PERMEATING IMPERMEABLE TERRAINS

Navis Princely M

Assistant Manager (P&M), L&T GeoStructure

Navis Princely’s dream to join L&T came true in 2016, and since then, there has been no looking back. A part of multiple projects from a lift irrigation scheme in Andhra Pradesh to piling and pile cap work in BHEL Ennore, to the construction of a Diaphragm Wall at the Chennai Metro, Navis says, “My learning curve has been steep and I am proud to be a part of the team constructing a cut-off wall at the Kanupur Irrigation Project in Odisha’s Keonjhar district.”

Faced with several logistical challenges due to the lack of proper roads and infrastructure, Navis mentions the mammoth task to mobilize, transport and operate the 170-ton trench cutter. “We had to identify and ensure that we had trained people to operate the cutter, to avoid any untoward incidents,” he cautions. Further, as the team was operating with trench cutters of 15 to 27 years’ vintage, extra care had to be taken to ensure that they were upgraded to meet current specifications and safety norms. He mentions the working platform they built at the site of Geocell and MS Plate to create a stable foundation for the free movement of manpower and heavy machinery, especially during the monsoon when the ground became wet and slushy. “Technology, automation, and digital apps have helped the team to effectively monitor project progress,” he adds.

The temperature-related failure of the trench cutter gearbox was a huge challenge, which they resolved with an intermediate cooling system to moderate the temperature and that improved productivity by up to 90%. In addition, hiring 500 kVA DG sets saved manpower cost and fuel consumption, which won them appreciation from Caterpillar, the OEM partner.

“I am proud to have been a part of the first-time use of ‘Reverse Circulation Drilling’ at the CMRL Project, which helped in its timely completion,” he recalls fondly. “It was an unforgettable moment when we had to take out a cutter frame weighing about 40 T using a BC32 cutter, when the BC40 trench cutter broke down at a depth of 32 metres.” Carried out during the time of the pandemic, the activity was roundly appreciated by the organization. In fact, one of his cherished moments is receiving accolades for the refurbishment of an indigenously made BC30 cutter.

Navis attributes his success to his supportive managers and teams. The constant motivation and appreciation from his project managers have enabled him to permeate into tough terrains, learn from challenges and grow as a professional.

A native of Nagercoil, in Kanyakumari, Navis is happily married to Jasmine Diana, a homemaker, and they are blessed with a son, Berin Kenneth, and daughter, Bernita. He loves playing badminton during his free time.

AT THE CUTTING EDGE

Abhishek Dash

Assistant Manager (P&M), L&T GeoStructure

Abhishek Dash is immensely proud to be a part of an organization that is shaping the future through its technological advancements and innovative solutions. With eyes gleaming, he says, “We are contributing to projects that have a lasting impact on society.”

A part of multiple projects varying from thermal power plants to building jetties to irrigation projects from 2011 till date, Abhishek has learnt a lot from these projects that has helped him develop his potential and grow professionally. These are obviously holding him in good stead at his present assignment at the Kanupur Cut-Off Wall Project.

He agrees that it is a challenging project in terms of terrain, varying ground conditions and access to site. “It is a pure trench cutter project involving operating heavy machinery,” Abhishek describes, “and safety is our topmost priority. We are also careful to follow the environmental regulations to ensure that we have proper erosion control measures in place to avoid disruptions to the ecosystem.” Following the adage of looking before you leap, thorough soil surveys were conducted to understand the soil conditions.

“Managing budgets arising due to unforeseen costs during execution was a challenge,” he remarks, “but by working together, dividing tasks, and creating a supportive environment, we have found answers to all those tough questions,” he smiles. “IoT implemented in devices has helped us in real-time and remote monitoring, preventive and predictive maintenance, datadriven decision making, improved safety and greater operational reliability.” Abhishek adds that the digital initiatives help to provide insights into the safety behaviour of the site engineers and proactively monitor their site performance. “Of course, these have saved us both cost and time and brought in greater transparency.”

Completing 360 piles of river stone and the 60 dia. intake well on river stone and the pump house are a few of his key achievements. Abhishek appreciates his seniors for their guidance, support, and advice. “They share with us their learnings from mistakes, which helped us articulate what to do and what not,” he says with a cheeky smile.

A native of Bhubaneswar, Odisha, Abhishek is married to Priyanka Senapati, and they are blessed with a daughter, Abhi Priya Dash, and the moment he held her for the first time is his life’s most cherished moment. In addition to playing badminton & cricket in his spare time, Abhishek loves to try his hand at cooking.

The learning and opportunities he has enjoyed at L&T have shaped him and Abhishek is delighted that he has been constantly pushing his boundaries to develop into a ‘Can Do’ man.

EXPERTLY MANAGING UNDERGROUND CHALLENGES

Saroj Paul

Assistant Manager (Execution), L&T GeoStructure

Adept in his role in execution, Saroj Paul goes to the crux of his task at the Kanupur Cut-Off Wall project in Odisha’s Keonjhar district. Due to the heterogeneous geological condition of their site, the team encountered fresh rock at shallower levels than the expected level of termination. “In such cases, to meet the contractual requirement of termination of the panel, we go for extra-cutting in the fresh hard rock with trench cutters (BC40 & BC32) that would have delayed completion of the panel,” he explains. They also found the going tough owing to frequent cutter breakdowns and with very low rate of penetration to show for their efforts. “Since the rock strata was so highly variable, we opted for the Open Panel Borehole method that reduced excessive workload on the cutter and was cost effective too,” he says with relief.

Delving deeper into his execution method, Saroj says, “To execute the confirmatory GTI and open panel boreholes, we finalized the termination depth of the panel precisely, which reduced over trenching in fresh rock, saved our machinery from frequent breakdowns and helped to utilize our resources optimally.

This approach also gave us a better and clearer understanding of the subsurface to design the structures,” he adds.

The normal practice of GTI (Geotechnical Investigation) in such cases would have been to start drilling from the ground level, but that would have been time consuming. “The alternative was to do GTI in open borehole,” points out Saroj, “which, however, has two challenges: one, to maintain verticality of the open borehole and the other was that due to the open panel drilling, the casing was breaking.” Despite these issues, the team went ahead with the open panel method wherever fresh, hard rock was encountered at shallow levels and to confirm the Rock Quality Designation (RQD) >75% as per contract requirement to terminate the trenching panels.

An 18 m long MS template frame was designed to maintain the verticality of the borehole in the open panel, and with GTI in the fabricated template frame, the team could confirm the termination of the trenching panel against the proposed depth. The GTI template frame serves as a support for the drilling rod and as a working platform for the GTI rig.

Appreciative of his Project Manager Praveen Pratap Singh’s support and commitment, Saroj says, “He guides the team to think proactively and emphasizes the importance of cultivating good-quality work at site. The dedication and active involvement of our team members have been exemplary too.”

A native of Kolkata, West Bengal, Saroj’s life partner is Arpita, a homemaker, and his life’s most joyous moment was his daughter Aadriti’s birth. He unwinds with sports, listening to music and reading.

ALWAYS LEARNING TO ENRICH HIS GEOTECHNICAL

KNOWLEDGE

G Arjun

Assistant Manager (Geologist), L&T GeoStructure

At home, G Arjun, as a geologist, is concerned about the health of the soil, while his wife, Saranya Sasidharan, pursuing her Ph.D. in Radar Meteorology, is interested in clouds and rainfall. We are sure they have found a common ground, just as he has found a firm footing in L&T after joining the company in 2021 at the HSR Project.

From a geological perspective, another significant milestone was the introduction of the open-panel borehole technique that revolutionized their approach to GTI. “Being a part of this innovative solution not only contributed to the project’s success but also expanded my skill set and problem-solving abilities,” he shares, adding that this solution reduced the strain on machinery and proved exceptionally efficient for geological analysis to address the significant variability in rock levels occurring within mere 2–3 m spans. “It significantly improved our ability to assess subsurface conditions, leading to remarkable progress in project delivery.”

Initially, having established panel terminations based on data from 30 GTI boreholes, spaced 40 m apart, they encountered fresh rock layers at shallower depths than the GTI data suggested during the trenching of panels. “The complex and uneven rock strata, influenced by various joints and shear zones, exhibited significant variations within just metres,” says Arjun, seriously. Apart from conducting confirmatory boreholes every 10–15 metres at the centre of the panel to ensure accurate information, the team deployed a frame when they encountered shallow rock layers unexpectedly, to carry out borehole drilling in the open panels.

On the digital front, Arjun mentions the use of AutoCAD to create profiles of GTI boreholes and as-built casted panels. “These visual representations on AutoCAD revealed rock level variations and problematic zones on-site that, in turn, enhanced our planning for GTI boreholes, ensuring optimal results and boosting overall operational efficiency.”

He is extremely appreciative of his Project Manager Praveen Pratap Singh’s exceptionally support and of his Manager Arun Balamurugan’s ready availability for guidance and suggestions.

Hailing from Kollam, Kerala, Arjun loves to travel and cycle when free. His most cherished moment is the joy on his parents’ faces when he bought them gifts from his first salary.

The defining moment for Abinash Mohanty at his present assignment at the Kanupur Cut-Off Wall Project for L&T GeoStructure was when they encountered many unpredictable difficulties initially during the tam grouting activities. “By applying and analysing the different grouting proportions and applied pressure ranges, we finally fixed the problem,” he shares, pleased with the result. For a technical professional with depth of experience in L&T, Abinash has had fair exposure to various challenges in his responsibilities as a Geotechnical Engineer, including Geotechnical Investigation Surveys, ground improvement and pile testing projects. Presently he is in the QA/QC Department.

His focus is to engage multi-skilled workmen capable of performing and achieving their targets, estimating, and arranging for the approximate drilling consumable items in advance to complete the GTI work in time. “I have trained my subordinates to execute the work as per the approved methodology and maintain daily field records in the appropriate formats, always focused to speed up project activity by changing some points in the work procedure with the client’s approval.” he shares. “I discuss with the Client regarding changes in the work procedure to speed up activities, submit the revised method statement and take the Client’s approval,” he flags his vital contribution.

A recurring challenge, especially at the earlier stages of any project, is the difficulty to get resources like drilling consumables tools, tackles, safety PPEs and such in time. “We therefore shifted a minimum quantity to get the GTI Survey started, and I am proud that I have successfully implemented this initiative at other projects too.”

At Kanupur, during the GTI work, the team found iron stone pieces inside the running borehole point before encountering the bed rock layer, rendering casting extremely difficult. “To address it, we first introduced a single-tube core barrel to cut through the iron ore strata and used the casing drill bit to redrill and extend the casing pipes further into the weathered rock top layer and thereby saved time.” When surface leakage appeared while executing the tam grouting activities, which forced them to repeat the grouting the next day thus delaying the process, the team finalized the pressure range and dosage of grout mix to be applied for the depth stage grouting to reduce the duration of stage grouting and avoid repetition.

Abinash is delighted with the technical training he has received with L&T, the types of jobs he has been fortunate to perform and the new things he has learned along the way. Hailing from Dharmasala, in Odisha’s Jajpur district, he is married to Namrata Samal, a homemaker. They are blessed with a son, Hitesh. His favourite hobby is to play cricket.

STAYING FOCUSED TO DELIVER UNDERGROUND

Parasmani Bhanu

Assistant Manager (Civil), L&T GeoStructure

A true-blood cricket enthusiast, Parasmani Bhanu’s most memorable moments are on a cricket field: M S Dhoni’s magnificent six to help India win the 2011 Cricket World Cup and Virat Kohli’s two sixes in the 19th over in the 2022 T20 World Cup to power India to a famous win over Pakistan. Despite his fascination for cricket, his focus is very much on his work and his desire to prove his mettle at his first project with L&T GeoStructure, the Kanupur Cut-Off Wall Project.

The team constructed a 10 m x 50 m sedimentation collecting tank with 3 m depth at site with an inlet at one end, an outlet at the other and a wall separator to reduce sediments passing into the outlet chamber. “During the breakdown of the desander plant, this tank is used for trenching,” he explains. “Its 50 m length allows the sediments to settle, and working-class bentonite passes to the delivery pump that has reduced cutter idling and boosted progress,” he remarks with a smile.

During the trenching of the panel, some deviations were observed in verticality due to subsurface strata layers. “To control such deviations and maintain the verticality of the cut-off wall panels, we conducted the Koden test on the panels at intervals of 5–10 metres,” he mentions. “In fact, using the Koden Report and a B-Tronic System in the cutter helped to monitor deviations and provide us with real-time data to rectify such deviations.”

Referring to a couple of ‘innovations’ at site that have helped the team push progress, Parasmani shares about the working platform they made at site using Geosynthetic material to ensure smooth movement of manpower, heavy machinery, and equipment, especially during the monsoon when underfoot conditions became wet & slushy. The working platform is maintained with the help of a drain to keep it slush free.

Even though Parasmani is at his first project, he is happy with the support he has received at site to perform. “Our Project Manager, Mr. Praveen Pratap Singh, has been most supportive and gives valuable inputs to perform our given tasks, while our seniors and team members are dedicated and are deeply involved in solving problems and boosting progress at site,” he says with gratitude.

Apart from his love for cricket, Parasmani loves to read too. A native of Saharsa, Bihar, he is married to Priyanka Jha, a homemaker, and they are blessed with a son, Adarsh Kashyap.

He is proud of the quality infrastructure that L&T constructs safely for the nation’s growth.

RAIN OR SEA OR WIND, HE ALWAYS DRIVES SAFETY

Yuvaraj Ravi

Assistant Manager (EHS), L&T GeoStructure

Receiving the one million safe manhours certification from the Client, Water Resource Department, Odisha, for achieving zero LTI at his Kanupur Cut-Off Wall Project was as satisfying as the Client’s appreciation for successfully completing the MTHL Project. “At Kanupur, the taste of success is sweeter because I have faced several challenges to establish a strong safety culture,” he says with vigour. “It is my first project involving marine locations, heavy monsoons, and gusty winds during heavy lifting operations, but despite these challenges, I have successfully met the customer’s requirements by regularly seeking feedback and setting benchmarks higher than their expectations.”

He has been pursuing his goal through effective communication, and instilling safety protocols, procedures, and practices among all project stakeholders through safety briefings, training sessions, and awareness programmes. Yuvaraj has also led several initiatives focused on engineering control measures like additional locking arrangements for the radial conveyor movement during cyclones or heavy winds at the M-01 batching plant and an electrostatic discharging pit installed near the High-Speed Diesel (HSD) storage facility that effectively discharges any accumulated static charges in the fuel bulker during fuel transfer from the tanker to the storage facility.

“The virtual audit at our site was a new experience for us at LTGS, and our intent was to receive no negative feedback from anyone about our operations, and demonstrate our implementation of strong safety procedures,” he shares. Yuvaraj and the team have received some noteworthy points from the virtual audit to strengthen their resolve to maintain safety in all their operations. As for environmental initiatives, he mentions aerobic decomposers installed in the workmen’s habitat that efficiently convert approximately 80 kgs of food and organic waste generated daily into valuable fertilizers, that are in turn utilized to develop green belt areas.

“Our Kanupur Project has been recognized for its Best Digital Initiatives adopted at site, by the LTGS management,” he shares proudly. “With virtual reality, we give a clear and immersive experience to help workmen understand potential hazards in a more vivid and impactful manner.” Apart from VR, real-time tracking and digital record-keeping have significantly enhanced their ability to address construction hazards and improve overall safety. “By leveraging these technological advancements, we can effectively communicate risks, track data, and ensure prompt corrective actions, ultimately fostering a safer working environment for all involved,” he remarks.

Yuvaraj praises the team’s excellent teamwork and is grateful for the support and guidance from his senior management including K P Ravinath, EHS Head, and Project Manager, Praveen Pratap Singh, who gives them complete freedom to implement initiatives.

Born and brought up in Salem district, Tamil Nadu, Yuvaraj is a bachelor who loves to spend his leisure time playing cricket, badminton, going on long car drives, and discovering new cities and places.

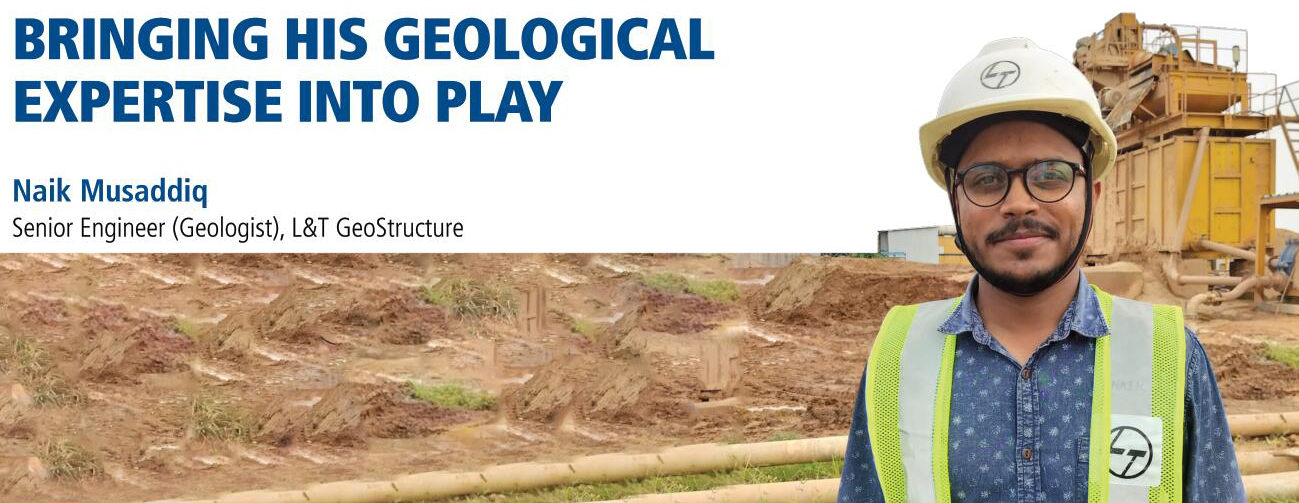

The Kanupur Cut-Off Wall Project, being executed by L&T GeoStructure in Odisha’s Keonjhar district, is where a dam is being constructed for irrigation purposes. “Earlier studies had revealed layers of boulders, cobbles, and pebbles on the left embankment, raising the threat of high underground seepage of water,” explains geologist Naik Musaddiq. “The cut-off wall is being built as a remedial measure to control the seepage and maintain the stability of the dam.” After encountering a highly undulating rock strata showing high variability within 2–3 m, for the termination of panels in accordance with criteria, Naik suggested the open panel borehole method. “Our GTI method has reduced excessive workload on machinery and has proved to be time and cost efficient,” Naik remarks.

It was also observed that the highly undulating rock strata was controlled largely by joints and shear zones, with considerably large variation in rock levels within 2–3 m in certain areas. “To solve this, where fresh rock was encountered at shallow levels, we executed boreholes in the open panels using guide frames designed at site, in addition to the confirmatory GTI boreholes, for which we finalized the termination depths of panels more precisely,” he says. “This reduced over trenching in fresh rock, saved the machinery from frequent breakdowns and improved resource utilization. We even found the open panel boreholes more time- and cost-effective than normal GTI boreholes.” Naik is happy that he got his first opportunity to introduce this initiative.

The GTI boreholes and as-built casted panel profiles were prepared using AutoCAD, giving the team an idea of the variation in the rock level and helping identify the problematic zones.

Delving deeper into his subject, Naik mentions that initially the termination of the panels was decided based on 30 GTI boreholes executed at intervals of 40 m and at 2–3 m offset from the centre of the cut-off wall. “During the trenching of the panels, we encountered fresh rock at levels shallower than expected based on the GTI data, to overcome which we decided to do confirmatory boreholes at 10–15 m intervals at the centre of panel.”

At his first project with L&T GeoStructure, Naik is appreciative of his Project Manager Praveen Pratap Singh’s support in procuring permissions from the client to execute open panel boreholes and finalize the termination of the panels. He cherishes the guidance and support of his Manager, Arun Balamurugan. “Our seniors and team members supported me with their knowledge in designing and preparing the guide frames,” says a thankful Naik.

From Aurangabad, Maharashtra, Naik’s better half is Humaira, a homemaker, and they are blessed with a son, Mustafiz. His pastimes are sports, movies, web series, and reading, and his most cherished moment is India’s victory over Australia in the 2011 Cricket World Cup quarter final.