After joining as a GET and spending 11+ years with L&T, K Dhandabani is elated that he has had the opportunity to work in different roles at his Sudair Solar PV IPP Project, which is also his first in the renewables space, having previously worked on substation and cable projects. “Since I have worked across departments, I have been able to easily implement several initiatives,” he says with vigour. “Initially, I worked as Planning Engineer and developed the project schedule and planned activities at a micro-level, then moved to the Procurement Department where my previous experience in planning helped in material delivery. Currently, I am working as a Site Construction Manager for the 450 MWp Block, and being aware of the constraints facing site execution, I am well prepared to carry out my duties,” he says confidently.

The Russian aggression in Ukraine has caused global disruptions, and the Sudair Project was not spared as the material being sourced from Europe stopped. The team had to endure a double whammy as supplies from China dried up too due to the pandemic. They swung into action, organizing weekly meetings with the suppliers, conducting micro-level monitoring of the raw material procurement right from the manufacture of equipment to delivery at the site. “In case, the supplier faced any raw material delivery issues, we immediately took an alternative route to quickly procure an alternative make with the Client’s approval to ensure that material delivery was on track,” adds Dhandabani, with a sense of urgency.

In terms of other initiatives at the site, he mentions introducing prefabricated cable trays based on site requirements, deploying pre-assembled equipment support structures, and replacing RCC staircases with prefabricated steel ones. “I have implemented the Smart Sheet Software to digitally monitor Project Schedule (Planning and Progress) that helped the Qatar operations to energize and close out the project,” he shares, proud of his contribution.

Dhandabani attributes his success in large measure to his Task Force Leader, Bharathi Kumar, for his timely decisions, and for guiding him through every cycle of the project. “I am thankful to my IS, Mr. Akilan, too for his continuous support in helping me reach my goal on time.”

A proud L&T-ite, who is impressed by the urge of his colleagues to achieve their targets and support the environment, Dhandabani’s most cherished moments are, as he describes, “ramming the last post of the Sudair Solar Project and the arrival of the first 380 MVA transformer at site,” he smiles.

Hailing from Laligam, in Tamil Nadu’s Dharmapuri District, Dhandabani is married to D. Vijayalakshmi, a homemaker, and they are blessed with one daughter, D. Sanjana Sree. When free, he loves playing cricket and watching movies.

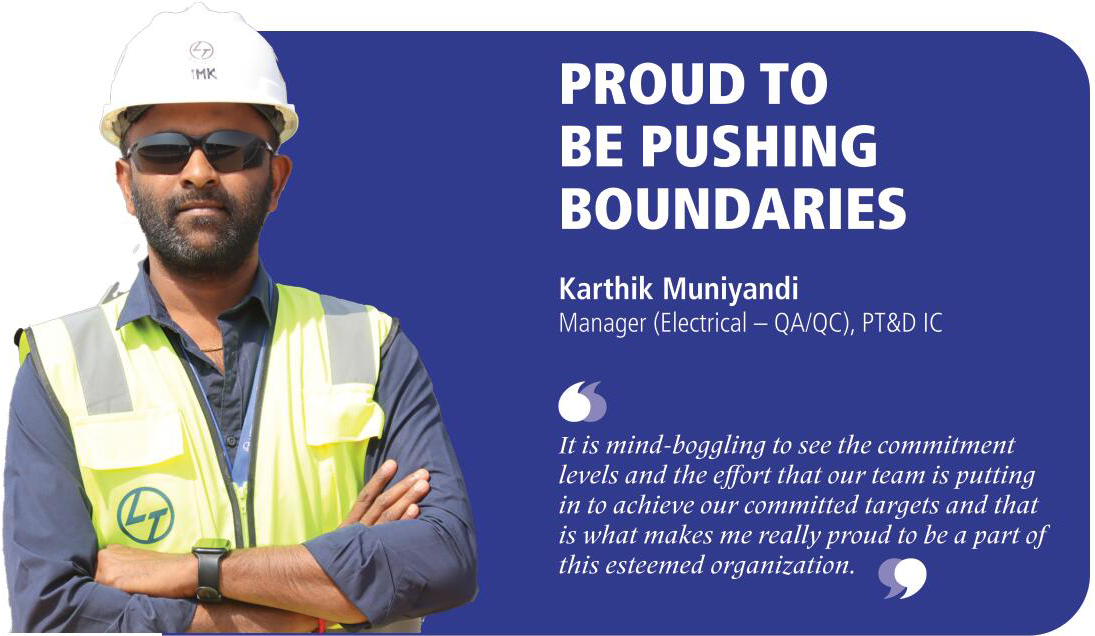

PT&D IC is executing the challenging Sudair Solar PV IPP, which is also L&T’s first GW-scale Solar PV Project in the Kingdom of Saudi Arabia, and Karthik Muniyandi, at his first project with the Company, is overwhelmed. “It is mind-boggling to see the commitment levels and the effort that our team is putting in to achieve our committed targets and that is what makes me really proud to be a part of this esteemed organization,” he says with barely repressed excitement.

Getting down to brass tacks, Karthik points out that the big challenges the team faces at the Sudair Project are site levelling, grading, and aligning the vertical posts (VPs) due to the hard strata and undulated terrain. “By adapting a new ramming methodology, we have installed the VPs as per the actual land profile,” he flags off, “that has reduced the levelling and grading work after. In fact, we have successfully maintained the VP alignment within accepted tolerances thanks to this new methodology.” The new process has significantly reduced rectification work too and that has improved progress. There were times when re-surveys had to be done frequently to verify the levels of all VPs before deploying this method. “The usage of SS cable ties has also been reduced by providing cable armour strands (scrap items) to hold the solar/string cables along the tracker structure.”

On the digital front, Karthik is glad that all quality and safety observations are being raised promptly and recorded for reference. “All material inspection requests and material approvals are through online applications that have considerably reduced paperwork,” he says with relief. “We use SharePoint to manage all documents and with digital solutions we have easy access to all cross-functional documents, and traceability is easy too.”

His air of positivity shows that Karthik is well-adjusted to both the organization and his role. “Our management team has never said “NO” to any of our requests for resource mobilization and/or material procurement to implement new initiatives to improve progress and productivity,” he says confidently. “Of course, the guidance and support from our senior management and team members have always been commendable that has propelled me to deliver my best,” he says with josh, adding, “Completion of 450 MWp PV modules installation works, string cables installation, QA/QC inspection, and testing & commissioning of all major PV equipment in just one month is the most indelible moment in my career and the best example of great teamwork that I have experienced till date.”

His air of positivity shows that Karthik is well-adjusted to both the organization and his role. “Our management team has never said “NO” to any of our requests for resource mobilization and/or material procurement to implement new initiatives to improve progress and productivity,” he says confidently. “Of course, the guidance and support from our senior management and team members have always been commendable that has propelled me to deliver my best,” he says with josh, adding, “Completion of 450 MWp PV modules installation works, string cables installation, QA/QC inspection, and testing & commissioning of all major PV equipment in just one month is the most indelible moment in my career and the best example of great teamwork that I have experienced till date.”

Hailing from Sathirakudi in Tamil Nadu’s Ramanathapuram district, Karthik is married to Janani, a homemaker, and they are blessed with two daughters, K Saanvika and K Mirthika. He loves playing cricket and reading when not stringing cables.

OVER THE MOON TO BE AN L&T-ITE!

Pradeep Raj Kumar

Assistant Manager (Civil), PT&D IC

“It was a proud moment to celebrate L&T’s role in the success of Chandrayaan-3,” gushes Pradeep Raj Kumar, all excited about what it means to be an L&T-ite. “The Company’s contribution to the country is well known, and I am very proud to be associated with such a big industry conglomerate.”

Celebrations of India’s Moon Mission aside, Pradeep is working at a project that will harness the power of the sun. While the Sudair Solar PV Project is his first at L&T, Pradeep brings with him rich experience as a veteran of solar projects. Citing an instance from one of his earlier solar power plant projects at Sakaka, Saudi Arabia, he mentions an issue they faced of the drilled holes filling with sand. “We closed the holes with sand-filled gunny bags, which reduced rework and helped us complete the project on time,” he says smilingly.

At the Sudair Project, the first GW-scale Solar PV Project in Saudi Arabia, Pradeep is in the Mechanical Works Department and aware of the significance of the project that envisions to energize 185,000 homes and offset close to 3 million tons of emissions. “Initially, we faced challenges in cutting and grading due to a mismatch in the levels of the topography and the existing ground,” he recalls, “that we overcame by taking the respective level of the ground and adjusting as per the available terrain.”

Given the undulated terrain at the site, installing the trackers has been a huge challenge for Pradeep and team. “With 33,014 trackers to be installed at the site, we took calculated risks to install them as per the existing terrain, that worked in our favour,” he says, calling it a defining moment in the project. He mentions the use of a laser level machine for ramming and tracker activities and adds proudly that the team has achieved a 10% increase in the tracker installation productivity thanks to their on-site training and continuous guidance with proactive follow-ups.

About his seniors, he says, “They have guided us at every step and encouraged us to take initiatives and decisions on site, which has helped us run the site smoothly.”

A native of Chennai, Pradeep holds the day he married his wife, Praveena, as his most memorable moment, and they are blessed with a daughter, Rithvika. Over weekends, he unwinds by playing cards.

At his 1st with L&T, the Sudair PV Project, after joining the company in 2021, Adil Khan strongly believes that for better performance and delivery, it is imperative to build bench strength. “I have trained and developed my subordinates to implement in-house LV Electrical works,” he says purposefully. “To increase productivity of LV DC and solar cable laying, we set daily targets, and based on their performance, rewarded them month on month.” The key, he adds, is to identify and divide the team based on their scalability and performance on specific activities.

In the beginning, the Sudair team was finding it difficult to identify and on-board proficient electrical subcontractors. “We therefore took a call to develop our own team to execute the 100 MWp LV electrical works,” shares Adil. “With regular training and strictly monitoring their progress, they gradually improved until they finally won the confidence of the LV cable electrical team. Later, we completed the 500 MW MV electrical work followed by the entire 1.8 GWp Sudair LV Electrical works in-house,” he says with a huge sense of satisfaction.

While developing in-house talent has been a note-worthy initiative, it has created the challenge of dealing with a multi-cultural and multinational workforce in Saudi Arabia. “It is difficult to achieve coordination and cooperation amongst a diverse group and to monitor performance and track their productivity, for the site is so widespread,” he says grimly. “To address this situation, we distribute the manpower and give the foremen daily targets every evening which are then monitored.”

Apart from developing an in-house team for DC testing, Adil is happy about implementing a double-run MV cable drum pulled simultaneously instead of a single-run MV cable drum pulled through a winch machine that has “increased our productivity by ensuring HSE and Quality,” he highlights. They have also optimized cost by modifying the LV/MV cable layouts.

About his team, Adil nods, “Yes, they are very supportive, encourage and appreciate us to take the initiative for new challenges in each phase of the project, and their seamless support and quick decisionmaking help us to achieve our deadlines and meet our targets.”

A native of Burdwan, West Bengal, Adil is still single and celebrates life by exploring new technologies and travelling to new places.

Impressed with L&T’s strong focus on sustainability and corporate social responsibility, Adil is proud to be a part of a company at the forefront of nation-building efforts. “It allows individuals to contribute to the country’s development, improve the quality of people’s lives, and create a legacy through the projects they work on.”

PT&D IC’s Sudair Solar PV IPP project is Mohamed Ubaiyathullah first with L&T, though he brings with him rich experience from having previously executed projects in Egypt and Morocco. He believes, and not without reason, that the best person to have beside you in a tough situation is yourself. “Before developing a plan, I first perform the major activities myself that helps me plan accurately,” he says, sharing his unique style of working. “That gives me the confidence to not only handle the overall activity but also be prepared to troubleshoot without disturbing other activities or the team. My aim is to be able to manage all activities independently.”

THE BEST PERSON TO HAVE IN A TOUGH SITUATION IS YOURSELF

Mohamed Ubaiyathullah

Assistant Manager (Electrical – T&C), PT&D IC

This, however, does not mean that he is a lone ranger. “Without team support, nothing is possible in any project,” he says with a shrug of his shoulders. “We have developed a good supportive team here to achieve our project targets as per our commitment.” His teams are trained and prepared to perform all activities so that anyone’s absence will not affect progress.

Such focus and teamwork are certainly helping Mohamed and team to push progress and achieve some tough targets. “One of the biggest challenges in this project was to energize 450 MW in one month, but we succeeded with the support of management and team effort,” he says with a punched fist. Carrying out the energization activities in one Block (450 MW) and parallelly coordinating the testing and troubleshooting in another Block (450 MW) were new challenges for him but, he held his own and as he says, “I believe one of the things I learnt was time management.”

The team has found in technology an able ally to help them execute this tough project. “Technology is aiding our activities to improve both progress and the safety quotient,” he remarks. “For example, during the energization, certain critical operations were carried out by the Digital Output signal of the RIO and, after energization, the equipment was being remotely monitored by the Digital Input Signal.”

In awe of the company he keeps, Mohamed says, “L&T’s visionary leadership, especially in our Sudair Project, is what makes me proud to be a part of this Company. I am equally obligated to my IS, Ganga Rajan, for giving me decision-taking authority at a critical phase that has helped me prove myself, and I will always live up to his trust,” his says passionately.

From Sirkali in Tamil Nadu, Mohamed is married to Chitti Noorul Jasina, a homemaker. Playing volleyball, badminton, and reading history books are his special interests.