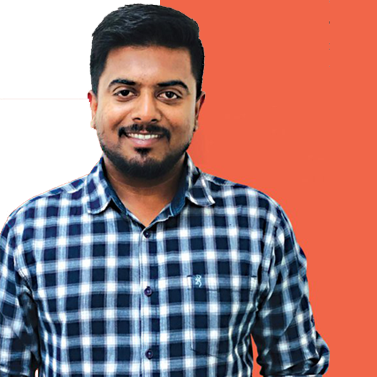

0.82 million safe manhours working under ‘live’ 400 kV overhead lines

A truly power-packed EHS performance!

Safety mesh provided between gantries for safe work

The PT&D team executing the installation of the 400 kV Line Connected Current Limiting Reactors in Qatar for client KAHRAMAA (Qatar General Electricity and Water Corporation) has been living on the edge, having to work continuously under ‘live’ 400 kV overhead lines. That they have negotiated the implementation safely till date, clocking 0.82 million safe manhours in the process, speaks volumes of their high EHS standards that Aravindan Jayachandran, Project Manager; Hari Kumar Mullakur, Senior EHS Manager; and their EHS team drive with almost missionary zeal.

Right from day one, as a team, we have been focused on maintaining ‘zero fatalities, zero LTI & zero restricted work & medical treatment cases’, and I am happy that we have kept our EHS record intact till date.

Hari Kumar Mullakur

Senior EHS Manager

The project, which aims to mitigate high short-circuit levels in the system, involves executing work inside live 400 kV substations of Abu Nakhla Super (ANS) and Logistics Zone Super (LZS), for the first time in KAHRAMAA’s network. The 400/220/132/11 kV Abu Nakhlah Super will have four units of 16 Ohm, 400 kV line connected current limiting reactors to be installed at 2×400 kV ANS – LZS and 2×400 kV ANS – MPCL OHL circuits. The 400/132/11 kV Logistic Zone Super will have two units of 16 Ohm, 400 kV line connected current limiting reactors to be installed at 2×400 kV MPCL – LZS OHL circuits, in both cases along with other associated equipment and works as required.

Our primary objectives are to deliver durable, dependable, and high-quality assets to the Client and at the same time protect the health, safety, and wellbeing of our personnel carrying out worksite activities.

Aravindan Jayachandran

Project Manager

Unwavering focus on Safety

“Right from day one, as a team, we have been focused on maintaining ‘zero fatalities, zero LTI & zero restricted work & medical treatment cases’, and I am happy that we have kept our EHS record intact till date,” enthuses Hari, although the going has been tough. “Our major threat is working continuously under ‘live’ 400 kV OHL lines,” he says grimly, “like transporting and installing the 400 kV current limiting reactors and other equipment, lifting package units, and civil work to construct a building. We have even been erecting OHL towers and stringing conductors adjacent to a ‘live’ OHL,” he adds for good measure.

“Our primary objectives are to deliver durable, dependable, and high-quality assets to the Client,” remarks Aravindan, “and at the same time protect the health, safety, and wellbeing of our personnel carrying out worksite activities.” Focused on safety, the team has been addressing every aspect at site including traffic, security, waste management, chance find, fire prevention, safe lifting operations, and offsetting the impact of the pandemic. “Over and above these, we have put in place specific and customized safety procedures, considering critical site conditions under the 400 kV OHLs, customer and contractual requirements, lender requirements, specifications, and standards,” observes Aravindan.

More than 260 job-specific awareness training sessions (internal & external) have been conducted primarily for employees involved in safety-critical activities, such as safety mesh installation, gantry erection & lifting operation close to 400 kV OHL, equipment operation, etc.

Mohammad Shakeel Ansari

EHS Superintendent

Though handicapped as they cannot deploy tower cranes because of the height restrictions, Hari and his team have been holding their own, overcoming the challenges of stagewise outages since they are working in an existing brownfield project. EHS Superintendents, Mohammad Shakeel Ansari and Rosh Raju Abraham, have been busy instituting various mitigatory measures like erecting temporary gantries to lift the 400 kV lines, installing a safety mesh between G2 and G3 to ensure safety when constructing the reactor building, positioning watch towers to monitor the safe clearance of equipment and OHL, and more.

Our housekeeping campaigns, with the involvement of the top management, are oriented towards protecting the nvironment, for effective and environment-friendly collection and disposal of waste.

Rosh Raju Abraham

EHS Superintendent

“We conducted trial pits to protect the underground utilities and have customized safety procedures and checklists for roof works,” Hari points out. While periodic OHL height surveys ensure safety, all equipment & steel reinforcement have been provided proper earthing. One must cross several goal posts before entering the OHL area, and 25 T small mobile cranes have been mobilized to maintain safe height from the safety mesh and OHL lines. As an additional precautionary measure, insulated/rubber gloves and rubber mats have been placed in the working area on rooftops under live OHLs.

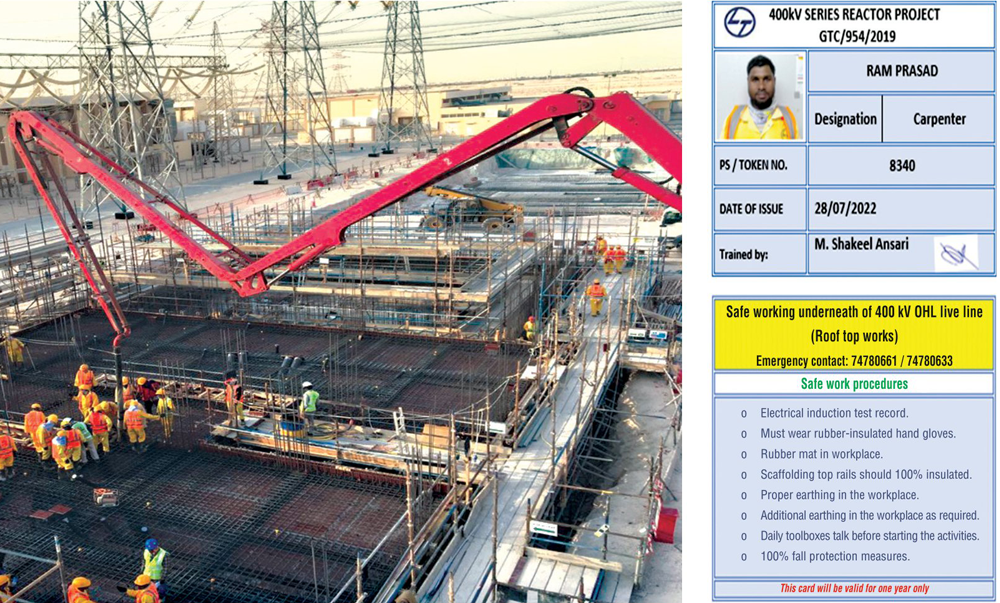

Training builds and sustains awareness

“We have customized internal safety procedures & checklists for the roof works, developed internal HSE training sessions for our people working under OHL, and provided ID cards,” shares Mohammad. “More than 260 jobspecific awareness training sessions (internal & external) have been conducted primarily for employees involved in safety-critical activities, such as safety mesh installation, gantry erection & lifting operation close to 400 kV OHL, equipment operation, etc. They also attend separate third party training and certifications.”

Regular checking of current induction & keeping record

An advanced brainstorming session involving all stakeholders threw up several interesting insights. “We even invited experts from our concrete suppliers to the session, who suggested a shorter boom length for the concrete pump,” points out Hari. The project management team, along with representatives from the client, conduct regular safety walkdowns to demonstrate the management’s commitment to safety, build a strong safety culture, and ensure effective EHS implementation.

“Every employee and all visitors at site have the authority, through the official Stop Work Policy, to stop work if they observe unsafe acts and/or conditions,” affirms Hari, “which is communicated to all employees and visitors during inductions and refresher training. All observations recorded during site EHS inspections and site visits by seniors have been closed out in time, well within the allotted timeframe,” smiles Hari winningly. The digital SHEILD app is also helping the team maintain their EHS performance.

Shorter boom-length pump used for concrete pouring in Reactor Building

Specific training ID card

Other awareness campaigns that keep Safety top of mind include road safety campaigns to enhance and emphasize site traffic rules and reduce traffic violations, during which drivers and operators are trained in defensive driving skills as well as road safety. Rosh explains, “Our housekeeping campaigns, with the involvement of the top management, are oriented towards protecting the environment, for effective and environment-friendly collection and disposal of waste.” There are campaigns too on lift operations to enhance awareness of workers and promote safe working practices.

“Safety is a small investment for a rich future,” says Aravindan, summing up his team’s concerted and coordinated efforts to maintain their 100% safety record. Here’s wishing them the very best to keep a safe thing going!