IT IS A MINING TOWN IN LOTUS LAND

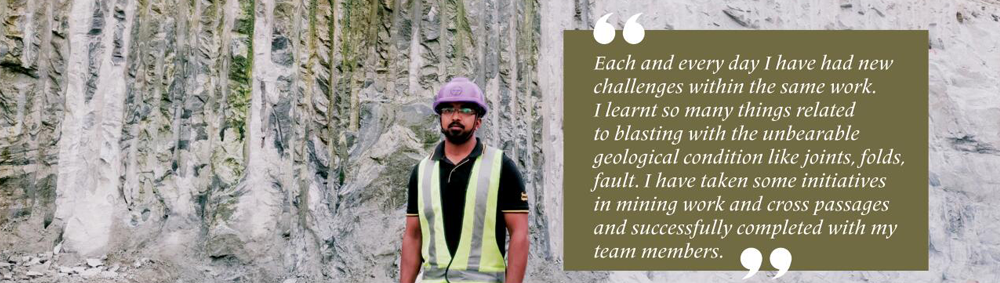

Santosh Kumar

Assistant Manager (Mines), HCI IC

At his second project with L&T, the Bangalore Metro RT-03 Project, young Santosh Kumar is having a blast! “I have controlled blasted just 2 m from residential buildings, maintaining ground vibrations within the DGMS ground vibration limits,” he shares, proud of his team’s achievement.

Continuing with his favourite subject of blasting, Santosh mentions that since the location for the station was hemmed in with buildings, public roads and a heritage building in the form of a mosque, they had to control the PPV (vibration). “We therefore opted for pre-split blasting with line drilling, maintaining proper delays and directing the connection sequence.” To control the AOR (Air Over Pressure) since there were aged people in the buildings that had glass doors and windows, the team used sandbags just above the TLD and rubber mats.

To excavate the cross passages, the team faced the threat of roof collapses due to over-excavating the top layer and bench collapses. “To address these issues, we applied shotcrete immediately after excavating in parts and applying plywood support to protect the face,” informs Santosh. “After implementing the double decking charging method, we observed that the excavated material was of equal size, that increased our speed of disposing the boulders and helped us complete the excavation 30 days earlier than the planned completion date,” he smiles. When excavating the cross passage, instead of installing 3 m long fore-poling SDA rods, they used 9 m fore-poling rods from the opening face to the opposite end of the cross passage, and that saved the team 8 days. Santosh mentions two mining software, Minex and Surpac, that are his aids for designing and planning the blast patterns for different rock strata.

He fondly recalls procuring the EC, CFE, and CFO for mines at his first project, the Medigadda Barrage, to solve local issues as a moment to cherish. “Whenever my initiatives for controlled blasting and productivity are used, it gives me a high,” he laughs, mentioning special thanks to Mr. N.S.S, at the RTO3 and Mr. U.V. Narasappa at the Medigadda Project for their unconditional support and motivation.

Still single, Santosh hails from Hazaribagh, Jharkhand, and indulges in some soft pursuits of sketching, painting, and poetry in his free time. A memorable trip to Coorg is another moment to cherish.

“Really, the rock strata at the RT-03, specially at the Cantonment Station, was very unpredictable, but we enjoyed throughout the blasting and finished the excavation having a depth of 21 m from the surface level, 200 m length & 30 m width, and the approximate rock quantity was 1,18,620 cum,” he says. “Each and every day I have had new challenges within the same work. I learnt so many things related to blasting with the unbearable geological conditions like joints, folds, faults. I have taken some initiatives in mining work and cross passages and successfully completed with my team members.”

“L&T gives us a platform that we deserve, to constantly keep growing and learning,” he signs off loftily.

HELPING CREATE BENCHMARKS UNDERGROUND

Gandupalli Diwakar

Senior Engineer (Civil), HCI IC

At the iconic Medigadda Barrage, G Diwakar’s first assignment after joining L&T as a DET, he enjoyed working with a team that set world records in speedy construction. At the Bangalore Metro RT-03 Project, his present assignment, he is still enjoying himself with another team creating benchmarks underground. “Bangalore has one of the toughest and most unpredictable geologies, with dense buildings and a busy railway track serving 68 passenger and goods trains every day, but despite these challenges, we set a new benchmark in BMRCL history by achieving 27 m tunnelling in one day,” he shares, proud of his team’s success.

Recalling the harrowing days of the pandemic that disrupted life at the site, he mentions how difficult it was to continue site activities, mobilize resources by following the government safety protocols and take all the necessary safety measures. Diwakar is delighted that in the face of such challenges, they stood together as a team, continued site activities and even completed commissioning the TBM without the support of the TBM manufacturer, CRCHI.

“Taking drag-through, a common practice in TBM mobilization within the station, as a challenge, we collected old data, and learning from it, made the necessary arrangements to complete it for both TBMs in 21 & 15 days, respectively, saving 44 days of the project base line,” shares a proud Diwakar.

To reduce the impact on the environment and save natural resources, the team opted for a STP (Slurry Treatment Plant), recycle and reuse water in the tunnelling operations to save approximately 3.34 lakh KL water in the process. “We have installed an ETP (Effluent Treatment Plant) to treat the wastewater for safe disposal to the environment,” he notes.

Digitalization is impacting Diwakar’s life. “We monitor the condition, status, and performance of the TBM machines with the help of IoT, and auto-generated TBM reports have reduced paperwork, increased efficiency and reduced TBM problem solving time.”

Expressing his appreciation for Mr. NSS for his guidance and support, he says that his mentorship has helped him incredibly to develop his skills both professionally and personally. “My sincere thanks to all my managers, especially Mr. Shasank & Mr. Jaydev and my teammates who have backed me no matter whatever the situation.”

Hailing from the small town of Srikakulam in Andhra Pradesh, Diwakar is still single and his life’s major supports are his parents, father a tailor and mother a homemaker, and his brother. “My hobbies include painting, creating artistic drawings and sports, and my most memorable moment is when I completed my Bachelor’s Degree while working,” he says happily.

“I am proud to be part of a nation builder like L&T, for it makes me feel that I am contributing something to my motherland,” he concludes on a high.

COMMITTED TO MAKING IT HAPPEN

Manish Kumar

Engineer (Civil), HCI IC

After successful stints at the CMRL UG-04 and CMRL UG-02 Projects, Manish Kumar brought his valuable experience to the Bangalore Metro RT-03 Project, in July 2019. “One of our main challenges was that 40% of our piling was in residential areas causing loud noise, with limited work timings,” recalls Manish with a sigh. “By strategically planning the locations, we ensured that piling in the affected areas was carried out during the day, and the non-affected areas during the night shift, thereby maintaining our productivity and minimizing disruption.”

With some agile planning to procure land clearances and manage groundwater at the Pottery Station, Manish and the team have helped drive efficiency. “Our schedules were adjusted based on the land clearances and sequence of activities reorganized accordingly,” he informs. A dedicated team was made responsible for operating the pumping wells and closely monitoring the high groundwater levels, while planed slopes were designed to channel surface water to specific pumping locations. “This helped us complete 80% of the soil excavation within six months,” he nods with satisfaction. Their daily breakdown of the monthly plan kept everyone alerted of any potential schedule slippages.

The structural work was impacted during TBM dragging, preventing simultaneous progress with civil work for several months. “Adopting a unified approach, we expedited the TBM dragging from one end of the station to the other, that opened up the front for station work, minimizing delays and improving efficiency,” shares Manish.

Apps like Conease and Procube have cut down manual work and streamlined the approval process. “The Safety War Room has acted as a third eye for us, to track any unsafe conditions or actions at site and address them promptly to minimize risks,” points out Manish.

He credits the Station Manager and Project Manager for standing by the team, giving them the freedom to implement ideas. “Their trust in our capabilities has made a big difference, apart from the recognition and reward system that has further motivated and incentivized us.”

A native of Shimla, Himachal Pradesh, Manish is still single and an all-rounder on the cricket field. “I also love listening to music, browsing the internet, exploring mountains, and camping. Whenever I get the chance, I make it a point not to miss enjoying these,” he says.

“An aspect of L&T that makes me proud is its unwavering commitment to excellence in engineering and construction, consistently delivering projects of exceptional quality and innovation,” Manish signs off.

LEARNING & IMPLEMENTING AS

SHE BUILDS HER CAREER

Anuradha Shaw

Junior Chargehand (Survey), HCI IC

The only hobby that she follows passionately is to travel and explore new places, and Anuradha Shaw’s 4-year tenure with L&T has been something similar: an opportunity to be exposed to new things, discover, and learn to implement new ways of working. “At the Bangalore Metro RT 03 Project, my first,” she says with a smile, “I have been involved with many departments, starting first with a station survey followed by tunnel survey that resulted in the successful completion of tunnelling works without any deviations. Then apart from material planning and digitalization efforts, I took care of Pocket Track execution at the Site Level, with a team of 10 people reporting to me,” she shares, her confidence shining through.

Certainly, being a woman in field service in construction has been a huge challenge in the learning and implementing phase, without any female co-worker for company. “My next challenge was to observe and adjust the survey points such that the TBM breakthrough should not deviate,” she says tightly. “Of course, accomplishing the assigned work is one thing but getting it certified by the clients for payments is another, which I successfully handled by following all the norms and solving all the queries of clients,” she says, pleased with her success. “Entering excavation of pocket track works has given me a chance to face unforeseen challenges like handling manpower, executing accurately to the drawings, and handling large equipment,” she shares with determination.

Anuradha’s learning curve has been steep, about survey instruments and implementation like, “Total station, TS16A, digital auto levels, permanent point fixing, height transfer, location point and reference line marking,” she reels off. “I have achieved 100% marks in all the projects by working on L&T Apps,” she points out, referring to her contribution in the sphere of digitalization, mentioning using Procube for progress monitoring and ConEase for concrete movement.

Fresh out of college after completing her education at Industrial Training Institute (ITI), Anuradha was pitched into the survey team, but she learnt to swim thanks to her seniors’ support, teaching her about survey instruments and processes. “My team members have been a massive support too on the field, but my source of motivation has been our Project Manager, who has always inspired me to learn new things and excel,” she flashes another smile.

“My best moment was being made permanent in the TC2 cadre after a year’s training,” she says with a huge sense of satisfaction. Hailing from Kolkata, West Bengal, Anuradha is yet single and for the time being focused on building her career with L&T.