raft level. I understood the issues involved, synchronized real time resource requirements and arranged man, material and equipment from a different site in the MP segment to fast track progress.”

On his home front, Divesh is from the holy city of Allahabad, married to Vandana, a homemaker, and they are blessed with three daughters, Kamakshi, Srishty and Niyati. He loves watching and playing cricket and keeping himself updated with the latest local and international news.

“At L&T, I love the opportunity of working with so many remarkable leaders,” says this staunch L&T-ite.

ONTIME DELIVERY IS THE ONLY WAY TO

DELIGHT A CLIENT

Ranjeet Singh Dham

Deputy General Manager (ELEC), WET IC

Ranjeet Singh Dham, Project Manager for MEICA (Mechanical & Piping, Electrical, Instrumentation & Automation) at the Integrated Industrial Wastewater Treatment Works Project in Doha, Qatar, shrugs nonchalantly that the only way to delight a client is to deliver his project in time and to quality. He has precisely demonstrated that by delivering the Industrial Sewage Treatment works -3A, well on time, much to his client’s delight.

After joining in 2003 on a Fixed Time Contract, he was absorbed by L&T into permanent employment in 2005 and adds that, “being identified for international assignments within a few initial years of my employment is a professional highpoint in my career.” Ranjeet’s has been an entirely international association with L&T beginning with the Lafarge Surma Cement project in Bangladesh followed by a couple of projects in Doha: the Phase 2 Expansion of the Doha South Sewage Treatment Plant and the Al Shamal Sewage Treatment Works. Then there was Phase 2 of the Jebel Ali Sewage Treatment Plant in Dubai followed by the Industrial Area Sewage Treatment Works – Phase 3A and presently, the Integrated Industrial Wastewater Treatment Works, both again in Doha.

The pandemic was his primary challenge because the waves hit when the project was at its peak. “As a senior member of the Project Management team, I was part of a committee to formulate & implement SOPs, adhere to the local & statutory directives & instructions and integrate them as part of the site execution plans, to ensure steady progress, mitigate delays, ensure the health & safety of the staff and workmen to minimize disruptions.”

Changing tack, he praises the benefits of digitalization to reduce dependence on paperwork or drawings with details and the availability of drawings & data on the go at site through mobiles, tabs, etc. “BIM Implementation has certainly and immensely improved execution avoiding utility clashes and the like,” he nods. “Communication and exchange of information is instantaneous through various apps, resulting in improved duration, better productivity, reduced rework.”

Personally, Ranjeet is delighted with the senior management having provided him with ample opportunities to grow and for trusting him with challenging assignments & added responsibilities and portfolios. “Having a very talented, energetic & closely bonded team, has repeatedly resulted in close coordination & implementation of plans, dynamic execution with ideas constantly pouring in that has resulted in one’s own performance improving even through the most difficult phases of the project execution,” he says earnestly.

Born in Ghaziabad but brought up and studied in Mumbai, Ranjeet is married to Harmit Kaur Dham, who was earlier working with Qatar Airway, but is presently at home looking after their 4-year-old son, Sanvir, with hopes to return to working soon. Movies are his go-to pastime.

DERIVING PRIDE FROM THE L&T BRAND!

T. Arulgnanam

Senior Construction Manager (Civil), WET IC

T. Arulgnanam recently completed 15 years with L&T, the highlight of his career so far: “It was a dream to join L&T during my studies, and it is my life fortune to be recognized as an L&T-ite,” he remarks, all smiles. Having joined L&T in 2006, Arul has worked on a clutch of challenging projects including various steel plant projects in MMH SBG, the Mega Lift Irrigation Project Clusters XIV and XV and is currently Planning Head at the Mega Lift Irrigation Project (MLIP) Clusters IX and XII.

Before the start of the project, Arul and team conducted ‘Grama Sabha’ awareness meetings with the villagers. “We explained how the project would benefit the public and highlighted the government’s interest towards the farmers’ financial sustainability.”

At the MLIP in Odisha, the team has faced disruptions such as ROW/ROU issues for the pipeline and transmission lines, damage/ theft of equipment, and political issues. “Another challenge was to mobilize workmen and subcontractors in the rural area and in the extreme temperatures of western Odisha,” adds Arul. “We developed local contractors to the extent possible, with proper quality and safety training and selected only on merit.”

“We have formed a team to interact with the local administration and mitigate the ROW/ROU problems,” he explains. To tackle the damage/theft issues, Arul and team took the help of the authorities to arrange for night patrols.

The project’s Outlet Management System (OMS) operating through SCADA/PLC is a first in Odisha’s irrigation projects. “The OMSs of all schemes can operate with real-time monitoring through SCADA from a central control room in a centralized pump house,” he clarifies.

“The client is very much happy with our teamwork,” beams Arul. “We have delivered water through OMS installed in every 4 Ha Chak and have received 52 Appreciation Certificates for our speedy progress, quality and safety systems implemented!”

Arul is grateful to his seniors and team members for their support to achieve considerable project progress. “The knowledge shared by our SBU Head SDM sir, Cluster Head KSS sir, and Project Head S S Mani sir; our EDRC team’s prompt completion of Design and Drawing approvals; and the efforts of the section in-charges, Planing team and engineers all deserve mention,” he conveys, acknowledging all round support. Digital tools like e-Pragathi, View EHS Power BI, WISA, QIR, P&M IoT and others have also been driving progress.

Arul is a native of Harur town in Dharmapuri, Tamil Nadu, married to Elavarasi, a home maker and they are blessed with two children, daughter Anvie Yuthika, who is in Class 7, and son Anirvaa Kavin, in Class 3. “The birth of my daughter is my most memorable personal moment,” he says, “as I had been praying for a girl child.” He enjoys walking, cycling in the morning and likes to make time for his family in his busy schedule.

16th June 2022 is a red-lettered day in Planning Manager, Madhup Sharma’s life when the 100 MLD Desalination Plant at Dahej, the first to be constructed by L&T, was inaugurated by the Gujarat Chief Minister, and started delivering water to the beneficiaries. “It was an enormously proud moment for me, my team and the whole of L&T, an achievement that was roundly appreciated by our client too,” he enthuses.

Armed with 11 years’ experience in planning, Madhup joined L&T in March 2017. His first assignment as Planning Manager was at the 60 MLD WTP Pithampur project where the commissioning of 50 km of MS 1000 mm dia pipeline at the first stroke without any leak or defect is the highpoint of Madhup’s career thus far. “It was a rainy day,” he smiles at the memory, “and the entire L&T team along with the Cluster Head and the client, MP-AKVN, started to celebrate when the water reached its destination.”

At Dahej, Madhup’s major challenges included procuring CRZ permissions from MoEF & CC, New Delhi to resume construction activity, deploy adequate workmen post the pandemic, mobilize resources for marine works and reduce time schedules for finishing works like brick, plaster & painting within the plant area. “Being our first sea-facing project, getting approvals was new for the team but we coordinated with the environmental consultant, MoEF officials for several inter departmental clearances of the design team,” he points out. “We proactively completed the prerequisite requirements well in advance at all stages of the project that won customer appreciation on various occasions.”

Being a JV, every proposal had to be approved by all parties concerned. “The intake structures were on the critical path with inherent challenges and innumerable risks that required meticulous planning, engaging specialized agencies, handling heavy reinforcement cage lifts, extremely deep excavation (39 meter), mud excavation through bucket and crane system, huge water ingress requiring continuous dewatering works. We handled them all well and efficiently,” he assures. Madhup flags off the introduction of Rapid Concrete as a major factor to reduce execution time by 3–4 months.

Various digital solutions like QIR app, Conquer, WISA and View EHS with BIM Dashboard helped the team maintain high quality and safety standards while Madhup calls out Dwaipayan Ghosh and Keyur Gohel for their invaluable contribution.

A native of Jaipur, Rajasthan, Madhup’s better half is Reena Pal, a homemaker and their son, Ishaan, is doing his 7th. A lover of snooker, Madhup likes to visit new places close to nature or history and watch documentaries. “I’m a proud L&T-ite that our customer carries its brand image as first choice to deliver a big project on time with high quality and safety standards,” he signs off.

“Our client, Qatar’s Public Works Authority, popularly known as ASHGHAL, wanted a STP with the world`s highest quality standard in sewage effluent treatment for Doha’s irrigation network,” informs Hariom Kumar, Planning Manager, at the 10MLD Industrial Wastewater Treatment project. “We started the ‘Concept to Commissioning’ project in November 2018, made the site office fully operational on day-1, completed and delivered the project in November 2021 well within the allotted time frame, clocking 4 million safe manhours, much to our client’s delight,” shares an equally delighted Hariom.

Since joining L&T as a PGET in April 2013, Hariom began in MIS at HQ Chennai, followed by a string of successes in the Middle East. He was Assistant Planning Manager at the 375MLD Jebel Ali Sewage Treatment Plant, Dubai (UAE) and later Planning Manager at the 30MLD Industrial Area Sewage Treatment Plant, Doha, before taking up his present assignment.

Elaborating on the highlights of his project, Hariom says that it has modern Sequential Batch Reactor (SBR) technology followed by Ultrafiltration & UV disinfection. “The sludge generated from SBR is being treated within the plant to achieve the required dry solid state for further disposal.”

The project has mopped up a bagful of awards including a RoSPA Gold in 2021 that have more than offset the several challenges that the team had to face due to the pandemic including suspension of construction, albeit for 28 days, lockdown of the Industrial Area Street that threw procurement of spare parts and workmen mobilization into disarray, issues in arranging visas for both staff & workmen and disruption in the supply chain.

He elaborates about their mitigation measures that were spot on. “We stuck to the basics of planning and to catch up with the listed remaining scope of works, we had lookahead plans divided into month, week & day, we re-sequenced the construction priority based on the commissioning priority and monitored the manhours spent vs achieved quantity at daily review meetings that were then reported to the management the same day because of which we were able to deliver.” His sense of achievement is evident. “Our Project Director, Vishal Sinha, always showed us the way forward, motivating us to achieve our project targets and I truly enjoy the freedom to express myself.”

Hailing from Bhagalpur, Bihar, Hariom is married to Neha Kumari, who has had to give up her job to support him and look after their 4-year-old son, Gyanav Bhardwaj. Playing cricket, table tennis, listening to spiritual music, and watching movies are his hobbies but, “on a weekend, a day well spent with family gives me utmost relaxation,” he smiles.

Hariom believes that L&T is a company that gives young engineers the freedom to take risks and grow and, at the same time, enhance their knowledge to take on higher managerial roles in future.

Single-handedly managing the stores at the 100 MLD Desalination plant project at Dahej, Gujarat, Lenka Bhaskara Rao feels fortunate to be part of an iconic project to build one of the country’s largest desalination plants, the first by L&T. “I am also proud to be part of a professionally managed organization, working to execute and deliver projects on time, and contribute to building the nation,” he says, his chest literally swelling with pride. Lenka joined the Company he so admires in September 2017 and was initially posted at the Dhandhusan to Redlaxmipura LIS project, Visnagar, Gujarat as Store In-charge after which he was transferred to his present assignment in September 2019.

“We are responsible for a lot of material handling, shifting, loading, and unloading activities but fortunately everything has gone well,” he smiles, but to start off with, his challenges were threefold: foreign supplies & vendor involvement; timely delivery of long lead items and inventory management due to the need for complex piping and large amount of equipment.

Lenka explains how he addressed his challenges. “I ensured regular follow-ups and coordination among the team members and escalated issues to appropriate levels whenever required, to avoid delays. We had regular meetings with foreign vendors for timely compliances from all stakeholders and I coordinated with both the planning and execution teams to understand their exact requirements to follow-up with vendors and ensure material availability as per the schedules.” He also coordinated to develop proper storage facilities for better inventory management.

“The ViewEHS permit system helped us to organize execution safely,” he remarks. “The most critical part was the safe unloading of the 32 MVA Transformer weighing some 45 MT and its placement directly at the erection point.” He introduced fortnightly review meetings for supply item updates to highlight supply related issues to the management and streamline them as per site requirements. “In these meetings, the vendors were asked to raise their issues to meet the committed timelines.” He proudly adds, “Our customer, Gujarat Industrial Development Corporation, has appreciated our inventory management mechanism, our proactive approach to commission works as per the committed schedule and the use of temperature-controlled storage system developed for RO Membranes.”

Lenka acknowledges the support from all his teammates from the execution, planning and accounts departments to raise timely requirements, get timely approvals and provide financial support.

Lenka hails from the village of Jonnavalasa in the Vizianagaram District of Andhra Pradesh. His wife, Syamala, is a homemaker and they are blessed with two daughters, Niharika & Himavarshini. “I like travelling and visiting places close to nature and get to explore my passion at least once in six months,” he smiles. A memory he cherishes most is that of his elder daughter’s marriage.